Builders use trowels and rubber spatulas to seal seams at joints. But trowels leave scratches on many surfaces, and rubber spatulas are not suitable for some types of work. Especially if there is a lot of work and deadlines are pressing. For this purpose, a special grouting gun was developed.

Its design is original and simple in execution. The mixture is filled into a syringe-like cylinder and applied evenly between the tile joints.

Gun device

The model for creating a syringe gun was a device that gently squeezed cream onto a cake. And thanks to different attachments, the thickness of the cream was varied, and various patterns could be drawn on the surface.

No patterns are needed for grouting. But filling the voids in this way was a brilliant solution. Now the device can be purchased at any hardware store.

The grout gun consists of the following components:

- The cylindrical body is made of various materials, but the most reliable is metal material.

- Piston seal (material may vary). Squeezes the sealant through the neck.

- Cone nozzle.

- A plunger that extracts the required amount of solution.

- Spring nozzle.

- Piston handle. They pull on it to fill the cylinder with a new portion of the mixture.

- Release handle (or electric button). Depending on the type of device.

- Protective shell. Prevents solution leakage.

- Fastening elements.

Many mechanisms are equipped with an automatic mechanism. Such devices operate on batteries. Those. Even with gentle pressure, the required amount of sealant comes out of the neck.

The nozzles for the neck of the tube are cast from plastic, which has increased strength. This is a material that can withstand high pressure.

Top 3 manufacturers of grout for decorative stone

Among the large number of manufacturers, there are only three whose products are of good quality. These include the following brands:

- Ceresit - sold exclusively in dry form; the packaging contains a table showing the proportions of dilution of the product before use;

- Kiilto - the mixture is sold in various shades, so there is no need to select a color; it is considered resistant to temperature changes;

- Mapei - this version of grout fits securely into the seam and does not fall out of it during operation; there is also a translucent version that repels dust and dirt;

Solutions from the listed brands adhere reliably and do not fade over time. The compositions are ideal for gypsum stone and brick and are considered light.

Branded grout for gray joints with added pigment Source nikastroy.ru

Types of syringe guns

The devices are used for filling and rubbing seams. They are different from each other. But essentially there are only two types of them:

- Guns that work with stone.

- For working with ceramic tiles.

They are equipped with a special mechanism that squeezes out a specially prepared mixture, like in a syringe. But different models may differ from each other in the following characteristics:

- The material from which all components of the pistol are made.

- Case color.

- Various volumes of cylinders for solution.

- Availability of additional components.

Models with a large cylinder have a reinforced body that can hold high pressure inside. Usually all elements are galvanized.

That is, the larger the cylinder volume, the more parts wear out. This is also due to the fact that at some sites we have to work in an accelerated mode. This affects the operation of the pistol.

Application over the entire tile surface

After dilution to a sour cream state, these grouts are applied to the entire surface of the tile and smoothed with a rubber float. After drying, the remaining grout is removed from the tile with a sponge using movements at 45 degrees to the tile. High-quality grout of this type does not require effort to remove residues. If an unsuccessful, dirty grout was chosen, or if the grout on the surface of the tile was forgotten and dried out, you can clean the tiles with cleaning agents to remove cement stains.

This type of grout can also be applied with a gun.

As an example of this type of grout, let's call Ardex BS.

Advantages of grout applied over the entire surface of the tile:

- versatility: these grouts are suitable not only for clinker, they can be used on any tile on the facade and in the interior

- increased wear resistance

Disadvantages of grout applied over the entire surface of the tile:

- high price compared to other types of grouts

- this type of grout is only suitable for smooth tiles

- narrow color range: Ardex BS is available in only four colors

Summarize

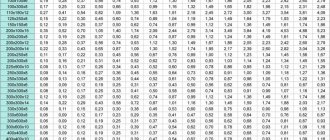

Comparison of different types of grout for clinker tiles

| Type of grout application | Advantages | Flaws |

| Semi-dry method | Low price. No plasticizers. | Grout is difficult to work with. The limit on the seam depth is at least 5 mm. Narrow color range: beige and gray. |

| From a pistol | Mass scale and simplicity of technology. Wide color palette. | Higher price. Presence of plasticizers. |

| Over the entire surface of the tile | Versatility - suitable for any tile, both on the facade and in the interior. Increased wear resistance. | High price compared to other types of grout. Suitable for smooth tiles only. Narrow color range. |

Filling the syringe gun

Depending on the model chosen, some guns are filled directly, but other devices have removable cartridges through which the sealant is filled.

