The finished look of the laid tiles will be given by competent, carefully executed grouting of the seams of the tile covering. This is the final touch on which the overall impression of the work done depends. In order not to spoil the joints between the tiles, and to perform this important operation successfully, you will need a good tool. Such a device will be a spatula for grouting, which will help put an end to renovation work in the bathroom.

The result of the work depends on the correctly selected grouting device, so it is important to know the types, features of the use of various spatulas and their care. The tool can become a universal acquisition for both a novice home craftsman and a professional specialist.

Description of the tool for troweling

A departure from its usual metal plastering and painting counterparts, the grouting spatula is made of a solid alloy piece of rubber with cut edges, like a knife blade. The plasticity of the material and the ability of the spatula to bend allow:

- work gently and carefully with decorative surfaces without the risk of damaging the surface;

- significantly facilitate the work of sealing hard-to-reach places thanks to its design features.

A distinctive feature of a rubber spatula, in contrast to its painting counterpart, is the large size of the tool, the working surface of which reaches 80 cm. In work, this factor creates an advantage, since it speeds up the grouting of a large surface of the walls or floor. Quite tiny models are often used, up to 4 cm, suitable for processing corners and difficult places.

For convenience, the rubber spatula is equipped with a wooden or plastic handle, which corresponds to the overall lightness and plasticity of the tool, adapted for grouting tile joints with various finishing compounds in the form of cement or epoxy mixtures. Varieties without handles are suitable for grouting in corners, difficult niches and other hard-to-reach areas.

Design

The design of spatulas for grouting joints is extremely simple and consists of two main components:

- Plastic working tool. It is a plate made of rubber or rubber. Can be either black or white. The edge intended for filling seams has a chamfer - a beveled, pointed end that ensures a tight fit to the surface. It is the chamfer that is the working area, and thanks to the bevel, uniform distribution of the grout mixture is ensured over the entire area.

- Handle. It can be different. Trapezoidal models are most often used because they fit comfortably in the palm of your hand. However, handles in the form of a bracket are considered the most practical, since they provide easy grip on the spatula and do not cause a feeling of fatigue even during prolonged use.

Note that the handle plays an important role. It provides the necessary pressure, thanks to which the mixture easily fills the seams. There are spatulas without a handle. They are convenient for grouting joints in hard-to-reach places (for example, behind pipes), but they are not suitable for long-term work, since the fingers get very tired from the tension.

Chamfering a work plate is also tricky. Thanks to its beveled shape, it helps to rub corners, completely covering and sealing them.

Manufacturing materials

Various materials are used to produce handles, including plastic, wood, and rubber. The working plate is made of rubber and rubber. The last option is the highest quality and most durable. This is due to increased resistance to chemicals included in grout mixtures. Cracks and other defects are less likely to appear on rubber spatulas.

Set of PVC spatulas

Why is spatula integrity so important?

Please note that the working edge of the spatula should always remain as smooth as possible, without bevels and all kinds of defects. Otherwise, a groove and various bulges will remain on the grout seam, which will subsequently lead to damage to the seam and depressurization.

In order for the grout joint to be durable, it is necessary to make it perfectly even and not protruding above the surface of the tile. It will be impossible to achieve such an effect with a damaged spatula.

Purpose of the spatula

The rubber spatula is intended for construction and repair work:

- for grouting tile joints and parquet joints;

- removing the remains of the construction mixture.

The work is of a finishing or restoration nature of varying complexity, so maintaining the surface without scratches or other damage is an important factor. Devices of different sizes are used depending on the size of the plane being processed.

The low price of a set of several instruments allows us to consider them a consumable item. Rubber is an ideal material in terms of quality characteristics for dense and reliable grouting of joints.

