The undoubted advantages of Weber Vetonit putty:

- the mixture is made from environmentally friendly raw materials - it does not emit toxic substances;

- moisture resistance - it is used even in the construction of swimming pools;

- the composition is powdery, so the surface of the wall being treated becomes perfectly smooth;

- a snowflake drawn on the packaging of the mixture indicates that it can be used at low temperatures for finishing the facade;

- the composition in diluted form can be stored for 24 hours.

Main competitive advantages

- These are environmentally friendly products that are created only from ingredients that are safe for humans and nature.

- Due to their excellent water resistance, the mixtures are versatile and can be used even in areas such as swimming pools (the packaging should be marked “waterproof mixture”).

- Powder mixtures have such a fine fraction that the applied layer acquires an ideal, almost mirror-like smoothness.

- The applied layers of putty are not afraid of adverse weather conditions, including frost, rain or hail, and therefore can reliably serve even for facade finishing for many years. In addition, products have been developed that can be applied even at sub-zero temperatures (snowflake marking on the packaging).

- The putty layer enhances the heat-insulating and noise-absorbing properties of the walls and ceiling.

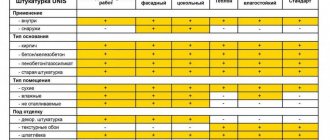

Types of putties and their descriptions

Vetonit putty is available in several types. Each product has its own unique composition and purpose. Thus, the following groups of materials can be distinguished:

- VH, V, TT - with these marks, mixtures that are made on the basis of cement are released for sale. Materials of this group are excellent for any type of premises; they can be used in the bathroom, kitchen and toilet (where there is high humidity).

- LR and KR - these markings indicate that the putty mixtures are intended for final leveling of walls and ceilings, resulting in a coating suitable for subsequent painting or wallpapering. Materials of this group cannot be used in rooms with high levels of humidity.

Vetonit VH

This type of product is best suited for use in conditions of high humidity. Vetonit vh putty, in addition to its main task of preparing the surface for subsequent painting, performs a protective function - it prevents the appearance of condensation on ceilings and load-bearing structures in rooms with high air humidity.

The product is presented in two versions: white and gray. The white model of Vetonit vh putty is simply irreplaceable if the surface is planned to be painted. The second option is used as a primary layer before laying tiles.

The main feature of this putty mixture is the ability to be used on surfaces made of a wide variety of materials. As the instructions say, the finishing putty can be used on plastered, concrete, stone (brick) walls and bases made of expanded clay, foam aerated concrete, and gas silicate blocks.

Vetonit LR and LR+

Vetonit finishing putty is in high demand on the building materials market; it has a unique composition, low cost and is easy to use. The Weber Vetonit lr putty model is designed for finishing dry rooms, therefore, compared to other brand products, it has a more viscous and dense structure. After applying the Vetonit finishing putty, they begin wallpapering the walls or painting work using specialized highly pigmented paints.

It is worth noting that this product is not suitable for leveling non-standard, volumetric planes, as well as large-sized objects. This is how most finishing compositions work, whose main task is to reduce the sharpness of the transitions between layers of plaster and paint and minimize surface unevenness. White base putty is best suited for plaster and chipboard surfaces.

The putty is available in different configurations, most often it can be found in a powder version in 25 kg bags. You can also see a ready-made putty mixture that does not need to be diluted with water.

There is also a product Vetonit LR+. This is a polymer putty from this collection. Due to its unique composition, it is ideal for finishing ceilings and walls in dry rooms. This is the starting and most popular model. Its distinctive characteristics are low consumption, quick drying, ease of use and a very affordable price. The diluted composition can be applied over smooth or rough surfaces (plasterboard and mineral materials).

On the Internet you can find many positive reviews about the use of this product, with most buyers appreciating the low consumption of material and its versatility. Plastering walls and ceilings with Vetonit allows you to prepare the surface for subsequent paint application.

Important! Vetonit lr plus putty is usually applied by spraying onto walls and ceilings made of plasterboard or particleboard. This starting mixture can also be used as an adhesive layer for installing gypsum boards.