If the solution is prepared at home, it is carefully poured into the cylinder using a spatula. Using the handle, pull the piston as far as possible towards you and fill the container. Then the cylinder is closed and, pressing the handle, the mixture is carefully applied to the surface.

The convenience of the device is obvious. There is no need to constantly apply the solution to the spatula. Simply fill the cylinder and work until you need to refill the gun.

Thus, with the help of this device, a large amount of work is performed in a short time, using only a few refills.

ATTENTION! When filling the gun, try to do it as carefully as possible so that the mixture does not splash throughout the room, and screw the cylinder tightly. Make sure it is sealed, otherwise it will leak through the cracks.

Moreover, with a syringe there is no need for additional protection of walls and ceilings from dirt. The device operates as carefully as possible if the owner follows the instructions and safety regulations.

Tile Cleaning Tools

The appearance of a tiled wall largely depends on how beautiful the seams are. There is a special mesh for grouting, which is used to grind the surface of the mixture in the cracks. A grout float is also suitable for this purpose.

2 methods of sanding seams have been developed: dry and wet. For the first, choose a grater with a fine mesh. The seams are not wetted with water, which leads to the formation of a large amount of dust during operation. For this reason, many craftsmen prefer to use the wet sanding method.

Before starting work, you need to buy a cellulose sponge needed to remove grout from the tiles. The process of using this device is simple: immerse the sponge in a container of water, lightly wring it out and clean the mixture from the tiles.

Using a pistol

To begin with, the tool should be filled with the prepared solution. The mixtures are sold either ready for use, or they must be diluted with water, according to the instructions.

Unlike a spatula, the mixture penetrates into hard-to-reach places and fills narrow cracks and voids. There is no need to sand the edges of the stone or tile. The paste under pressure is evenly wedged at the joints.

ATTENTION! The device cannot be used for working with bricks. Because it contains sand, therefore, sand will not allow the paste to distribute normally.

Each grout has its own unique composition and density. To do this, you need to consult with the store salesperson so that he can recommend the right mixture for repair work.

The grout must be used within 40 minutes after depressurization (or preparation). In this case, experts recommend using dry analogues. Those. – diluted, worked, prepared the next solution.

All joints are cleaned of dust and debris, then moistened with a spray bottle. Then they start working. When the solution hardens, it is expanded. For this purpose, jointing is used.

ATTENTION! There is one nuance in working with a pistol. It can only be used on a damp surface. Therefore, before moving on to other materials, you have to modify the surface with a spatula.

New in construction

The development of technology and the emergence of new materials has not spared such an industry as construction.

New types of building materials have significantly improved both the quality of the houses being built and the attractiveness of the finishing. This also applies to the material of walls, roofing, windows, insulation and fire safety, and finishing materials. Finishing work is now experiencing a real boom. Every year new technologies and devices appear that improve the quality of finishing, new types of finishing materials. For example, instead of glue or cement, glue is now used to manually stick PVC tiles onto concrete surfaces - foam, located in a pressure cylinder. Using a special gun, the foam comes out of the nozzle and is evenly applied to the surface. The clutch is fast and of high quality. Also, instead of spatulas, a gun is used to grout joints in decorative masonry between stones, with which the joints are filled very quickly and efficiently.

Main characteristics of the tool

According to their characteristics, pistols are divided into two types:

- Skeletal devices.

- Tubular option.

The skeletal type is considered a reliable device, because The design is based on a durable metal frame that does not deform from prolonged use. The materials from which the parts are made do not bend or rust.

Therefore, such options are often purchased by professionals who constantly use this device.

The average cylinder volume in a tubular gun is 300 ml. But it can increase, depending on the type of structure. But metal analogues weigh more, so beginners’ hands may get tired at first.

But even among plastic models there are quite high-quality pistols. Such devices are usually made of high-strength plastic. Therefore, even if you bought a tubular version, used it and put it somewhere in the garage or on the balcony, if you store it correctly, then the plastic will not deteriorate and can be reused.

