To work with cork, it is important to choose the right glue. The strength and reliability of the future coating depends on it. After all, the cost of a cork base exceeds the cost of many coatings.

Cork glue must have qualities without which it is impossible to obtain a good cork floor. These requirements include:

- stability during temperature fluctuations;

- absence of toxic substances; wear resistance;

- water resistance;

- neutral attitude towards the floor surface.

Types of floor glue

Today there is a large assortment of glues on the market that are used to work with cork coatings. It is divided into two main types: contact and universal.

The contact solution is based on polychloroprene and synthetic resin. This glue allows you to get a durable coating. The work is done quickly and accurately, as the composition hardens quickly.

It is important to maintain the accuracy of laying the tiles. Once the tile has stuck, it is impossible to correct the position. The glue sets tightly.

Types of cork flooring

Common disadvantages of DecolVern and Moment

DecolVern and “Moment” have three significant disadvantages that can cause great harm to beginners:

- Starting polymerization with a limited period.

- After pressing the slab to the surface, you cannot tear it off, as the glue sets instantly. You need skills, clear markings, dexterity.

- These adhesives are not recommended for attaching cork wallpaper. They do not allow for adjustments; the coating is immediately firmly fixed, and due to its small thickness, there is a risk of damage to the wallpaper when torn off the wall.

The complete drying time for such adhesives is impressive and is a day for Moment, two days for DecolVern brand glue.

Contact adhesive technology

To obtain a high-quality foundation, it is necessary to fulfill the technological requirements and adhere to the sequence:

- clean from dirt;

- carry out alignment;

- mark the gluing areas;

- coat the working side of the tile with glue;

- wait until the glue dries;

- Press the plug tightly to the base.

The glue is applied to the surface with a notched trowel or a special roller. The base and inner side of the cork coating are lubricated. Then wait two to three minutes. The solution will dry, you can work.

Press the tile tightly to the base and hold it under pressure for half a minute. During this time, the glue will set and the tile will be firmly glued to the base.

Glue "Wakol D3540"

How to glue cork coverings to the wall: instructions

If this is your first time gluing eco-friendly cork material yourself, then carefully study the recommendations.

- Preparing the base. To ensure that the finish does not lag behind the base, it must be properly prepared. The walls are cleaned of old cladding; if there are cracks, they need to be filled with cement mortar and leveled to the building level. For better adhesion, the surface is primed and dried.

- Marking walls and materials. If the panels are not laid from ceiling to floor, but on part of a horizontal plane, you need to use a plumb line to outline the boundaries of the cladding.

- Pruning. Panels or rolled materials do not bend. Therefore, in the corners or on protrusions, the canvas is cut with a mounting blade for joining.

- Distribution of adhesive mass. The adhesive solution is applied in a thin layer to the wall and facing sheet with a roller, flat brush or spatula.

- Installation. To form a viscous film on the surface of the solution, leave it at room temperature for 15–20 minutes. After this, the element is applied to the base, focusing on the markings, and pressed against the wall.

- To ensure that the cork panels fit evenly, the top is rolled with a plastic or rubber roller.

Universal types of floor adhesive

There are several universal adhesives for installing cork coverings. Water-based acrylic adhesive is used in rooms with low traffic, where heavy furniture is not installed.

These varieties differ in technological features:

- Only the surface to be glued is lubricated;

- the base is acrylic diluted in water;

- glues tiles only in small rooms;

- low cost.

Excellent adhesion to PVA cork. But working with such a substance requires care and increased care.

There are many varieties of PVA. Some of them cause shrinkage of the surface at the joints. Others form cracks on the surface.

To glue the cork with waterproof PVA, apply the product to the surface of the tile and base. Wait until it dries. Then place the tile in the desired place and press firmly. After a minute, the pressure can be removed, the glue will set, and the tile will be glued.

PVA glue for cork

Purpose of the material

To make the cork backing, crushed and compressed cork tree bark is used, so the material is environmentally friendly, natural and safe.

Production of cork fabric

The substrate is produced in the form of roll or sheet material with a thickness of 2 – 4 mm. The material is durable, moisture-resistant, resistant to mold and mildew. Like any wood-based material, cork has high heat and sound insulation properties, and is easy to install and cut.

When purchasing material, attention should be paid to the integrity of its packaging.

The purpose of the substrate is as follows:

- Allows you to level the surface of the base and prevent deformation of the laminate or parquet board.

- Eliminates displacement of parquet dies.

