A door closer is a mechanism that is designed to reliably close entrance doors. It presses the blade against the seals along the contour or creates the necessary force sufficient to trigger the lock latch. The door can close abruptly and with a sound, or smoothly and without making sounds, and can also pause.

Adjusting the door closer is a mandatory measure to extend the service life and maintain the performance characteristics of the mechanism.

It is subject to constant loads; frequent closing and opening of the door leads to imbalance of the elements of the device, and therefore requires periodic maintenance and repair, both for preventive purposes and if necessary.

Types of door closers

The purpose of the mechanisms is to ensure smooth opening/closing of door leaves with adjustable force and speed, and to pause in the open position to facilitate passage for people with special needs. Such door functioning parameters eliminate knocks and mechanism breakdowns due to excessive mechanical forces. To complete the assigned tasks, energy is required; it is accumulated during the opening of the door leaf. We will look at how the mechanism works in detail below, but now we need to familiarize ourselves with their types.

Door closer

Table. Types of door closers

| Closer type | Brief description and technical parameters |

| Traditional and simplest model. When the door is opened, the metal lever compresses the spring, then it returns to its original state and closes the door. Spring closers are very reliable and cheap, but they have one unpleasant drawback - the doors slam a lot. This not only irritates users, but also causes damage to door locks. |

| A more modern mechanism has a metal rod sliding (slide) along a special guide. It is most often used for interior doors with low weight. Heavy blades have a significant moment of inertia, which complicates the operation of the mechanism. |

| A more reliable and most common option, a very reliable device. Universal purpose, has no restrictions on the weight and size of doors. |

When buying any mechanisms, you should always keep in mind a simple dependence: the simpler the device, the more reliable it is. This is an axiom for all engineering designs, keep it in mind when making your final decision.

How to choose a door closer

Prices for door closers

Door closers

Adjustment of aftershock

Setting up the door closer to install the door closer ensures that the door leaf adheres to the frame and allows you to leave a small gap before slamming, i.e. does not completely close the door structure. By adjustment, you can adjust the slow closing of the block, reducing the force of the clap.

Using screw No. 2, you can adjust the speed at which the structure will slam shut. When 10-15° remain before the door leaf closes, the deceleration will work.

Consequences of improper use

Despite the fact that high-quality devices have fairly high durability, they also sometimes experience premature failure.

If used incorrectly, even high-quality door closers fail

- Mechanical breakdowns of the closer: deformation of the rods, disruption of the functionality of the piston. Such breakdowns appear as a result of improper use of doors and excessive physical effort on the door leaf.

- There are situations when mechanisms use oil that is not intended for operation at sub-zero temperatures. It sharply increases viscosity, doors open/close with difficulty, and great physical effort is required.

- Sealing failure and oil leakage. The seals cannot withstand the pressure and burst. When using the doors, oil gradually leaks and air takes its place. In addition to deteriorating the appearance of the doors, the performance of the door closer is impaired.

- Installation of a rigid closer on plastic doors. These structures cannot withstand significant forces, the elements of the door frame become loose over time, and the mechanism body falls with all the extremely negative consequences.

The type of closer must match the door design

We remind you once again that the duration of use of the door closer largely depends on the consumers. If they follow all the manufacturers' recommendations, then no unexpected problems will arise.

Prices for entrance doors

Entrance doors

When adjustment is needed

Experts recommend adjusting the mechanism immediately after installing the door closer, and not only during operation of the doors. Inspection and correction of minor problems is carried out at least 2 times a year, with frequent fluctuations in temperature indoors and outdoors - more often. This is due to the fact that the lubricating fluid depends on the temperature parameters of the environment and affects the parts of the closer.

Carrying out seasonal adjustments is a regular part of maintenance.

With large temperature fluctuations, the front door mechanism quickly wears out and becomes faulty. Therefore, it is better, when the first signs of damage to the closer occur, to pull it to the desired position, check the tightness to detect oil leaks and eliminate the malfunction.

In case of complex breakdowns, adjusting the door closer on your own is ineffective. Experts recommend carrying out repair work or replacing it.