KR and TT products

Marking KR means that the putty is finishing. Before using it, the VH starting solution is first used. Vetonit TT putty is a universal composition that can be used both as a starting and finishing coating. In addition, this material is also suitable for finishing facades.

Compound

Depending on the type of plaster, its composition differs . Thus, Vetonit EP contains cement and lime. The main component of the most common Vetonit TT mixture is cement. The basis of “Vetonit T” is adhesive organic binders. “Vetonit L” is a plaster with a polymer binder. Therefore, it is necessary to first study the composition of the mixture.

Colors

This product is intended primarily for subsequent painting, so neutral colors are provided: white, gray and light gray.

Layer thickness

Vetonite can be applied in a layer of 2 – 10 mm, the maximum thickness is 3 cm . Please note that it may differ depending on the type of mixture. More details can be found in the following tables.

Adhesion (stickiness)

The plaster has a high level of stickiness. On average, the adhesion strength is 0.5 MPa.

Frost resistance, moisture resistance

The dry powder is quite frost-resistant. It is capable of withstanding 75-100 cycles of complete freezing and defrosting . Therefore, this product is recommended in regions with cold climates.

Strength

The strength of different types of plasters differs slightly. Thus, a gypsum-based mixture is less durable than a cement-based mixture. On average, one month after plastering, the surface can withstand a load of 6-8 MPa.

Having examined the technical characteristics, we can come to the conclusion that Vetonit is indeed an ideal material for interior and facade plastering work.

More details about the most common types of mixtures can be found in the tables:

| Vetonit plasters. Specifications | |||

| Brand name | «Vetonit EP» | «Vetonit TT» | «Plaster» |

| Layer thickness (mm) | 2–50 (100) | 2–7 (30) | 5-50 |

| Fraction (mm) | 1 | 1 | |

| Operating temperature (degrees C) | 10 | 5 | 5 |

| Water consumption (l/kg) | 0,46–0,5 | 0,24 | 0,4 |

| Viability (h) | 6 | 4 | |

| Drying time (days) | 1–2 | 1 | 1–7 |

| Consumption (kg/sq.m/mm) | 0,5 | 1,2 | 1 |

| Cost (RUB/kg) | – | 10,53 | 9,41 |

| Basic plasters "Vetonit". Specifications | |||

| Brand name | «Vetonit V» | «Vetonit T» | «Vetonit L» |

| Astringent | Cement | Organic glue | Polymer glue |

| Layer thickness – full level. (mm) | 1–3 | 1–2 | 1–2 |

| Layer thickness – partial leveling. (mm) | 1–5 | 1–5 | 1–5 |

| Fraction (mm) | 0,6 | 0,6 | 0,6 |

| Operating temperature (degrees C) | 5 | 10 | 10 |

| Water consumption (l/25 kg) | 7–8 | 7 | 7 |

| Viability (h) | 4 | 12 | 24 |

| Drying time (days) | 1 | 1 | 1 |

After studying the technical specifications, you can begin plastering work.

The main advantages of weber.vetonit LR+

I counted three of them:

- Ease of application with almost complete absence of layer differences. If you wish and have the proper skill, you can putty the surface under the wallpaper so that sanding is not required at all.

- If necessary, the putty can be sanded very easily due to its somewhat loose nature. And this is very important. For example, gypsum Fugenfüller (universal putty from Knauf) is incredibly difficult to sand. When I tried Vetonit for the first time after it, I was amazed - no effort.

- Surprisingly long lifespan. If you mix too much putty and don’t have time to use it all, just cover the container with a lid. The next day it will be waiting for you in the same condition in which you left it. It has been verified that for 2-3 days she calmly waits in the wings in a bucket, ready to work. You just need to stir it one more time.

Of course, the hero of the article also has a drawback. This is a lack of moisture resistance.

Let's say we are wallpapering. We glued the strip, when suddenly we noticed a crease or a bubble that simply couldn’t be smoothed out. Needs to be removed and re-glued. So, there is some probability that the strip will be partially removed along with the putty. To be honest, this has never happened to me before, because I carefully prime the surface before and after puttingty, plus I apply it in a certain way so that it lays more tightly. But such cases are known. But I don’t know of any other shortcomings.

