One of the most common tools for applying paint is a paint roller.

However, coloring is far from the only area of its application, and to solve each problem, its corresponding type is selected, of which there are more than a dozen.

The tools have different coatings on the working part, sizes and shapes, and include special types.

At the same time, the characteristics of the surface being processed, the material being applied and the conditions of use completely determine which roller to choose for specific tasks.

Further on, what is this tool for, what are its advantages, features, main types and their estimated cost.

Purpose and operating principle of rollers

The purpose of the roller depends on its coat, which is discussed in more detail below.

This is how, in fact, the main division into types is carried out, for example:

- Paint rollers - used for applying various paint coatings.

The roller coat absorbs the paint, after which painting is performed by rolling the rotating part (roller) over the surface to be treated. - Models for plastering - to create texture on a freshly plastered surface.

In other words, on the working part of the roller there is a three-dimensional pattern that pushes through the top layer of plaster or any other material with similar parameters, leaving an imprint. - Options for self-leveling floors - used to remove air from a newly poured solution.

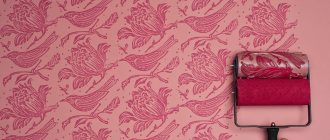

What is the textured roller used for?

At its core, a textured roller is a common device that is used for painting work. But the surface of such a device is corrugated and contains a specific pattern. On the Internet you can find many photos of different types of patterns on a textured roller.

Painting products have a soft fleecy or spongy surface. They are used to apply paint to a surface. Textured rollers have a harder surface on which the pattern is applied.

With light pressure on fresh plaster, such a roller will leave a pattern, according to the one applied to the surface itself. The use of textured rollers in rooms where the walls are plastered with a decorative composition is quite popular.

Reference! The shorter the pile on the roller coat, the less prominent the pattern will be.

Device and characteristics

The design of the roller, regardless of its purpose, includes two main elements:

- The machine consists of a clasp and a handle. The first is a metal base on which the working part is attached. The entire structure is made in the form of a curved rod with a handle for holding.

- Working part. In most cases, this is a roller (reel) in the form of a tube made of plastic, on top of which a coating of various materials is applied, depending on the purpose. The working surface is called a fur coat.

Construction stores sell both assembled rollers and in the form of component parts: a roller with a fur coat and a clasp.

The latter option is preferable for large-scale work, since when the coat wears out, you can save money by purchasing only a replacement element and installing it on the clasp.

Dimensions and weight

Rollers are divided into the following types according to the width and diameter of the working cylinder:

- Mini roller – up to 150 mm and about 15 mm, respectively. Suitable for processing small areas, surfaces with complex terrain or places that are difficult to reach.

- Midi roller – 150 – 250 mm and 50 – 90 mm, respectively. A universal size, which is suitable for most jobs, including painting smooth or slightly embossed surfaces, leveling wallpaper when pasting.

- Maxi-roller – more than 250 mm and more than 80 mm, respectively. The work requires certain skills, since the tool belongs to the professional class. It is used when carrying out facade work, especially if the texture of the surface being treated has many irregularities.

Additional roller sizes include:

- Rod diameter (inner diameter of the cylinder). For most models it is 6 or 8 mm.

- The length of the handle also varies, and in accordance with this parameter, the rollers can be divided into: short - up to 350 mm, medium - from 350 to 450 mm, long - more than 500 mm. If necessary, you can purchase a special extension cord, which, in turn, can be telescopic.

In this case, the increase in the length of the roller can be 70–400 cm. - Weight – 100 – 300 g depending on the material and length of the handle. For rolling models, handle extensions are used, the weight of which can exceed 1 kg.

NOTE:

The given divisions of rollers into subtypes by size are purely arbitrary, and each manufacturer is independently able to classify their products based on personal preferences.

Another characteristic is the length of the pile.

For each fur coat material it is individual.

In addition, a fleecy coating is usually called a fur coat, and a bobbin with a lint-free coating is simply called a roller.

How to understand tool sizes

Rollers have their own division by size. To have a visual representation of this topic, you can view photos of paint rollers. You will find that having different parameters makes the workflow much easier. Comfortable conditions for working with the tool are created.

First of all, the dimensions of the main part – the cylinder – are taken into account. The handle parameters are of lesser importance. This characteristic breaks down instruments into the following types:

- Type – mini. The cylinder has a diameter of no more than 9 cm and a height of about 15 cm. The product is suitable for painting surfaces in hard-to-reach places.