If problems arise with the device settings, the parameters are adjusted. This procedure is performed if the mechanism turns out to be difficult to open, as well as with a door that closes quickly and sharply or takes a long time to pull.

How to adjust the door closer after installation

The function of a modern closing device is no different from the operation of the previous “antediluvian” springs, which were previously installed at the entrance to the front doors of residential buildings, organizations, and shops. Their big disadvantage was the sharp slamming of the door with a loud knock. Such a rapid closing of the front door was inconvenient and quite dangerous, especially for children, who could easily get their hands pinched. A modern door closer, its installation and adjustment, solve the problem of noise in the entrance, forcing the door structure to work in the prescribed mode.

The main working mechanism of any closer is a spring-loaded hydraulic shock absorber. Oil circulates from one chamber to another thanks to a system of valves that set the valve to move in different directions. The viscosity of the oil composition ensures smooth closing and opening of the door.

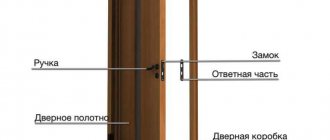

The closing device is installed indoors so that it cannot be removed from the outside. This protects the mechanism from dirt, dust, and also creates additional safety for residents. For installation you need instructions and tools:

- screwdriver;

- ruler;

- drill;

- pencil for marking.

The fasteners are included in the kit, which the manufacturers supplement with installation templates, which display all the components of the mechanism in full size and the location of the holes for fastening. Installation begins with fastening the housing, which is then connected to the traction lever. All steps are described in detail in the instructions, following which the installation is carried out quickly and without problems.

The device parameters, as well as adjustment methods, depend on the type of closing mechanism. There are two of them.

- Cam. The cam, as the main moving part, moves thanks to the rollers and presses on the spring, which smoothly guides the blade. The systems work well on lightweight doors.

- Serrated. The movement occurs due to a gear that transfers energy to a spring. The mechanism can be used for sashes with significant weight.

Depending on the location and method of installation, door closers are classified into one of three types.

- Floor. The name speaks for itself, the system is adjustable from below. The installation is carried out together with the installation of the door frame, planning in advance. The systems are used at the entrances to large buildings.

- Overhead. This is the most commonly used automatic closer. The device is installed on top, connecting the box and the canvas itself. Such mechanisms are always used for metal doors in residential buildings because they are easy to use and maintain.

- Hidden. This type of mechanism is rare. It is mounted directly into the door hinges or into the end of the door frame. Allows you not to disturb the interior of the room, is expensive, and has an increased degree of safety.

Selecting the door speed

After installation is completed, it is necessary to adjust the door closer so that the speed of door movement is most convenient during operation. Each device is equipped with special screws for adjusting the blade stroke. If it moves too quickly, it will be enough to turn the screw clockwise ½ turn. If the movement is too slow, turn the screw counterclockwise the same half turn.

Adjustment is carried out by trial until the speed is optimal. High closing speed is good for limiting the entry of strangers, insects and cold air. But for interior doors or kitchen cabinet doors, they usually set the movement to slow. This adjustment technique applies to all types of closers. The essence of the process is that the more the screws are tightened, the slower the oil flows from one cavity to another, the slower the system operates.

Installing the exhaust

When setting up the closer, special attention should be paid to adjusting the aftershock. This is the speed at which the door travels its final trajectory. When the high-speed slam is selected, it may slam shut with a loud noise, which destroys the box. Therefore, it is necessary to adjust the door closer so that the closing speed is low.

Setting the closing speed is similar to adjusting the general speed with the difference that the closing speed is provided only on the last 15-25 cm of the trajectory of the outer edge of the door. The higher the speed is set, the stronger the force of impact of the sash on the jamb. When choosing the passage speed at the end of the movement path, it is optimal to set the average value when closing is relatively fast, but without hitting the door frame. The aftershock is set by turning screw No. 2, which will adjust the movement of the canvas in such a way that the movement will first slow down, and then it will completely adjoin the jamb.