- Protects decorative material from moisture.

- Acts as a noise and heat insulating material.

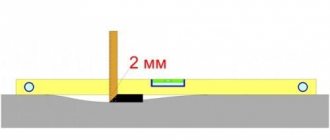

The thickness of the substrate is selected depending on the base material and its quality. If the floor is uneven, then use a substrate up to 20 mm thick. For a flat concrete floor, choose a material no thicker than 2 mm.

Popular brands of cork flooring adhesive

Wakol D3540 glue is considered a popular water-based, odorless product. Consumers speak of it as an economical adhesive that is used to create “warm floors.” The disadvantage of this composition is the long drying time.

Another popular composition for working with cork is the German odorless contact adhesive - “Stauf Multicontact”. This universal product is suitable for working with “warm floors”, but it takes a lot of time to soak.

Contact adhesive "UZIN" copes well with elastic coatings. The composition is distinguished by its versatility and efficiency. It has only one drawback - it is expensive.

Water-based adhesive "Stauf Multicontact"

Laying cork underlayment: what to consider

When choosing a substrate, you should pay attention to the thickness of the laminate. If it is less than 8 mm, then a lining of 2 mm is suitable; if it is larger, then the thickness of the cork should be 3 mm.

Note! Material 3–4 mm thick will help hide floor unevenness not exceeding 2 mm.

Installing a dry screed does not take much time

The cork underlay is laid on a flat base, so if there are significant defects and differences, preparatory measures are taken to level the floor. Comprehensive preparation of a concrete base includes the following activities:

- Removing garbage.

- Joining and sealing damage and cracks with cement mortar.

- Leveling the base by pouring screed, self-leveling mortar, laying semi-dry or dry screed.

Prices for various types of screeds and self-leveling floors

Screeds and self-leveling floors

Leveling the concrete base

If the base is wooden, then the boards are tightened, fixed, and if necessary, the surface is scraped and sanded. Damaged boards are replaced with new ones.

There are two ways to lay the backing - adhesive and double-sided tape.

Solvent adhesives

Such products have a specific smell, but are much cheaper than universal ones. Therefore, they are bought more often than water ones.

Bunitex glue glues cork tiles economically. The holding time is minimal. However, it also has several serious disadvantages:

- toxic;

- fast setting;

- for operation at high temperatures requires the use of special additives.

Contact glue “Bunitex”

Another type of glue is “Cork house”. The benefits include:

- plastic;

- high adhesion;

- has no smell;

- lack of toluene;

- moisture resistance.

The disadvantage is considered to be high flammability. Glue is a fire hazard.

To glue the cork, use universal glue “Moment”, produced in our country. Its main advantage is moisture resistance and a neutral attitude towards aggressive environments (acids, oils, alkalis). “Moment” is economical and contains no toluene.

A negative quality of “Moment” is its high flammability. It sets too quickly and requires careful handling. The work must be carried out quickly and accurately.

Applying glue for gluing cork

Photos of interiors

Cork tiles on walls

Cork wallpaper in the living room interior

In the desktop area

Traffic jam in the dining area

Wall decoration using cork

Cork in a monochrome interior

Light cork wallpaper

Traffic jam on the balcony

Source

The nuances of working with cork

Gluing the cork covering requires care and precision. To obtain a durable floor, it is important to create the necessary physical pressure. The gluing time does not matter.

Press the tile onto the base coated with glue for 30 seconds.

Since all types of glue set quickly, within an hour you can wet clean the cork covering.

Before installing cork slabs, it is necessary to prepare the surface. It must be thoroughly cleaned and dried. Dirt and accumulated dust cause poor-quality gluing.

A hair dryer will help dry the surface.

Gluing the cork base is performed at temperatures above 17 degrees. The building must have good ventilation to remove the unpleasant odor generated by the glue.

Universal glue does not lose its properties at low temperatures.

Even a beginner can create a cork coating. You just need to study the instructions on how to use the glue and follow the technological sequence.

You can learn about the features of the process and recommendations for laying cork fabric onto glue from the video below.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

Price issue

Cork is a fairly expensive material . But the health safety, unique properties and durability of the material make the costs commensurate with the benefits of using cork wall coverings.

Cork wallpaper on a paper basis . Price - from 225 rub. per m2;

Baseless roll stopper . Price - from 225 rub. per m2;

Cork slabs . Price - from 432 rubles. per m2;

Glue for cork - average price - 116 rubles. for 1.5 kg. Glue consumption – from 350g/m2.