- Type - midi. The diameter is the same, but the height is increased to 20 cm. The tool is universal and is recommended for finishing walls, ceilings and other wide surfaces. An additional advantage is the low weight of the roller.

- Maxi type The length of the roller reaches 30 cm, and the diameter is 8 cm. This roller is a professional tool. Accordingly, its price will be significantly higher than previous types.

This tool can be used both on interior and exterior façade work.

Types of rollers and fur coats

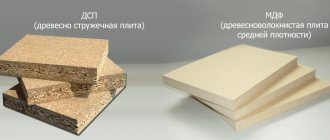

According to the domestic classification, paint rollers are divided into:

- VMP – fur nozzle for painting floors.

- VP is a foam nozzle designed for water-based adhesive compositions.

- VMU – natural fur. The product is intended for painting corners.

- VM – fur covering.

According to the classification of foreign manufacturers, rollers are:

- PE – polyester based

- N – based on natural material

- PC – from polyacrylic modifications

- PA – from varieties of polyamides

So, depending on the material of the working surface, the roller coat is:

- Polyamide - made of artificial fiber with increased wear resistance to abrasion and chemical attack.

The main purpose is the application of water-dispersion paints. The length of the pile is 8 - 20 mm, and the longer it is, the easier it is to apply the coating to a rough surface. - Polyacrylic (acrylic) – has a dense pile, which reduces paint splashing during operation. Made from polyacrylonitrile, which is a synthetic fiber reminiscent of wool, and in most respects it is the same as the previous version.

Attention!

It is not intended for working with materials with aggressive components, which means it is suitable for applying water-based paints.

- Polyester - polyester, reminiscent of padding polyester. Extremely cheap to produce, has excellent absorption and retention properties.

When working on the surface being treated, it does not leave lint. The advantages are compensated by low mechanical resistance and the same durability. - Fur is a generalized name for two types of fur coats. Thus, the option made from natural fur is made from sheep wool and is suitable for treating any surface with varnishes, enamels, water-dispersion, and oil paints.

NOTE:

Not recommended for use with lime-based compounds.

Options made of faux fur - vestan, are used for applying any type of paint, and therefore are universal.

- Velor - plush pile is supported by a fabric base.

Suitable for finishing work on smooth surfaces. Tolerates solvents well. - Foam rubber. It is used for applying water-based varnishes, as well as water-dispersion paints. Essentially, this is polyurethane, which, among its other technical characteristics, has a density, the indicator of which is directly dependent on its service life.

The fur coat does not cake and quickly restores its original shape. The fibers are arranged in such a way that during operation they leave small air bubbles, which means an uneven final surface. - Flock is a textile base with glued polyurethane fiber. Features include strength, environmental friendliness of the material, and water resistance.

- Nylon is a representative of polyamide, which means it has the same properties.

- Felt is an environmentally friendly soft fur coat, suitable for various types of surfaces.

Felt copes well with paints based on aggressive solvents. - Thread - a roller made of fluffed nylon or polyacrylic thread, another name for a thread coat. Designed to work with water-based and oil-based paints.

- Rubber - most often the pressure roller is designed to expel air and increase adhesion when gluing wallpaper.

- Made of microfiber - suitable for working with antiseptics, impregnations, primers, glazes, as well as water-based paints. Microfiber has good absorbency and impact; it is used when processing both completely smooth surfaces and those with slight roughness.

They also use silicone coats for applying decorative patterns and leather coats for working with Venetian plaster.

Latex paints require a synthetic coat.

As for the rollers, the most common materials used are plastic and aluminum, and less commonly, wooden ones.

Rollers with plastic rollers are generally the cheapest due to their ease of manufacture.

It should be noted that the roller may have a connecting seam or be seamless.

The latter option is preferable, since otherwise the movement of the roller along the surface to be treated is hampered at the seam site, which leads to disruption of the uniformity of the applied paint layer.

The presence of a seam is also eliminated by the so-called circular knitted base of the fur coat with a uniform layer of roller coating.

Fastening fur coats

Depending on the type of attachment of the fur coat to the roller, the tool can be:

- Glued – with a non-removable working surface. A narrow strip of fur coat is wrapped around the base with glue applied, forming a joint joint to joint. This type of fur coat fastening system is seamless, since the seam runs in a spiral, which means that the paint is applied evenly during operation.