Calibrating the open position

In some cases, it is required that the doors be held open, for example, when furniture is being transported, or parents call a doctor to see their child, but there is no intercom. Adjustment of the “open door” mode in the door closer system is provided and performed simply.

Many models of top-mounted systems have a “hold open” option. To set the mode, you need to set the door at 90° and attach a special lock that will keep the door open as long as needed. If you open the sash to a different degree, the system will work without holding. When the need for open doors disappears, you need to pull the sash towards you, and the setting will be removed automatically.

Open position

In some cases, it may be necessary to hold the door open for quite a long time. Let's look at how to adjust the door closer so that the doors do not slam, but remain open.

Many door closer models have a special “hold open” function for this purpose. To set it to this mode, you need to open the door about 90 degrees and then tighten the special lock. After such simple manipulations, you will be able to leave the door open when swinging it open to the set degree. A special lock will work in the closer, which will hold it in this position for as long as necessary. When it is necessary to close the door, simply pull it towards you and the lock will be released. If the door is not fully opened, it will move as usual, without delay.

Additional functions of the closer are adjusted with screws specially designed for them.

How do you know if adjustment is required?

In order not to wait for signals from the closer about the need for adjustment, you should check the functionality every 3 months - this is a fairly long period. Prevention will provide an opportunity to detect a malfunction at the initial stage, adjust the work, and replace it.

It is imperative to adjust the closer for the changing seasons. The mechanism is hydraulic and has oil inside, which changes its consistency as the temperature increases or decreases. When the temperature is closer to winter, the oil thickens, and in the summer it becomes liquid.

The operation of the structure should be corrected when problems are detected. Among them:

- braking of the door leaf when closing;

- slamming at high speed;

- jerky movement.

If the closer is broken, then the effectiveness of the adjustment is reduced to a minimum - it needs to be repaired.

What exactly can be adjusted

Special “settings” of the closer involve adjusting three of its functions:

- Door closing speed. It is important, since strangers may have time to enter behind a resident walking into the entrance. It is important that the door closes at intervals of 5–7 seconds per person. In addition, when the door closes slowly, cold comes into the entrance, insects fly, and homeless animals run.

- Intermediate travel of the web. This refers to the speed of attraction of the leaf to the magnet. That is, the interval of movement of the canvas after full opening. By adjusting this parameter, you can ensure that the sash is always open.

- Damn it. That is, direct contact of the door with the trap or magnet. It is undesirable for a door with a closer to hit the frame with all its might. This is uncomfortable for the user and harmful to the casher/magnet.

Interesting: Do-it-yourself adjustment of plastic windows

Door speed selection

The closer can have several functions. Almost every action can be corrected in a simple way. The first important point is adjusting the speed of the front door closer. In other words, it depends on how quickly the door opens and closes. Standard overhead models have two screws on their body; the first screw is responsible for adjusting the speed, but it can be turned a limited number of times.

The speed of the closer is adjusted using two adjusting screws: 1 - speed of movement of the blade, 2 - speed of closing

By adjusting the spring tension level, you can either weaken or stiffen the door closer. Depending on the direction of scrolling, you can tighten it or loosen it, which will ensure freer movement of the blade.

Please note that one turn of the screw is sufficient for adjustment; you cannot turn the screw twice, otherwise the device may depressurize and oil will leak out.

What to do if nothing works out?

There are several reasons why the setup may not produce results:

- An inappropriate mechanism has been selected, the door is too heavy, and heavy objects are frequently hung on the door leaf.

- Incorrect fastening of the iron angle, misalignment of parts.

- Displacement of the holes for the screws on which the device is attached, unscrewing.

If one of the above points applies, then there are only two options - change the door, install a different closer. There is a third option - try to fix it yourself, but lack of experience can lead to worsening.

The lever must be positioned strictly perpendicular to the canvas, otherwise one of the parts must be moved.

