Every car enthusiast at one time is faced with the need to paint/touch up his car. To simplify this task, modern cars have a special plate - Vin Plate. In addition to the basic data about the car, the paint code in which the car is painted is also indicated. Knowing this number, you can paint it without any problems, without fear that the main color of the car will differ from the tinted one.

Why check paint thickness at all?

The thickness of the paint coating (LPC) determines whether the car body has been repainted or repaired after an accident. This means that it is possible to determine whether there were any accidents at all.

A car is painted in two cases:

- For cosmetic purposes - due to a scratch or minor accident.

- After a serious accident.

Not only a used car, but also a new one can be tinted. If you are not an expert, it is difficult to determine by eye whether a car is painted: with careful repairs, the coating cannot be distinguished. Therefore, you need to measure it with a thickness gauge.

You can still buy a car after cosmetic painting, for example with a repainted wing, even if the thickness gauge shows deviations from the norm. But deviations are a reason for bargaining.

If the car was in a serious accident in which the body structure was damaged, then it is not a car, but junk on wheels. Being in such a car is life-threatening: you never know what kind of damage remains in the body, what could come off or jam, and in the event of an accident there is generally a huge risk. You can buy such a car only for spare parts.

It is important to understand the reason for the painting and exclude a serious accident. Ask to dictate the car's VIN - identification number - and check the car's history on the traffic police website. If the car is from Moscow, additionally check it with the Autocode service. This way you will find out whether the car was in an accident and in what circumstances. It's free.

If the seller refuses to name the wine, do not buy the car. Most likely, they are trying to cruelly deceive you.

Where to look

With each new brand of car, Chevrolet creators come up with new places to write paint codes. The range of locations is so wide that some car owners have difficulty finding a Vin Plate with a paint code. In most cases, the board with all the data regarding the car is located either on the glove compartment lid or under the hood.

Some cars intended for sale in the CIS may not have a paint number indicated at all. In this case, in order to find the right paint using the VIN code, you will have to contact the dealer.

From the photo below you can see where the plate for each Chevrolet brand is located.

What is a thickness gauge

A thickness gauge is a device for measuring the thickness of a paint coating. Looks like a small box.

There are many models of thickness gauges on the market, just like smartphones.

Some thickness gauges work at temperatures below zero, others do not. Some models measure aluminum parts, others only work on steel surfaces.

I recommend using professional thickness gauges - these are, for example, models Etari ET111, Etari ET11 P, Autotest 112. You can buy one for 5000-7000 rubles.

But if you change your car every three years or less often and don’t plan to use a thickness gauge often, then there’s no point in buying one. You can just rent. It costs from 300 to 500 rubles per day.

Hundreds of thickness gauges are rented out on Avito

Let's sum it up

If you would like to see the table, please use the data in this post. You can determine the painted areas without viewing the original information on the car. The thickness of the car's paintwork will be uneven; it is often possible to visually determine the places where painting was done. But sometimes this task will be quite difficult. You will have to conduct a more detailed analysis at a service station, paying money for diagnostics. Buying a car without checking the paint today is dangerous, as you may end up purchasing a low-quality option.

In the automotive market, every second car went through a painting procedure after purchase. And determining this fact will allow you to knock several hundred dollars off the cost of a used car. So preparing for a body survey can really pay off. If you do not find any signs of repair, then you can safely buy such a car and enjoy its operation. Most likely, what you have in front of you is a truly undamaged car, which is quite difficult to find today. Use the information provided and choose a car to buy based on important criteria.

If it is completely poured correctly, the layer is even.

| whether the car has been beaten or tinted |

Touch-up is not a problem, if anything. By measuring the thickness, you need to look at the nature of the coloring. The body can be repainted completely or in separate panels at the factory, if it has not passed technical control for contamination of the paintwork, for example.

Damage should be looked for not by the paint, but by the strength elements and sealant at the joints of parts

__________________ The goal is the horizon. There is no point in wasting time arguing with a person whose opinion you are not interested in. From my thoughts it was written down correctly and read by me before sending

Most of the used cars are real rubbish, the problem is in the bodies and their characteristics. Damaged and restored cars are often found - it is not safe to buy these. But how can a beginner recognize a damaged car? You can recognize it, you just need to know what thickness of paint should be on cars.

What the thickness gauge will show

Using a thickness gauge is simple: take a calibrated device and apply it to the car body at a right angle. It will immediately show the coating thickness in micrometers. One micrometer is one thousandth of a millimeter.

I applied the thickness gauge to the body of my car. Coating thickness - 117 microns. Everything is fine, my car was not painted (I already knew this, but for your use as an example)

The higher the value the thickness gauge shows, the larger the paint layer and the higher the likelihood that this car was repaired after an accident. Typically, the factory paint layer on steel parts of a car is no more than 200 microns.

