It would seem that the first rubber spatula you come across for grouting joints, or even an ordinary rubber band, would be suitable for jointing. But the ease of doing the job and the final result will depend on the quality of the tool. If you often lay tiles or simply value ease of use, this article is for you. In it I will talk about the tool for grouting tiles, its choice and differences.

In the photo you can see several options for rubber spatulas

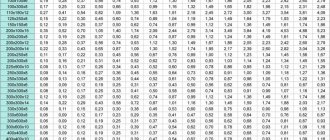

- The first spatula is the most popular. It has a comfortable handle, but a small work surface, which reduces work productivity. Imagine how much time it will take to grout a mosaic with such a tool.

- The second option has an inconvenient handle, so it is more difficult for them to work, and your hands will get dirty.

- A third corner spatula will sometimes be convenient for plastering work, filling joints between decorative stones, in corners or in figured friezes.

- The fourth trapezoidal rubber spatula from Raimondi is better than all previous options: it has a comfortable handle and a large working surface. Essentially this is an improved version of the second option.

- Number 5 shows several options for grouting spatulas from the Raimondi catalog. Many tilers prefer to work with such floats. They have replaceable nozzles made of rubber or caoutchouc. Such a tool can easily last even ten years, you can see proof of this in the photo. But when working with it, you need to carefully squeeze out the rubber from the remaining grout, otherwise it will lose its elasticity over time. Therefore, I have now switched to a thick rubber nozzle with a cone. With the sharp edge of a grater it is easy to press the mixture even in corners. The rubber is easy to clean and does not become clogged with the mixture.

The spatula with a rubber attachment lasted about 10 years. Over time, the side became uneven, so I had to sand it with a grinder.

Why not use a regular spatula?

There are a number of restrictions that must be taken into account before starting work. Spatulas intended for applying putty are made of metal, since they bear heavy loads. The working edge turns out to be very sharp. Let us remind you that grouting is carried out at the finishing stage, after laying the tiles or floor tiles. If you rub the mixture with a regular spatula, the sharp metal edge can leave scratches, abrasions and other defects on the surface of the tile.

A tile grouting spatula is ideal for this purpose. It is softer, and therefore has a delicate effect on the surface of ceramic tiles, protecting against scratches and other mechanical defects. In addition, the variety of these devices helps you choose a spatula for a wide variety of jobs and in any conditions.

Set of spatulas for forming seams

Rating of quality spatulas for putty

Budget (up to 100 rubles)

Mirax 1000-030_z01 30 mm

The review begins with the most budget scraper on Yandex Market. It is designed for working with heavy solutions and has a working surface width of 3 cm. Thanks to its compact size, the tool can be used in hard-to-reach places, as well as for performing a small amount of work. The blade is made of stainless steel and is not subject to corrosion. The round wooden handle fits comfortably in the palm of your hand and does not slip out. There is a hole on the handle for wall mounting. The average price of a product is 18 rubles.

Mirax 1000-030_z01 30 mm

Advantages:

- the product is inexpensive;

- due to its low cost, the model is widespread and is sold in any hardware store;

- can work with heavy solutions;

- Can be used in hard to reach places.

Flaws:

- the small width of the working surface does not allow the tool to be used over large areas.

BISON mm

Another popular model that is on sale everywhere. Like the previous contender, the blade in the spatula is made of stainless steel, but the handle is plastic. The working surface width of 6 cm makes the scraper universal, allowing it to be used not only in narrow places, but also in wide areas. Most often it is used to level putty during finishing. The handle with a relief pattern fits comfortably in the palm of your hand and has a significant advantage over a wooden one - it does not swell when in contact with water and is well attached to the blade. The product is manufactured in Russia, and can be found not only in construction hypermarkets, but also ordered online in an online store. The handle has a hole for wall mounting. The average unit price is 22 rubles.

BISON 10077-06 60 mm

Advantages:

- low price;

- universal purpose;

- water resistant handle;

- a large number of positive customer reviews;

- easy to find on sale.

Flaws:

- The handle is made of low quality plastic, and even a new one looks unpresentable.

Eurotex 020605-100 100 mm

The spatula resembles the previous contender in appearance and has a larger blade width (10 cm). A scraper spatula is used to apply and level putty on various surfaces. The blade material is stainless steel, the handle is made of plastic. The weight of the product is 89 grams, thanks to which the hand does not get tired when working. The handle has slots to prevent it from slipping out of your hands. The average price of a product is 40 rubles.

Eurotex 020605-100 100 mm

Advantages:

- universal purpose;

- light weight;

- elastic steel.

Flaws:

- not detected.