Removing joints in brickwork

An unsealed seam is often hidden behind the facade of any built house. The reason for this is the poor quality work of the builders. After all, when laying bricks, cement mortar should be applied to the entire surface of the masonry, and not in pieces, as unscrupulous workers do.

The plaster may partially fly off over time, and an empty seam will appear. It looks just terrible. The void between the seams in the masonry can eventually lead to the destruction of the latter. Brick laying should be treated well at the initial stage of construction to avoid such problems, but often sealing seams is not uncommon.

If the damaged wall is minimally destroyed and there are few such seams, then this can be easily and quickly eliminated. To do this, you need to have a screwdriver or chisel on hand.

The seam is cleaned of old mortar using a brush or screwdriver.

Using these tools, you need to carefully remove the remains of the old mortar from the seams of the brickwork and under no circumstances push it back; absolutely nothing should remain in the seams. Then you need to moisten the brick with water, because dry material absorbs a lot of liquid from the solution. After these steps, you can safely begin filling the joints in the brick walls with fresh cement mortar. It should be mixed dryer so that there is as little water as possible, this is done to avoid cement leakage.

The first step is to cover the vertical seam, and then the horizontal one. The seams must be sealed until they are completely filled. The finished solution should adhere well both inside and outside the masonry. For the inside of the joints, the cement mortar may be wetter than for the outside.

It is necessary to embroider a brickwork seam, strictly observing the shape of the groove so that it does not differ from other seams.

To joint the brickwork, you need to use a piece of hose together with a trowel. At the final stage of sealing the wall, it is necessary to remove the remaining mortar and gravel, and after complete drying, it is necessary to clean off the convex deposits of cement.

Quite recently, a new trend in construction has appeared, a kind of decor: when filling the joints of brickwork, coal is added to the mortar, the composition becomes black. This allows you to emphasize the beauty of the building, emphasizes the accuracy of the work done, and highlights the structure of the brick wall.

If the brickwork is made of white brick, you can whitewash the wall, it looks very beautiful. But if the brick has other shades, there is no need to whitewash it.

Joint jointing can also be done during the actual laying of bricks. This approach saves time in the future. Here, again, several types of such processing can be distinguished:

This type of seam processing is used quite rarely. You can use a metal corner or other V-shaped object as a tool. Using such a simple device you can get an additional line in the center of the seam. The V-shaped joint of the masonry looks unusual, which has a positive effect on the appearance of the surface.

How to choose a grout gun?

When choosing a tool, you should pay attention to the following characteristics:

- When squeezing out the mixture, it should come out through the spout, and not between the cracks of the elements.

- If you choose an economy option - a plastic gun. Make sure that all parts are made of reinforced material.

- The amount of work performed depends on the volume of the cylinder. Therefore, think about how much repair work you will have to do so that you do not have to dilute the solution so often.

- Some types of surfaces will still have to be treated with a spatula - keep this in mind.

- If you choose an automatic model, pay attention to the battery power.

- The instructions indicate which mixtures the device is compatible with. Try to use these types of grout.

- Steel and metal models are reliable, but also more expensive.

- When you press the handle, the seal should move smoothly, not tightly. Those. The master should not experience difficulties with the device.

- When choosing a tool, take it in your hands. Feel how it “sits” in your hands. Is it convenient to use?

Comparison of high-quality and low-quality pistols

Of course, in the diverse assortment of syringe guns you can find both high-quality and mediocre models. A sign of a high-quality product is that when extruding, the mixture comes only from the working part, but if it is made poorly, the mixture may flow out from the back part. A good tool uses the solution as efficiently as possible without wasting a drop.

Poor quality equipment leads to unnecessary costs, and this is not only financially unprofitable, but also forces you to spend additional time solving this problem. It is recommended to buy only proven tools to avoid additional difficulties.

When using high-quality tools, the work proceeds carefully - the master’s hands, the room, and the surface do not get dirty. Using a low-quality product, it is impossible to sand the seam so well. If you draw comparative lines made using a spatula and a gun, then the difference is obvious - preference is given to the latter. This is easily explained by the fact that using a high-quality option, the time to complete the work is reduced, the process becomes cleaner, and the quality of the finished work is much higher.

When using a gun, the joints are grouted evenly, which makes them more resistant to frost and thawing, as well as to the appearance of cracks and voids.