I just can’t recommend using it for painting. Still, its fraction is too large for this, and visually the surface turns out to be rougher than when using Sheetrock. But I am a sophisticated user; for you, such a surface will most likely be more than acceptable. Once I had to paint the ceiling on the loggia using Vetonit (there was no choice), I carefully sanded it and covered it with two layers of white paint. I couldn't see any defects from the floor, not even the slightest. This is the ceiling:

Usually it is enough to apply the putty in two layers. The first one slightly trims the surface, the second one is finishing. Moreover, the second layer is applied only when the first is completely dry. If applied minimally, drying occurs in 3-4 hours. A layer 5 mm thick will dry for at least a day.

Scope of application

The manufacturing company offers modern customers complete complex solutions in the field of construction: from the starting and finishing coating of walls to the insulation of facades.

All types of putties produced at the company's factories are ideal for finishing work indoors and on its façade.

Most of the mixtures are made on the basis of polymer components, which are binders in finished form. After the putty is applied to the wall or ceiling, it hardens, after which you can glue wallpaper or simply paint the surface.

Depending on which putty is chosen: for dry rooms or rooms with high humidity, Vetonit will ensure the ideal appearance of the treated surfaces. After the walls have dried, they can be finished with tiles, glass or plastic.

Putty is also used for high-quality sealing of plasterboard slabs, on the surface of which cracks are subsequently excluded.

After the wall puttying process is completed, an unpleasant odor may appear in the room. However, it will disappear immediately after the mixture dries. This feature is inherent in many materials for construction work.

If Vetonit gypsum plaster is used, then after the work is completed you can apply putty to it - a high-quality mixture will extend its service life. When choosing a moisture-resistant mixture marked VH on the packaging for work in wet areas (bathroom, kitchen or swimming pool), you don’t have to worry - it is not afraid of a humid environment. That is why this composition is often used when treating warehouses and the facade of a building.

Special mixtures such as Vetonit TT are also used on surfaces consisting of ceramic bricks or aerated concrete. This putty is frost-resistant, neither mold nor mildew will appear on it, which is very important in regions where a cold and humid climate prevails.

What is the difference between Vetonit KR and LR?

The company produces different putty compositions, and the choice is easier to make if you understand the differences between similar types. So often the choice falls between LR and CR species. Vetonit KR LR the differences between them are insignificant, so the choice becomes even more difficult. But they can all be distinguished.

What is the difference between Vetonit LR and KR, the most important distinguishing property is the constituent components. KR is made from organic substances, and LR from synthetic ones. It is difficult to say for sure that the first option is better than the second, or vice versa, but experts note that the KR type emits an unpleasant odor.

The LR species has various subspecies, which allows you to select the desired option more accurately. But the KR is also produced in small containers, which makes it possible not to worry about throwing out excess after completion of work, if 25 kilograms turned out to be too much.

There are no other points in which they differ, so the choice is mainly made from personal preferences, taking into account the characteristics of the surface being treated.

The LR species has various subspecies, which allows you to select the desired option more accurately.

How much material is needed for finishing?

The main criterion when choosing a product for puttying surfaces in domestic conditions is product consumption. As for Weber putty, all models in this series have different viscosities. Thus, the version of Weber Vetonit lr putty, as well as individual modifications of Vetonit kr putty, have different consumption.

Before purchasing a putty mixture, you need to calculate the required amount of material. To make it clearer, let’s look at the consumption of Vetonit kr putty as an example. When finishing walls, about 1.2 kg of ready-made mortar is consumed per 1 m2 of surface, while seven liters of water are enough to dilute the mixture (this figure may vary depending on the structure of the material).

Tips for choosing

According to experts, all Vetonit products have two important qualities: they are very convenient and trouble-free to apply to the surface, and preparing the finished mixture takes a matter of minutes.

True, it is necessary to take into account useful tips when working with the material:

- It is important to remember that the remainder of the mixture should never be poured into the sink or toilet.

- Before applying putty, the surface of the walls or ceiling must be thoroughly dried.

- For a basement or bathroom, you should choose only Vetonit TT packaging, since it is universal and not afraid of moisture, and it is also made on a cement base. This composition must be mixed with water in a proportion of 25 kg per 6 liters of water.