STAYER 1010-H4 120 mm

The product is a set of four scrapers with different working surface widths - 50, 80, 100, 120 mm. All of them are made of plastic and can be used both for finishing work and for puttying during cosmetic treatment of cars. Due to the fact that the set includes scrapers with different widths, the user can select one or another tool depending on the specific need. Although the scrapers are made of plastic, they are durable when handled correctly and are resistant to water. The German brand has proven itself well, and according to buyers, the set is worth its price. The cross-section of the scrapers is trapezoidal, each of them has a hole for mounting on the wall. The average price of goods is 30 rubles per set.

STAYER 1010-H4 120 mm

Advantages:

- low price;

- different sizes of scrapers in the set allow you to perform work of any complexity;

- easy to clean;

- can be used in automotive repair.

Flaws:

- not suitable for working with heavy mortars, as well as mixtures with solid inclusions (decorative pebble plaster, etc.).

SIBIN 10079-200 200 mm

The tool is used for facade work, which is facilitated by the large width of the working surface. It is made in Russia and is widely distributed in construction stores. The blade is made of stainless steel and is not subject to corrosion. The handle is plastic, with a large hole in the middle (for wall mounting), fits comfortably in the palm of your hand and does not slip out. The manufacturer provides a 12-month warranty on the tool, which is rare for this type of product. The thickness of the steel sheet is 1 mm, it bends easily and follows the surface of the wall. The average price of a product is 35 rubles.

SIBIN 10079-200 200 mm

Advantages:

- low cost;

- there is a 12 month warranty;

- ergonomic handle;

- elastic steel.

Flaws:

- narrow scope of application (only for large areas).

STAYER PROFESSIONAL 1009-10-04 100 mm

The model differs from the previous ones by the presence of teeth. As is clear from the name of the product, it belongs to the professional category. It is used for applying putty and adhesive solutions. Most often, the tool is used in tiling work, when laying tiles and porcelain tiles, and leveling putty. The 4 mm teeth allow you to create grooves that promote a tight fit and remove excess air from under the facing material being laid. The blade width of 100 mm ensures universal use not only in hard-to-reach places, but also over large areas. Light weight (70 grams) facilitates the process of applying and leveling the putty. The handle is made of plastic with an anti-slip coating and has a wide hole in the middle for wall mounting. The average price of a product is 55 rubles.

STAYER PROFESSIONAL 1009-10-04 100 mm

Advantages:

- the rigid blade allows you to work with heavy mixtures;

- light weight;

- low cost;

- can be used for facade work.

Flaws:

- narrow scope of application;

- It is difficult to find on sale, since the product is unpopular.

Average price category (from 100 to 500 rubles)

Unlike products that were included in the budget price category, the tools in question are distinguished not by plastic or wood, but by a rubberized handle that fits comfortably in the palm of your hand and is securely fixed in it.

BAUMAUTO BM-33911 25 mm

BAUMAUTO is one of the best manufacturers of auto tools for repairing body parts; its products are distinguished by high-quality materials and fitted elements. The spatula has a small working surface width, which allows you to smooth the mixture in hard-to-reach places and small areas. The stainless steel of the working element is flexible, follows the curves of the treated area, while smoothing out unevenness and leveling them out.

The rubber handle has a hole at the top for wall mounting. The product belongs to the professional line and is sold only in specialized stores. You can find a large number of positive customer reviews of the product online. The average price of a product is 105 rubles.

BAUMAUTO BM-33911 25 mm

Advantages:

- plastic working part;

- rubberized handle;

- low cost;

- many positive customer reviews;

- the new product can be sold separately or in a set with scrapers of other sizes, which allows you to perform different types of work (used not only for starting, but also for finishing putty).

Flaws:

- The brand's products are professional, and many buyers may have difficulties with where to buy the tool - it is sold only in car dealerships.

Sibrteh 85575 300 mm

The model is designed for performing facade work, and eliminates the main mistake when choosing spatulas, which many buyers make - buying a product with a wide working blade without a stiffener. It is designed to prevent bending and creasing of the blade when applying heavy solutions. The function of the stiffener in the product is performed by an aluminum plate that is resistant to aggressive environments and water. This design is considered the best when leveling putty in a thick layer and for solutions containing solid inclusions (pebbles, grains, etc.).

The handle of the product is two-component, made of rubber and plastic, provides ergonomic placement in the palm and allows you to operate the scraper comfortably. There are two holes in the upper part. The working width of the model is 300 mm, length – 215. Due to its heavy weight (almost 300 grams), only a physically strong person can work with the scraper, so it is not suitable for women. The product comes with a small instruction manual, which tells you how to apply the putty with a putty knife and how to hold it correctly so that your hand does not get tired. The description also provides information on how to prepare the product for use and how to clean the putty from the putty knife. The manufacturer manufactures products in Russia, so finding the product in the store will not be difficult. The average price of a product is 230 rubles.