When using a pistol syringe, you do not have to constantly waste time drawing up the next portion of the solution.

In some cases, you simply cannot do without the use of this device:

- the need for the cleanest possible work;

- short time.

Not in all situations a gun can replace a spatula. The device can only work with sufficiently wet grout. When grouting joints between the following materials, you will have to work with a spatula:

- brick;

- pig;

- clinker tiles;

- natural stone.

Another disadvantage of the gun compared to a spatula is its relatively high cost. The price of an ordinary pistol is about one and a half thousand rubles. Naturally, an amateur should not purchase a product for a one-time job, because after its completion the tool will not be useful for a long time. However, for a professional, this device can bring a lot of benefits.

To grout the joints of ceramic tiles, you should use a rubber spatula.

What mixtures are not suitable for a pistol?

Usually, when choosing a grout or sealant, pay attention to its thickness.

ATTENTION! In the instructions, some manufacturing companies post a list of consumables that they recommend using.

It is not advisable to use the following types of mixtures for this device:

- The mixture used for the “Boar” tiles.

- For brick products, especially at the joints between brick and tile.

- For clinker tiles.

- For grouting natural stone.

ATTENTION! There may be exceptions for all options (except for Cypripich). If you use an electric gun, even such thick mixtures can be used. But only if there are no other options.

There are also recommended mixtures for each type of tile. Before buying it, ask the seller whether it is suitable for working with this particular material.

Applying grout using a semi-dry method

To work with such grouts, water is added to the mixture so that it does not become liquid, but acquires the consistency of wet sand. After thinning, the grout is pressed into the joint with a special tool - a mason's jointer. Wet grout is applied from a hard horizontal surface (from a sheet of plywood, for example) with jointing, selected according to the thickness of the seam, between the tiles. The tool must be selected not only according to the thickness of the seam, but also according to its length (for transverse seams you need a tool with a short blade).

This type of grout is characterized by a rough texture. We recommend it primarily for thermal panels with hand-formed tiles. This combination creates a pleasant old brick effect.

As an example of this type of grout, let's call Quick-Mix RFS.

Advantages of grout applied using a semi-dry method:

- low price

- no plasticizers

Disadvantages of grout applied using a semi-dry method:

- at the moment there are few specialists capable of competently working with this type of grout

- The seam depth must be at least 5 mm

- narrow color palette: Quick Mix RFS is available in only two colors: beige and gray.

Why is a gun better than a spatula?

The gun was designed to reach those places where a spatula simply cannot. But in addition to these qualities, it has its own advantages:

- all putty is distributed evenly between the joints;

- the mixture fills all voids, even the smallest ones;

- the work is carried out neatly, without splashing the solution;

- Due to the fact that there is no need to constantly make the mixture, the work time is reduced.

Types and characteristics

Many sources write about the existence of two types of fire-resistant grout:

- cement;

- epoxy.

The heat resistance and safety of the cement-based mineral composition is beyond doubt. As for epoxy grout, it can be recommended for use in residential premises with great caution.

Based on polymer resins

Epoxy resins are synthetic polymers of organic nature that burn very well, like any organic material. To improve performance, modifiers are added to monomers.

The flammability of epoxides can be reduced by introducing halogen and phosphorus-containing compounds into the structure, which is carried out in technological processes. Consequently, heat-resistant grouts may contain toxic substances.

Manufacturers recommend using them in industrial environments. If they offer epoxy compounds for grouting home stoves and fireplaces, you need to look at the certificates to make sure the products are safe.

It is best not to take risks in the absence of accurate information about the composition of the epoxy product, and purchase a heat-resistant cement-based grout.

If the composition is known and safe, then you can use epoxy grout, especially since it often has the form of pastes, which is very convenient when applied to the space between the seams.

Cement based

Cement-based joint sealers have undoubted heat-resistant qualities because they are made on the basis of Portland cement.

Portland cement contains up to 80% calcium silicates, which is obtained by sintering crushed clinker and gypsum.

Calcium silicate enters Portland cement from clinker powder, which in turn is obtained from clay and limestone. Thus, the composition of heat-resistant grout for joints is almost completely free of flammable substances.

There is a dry compound for sealing joints on sale, which must be diluted with water before use according to the recommendations on the package.