Readings above 200 microns indicate repainting.

Readings of up to 300 microns occur if a cosmetic defect has been painted over on the car, for example a scratch from a key. This does not affect the safety of passengers in any way, but you can still bargain.

Readings closer to 1000 microns indicate that there is still putty under the paint. A body element with such indications was definitely severely deformed in an accident and was puttied during repairs. If the work is done poorly, the paint on the putty may crack and fall off over time.

Features of the paint layer at the factory - thickness and composition

Not all potential car buyers on the free market understand why there is such a stir around paintwork. Many brands of modern cars even indicate the exact thickness of the paintwork in the car documents. When choosing a used car with the right approach, it is necessary to examine the paintwork layer to check for its thickening in certain places. The thing is that the values from the table are of great importance for some reasons:

- Only high-quality components are used in the factory layer of paints and varnishes;

- the guarantee of the absence of putty gives hope for a long service life of metal body parts;

- with any car body repair, the quality of the paint will no longer be the same as it was at the factory;

- even budget brands try to do the painting as efficiently as possible to protect all parts;

- if the thickness of the paint layer is too small or too high, problems in car operation are guaranteed.

This is why you need a thickness table, which will help you find out the original parameters for each model. But the thickness of paint on cars must be assessed qualitatively. For this purpose, special equipment called a paint thickness gauge is used. With such a simple feature, you can examine the entire car and draw conclusions on the condition of the paintwork. To conduct such research, you do not need to be an expert in the field of auto enamel and painting processes.

How to determine damage using a thickness gauge?

It will not be difficult to conduct research on any brand of car using such a tool. You will need the original paint thickness on the car, which can be found in the table. Write down or remember this value. Then use the device to determine the paintwork indicators on all parts of the car. This procedure is carried out in a few minutes and does not require any special skills. But it is important to do everything accurately and without doubt.

The only caveat worth remembering here is the quality of the device. Sometimes the data from the table will not agree completely because the thickness gauge can be a little deceiving. If the deviation is within 10-15%, you can ignore such moments. But exceeding the permissible values by several times is a guarantee of poor-quality body repairs to the car. Most often, paintwork in such places can be visually distinguished from factory coatings.

How to calibrate a thickness gauge

To give accurate results, the thickness gauge must be calibrated. Calibration gets lost due to temperature changes or if the battery runs out.

To calibrate the thickness gauge, metal plates are used, which are sold with it. If you rent an instrument, ask the owner to calibrate it in front of you and provide you with rental calibration plates just in case.

The calibration plates look like this:

My thickness gauge has two gauge plates because it works on both steel and aluminum parts. The device must be calibrated separately for steel and aluminum. If the thickness gauge only works on one metal, there will be one plate.

The kit usually includes a special calibration film, which is used for adjustment.

The calibration process is simple - place the thickness gauge on the plate and reset the readings to zero:

We apply the calibration film to the plate and place the device on top:

The thickness gauge should show the numbers printed on the film. If this does not happen, repeat the procedure.

Minor repairs

In specialized stores and service stations you can purchase the necessary paint in any packaging. Minimum - 30 ml (small bottle with a brush), maximum - unlimited.

Depending on the volume, the paint is sold in:

- bottles;

- aerosols;

- retouching kits;

- plastic or metal containers.

Before touch-up painting, it is worth remembering that the paint should be applied to an already prepared surface.

Sequence of painting repairs:

- cleaning from dirt and rust;

- for better adhesion on the surface, it is advisable to walk with an abrasive material;

- degrease;

- prime (if necessary);

- paint;

- open with varnish (if necessary);

- varnish.

What to check on the car

It is necessary to check at least five points on one body element. One body element is, for example, the roof of a car, or the hood, or each fender, or door. We check each element with five applications of a thickness gauge: along the edges and in the center. Be sure to check the body pillars - these are the parts of the body from the bottom glass line to the roof.

The thickness gauge must be applied perpendicularly. If you apply it at a different angle, the readings will be inflated.

It happens that not the entire body element is repaired or painted, but only a part. The transition point is usually the stamping or the area where the body has a relief. If you check a body element with a relief with a thickness gauge, check the elements both above and below the relief. Otherwise, you may hit a part of the wing with the device that was not damaged in the accident, and below that same wing there may be a greasy layer of putty.

It is not enough to check only the external elements of the body with a thickness gauge. To exclude repairs after a serious accident, you definitely need to check the body and measure the paintwork of the frame inside.

Open the door and gain access to the racks. You open the hood and get access to the wing shelf and cups. The thickness gauge readings there should not exceed 100 microns.