Sibrteh 85575 300 mm

Advantages:

- ergonomic handle;

- there is a stiffening rib;

- easy to find on sale.

Flaws:

- the heavy weight does not allow women to use the tool.

Kapriol 23144 40 mm

The Italian brand is well known in the production of work clothing and footwear, and recently it has also launched its own line of tools for construction and repair. The model under consideration stands out among competitors not only in appearance, but also in a number of characteristics - the working blade is made of hardened steel with a chrome coating. Thanks to this, the solution easily glides along the blade, does not stick to it, and is evenly distributed over the surface being treated.

The handle has a proprietary two-component ProGrip coating, which provides not only a comfortable grip, but also has anti-slip properties. The scraper is used in finishing for processing walls and ceilings; it can be used in hard-to-reach places. Suitable for puttying drywall. The working width of the blade is 40 mm, the structure – semi-rigid – ensures smoothing out unevenness, while maintaining the given shape and not bending. Among the advice from builders, you can find recommendations to buy tools only in trusted stores, since you can often find fakes on sale, not the original. It is not recommended to order a model via the Internet, since it is impossible to determine a fake from a photo. The average price of a product is 300 rubles.

Kapriol 23144 40 mm

Advantages:

- one of the most ergonomic models on sale;

- light weight;

- There is an anti-slip coating.

Flaws:

- high price;

- There are often fakes on sale.

L'Outil Parfait 2602003 30 mm

The review continues with the product of another well-known brand in construction, which has proven itself to be good value for money. The working surface of the product is made of stainless steel, which is polished to a mirror surface. This facilitates quick and uniform application of the solution to the surface to be treated. The handle of the product is two-component, consists of plastic and rubber, and has an anti-slip coating. A working width of 300 mm allows you to apply the solution to hard-to-reach places; the scraper can also be used for grouting joints between tiles. Buyers note the optimal length of the handle, as well as the light weight of the product, which allows you to work with it for a long time without fatigue. According to some buyers, this is one of the best products that can be bought for comparable money. Despite how much the model costs (depending on the store, the unit price can reach up to 400 rubles), it is popular and is available for sale in most construction supermarkets.

L'Outil Parfait 2602003 30 mm

Advantages:

- light weight;

- ergonomic handle;

- can be used in hard-to-reach places;

- easy to find on sale.

Flaws:

- high price.

Expensive (over 500 rubles)

ERGOPLANE 150x0.5 mm

The review continues with a tool for mechanized putty from the famous Polish company OLEJNIK JL. This company is a direct competitor of the famous STORCH brand, is not inferior to its products in quality, but at the same time has an affordable price, allowing Russian builders to use world-class spatulas.

The model in question is used for machine putty, and therefore differs in appearance from the spatulas that were presented in the rating earlier. Main parameters of the product: the base is made of aluminum, the working blade is replaceable, made of stainless steel. The width of the working blade is 15 cm, the width is half a millimeter. Thanks to this, the blade holds its shape during operation and levels the putty over all surface irregularities. To ensure that no unevenness or depressions remain after passing, the blade is polished to a mirror shine. The tool performed best in applying the starting layer. The average price of a product is 1,600 rubles.

ERGOPLANE 150x0.5 mm

Advantages:

- high-quality materials and assembly;

- low cost;

- A replacement blade can be purchased separately, saving on the cost of completely replacing the product in the event of a breakdown.

Flaws:

- difficult to find on sale, since the product is not widely distributed;

- high price;

- Suitable for professional use only.

Master Color 30-2714 350 mm

The products of the Russian manufacturer Master Color have been on the construction products market relatively recently, but during this time they have gained the trust of buyers due to their good price-quality ratio. The model in question is intended for facade work. The working blade is made of stainless steel, with an aluminum base, which serves as a stiffener. Both of these materials are not subject to corrosion and are not afraid of contact with water. The width of the canvas is 35 cm.

The handle is two-component, consists of rubber and plastic with an anti-slip coating. For ease of placement in the master’s palm, it is attached to the base not perpendicularly, but with a slight tilt to the side. There is a hole at the top of the arm for wall mounting. Users note a flexible canvas that has no roughness and applies the solution evenly, without gaps. The model can be used for both the starting and finishing layers. The tool performed well both when applying putty and when sealing tile joints. The average price of a product is 900 rubles.

Master Color 30-2714 350 mm

Advantages:

- can be bought at any hardware store;

- ergonomic handle;

- a large number of positive customer reviews.

Flaws:

- due to the heavy weight, when working with a spatula for a long time, the hand of the master gets tired;

- high price.