The product retains its properties when heated to 400 ℃, which, taking into account its application to the outer surface, is a very good indicator.

Varieties for internal grouting of ovens have even greater heat-resistant properties, withstanding temperatures up to 1700 ℃. Typically, heat-resistant products are gray or white in color, because the addition of any pigment will worsen the heat-resistant properties and reduce the density of the composition.

For external grouts, the addition of pigments is allowed, so you can choose the option of a colored product that is in harmony with the appearance of the entire cladding.

Disadvantages of a syringe

But the device has its drawbacks. And the biggest problem is working in a damp environment. That is, before each grouting you have to wet the walls. And then it is still finalized with a trowel.

If the solution is too thick and dense, it will not be suitable for some materials.

And, of course, the price - buying a trowel is much cheaper than a high-tech device. But if it pays for itself, then it's worth it.

We also recommend looking at - Tool for grouting tiles

Which tile grout is best?

Ceramics is one of the most versatile finishing materials. The tiles differ in composition, water absorption coefficient, and format. Tiles, porcelain tiles, and mosaics are used to cover surfaces that are exposed to aggressive influences of varying intensity. For these reasons, grout for finishing the walls of a research laboratory differs from grout intended for a kitchen in a city apartment, not only in price, but also in technical characteristics. Manufacturers are forced to produce mixtures with different parameters; it is impossible to find a universal grout. Our experts recommend the following options based on the scope of application:

- Litokol Starlike – for interior work and exclusive projects;

- Mapei Kerapoxy Design – for renovations in a swimming pool, city apartment;

- Living paint Diamond - will help create an original atmosphere at low cost;

- Ceresit CS 25 – when sealing joints between the bathtub and tiles;

- Kiilto Saumalaasti is the best solution for a good apartment renovation;

- Perel RL summer – for large volumes of finishing work.

All grouts presented in the review will help to carry out repairs taking into account the requirements of SNiP, but only grouts that are characterized by increased wear resistance and chemical resistance are worthy of the title of the best in their categories.

Which gun to buy for stone grouting?

Fit 14256

The improved model features a reinforced steel body. The drum volume is 600 g. The accuracy of applying the solution remains the same. It easily copes with thin joints. At the same time, the weight of the device is only 500 g. The specialist’s hand does not get tired during repair work.

Blast Tube

Refers to inexpensive devices. But at the same time, the quality of the solution application does not decrease. At the base of the model is an aluminum tube into which the solution is filled. The only drawback of the device is the presence of plastic parts.

Consequently, wear and tear increases significantly. But the gun is held very comfortably in the hands - the master does not need to make much effort to cover the seams.

Metabo kpa 18 ltx

Dear model. When you press the release button, additional pressure is created inside, which squeezes out mixtures based on viscous substances (for example, sealants). The device has a built-in battery. Additionally, the kit includes the following components:

- discs for squeezing out substances of different densities;

- convenient holder.

The gun tube reaches 400 mm. The device has a number of additional mechanisms that prevent leakage.

The special Metabo Quick system automatically changes cartridges. And the handle heats the mixture to the desired temperature.

How to choose?

To choose a grout gun, you need to take into account the design features of the seams, as well as the conditions for using the tool.

When looking for a suitable pistol, you should first pay attention to the following features:

- Reliability. The design of the pistol must be as strong as possible so that at the most inopportune moment it does not deform, crack, or simply fail. If it is necessary to carry out numerous and long-term work with increased load on the tool, it is worth considering varieties with a rigid steel base. A body made of plastic or aluminum will perform well when working with clinker tile seams. In this case, preference is given to the accuracy of application, but not to the performance of the tool.

- Ease of use of consumables. As you know, consumables and sealants for filling joints are supplied either in ready-made tubes or in the form of a dry mixture, which is pre-diluted before work. Depending on the working conditions and the type of sealant, you need to choose the type of gun in the form of a syringe or with a hollow steel body where the cartridge is placed. You need to calculate in advance the time spent on recharging and the speed of use of consumables.

- Complete set and additional accessories. If the tool comes with any additional attachments or other elements, then the operating process can be significantly simplified, and the quality of application of the substance will also improve. It will be especially convenient for the master if the kit includes a gun stand, various holders, additional handles or special tips for different types of work.