- Thermo-glued - the fur coat is soldered into a cylindrical base. The design is more durable and reliable due to the absence of glue.

- Sewn - rectangular fabric sewn to fit the shape of a sleeve.

- With a replaceable coat.

In the latter case, a quick-release system of one of the options is used to attach the fur coat:

– Rod (clasp) – a monolithic handle with a rod onto which a roller with a rotation and fixation device mounted inside is placed. The simplest option.

– Frame – the fur coat is fixed on a roller made in the form of a hollow cylinder-frame. The clasp contains bearings on which the equipment is installed. That's why this tool is called a frame roller.

There is also a so-called special fastening system, implemented on long rollers.

The rectangular frame has an axis secured by means of a thread, onto which a roller with end bushings is mounted.

Painting walls with a roller

Painting walls with a paint roller, a process that will include several stages:

- Preparatory. It is necessary to prepare the surface for work by filling up uneven areas with putty or plaster, and covering the base with soil. Once the primer has dried, you can begin painting.

The roller itself must be prepared for work: the tool is soaked for 2-3 hours in a soap solution, washed and dried. The stage of preparing the roller for use cannot be ignored, as otherwise the product may leave fluff and threads on the painted surface.

- Having prepared the surfaces and tools, you can proceed to painting. To do this, the paintwork material is poured into a special deep container and the roller is dipped into it. Important! The roller should not just be dipped, but rolled out over the container, so the paint will lie more evenly on the coating of the cylinder. You need to roll the roller over the bath several times.

- Next, you should decide on the place to start work; it is preferable to start painting from the corner area of the room and then move in any convenient direction.

- Using a roller, you need to evenly paint the surface and make sure that there are no gaps or drips. To do this, you should not put too much pressure on the tool and all movements should be made as smoothly as possible, in the direction from top to bottom.

In order for the surface to acquire an intense color, the paint is applied in several layers. It will not be possible to paint the corners completely with a roller: special brushes are used for this work.

Types of rollers and their prices

Each construction roller can be classified into one of the following types:

- Painting – used for applying paint and varnish coating. The price depends on the material of the fur coat, ranging from 100 to 1200 rubles and above.

- Special – for performing other tasks.

The first option, depending on the fur coat or the design of the clasp, can be:

Universal

Suitable for working with any flat surfaces, including ceilings and walls, capable of applying enamels, varnishes and paints.

For working with specific compositions, for example, exclusively for applying water-based paints.

Radiator

Roller on a wire extended handle with a thin roller.

Purpose – painting the back surfaces of pipes and radiators, where it is impossible to reach with a regular clasp roller.

The cheapest one will cost 50 rubles.

Facade

Its characteristic feature is the large diameter of the roller, which increases the working surface area, a long handle, and most importantly, the presence in the design of a bearing that slows down rotation at high speeds.

As a rule, such a roller has a longer pile, and in combination with other characteristics, it increases the convenience and speed of processing surfaces with a large area.

Facade tools are often produced with a telescopic handle, which largely distinguishes them from models for interior work.

Price – from 200 rubles.

Angular

It has a small width roller that resembles a wheel, which allows you to easily paint corners and similar hard-to-reach places.

Price – from 130 rubles.

Special rollers include the following options:

Pressing (smooth)

They are used for applying adhesives, but mostly to remove air bubbles from under the material, mainly wallpaper.

This type of wallpaper roller has a rubber or polyurethane roller coating, also called a rolling roller.

The tool comes with a conical roller or a “barrel” shape.

At the same time, the rollers for wallpaper and for wallpaper seams are different.

Price – from 70 rubles.

Needle

There are several types of tools depending on their purpose.

For example, a drywall roller has sharp spikes on the working surface, which pierce the surface when rolled.

This is done so that the inner layer is better saturated with moisture for the subsequent giving of a certain shape to the sheet, say, under an arch.

Options for self-leveling floors can be studded with soft needles designed to remove air bubbles from the thickness of the poured material.

Price – from 200 rubles.

Textured

The general name for rollers for forming textured surfaces.

Thus, a structural tool has a coat that gives plastered and putty surfaces (in principle, from any structural composition) a decorative texture.

Another name is decorative roller.

Paneled (patterned)

It is quite rare on sale, and its purpose is decorative painting, excluding the use of a stencil.