ANZA 649290 100 mm

Tools from the Swedish brand are much more expensive than their Russian counterparts, but experienced builders recommend buying spatulas of this particular brand whenever possible. This recommendation is primarily due to the fact that the brand’s products are more durable and reliable than their competitors. This is indirectly evidenced by the 12-month warranty that the manufacturer provides for its products (which is rare for this type of product). The model in question is made of stainless steel, the working blade has a cone shape. This shape allows you not only to level solutions or mixtures over the surface, but also to use the tool for other types of work.

So, with its help you can clean walls from wallpaper, or work with wooden surfaces. If you need to treat an area that is difficult to reach, you can purchase a proprietary extension cord that allows you to apply the mixture at a great distance from the master. In addition to putty, a spatula can be used to level sealant, glue, and any other viscous composition. The width of the working blade is 10 cm, it is made of polished stainless steel. The handle is plastic, with rubberized inserts, and has a shape that follows the curve of a person’s hand. There is an anti-slip coating. There is a hole in the top for wall mounting. The average price of a product is 750 rubles.

ANZA 649290 100 mm

Advantages:

- universal purpose;

- can be used in conjunction with a tripod with extension function;

- The manufacturer provides a 12 month warranty.

Flaws:

- high price.

Kraftool 10036-450 450 mm

The model is manufactured in Taiwan. It is intended for facade work and has an increased working blade width of 45 cm. The tool is designed for applying plaster or putty on surfaces with a large plane. The working blade is profiled, made of stainless steel. There is an aluminum stiffener.

The handle is ergonomic, the shape follows the curve of the human palm. Slots are made on the handle in such a way as to reduce the load on the master’s hand while working with a spatula. It is made of plastic with a rubberized coating, which has anti-slip properties. The manufacturer claims a 2-year warranty, which indicates the reliability and durability of the product. Among the customer reviews, you can find the opinion that the blade is a bit thin, which is why it plays with little effort. However, this thickness of the canvas allows for smooth gliding over the surface and improves the quality of application of the solution. Some users also do not like the grip of the handle - they claim that it is more convenient to work with the standard shape. The large weight of the spatula does not allow untrained people to use it, as the hand quickly begins to get tired. The average price of a product is 950 rubles.

Kraftool 10036-450 450 mm

Advantages:

- high-quality manufacturing materials;

- there is a stiffening rib;

- anti-slip handle.

Flaws:

- There are conflicting reviews of the spatula online – some consider it convenient, others – on the contrary;

- high price.

What are the benefits of spatulas of this type?

These useful devices have many advantages over other spatulas:

- Low cost. The price of spatulas intended for grouting joints varies from 35 to 80 rubles. Due to this, they are often classified as consumables, although many experienced craftsmen carefully care for spatulas and use them many times.

- Ease of use. Grout trowels come in all sorts of shapes. The ergonomics of these devices are thought out to the smallest detail: the spatula fits easily in the hand, and thanks to its light weight, it allows you to work for a long time.

- High quality finishing work. Despite its plasticity, the spatula easily pushes in the grout mixture, and only 2 movements are required: the first is to fill the joints, the second is to remove the excess.

In addition, these spatulas are large in size. This increases the speed of finishing work. Some spatulas reach a length of 80 cm, making them suitable for filling joints on walls or floor surfaces.

About quality, manufacturers and cost

The secret to fast and high-quality work by professionals is to use the appropriate tool. Many companies, including the domestic Zubr, as well as foreign brands STAYER, SPARTA, FIT, have taken into account all the operating features of rubber spatulas, and therefore offer customers the most ergonomic, high-quality, durable, and universal tools.

In construction stores you can find the necessary tools at retail; in some companies it is possible to purchase spatulas in small and large wholesale. The price per piece is determined by its size, design features and materials used, so on average the cost varies from 45 to 80 rubles. Spatulas are also sold in sets consisting of three pieces of different sizes 40, 60, 80 mm. The price for it will be in the range of 50-80 rubles. White rubber spatulas will have a higher cost, by about 10%. If you purchase tools in bulk, in particular small ones, as consumables, then the lowest price is for 1 piece. will be up to 35 rubles.

When to use these spatulas

This is an important aspect that deserves attention. The grout mixture is applied only after the tile adhesive has completely dried. Please note that pressure is applied to the spatula and the surface (otherwise the grout will not fill all the voids). Therefore, uncured tile adhesive may wrinkle, and level differences will appear on the surface.

On average, the drying process for tile adhesive takes about 24 hours. However, it is recommended to check the manufacturer's instructions on the packaging of the dry mixture.