How to repair a door closer

In order to fix a door closer breakdown with your own hands, you must first of all figure out its cause. The most common causes of malfunctions are:

- weather conditions - rain, constant humidity, temperature changes (dangerous for metal outer parts and plastic boxes);

- quick closing of the door manually at a speed that does not correspond to the set settings;

- blocking a door that does not have an “open door” function with any objects;

- incorrect choice of closer, the power of which is not enough for a heavy door. The mechanism will be overloaded, which can also occur if you hang and roll on the canvas, as children like to do.

Frequent breakdowns.

- Oil leakage may occur due to a crack in the housing. Without oil, the closer will turn into an ordinary spring and will slam the door with a deafening roar. The malfunction must be eliminated very quickly, otherwise the entire mechanism will have to be replaced. If you find a small leak, you can use sealant. If there is a significant gap and a large loss of oil, repairing the closer will not help; the device will have to be replaced.

Sometimes when manufacturing a product, manufacturers allow it to be underfilled, then it must be topped up with regular synthetic motor oil or shock absorber fluid through the screw holes.

- Bar deformation. You need to pay attention to this element first. The rod can be made of ordinary steel and rust. The rusty areas should be cleaned and treated with anti-corrosion lubricant.

The break is eliminated by welding and thoroughly cleaning the seams. Curves and bends can be smoothed out with a hammer, but there is a risk that the part will not withstand the load and will burst. If the damage to the part is too serious, it is better to replace the damaged fragment with a new one.

Features of some models

The most common door closers among users are “Dorma” TS-68, “Diplomat”, “GEZE” TS 4000. Each model has its own characteristics of regulating such devices.

"Dorma" TS-68 is a classic top-mounted model. Its peculiarity is that the mechanism is equipped with a special lever to change the door locking force.

The Diplomat model is characterized by simple installation and maintenance of the mechanism. Adjusting the door closer includes the stages of spring tension and opening and closing adjustments. Some modifications of the “Diplomat” do not have a clap setting. The devices operate on the principle of hydromechanics.

"GEZE" TS 4000 is a popular top door mechanism model among users. The closer can adjust the opening damping, adjust the thermostable closing speed at the front and the final closing using a lever rod.

Limitations in adjusting the closer

In order for the device to operate reliably and be easily adjusted, certain restrictions must be observed during its operation.

- When adjusting the mechanism, the screws cannot be turned from the original position by more than 2 turns. If the rule is not followed, oil will leak out, which will have a bad effect on the functionality of the structure, and repairing a door closer at home is quite complicated.

- During installation, care must be taken to ensure that the structure is not distorted, otherwise breakdowns are inevitable.

- It is unacceptable to prop an open door with various objects. There is a special option for this.

- Loading the canvas with heavy objects is prohibited, since the additional weight will cause the diagonal to skew.

If you take into account these simple restrictions and adjust the device in a timely manner, you will be able to use all the conveniences of the closer for a long time.

Device types

The mechanism controls the movement of the web (closer). It sets the movement mode: speeds up or slows down the closing process, gives softness and ease to the sliding of the sash. There are several operating principles.

In practice, two types are used:

- The sliding rod operates the spring and piston system. One piston opens, the other brakes. The sliding type design is compact and reliable, suitable for lightweight doors.

- With a lever-type gear transmission - the most common class of locking structures. A reliable combination of spring rod and gear allows you to install devices on massive doors.

The main requirement for choosing a door closing regulator is that it must correspond to its parameters; the more massive the door leaf, the more powerful the door closer is needed.

Based on the location of the control units on the door, the following groups are distinguished:

- upper;

- floor mounted systems;

- hidden.

Upper. A widespread class of door closers. The combination of low price and reliable operation makes them popular among the population. They are installed at the top of the sash, which is very practical during installation. Manufacturers produce special oil-filled devices for external doors, adapted for use in hot or frosty climates.

Floor holders. They have proven themselves well in office premises, shopping centers, banks, where there are increased requirements for the appearance of doors. Flooring systems are built into the flooring and are practically invisible to visitors. Sliding type regulator designs are used and are designed for doors weighing up to 100 kg.

Internal devices. The devices are indispensable where careful cosmetic finishing and an impeccable front façade are required.