This painting tool is designed for applying paneling.

The frame type of construction allows you to install a roller with any pattern of interest.

In addition to the classic mechanical rollers, which periodically have to be dipped into a tray of paint, there are options with a refill function.

They are designed to work with liquid water-based compositions, and the roller design has a side cover that locks the internal cavity into which paint is poured.

On the one hand, such a roller is convenient to use, on the other hand, it is disposable, since even if you rinse it well after use, the next time you use it, the paint will no longer appear on the fur coat with its original effectiveness.

Care instructions

In order for the roller to last a long time and not have to be thrown away after finishing work, you should know how to properly care for the tool. If water-based paints were used when working with a roller, the roller should be rinsed in clean water and do not wring out its coat. The tool is hung on a nail and left until completely dry.

If the roller was used to apply varnish or acrylic-based composition, a specialized product should be used to wash it. Such a product can be purchased at any store that sells materials and tools for finishing work, and the roller should be cleaned immediately after finishing the surface painting process, otherwise the tool will be hopelessly damaged.

We hope that after reading this instructional article, you will get a clear idea of the design, types, and purpose of a paint roller and will be able to choose a useful and high-quality tool for your repair.

Which roller should you choose?

In most cases, a medium-sized roller is suitable for use at home, especially if the master does not have decent experience in performing painting work.

For cosmetic repairs, a tool with a foam working surface will do.

Due to its low cost, it is not a pity to throw it away, and in the process of coloring it has repeatedly proven its sufficient effectiveness.

Important!

The length of the pile, as well as the material of the fur coat itself, is selected based solely on the paint used.

High quality coating is provided by a roller with a velor coat.

For professional work, it is better to buy several rollers of different sizes with replaceable coats.

This will allow you to take from existing tools the optimal width to complete the task without unnecessary trips to the hardware store.

Sometimes a paint roller is used to paint a car.

This method of applying paint is advisable solely from the point of view of economy if it is necessary to restore the coating of a vehicle intended for some off-road walking.

Extremely low quality of work is guaranteed even if an experienced painter with the most sophisticated roller gets to work.

To apply paintwork to the car body, you should use a tool designed for this purpose - a spray gun.

Some tips for a beginner painter

It is not difficult for professionals to choose the right paint roller, but for a novice molarist who has not held this tool in his hands, he cannot do without the help of advice. Let's look at some tips and recommendations from experts:

If you have planned to paint walls and ceilings, and you still have the desire to finish the job faster by choosing a large-sized roller, our advice is, under no circumstances do this; it is better to opt for a medium-sized tool.- Choose a paint roller that does not have seams, since when applying paintwork, it will leave a lot of marks and streaks.

- When choosing, pay attention to the color of the fur coat; it should be light in color. Since over time, dark pile can fall out onto the surface being painted, creating a lot of inconvenience.

- It would be useful to make sure, by holding the handle of the instrument, that all your fingers comfortably clasp it.

- If you plan to paint the surface in different shades, then we recommend that you stock up on several rollers. Of course, you can do painting work with one tool, but in this case you will have to thoroughly wash it, dry it and roll it out.

- To avoid getting lint on the wall or ceiling you are painting, you can use masking tape by rolling the roller along its adhesive side.

- To ensure uniform impregnation of the roller, it is recommended to simultaneously purchase a special container for paint.

And in conclusion, I would like to say that after studying the material we provided, “Paint rollers, as well as their types and sizes,” you will already pay due attention when choosing this painting tool, so that using it will be nothing but a pleasure.

What you need to know about rollers?

Each roller manufacturer names the material used to make the fur coat differently.

For example, foam rubber is moltoprene, or polyester is polyester. Moreover, instruments made from the same material sometimes have completely different colors, indicating quality.

Polyacrylic options similar to lamb fur are available in blue, yellow and light green (indicated in ascending order of quality).

The same foam rubber can be thick yellow and dark blue.

Attention!

The quality of the final result of painting work is influenced not only by the roller, but also by the paints used.

When choosing the latter, special attention should be paid to such properties as coverage (coverability, concealability) and consumption.

What to consider when choosing and using?

Each type of paint has its own material

So, for primer and antiseptic, you can safely buy an inexpensive roller with any working surface material. Whether it is foam rubber, polyacrylic or polyester is not so important in this case, since these compositions are practically neutral. At the same time, thick varnishes and paints require fluffy coats with high chemical resistance - for oil-based or alkyd-based compositions, only fur and velor rollers are suitable.