How to make the right choice

When choosing a tool, you should take a closer look at the following details:

- the rubber sheet must be sharpened, this is important for troweling work;

- evaluate the rigidity of the spatula and compare it with the characteristics of the materials (tiles, stone, composition of the grout mixture);

- convenience of the handle (if it is wooden, then the application of drying oil is required to extend its service life).

A rubber spatula will help you work successfully and with pleasure, and achieve beautiful, high-quality results.

Let's talk about the appointment

Spatulas are intended for filling joints between fragments of ceramic tiles, but this does not limit the scope of application of these tools. Rubber/rubber spatulas are actively used when laying mosaics and other fragmented surfaces, the joints between which must be filled with a grout mixture.

It was assumed above that spatulas are used at the finishing stage of finishing work, and this is the main purpose of these tools. However, the plastic and soft structure of the spatula makes it suitable for restoration work: this protects the surface from damage.

Why should you use a spatula?

There are many devices suitable for grouting joints between tiles. Some craftsmen apply the mixture with their finger and use it to smooth it over the entire groove. This method has many disadvantages, including:

- uneven surface;

- uneven filling of seams;

- dirt;

- difficulties working with dry mixtures, etc.

For a long time, rubber braided cables with a cross section of 6-10 mm were used for grouting. This somewhat saved the situation, but still the grouting procedure remained not very accurate and took a lot of time.

Spatulas made in factory conditions help to get rid of unnecessary difficulties. With their help it is provided:

- filling of seams as tightly as possible;

- saving grout mixture;

- sealing the seams, which contributes to their durability.

Tools for cleaning tile grout

The last step in creating seams is cleaning the surface; there are 2 methods. In most cases, preference is given to the “wet” method, because there is no dust left behind. But with the help of dry cleaning, the result is achieved no worse than in the case of the wet method.

Wet cleaning

Use a cellulose sponge, which is moistened with water, wring out a little and sand the seams and clean the surface.

Dry cleaning

A grater with a fine mesh is used. There is no need to wet the seams with water during the sanding process.

Design

The design of spatulas for grouting joints is extremely simple and consists of two main components:

- Plastic working tool. It is a plate made of rubber or rubber. Can be either black or white. The edge intended for filling seams has a chamfer - a beveled, pointed end that ensures a tight fit to the surface. It is the chamfer that is the working area, and thanks to the bevel, uniform distribution of the grout mixture is ensured over the entire area.

- Handle. It can be different. Trapezoidal models are most often used because they fit comfortably in the palm of your hand. However, handles in the form of a bracket are considered the most practical, since they provide easy grip on the spatula and do not cause a feeling of fatigue even during prolonged use.

Note that the handle plays an important role. It provides the necessary pressure, thanks to which the mixture easily fills the seams. There are spatulas without a handle. They are convenient for grouting joints in hard-to-reach places (for example, behind pipes), but they are not suitable for long-term work, since the fingers get very tired from the tension.

Chamfering a work plate is also tricky. Thanks to its beveled shape, it helps to rub corners, completely covering and sealing them.

Manufacturing materials

Various materials are used to produce handles, including plastic, wood, and rubber. The working plate is made of rubber and rubber. The last option is the highest quality and most durable. This is due to increased resistance to chemicals included in grout mixtures. Cracks and other defects are less likely to appear on rubber spatulas.

Set of PVC spatulas

Why is spatula integrity so important?

Please note that the working edge of the spatula should always remain as smooth as possible, without bevels and all kinds of defects. Otherwise, a groove and various bulges will remain on the grout seam, which will subsequently lead to damage to the seam and depressurization.

In order for the grout joint to be durable, it is necessary to make it perfectly even and not protruding above the surface of the tile. It will be impossible to achieve such an effect with a damaged spatula.

Summary of Tool Selection

Each master must choose a tool for himself, focusing on his skills, abilities and ease of work. It is worth taking into account the characteristics of the material with which you will need to work. Everyone decides for themselves which tool is more convenient to apply the mixture.

These are basically rubber spatulas. If grouting occurs on the wall, then it is more convenient to do it with a gun.

We must not forget about sanding using special smoothers.

When choosing a tool, it is important to understand that it will be used to achieve high-quality and reliable seams between ceramic tile elements.

Types of spatulas

These tools are divided by type of work. Their shape, ergonomics and other indicators largely depend on this.

The color of the spatula directly indicates the degree of hardness. White instruments are considered soft. They are suitable for the last stage of processing, when the main stage of work is completely completed. Black spatulas are more rigid, and therefore are used for grouting joints on uneven, bumpy surfaces.

Based on their purpose, spatulas are divided into several key types.

Soft planning

They have a characteristic shape and are sold with or without a handle. The chamfer is located at an angle of 45 degrees. The shape of the spatula itself can be rectangular or trapezoidal.