Tool requirements

The design of the spatula, at first glance, is so simple that it seems impossible to damage the tool. But practice shows that there are details and properties that affect the comfort and productivity of work:

- pen. It must be adapted for long-term use through a convenient design that prevents hands from being contaminated with the grout mixture. The shape of the handle should facilitate applying pressure to the grout mixture, filling the seam or tile joint. Sufficient pressure will compact the composition and enhance performance;

- rubber sheet. The shape, density, and plastic properties should serve to unhindered collection of excess mixture from the tiles after filling the joints, and the cone-shaped edges should serve to press the grout even in the corners. Surface cleaning must be complete, without the possibility of filling pores and small cracks.

Rubber and rubber blades of spatulas are similar in appearance, but differ significantly in wear resistance and durability. The versatility of rubber lies in its water resistance and chemical resistance. Rubber ages quickly and either degrades or becomes brittle and breaks.

Rubber spatula

Rubber spatula

Multilayer rubber spatula

Which rubber spatula for grouting joints is more convenient to work with?

The most convenient is a rubber rectangular spatula with a handle, since it has a large surface, which allows grouting to be done quickly and efficiently.

Soft rubber allows the seams to be filled tightly, which eliminates the formation of voids in the joints and, accordingly, extends the service life of the tiles. The tapered edges allow the grout mixture to be pressed even into corners, which prevents the formation of voids.

The handle can be made of either wood or plastic.

Types of spatulas

Among the huge variety of spatulas, these devices may vary:

- by shape: the trapezoidal rubber spatula is in first place in popularity, followed by a rectangular one, then a rectangular one with a rounded edge, a figure eight and a wedge-shaped one;

- by color: the main colors of rubber are black and white. This is not just coloring, but a reflection of the rigidity of the canvas. The black version is tougher. They are more effective at compacting grout without leaving voids. The white version is more delicate, softer, suitable for finishing joints, as well as tile seams;

- by types of handles: Many instruments are equipped with a trapezoidal plastic handle. This is a convenient option, but it is believed that the handle-bracket is more conducive to efficiency in work. The price of such models is higher. The choice depends on the volume of work and intensity of use. Options for grouting tools with wooden handles or holders are also found, as are solid rubber sheets without handles;

- by purpose: grouting and for grouting: Filling joints with cement or epoxy grout is done with the main types of spatulas. The jointing is done with a special round rubber spatula. This variety was introduced by Kiilto, and then other manufacturers began to add similar models to grout packages.

There has always been a need for such a device for forming a seam; before, craftsmen used improvised means, using a piece of electrical cable with a cross-section of 6-10 mm.

It should be noted that a round trowel can be used effectively when the grout is soft, but with hard grout it is more difficult to form a joint.

Invisible moments of working with a rubber spatula

Grouting work should not be carried out before the tile adhesive is completely dry, as it will cause deformation of the tile surface.

At what angle and how to apply grout with a rubber spatula

Before grouting, you need to prepare the materials that will be needed to remove excess grout from the surface of the tiles.

Grout

Apply to a clean, dry surface. The temperature in the room where the work is carried out is not lower than 10-15 degrees. The highest air humidity is no more than 55%. Dust is unacceptable. It will not be better if direct rays of the sun hit the grout until it completely sets.

The tip of the spatula must be rounded or sharpened before use. If a new tool is used, then manufacturers do this when releasing products from the assembly line.

Excellent work between tiles

A wonderful spatula can be bent into different shapes, after which it will return to its first position. This is a result of the flexibility of the rubber from which the product is made. If the tool does not change shape or is difficult to change, it means that it is made of pure rubber or poor quality materials based on composites. It is better to refuse to work with such a canvas.

Putty knife

for putty and

the spatula for grouting are separated, thanks to this they cannot replace each other during work.

Tools must be washed after work, since the remaining mixture destroys the structure of the spatula blade and may subsequently cause difficulties during use. Once the composition has dried, it is difficult to clean off the spatula.

Cleaning tiles from excess grout

The tool is easy to manufacture, which is why there are many products on the market made from low-quality raw materials. To avoid problems during operation, when purchasing, you must try to adjust the shape of the canvas by checking its plasticity.