- Small sliding type design, mounted inside the door frame or leaf.

- The loop closer is a compact device. The range of application is limited: do not install on heavy doors; wears out quickly; special precision of installation on the doorway is required.

What should you avoid when setting up a door closer yourself?

Some useful tips to help avoid mechanism failure:

- When adjusting the operation, you cannot turn the screw more than two turns from the zero point, because the mechanism contains oil that can leak.

- Distortions damage any mechanisms, so the angles must be carefully checked during installation.

- Do not press on the canvas and mechanism with heavy objects.

- Do not hang heavy things on the door leaf, so as not to skew the diagonal.

- Don't prop it up.

By observing these points, you prolong the operation of the mechanism.

Adjusting the closer during installation

The main adjustable parameters are: closing force, opening angle, and speed of movement of the blade. If the movement is too tight, children will not be able to use the doors, pets will be pressed against each other, and additional stress will occur during loading and unloading operations. And closing doors abruptly can result in bumps, bruises and pinched limbs.

Door movement speed

Once installation is complete, you need to learn how to adjust the door closer for ease of use. Self-adjustment of force is set with a screw. If the doors are too fast, turn the screw half a turn clockwise. With slow movements, the screw moves in the opposite direction by half a turn. The looser the screws are, the faster the oil moves through the structure and the faster the device operates.

After trying to turn the screws in different directions several times, you will understand what speed is appropriate. For entrance doors and balcony doors, quick closing is installed. It allows less insects, drafts and strangers to enter. Slow speed is set for interior paintings.

Installation of aftershock

It is very important to adjust the door closer according to the closing force. With a strong bang and rumble, the door frame will collapse. Therefore, it is necessary to find the optimal speed.

The aftershock acts on the last 25cm. from the outer edge of the door. It is adjusted in the same way as the main stroke - by changing the position of the screw. It needs to be turned so that the speed does not hit the jamb and blades too much. Usually the middle position is set, at which the structure is slowed down with a neat, complete connection.

Open Position Calibration

It is often necessary to keep the doors open when there is no intercom or when transporting furniture. This adjustment of door closers is made if the “hold open” functionality is available. Configuration occurs in the following way:

- Open the door at 90 degrees.

- A special lock is attached to keep the doors open.

Interesting! If you set a different degree, the function will not work.

To return the doors from a fixed position, the leaves are pulled towards themselves.

Why can't I install a door closer?

Sometimes, having prepared well for installation and carried out everything in accordance with the manufacturer’s instructions, it is not possible to complete the installation. The reason for failure may be the incorrect selection of parts.

Don't miss: How to properly embed a lock into an interior door: instructions for installing a lock, do-it-yourself latches

Currently, there are many models of door closers produced for different types of door leaves. This especially often occurs when selecting a mechanism for metal doors. Perhaps the angle for securing the mechanism was set incorrectly, or the holes in the screws were displaced. Also, the purchased design may not match the width and weight of the canvas.

Sometimes, to successfully install a door closer, you need to move one link. To check, look at the evenness of the lever - if the position is not perpendicular to the doors (displacement), the link will need to be moved.

If, when checking the installation of the angle and displacement of the holes, no deviations are identified, then a complete replacement of the device will be required. You will need to select a closer with more power.

Tips and tricks

In order for the mechanism to work correctly, certain measures must be observed:

- You should not prop the door with objects, because to fix the position it is enough to twist the screws.

- Before adjusting, you should read its instructions to become familiar with the permissible standards regulated by the manufacturer.

- When buying a mechanism, you should know the temperature conditions under which it will operate, because many models are designed for warm rooms.

- If a malfunction is detected, you should call a technician so that your actions do not aggravate the problem.

- The floor closer is installed at the door installation stage, which must be taken into account when purchasing the device.

The adjustment is carried out by carefully rotating the screws, because it is easy to disrupt the hydraulics, which will lead to a malfunction of the mechanism, which will be difficult or almost impossible to restore. Before setting up, you need to make sure that the reason for the poor operation of the device is in the closer.