Spatulas of this type are intended for filling joints with cement mixture. They are used when laying large ceramic tiles. These tools are characterized by increased rigidity and, with proper care, can serve the master for a long time.

Painting rubber

It has a recognizable shape, thoughtful and simple ergonomics, and low weight. The chamfer of the working surface is much smaller than that of a leveling spatula, but at the same time it also ensures high-quality filling of seams. It is recommended to use rubber models. They are more expensive, but much more resistant to aggressive compounds.

These spatulas are considered universal. One such tool is enough to grout joints in the bathroom or kitchen. If necessary, you can purchase spatulas of different sizes. This set is suitable for processing any surface, even in hard-to-reach places.

For filling tile joints

This type differs from the above in its unique shape. The spatula is made in the form of a handle and has a wedge-shaped working tool, thanks to which it is easy to fill corners with grout mixture. The edge size does not exceed 10 centimeters, which greatly simplifies the work with grouting materials.

As a rule, these spatulas have a cast design and are made of rubber. Thanks to this, they are considered dense, durable and of high quality.

Jointing

The jointing spatula has an unusual shape. Its main purpose is to create smooth, round seams. It is indispensable when it is necessary to fill the seams between tiles with semicircular edges. The spatula is very easy to use and helps create a decorative profile.

Types of combs for laying tiles

The simplest comb for laying tiles on the floor or walls is a trapezoidal plate with a handle attached to it. It can be fixed to the working plane or perpendicular to it. On sale you can find a universal comb with smooth and jagged edges, but it does not have a handle, so it is physically more difficult to work with it. By what parameters do the combs differ from each other:

- Size. Working surface width from 10 to 45 cm.

- Type of teeth. This indicator determines what kind of adhesive mixture you can work with. Semicircular ones are suitable for cement or synthetic compositions, and triangular ones are good for working with mobile mixtures applied in a thin layer.

- Material. Rubber or caoutchouc is suitable for grouting joints, and metal is suitable for applying adhesive composition. It is not recommended to use plastic for the same purposes; it is too short-lived. Burrs will quickly appear on the plastic surface.

Each tooth shape in the working area has its own numerical designation. So, for laying PVC tiles, A1 or A2 is suitable - a comb with frequently spaced triangular teeth.

How to use a spatula

Using spatulas for grouting materials does not cause any difficulties. Turning the tool with a chamfer in the direction of movement of the hand, it is necessary to apply the grout mixture to the surface and run the spatula along the seam. This is followed by a second movement that removes excess, filling the joints.

This technique is simple, effective and convenient. It is considered universal because it helps fill the seams between tiles, as well as process the edges of linoleum, parquet and other surfaces that have characteristic joints.

The spatula must be completely dry, and this is extremely important. Even a small amount of moisture can lead to the dissolution of the grout mixture, as a result of which it will quickly dry out and lose its quality. The spatula must be held perpendicularly, at an angle of 90 degrees relative to the surface. To ensure that removing excess grout does not cause difficulties, it is recommended to use a foam float; it will help speed up the process.

Tool requirements

The design of the spatula, at first glance, is so simple that it seems impossible to damage the tool. But practice shows that there are details and properties that affect the comfort and productivity of work:

- pen. It must be adapted for long-term use through a convenient design that prevents hands from being contaminated with the grout mixture. The shape of the handle should facilitate applying pressure to the grout mixture, filling the seam or tile joint. Sufficient pressure will compact the composition and enhance performance;

- rubber sheet. The shape, density, and plastic properties should serve to unhindered collection of excess mixture from the tiles after filling the joints, and the cone-shaped edges should serve to press the grout even in the corners. Surface cleaning must be complete, without the possibility of filling pores and small cracks.

Rubber and rubber blades of spatulas are similar in appearance, but differ significantly in wear resistance and durability. The versatility of rubber lies in its water resistance and chemical resistance. Rubber ages quickly and either degrades or becomes brittle and breaks.

Rubber spatula

Rubber spatula

Multilayer rubber spatula

How to care for your instrument

If you plan to use the spatula for a long time, it is recommended to pay special attention to its cleaning. When drying and hardening, the grout mixture eats into the rubber surface of the working edge, and its removal leads to damage to the tool. Therefore, it is recommended to thoroughly rinse or soak the spatula after each working cycle. This procedure does not take much time, but it will help get rid of many problems.

It is recommended to store the spatula strictly in an upright position. It should not be kept together with other tools. The elastic rubber may bend and the spatula will be unsuitable for further work.

To remove grout without leaving any residue, it is recommended to use a cellulose combination sponge. It will help to completely clean the spatula and maintain its integrity. This sponge is indispensable when working with grout mixtures based on epoxy resins.