You will learn about how to grout joints and keep the tiles clean from the video:

How to use the tool correctly and in what cases

The technical rubber of the tool is perfectly sharpened: the blade is cut at an angle during production. The chamfer location is the working side of the spatula. The tool is ideally suited for difficult areas, adapts to any shape: cylinder, arc, cone. Models without handles of various shapes are needed for grouting seams, joints behind pipes, in arched finishes, and niches. The rubber tool is suitable for processing seams of tiles and decorative stone, sealing joints of linoleum, parquet, and ceramics. Puttying work cannot be carried out with a rubber spatula. Neither the design nor the handle are suitable for these types of work.

Experts believe that the process of grouting with a rubber tool is convenient and can be adjusted in two basic movements: bring the mixture on a spatula to the depth of the seam, and then remove excess from the surface. The jointing gives the finished look, the final relief. Sometimes jointing is done with the rounded side of a rubber spatula, sometimes with an adapted handle or a separate tool.

The main thing to remember is that grouting work is carried out after the tile adhesive has completely dried.

Remains of dry grout are removed from the surface with a clean or new (if available) rubber spatula. If you washed it, you need to wait until it dries completely. You need to hold the tool almost perpendicularly, do not press too hard so as not to remove the applied mixture from the joints of the tile or stone.

Tools for cleaning tile grout

- Skipper bucket with squeezing rollers. Very convenient for cleaning off grout residues, especially if you are using an epoxy-based mixture.

- Cellulose combined sponge. Needed to clean off epoxy grout residues. More durable than regular foam rubber, seams form faster.

- Foam rubber graters. To remove any remaining mixture. I recommend doing final cleaning the next day of white deposits using a felt welding glove.

Skipper bucket with wringer rollers

Cellulose combination sponge

Foam rubber grater

About quality, manufacturers and cost

Using the “right” tool is the key to successful and high-quality work and a professional approach to finishing. Manufacturers of STAYER, SPARTA, FIT, and domestic companies took into account the experience and practice of using spatulas to make them as convenient and versatile as possible.

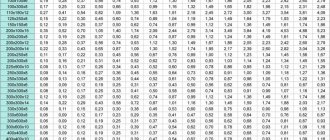

You can purchase tools at retail, small and large wholesale. Depending on the size and design features, the price per piece averages from 45 to 80 rubles. The cost of sets of three rubber spatulas (40 mm, 60 mm, 80 mm) ranges from 50 to 80 rubles. White rubber is valued higher, by about 10%. Purchasing tools in small wholesale (as consumables) is the most profitable: the price per piece is no more than 35 rubles.

Rubber spatula Bison

Rubber spatula STAYER

Instrument care

Inexpensive rubber spatulas can be considered a consumable item and should not be saved if the repair work is completed and the tool is no longer needed. Those who are professionally engaged in finishing work are sorry to part with a convenient device and will need the following advice:

- You can extend the service life of the tool by regularly cleaning its surface from building mixtures;

- you should monitor the appearance of microcracks, their appearance will interfere with the elasticity of the tool, since the solution will get into the cracks;

- The edges of the rubber sheet must be smooth, without nicks or cracks. If you want to keep the tool in working condition, you can carefully trim the damaged areas.

Correct, careful use will significantly increase the service life of the spatula.

Rubber or Rubber?

Spatulas with rubber and rubber sheets are similar in appearance. Therefore, when purchasing a tool, you should immediately clarify what the working surface is made of, since the quality and service life of the device depend on this. Rubber is universal, wear-resistant, durable. It is resistant to chemicals and waterproof. Rubber, on the contrary, wears out quickly, becomes brittle, breaks and can even decompose.

How to make the right choice

When choosing a tool, you should take a closer look at the following details:

- the rubber sheet must be sharpened, this is important for troweling work;

- evaluate the rigidity of the spatula and compare it with the characteristics of the materials (tiles, stone, composition of the grout mixture);

- convenience of the handle (if it is wooden, then the application of drying oil is required to extend its service life).

A rubber spatula will help you work successfully and with pleasure, and achieve beautiful, high-quality results.