- The surface to be treated must be clean, free from stains and dust, and if it is very dry, it should be moistened.

- The minimum layer of the applied mixture is 0.5 mm, the maximum is 0.7 mm.

- It is necessary to putty the surface with “Vetonit” on an adhesive base when everything is already dry, and only then glue the wallpaper.

Purpose and technical characteristics, consumption

Vetonit KR putty is applied as a final layer to create an ideal surface without even small irregularities. After using the solution, a layer is created that has a decorative property; for this reason, when processing the ceiling base, sometimes further finishing is not carried out.

Vetonit KR putty is sold in the form of a powder mixture, so you need to prepare the composition for application by adding water in the required proportions.

Areas of use:

- Final preparation of plasterboard ceiling and wall bases;

- To apply material for leveling on chipboard;

- Suitable for cement-lime base;

- Designed for use in rooms with moderate and humid microclimates;

- If the spray technique is used, then particleboard and porous-fiber walls can be treated.

The solution cannot be used for the following materials:

- It will not withstand constant damp exposure, so it is not used in rooms with high humidity;

- Not suitable for laying tile material;

- Not used for flooring.

Vetonit KR technical characteristics:

- Consists of an organic adhesive substance and organic limestone;

- White color;

- Temperature indicators for operation from +10 to +30 degrees;

- The average consumption level when creating a millimeter layer is one kilogram per square meter of surface;

- Complete drying lasts 1-2 days, the period is affected by the thickness of the layer;

- Not moisture resistant;

- Packed in a thick paper bag;

- Available in volumes of 5 and 25 kilograms;

- Unopened composition can be stored for one year.

Vetonit KR putty is applied as a final layer to create an ideal surface without even small irregularities.

Preparation of the solution

To prepare putty with optimal structure and consistency, dilute the dry mixture with water in accordance with the proportions indicated on the package. The result should be a homogeneous mass of medium density.

Before diluting the putty mixture, you should know that water must be added to the solution in portions, and its temperature should be approximately 20 degrees.

There are some professional tips to follow:

- After the finished putty has infused a little (for 10-15 minutes) and acquires a more uniform texture, it should be thoroughly mixed again using a construction mixer.

- After mixing the solution, no more than 24 hours should pass until the putty is applied, otherwise the mixture will lose its properties and harden.

- If there is still dry mixture left in the package, it is recommended to store it in a cool (but dry) and dark place.

Advantages and disadvantages

Vetonit KR finishing putty has its positive and negative sides. To understand whether you should use a surface treatment product, you need to study all the features in advance. Among the advantages are the following:

- After completing the putty work, sanding is not difficult; the layer is easy to process;

- Can be used for a variety of materials: plasterboard sheets and gypsum base, mineral, wood, painted wall, base made of organic minerals, concrete, expanded clay concrete blocks;

- After preparing the solution, the properties are retained for 24 hours;

- It is allowed to treat the base with a spatula or using a spraying tool;

- Treating the plastered layer with putty helps to obtain a smooth and white base.

Among the disadvantages are:

- It is not permissible to use it for treating floors;

- It is not moisture resistant, so the area of use is limited to rooms with average humidity levels.

After completing the putty work, sanding is not difficult; the layer is easy to process.

Methods for applying putty

Leveling walls with putty is done in two ways:

- mechanical spraying (using special equipment);

- applying the putty mixture manually (using spatulas of different sizes).

The latter option is more often applicable for putty polymer materials. It all depends only on the personal preferences and tasks of the person performing the construction work. The putty layer should not exceed 5 mm, otherwise the coating will dry out for a long time and unevenly.

When applying several layers of putty, each subsequent layer is applied only after the previous one has completely hardened.

Execution of work

The finished solution is applied to a previously prepared surface by mechanized or manual means. The putty solution is applied to the base and leveled using a two-handed steel spatula. When processing small areas, you can use a metal spatula 30 cm wide. If it is necessary to apply the material in two layers, you should wait until the previous one has completely dried. After application and drying, the surface is treated with sandpaper and removed from dust. And after all the work done and complete drying, the surface is ready for the subsequent application of decorative materials: painting, wallpapering, etc. , and can also be composed in the form of a “fur coat” after the mechanized spraying method.