This is all you need to know about caring for and working with plastic spatulas. Now you can easily make high-quality seams that will last for many years.

Recommendations for use

To make an even seam made of silicone sealant, the composition is applied to a clean and dry surface using a special gun. Then moisten the spatula in a soapy solution to prevent it from sticking.

Now you can carefully remove the excess sealant and clean it into a specially designed container. The corner seam is neat if you use masking tape, which is removed when the composition has completely hardened. Between the two tapes leave space for the sealing agent.

Using spatulas, you can make a seam filled with sealant as even, beautiful, and convex as possible. Professionals will be more suited to tools in a set for any occasion. For those who occasionally encounter such a need, you can buy a couple of universal devices or make a spatula yourself from scrap materials at home.

The nuances of working with a rubber spatula

Grouting work should not be carried out until the tile adhesive has completely dried, as this will cause deformation of the tile canvas.

At what angle and how to apply grout with a rubber spatula

Before grouting, you need to prepare the materials that will be needed to remove excess grout from the surface of the tiles.

The grout is applied to a clean, dry surface. The temperature in the room in which the work is performed is not lower than 10-15 degrees. Maximum air humidity is no more than 55%. Dust is unacceptable. It is not advisable for the grout to be exposed to direct sunlight until it is completely dry.

The tip of the spatula must be rounded or sharpened before use. If a new tool is used, then manufacturers do this when releasing products from the assembly line.

High-quality grouting of tile joints

The ideal spatula can be bent into any shape, then it will return to its original position. This is a result of the elasticity of the rubber from which the product is made. If the tool cannot be reshaped or it is difficult to do so, it means that it is made of pure rubber or low-quality composite materials. It is better to refuse to work with such a canvas.

The putty spatula and the grout spatula are different, so they cannot replace each other when working.

Tools must be washed after work, as the remaining mixture destroys the structure of the spatula blade and may cause further difficulties during use. Once the composition has dried, it is difficult to clean off the spatula.

Cleaning tiles from excess grout

The tool is easy to manufacture, so there are many products on the market made from low-quality raw materials. To avoid problems during operation, you need to try changing the shape of the canvas during purchase, checking its elasticity.

You will learn how to grout joints and keep the tiles clean from the video:

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

Partial removal of the top layer of grout

To clean the grout from the tiles, it is enough to use chemicals. How to remove grout?

- Using a thin paint brush, apply the chemical to the seam.

- Leave for 5 hours until the grout layer softens.

- Use a paint knife or screwdriver to remove the filler.

Folk remedies are often used to work with tile joints. In order not to spend money on expensive chemicals, you can prepare effective solvents at home. Ordinary vinegar and ammonia have a destructive effect on the surface layer of putty. Citric acid and a mixture of glycerin and water also effectively cleans tile grout.

How to grout seams on the floor

Cement or epoxy mixtures are used to treat flooring joints. The compositions are resistant to mechanical damage and are not subject to abrasion. To increase the service life, after grouting the floor tiles, the joints are coated with silicone sealants - not necessary, but reliable. The technology for grouting joints on the floor between porcelain stoneware tiles is practically no different from processing vertical surfaces with your own hands:

- Prepare tools - a set of spatulas, a drill, a construction knife, a grater, foam sponges, a container for mixture and water, and rags.

- Remove the fastening crosses, clean the floor, and “sweep” it with a paint brush.

- Prepare the solution: add the cement mixture to water or latex, gradually mixing.

- If you are using a drill, you need to turn the tool on at 300 rpm so that there are no air bubbles in the paste.

- Before applying cement grout, the joints are moistened for better adhesion of the composition to the base of the floor.

The next process is to fill the gaps between the tiles. Grouting of floor tiles at the seams is done diagonally, and you need to start work from the far corner of the room, moving towards the entrance to the room. The mixture must be rubbed in with pressure, completely filling the voids between the fragments of the floor covering. After preparing the base, grouting the tiles in the bathroom with your own hands is done as follows:

- A square meter of tile is wetted at the joints, but there should be no drops of water.

2. Use the grout prepared for the joints between the tiles to fill the gaps, scooping the required amount of mixture onto a spatula.

3. Some craftsmen rub in the composition with a special grater, others use a spatula - it depends on the tile (porous, textured).

4. Rub the mixture diagonally with light pressure, repeating the steps two to three times.

5. Excess mass is immediately removed with a spatula, holding the tool vertically to the surface.

After treating one or two squares of the flooring area, the area is cleaned of grout with warm water or special means. You can use a construction bag (cone) to fill the solution. The required amount of paste is placed in it and squeezed into the gaps, smoothing the mixture with a grater or spatula. After 15-20 minutes, go over the seams with a damp sponge to level the mixture and complete the jointing. While the composition dries, begin processing the next square. If epoxy material is used, mix enough paste to produce a solution within an hour. The seam is considered ideal if it is recessed relative to the joints of the tiles and has a smooth structure.