The body in the photo has a molding - a relief. Such a door could be repaired locally, for example, only below the relief. The relief part allows you to make the transition of paint shade, which may differ from the factory one, visually invisible. Such a relief door must be checked both at the top and at the bottom Aluminum parts

Before inspecting a car, it is useful to find out whether the car model you are interested in has aluminum parts. For example, many Audi, BMW, and Range Rovers have aluminum hoods, front fenders, and doors. To measure the coating on such parts, you need a thickness gauge capable of working on aluminum, such as the Etari ET 555.

No special settings are needed - switching between ferrous and non-ferrous metals usually occurs automatically. The type of metal is indicated on the device screen: aluminum or steel. Factory values for aluminum parts differ from those for steel parts by 1.5–2 times less.

If there should be an aluminum part on the car, but the thickness gauge recognizes it as steel, then the part has been replaced with a non-original one. This is also a sign of an accident in the car's history.

Colors used for Chevrolet Lacetti

It is difficult to list all the colors used to paint the Lacetti. In addition to the basic black, blue, green and red colors, their transitional and mixed versions are also used. The colors for hatchbacks, sedans and station wagons are the same.

In addition to color, paints also differ in nature. They can be:

- Acrylic. These are 2-component mixtures consisting of a coloring component and a hardener.

- Polyurethane. There are several types: 2-component, powder or drying at elevated temperatures. They are distinguished by increased wear and operational resistance.

- Basic. These are paints with a beautiful decorative look. Apply in 1-2 layers and after drying, additionally coated with a thin layer of varnish.

| Color | Code | Photo |

| Blue | 15U/WA151L | |

| CHE9154 | ||

| 127A | ||

| 8991 | ||

| 895T | ||

| White | 11U/WA143L | |

| Black | GQR | |

| CHEGAR | ||

| 690F | ||

| 501Q | ||

| 19 | ||

| Red | CHE3050 | |

| CHE3051 | ||

| CHE3041 | ||

| 547 | ||

| Green | CHE6002 | |

| CHE556FP | ||

| CHE680HP | ||

| 387E | ||

| CHE9524 |

Plastic parts

The thickness gauge does not work on plastic parts. Modern cars have bumpers, door handles, exterior mirror housings, and sometimes other parts made of plastic. For example, the Peugeot 408 has plastic front fenders.

It is better to study the features of a specific car model before inspection. To do this, just watch 5-10 videos with an inspection of the car you need on YouTube.

A thickness gauge on a dirty car may fail or break.

It is wrong to use a thickness gauge on a dirty car. Firstly, the readings may be incorrect. Secondly, using a thickness gauge on a dirty body spoils both the device and the car’s paint.

Wash your car before checking. You need to inspect a clean car. This is useful not only for the thickness gauge, but also for finding defects. It looks better when clean.

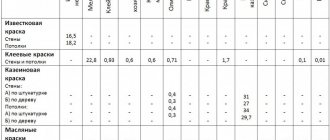

Table and explanations for checking the optimal paint thickness

Only original data from the manufacturer may be used. But in reality, you don’t even have to look at the table, sticking to the data for all cars. This range is up to 165 microns, but not thinner than 75, as we discussed above. It is in this spectrum that painting mechanisms operate in factories. To keep track of such a parameter as the thickness of paintwork on cars, a table is not always needed. You can use a simple method for determining the quality of paintwork:

- take a thickness gauge and apply it to three points on large body parts, write down the data;

- then use the device to check the most frequently repaired areas on the car body;

- record the thickness of the paint on the fenders, sills, bumper, front of the hood and rear of the trunk lid;

- then the easiest way is to identify repaired places and ask the car owner a question about these locations;

- If a more thorough check is required, you can send the car to a service station and carry out expert diagnostics.

You can check the car yourself in two minutes if you know the original paintwork indicators or stick to the middle spectrum. You should only be careful in cases where the car has been completely repainted. In such a situation, you may not understand the difference between different parts and take the obtained indicators as original. But when painting with a conventional spray gun, it will never be possible to achieve a uniform paint thickness within the factory standard.

Factory paint performance

Factory paint provides protection to the metal base of the body, as well as other layers that are applied to it - galvanization, primer. Only strict adherence to technology ensures the required durability of the body service. How much will the total thickness of the coating made at the factory be? For most cars, the indicator is in the range of 70-180 microns, while the spread across the car can be 20-25 microns, for one part - 10-15 microns. For the following elements, a layer thickness of 50-90 microns is allowed:

- door pillars;

- thresholds;

- trunk;

- engine compartment space.

It is impossible to paint a car without this error, even at the factory. The paint and varnish product may be unevenly distributed in different areas: for example, in horizontal areas the layer will inevitably be thicker than in vertical ones. Also, during painting, shagreen appears - surface roughness. Painting indicators also differ for parts made of non-ferrous and ferrous metals. Thus, even on a new car, the readings may vary when measured by the device.