Note:

Not only the composition of the coloring material matters, but also its color. So, for applying white paint to the ceiling or walls, a microfiber roller is quite suitable. It is also good for light colors. However, it is better to apply bright, saturated colors with a roller with a higher degree of coverage: at one time such a tool allows you to apply a thick layer of paint, making even a single-layer coating as dense as possible.

A replaceable fur coat is not always good

Today in stores you can easily purchase both a “solid” roller and individual structural elements. This is very convenient, since fur coats tend to quickly become unusable - especially during long-term repairs and, especially, construction work. But you should take into account the fact that the replaceable coat is attached to the roller using special plugs - as a result, traces of seams may remain on the surface to be painted

. This is not always critical, but in many cases the finish runs the risk of becoming more “spectacular” than expected. Therefore, for those who strive for a high-quality and accurate result, it would be more reasonable to buy a regular paint roller with a permanent coat: seamless gluing/thermal welding technology allows you to avoid “surprises”.

Surface matters too

For those who decide to buy a roller for painting the ceiling

, it’s worth taking a closer look at products made of fur, velor or polyamide. Special ceiling rollers with an uneven structure are also produced: their inner layer is denser than the outer one. Thanks to this, the tool distributes the liquid composition most evenly, releasing an additional portion of paint only with stronger pressure. Often, ceiling rollers are also equipped with a semicircular casing designed to protect the painter from falling splashes. To treat high ceilings, it is best to buy a paint roller of this type.

For painting uneven and hard-to-reach surfaces

rollers with a specific design are used. Width-adjustable sliding mechanisms are great for painting large areas, parallel handles are ideal for working in hard-to-reach areas, and swivel designs help when working with pipes.

Textured non-woven wallpaper

It is best to paint with a medium or long pile roller.

Care is important

Throwing the roller in the trash immediately after painting is not a bad idea if you are dealing with a cheap foam product. If the work is carried out with a fleecy, already well-proven tool, it is worth paying a little attention to it. A couple of minutes or a little more - depends on the coloring composition.

So, water-soluble paint can be washed off with running water, preferably warm. To clean a fur coat from aggressive compounds, it is recommended to use “heavier artillery” - solvent or kerosene, and after soaking, wash it in a soapy solution.

It is recommended to dry the roller in a heated room - vertically, hanging or supported by a handle.

Note:

if the tool is planned to be used for re-painting with the same color and composition, there is no need to wash the tool. For 3-4 days it can be wrapped in plastic film or a bag. And after finishing the work, the roller is thoroughly cleaned of all excess.

Need to know where to buy

It’s no secret that today you can buy tools (and more) in an online store without high markups. This is both profitable and convenient. But is there a loss in the quality of the goods? The question is quite reasonable, so you should only trust a reliable store and trusted brands.

The online catalog Valles.ru presents tools from Sherwin-Williams, Maestro, Rexant, Pentrilo, HEADMAN, Fit and many other famous manufacturers. You can buy a paint roller for painting, as well as a textured decorative roller in the online store with fast delivery to any region of Russia.

For all questions, we are waiting for your calls: +7 (861) 241-08-80.

Caring for a textured roller

In order for the structure to serve longer, you need to properly monitor it. How to do it? After using the roller, it is immediately cleaned with a solution; this can be done in ordinary water. Next, it is dried evenly using the hanging method. It is important to ensure that there are no plaster residues in areas with texture.

Important! Wooden rollers react very strongly to water, so you should not keep them in water for too long. It is best to wash such structures with detergent.

Using a roller is not that difficult, but it allows you to create a large number of interesting design solutions. The main thing is to study the instructions for using the textured roller.

How to make a roller with your own hands

You can make a textured roller with your own hands. From improvised means or old tools, you can make a design that will be no worse than a professional device. The manufacturing process is simple:

- Create a blank, the basis for which will be a wooden rolling pin.

- A metal pin is inserted into the drilled hole.

- The pin is bent in the form of a handle with a convenient holder.

- The side holes are plugged with glue.

- A pattern is applied to the surface of the rolling pin.

If desired, such a roller is covered with a softer material so that it is not difficult to use the structure. But even without additional materials, such a roller can be used.