Differences from grout on walls

There is no significant difference between how to properly grout tiles on the wall and on the floor. The technology remains unchanged, and the work is performed in the same order - drying the tile adhesive, preparing the surface, preparing the solution, applying the mixture, cleaning the tiles from excess grout. Minor differences in operation:

- The floor composition should be more resistant to mechanical damage.

- On the wall, grouting the tile joints is done vertically from top to bottom; it is more convenient to work with a spatula.

- The floor covering is processed diagonally; you can use a spatula, grater, or construction bag.

After the mixture has completely dried, you can treat the seams with silicone sealant. The transparent substance reliably protects the grout from moisture absorption and gives the composition dirt-repellent properties. The tube of sealant has a nozzle or brush for easy application.

Width of grout joints

A controversial issue that professional builders do not give an exact answer to is the width of grout joints. You need to be guided by a simple rule - a wide gap between the tiles reduces the solidity and mechanical strength of the coating, but visually gives the surface strict geometric lines . Recommendations from the experts:

- The length of the tile on one side is less than 10 cm - the seam is 1-3 mm.

- The size of the material is more than 10 cm on the side - the joint will be 2-8 mm.

- For clinker tiles, it is correct to grout joints of 8-15 mm.

- Between small fragments of the mosaic you need to leave 1-3 mm.

- Extruded tiles with large edges (up to 30 cm) are grouted with joints 4-10 mm thick.

A large gap (up to 12 mm) is left between irregularly shaped products so as not to draw attention to the geometry of the products. The seams on the floor can be made wider than on the walls. To restore the old coating, you can re-process the joints. This applies to cement grouts, which are susceptible to cracking if the technology for preparing and applying the solution is violated. Old seams are treated with sandpaper, dust and grout residues are thoroughly cleaned, and covered with fresh mixture. In some cases, it is more convenient to restore tile joints by painting. To completely replace the sealant, a special cleaner is poured onto the old grout. When the grout softens, it is removed with a joint compound. After cleaning the gaps, you need to grout the ceramic tiles again, adhering to the technology described above.

Finishing tiles using grout mixtures requires care and skill. Not all craftsmen will be able to obtain impeccable quality grout the first time. It is important to carry out the work gradually, filling small areas of the walls or ceiling, so that there is an opportunity to correct mistakes. The result of painstaking work will exceed the expectations of the master - after grouting the joints, the tiles acquire a beautiful visual effect.

Simple methods for grouting tile joints (2 videos)

Types and methods of grouting tile joints (20 photos)

How to remove old grout

If the old putty has “clung” to the glossy ceramic surface, then first try to remove the dried grout in a gentle way - using a damp sponge. If there is no positive result, try to wipe off the dirt with the hard side of a kitchen sponge. It is better to clean embossed and matte products using chemicals.

Over time, tile joints lose their shine, crack, and become less clean. To remove old grout from tile joints, there are two methods.

Mechanical removal

Sandpaper will help remove old grout from tile joints. To do this you need:

- Choose fine paper.

- Fold in half and get a thin bend.

- Work over the grout surface without touching the ceramic edges.

- Rinse the treated surface with water.

- Wipe dry.

In hard-to-reach places, use toothbrushes with cleaning powder. What tools do you need to prepare for the job?

Available means

To remove dried filler, just take a screwdriver and run it along the seam. It may take a sufficient amount of time, but the possibility of damaging the coating will be minimized.

Painting knife

The tool must be held comfortably in the hand so as not to accidentally cause injury. How to remove old grout with a knife: step-by-step instructions:

- place the knife in the center of the seam;

- make a recess along the entire length of the seam;

- remove grout from the edges of adjacent slabs;

- carefully clean the edges with sandpaper, antiseptic and primer;

- let the primer dry;

- fill the seam with fresh filler.

Seam opener

Designed specifically for cleaning tile joints. The tool is convenient to work with, but most craftsmen do not spend money on it and try to use available tools.

Household granulator Dremel

It is an electric jigsaw with a flat half-disk. Using the tool, the seams can be removed in a few minutes.

Other power tools

To open the joints, it is allowed to use an electric drill or screwdriver. It is important to choose a thin drill so as not to damage the tiles.

Softening compounds

In the fight against pollution, special products for removing grout from tiles are widely used. Chemical reagents successfully wash away grease stains, stains, and old putty without harming the surface of ceramic products.

Advice. Work with aggressive chemicals should be carried out in strict accordance with the instructions for use. Don't forget about personal protective equipment!