Currently, metal siding is gaining great popularity due to the fact that it is a material that can provide a reliable, durable and wear-resistant exterior coating for the home. One of the most prominent representatives of this trend, due to its natural and aesthetic appearance, is considered to be products that imitate logs. Having high resistance to possible influences of environmental factors, the presented material does not require regular maintenance.

The relevance of using such a product, among other things, is due to its accessibility and ease of installation. In this article we will tell you how to install metal siding with your own hands (under timber, logs), give step-by-step instructions, and also demonstrate diagrams, photos and videos.

Production

Production of metal siding

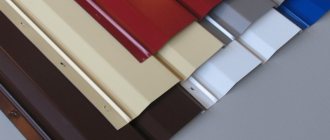

The material itself is made of galvanized steel sheets treated with a polymer composition, imitating calibrated logs. The production of such products is based on applying a pattern to the profile using the “Printtech” technology (photo offset), which provides a realistic, as close as possible appearance of a natural painted tree trunk. Metal siding on the market is replete with its color range and is sold in rolls with a sheet width of 188 mm, a profile height of 31 mm and a length of 80 to 800 cm.

Tools and consumables

Any construction operation and type of material involves the use of individual tools and components. In our case, to implement our plans, we will need to prepare the following tools and devices:

- galvanized self-tapping screws with a press washer;

- dowel-nails;

- building level and tape measure;

- grinder or metal scissors;

- screwdriver or drill with a set of bits and drills;

- ladder.

An important aesthetic function in finishing a house with metal siding is played by additional details: internal and external corners, slopes, joining strips, starting and finishing guides, the use of which allows you to give the structure overall completeness and a neat appearance.

Areas of use

Siding has been used for many years to protect and insulate load-bearing walls of buildings. The most popular type of metal siding is “ship plank”. This type of finishing looks great both on one-story private houses and on tall buildings consisting of several floors.

Appearance is not the only advantage of this finishing material. Another equally important reason why the choice is made in favor of this particular type of siding is its low price. In addition, the sheathing process itself is inexpensive.

Marking

Having decided on the material, before fixing the brackets, you should clean the walls and apply markings on them. Initially, using a broom or broom, you need to sweep away any remaining dust and dirt from the future surface. At the same time, to simplify access, it would be useful to use a stepladder or scaffolding. In addition, the presented devices will be useful in the future, when installing facing sheets.

Having finished with this activity, you must draw out the future surface with horizontal and vertical lines at a distance of 50–70 cm relative to each other, and the intersection points of these guides will subsequently become the locations of the brackets.

Correct marking is the key to a durable and even finish, so its application should be approached with special care, not forgetting to use a building level and measure the same intervals each time.

Features of choice

In construction stores you can find “ship planks” from different manufacturers. There is almost no difference between them.

There are only two main differences:

- The thickness of the polymer layer, which plays an important role in protecting the boards from negative influences.

- Substances included in the composition. Different manufacturers may add different materials to their products.

When choosing metal siding, you need to pay attention not only to its properties, but also to its aesthetic qualities. The first step is to study the technical specifications. Be sure to clarify what substance is used as a protective coating.

You also need to find out whether the material will require maintenance during operation. If the answer to this question is positive, then it is advisable to refuse to purchase this type of material, since maintaining the outer cladding of a building is quite problematic at any time of the year, especially in winter. It is better to look for some other variety that will no longer require careful care. Fortunately, this material is quite popular and widespread, and finding samples with a surface more resistant to negative influences is not so difficult.

As for the color of metal siding, it is better to give preference to soft and calm tones, since brighter shades will soon lose their attractive appearance anyway, becoming covered with a layer of dust. It will look especially unsightly in clean areas.

When choosing a “ship plank”, as when choosing any other product, you inevitably have to pay attention to the cost. There is no need to rush to purchase large quantities of material if it is sold at a low price. Here you need to understand that low cost indicates low quality of the product.

Before purchasing the material, you must find out whether it contains additional elements and whether they correspond in all respects to the main panels. If this is not done in time, the installation will result in the formation of a mismatched surface consisting of elements that do not correspond to each other at all.

Placing bracket supports

Placement of bracket supports

Installation of brackets is carried out along the perimeter of the entire surface from bottom to top, taking into account a number of important points:

- Fastening is carried out depending on the type of surface to be finished using 40 mm self-tapping screws or anchor bolts;

- let's start placing connecting strips - as a rule, these products consist of perforated metal sheets containing through cuts of given sizes and located in a certain sequence; in our case, since it is planned to place metal siding under the log, we place the guide profiles vertically and attach them to the brackets using 4.2 × 16 mm self-tapping screws;

- the guides are installed in such a way that there is a gap of at least 10 mm between them;

- We additionally install guide strips around the perimeter of windows and doors;

- At the corners of the structure, installation of the profile is carried out taking into account the subsequent fixation of the corner strips.

Of course, an alternative to metal brackets can easily be wooden blocks, the cost of which is several times lower, but metal products have a number of significant advantages that eliminate subsequent deformation of the surface and ensure reliable operation.

Recommendations for working with metal siding for exterior home decoration

Self-installation of metal siding is not difficult, but, like any construction process, it requires certain knowledge.

- It is necessary to calculate in advance the amount of material required for finishing. Some manufacturers' websites have online calculators that are convenient for making calculations. If you want to do this yourself, then you need to take measurements of all areas of the facade that will be finished. It is recommended to sketch out how and where the siding will be located, and indicate the combination of colors, if any. This will make it easier to calculate the amount of finishing.

- In parallel with metal siding, fractional elements (slopes, soffits, platbands, overlays, etc.) and related materials are calculated.

- It is better to order cutting of siding into pieces according to your measurements from specialists. At home, cutting is done with a jigsaw or reciprocating saw.

- All finishing elements are mounted taking into account a thermal gap of 1 mm between the metal and the screw head. This is necessary so that the parts do not deform during thermal expansion.

- Before installation work, you must carefully study the instructions for working with the selected material.

- Before installation, purchased metal siding is stored horizontally on a flat surface away from the street.

Failure to follow the recommendations may lead to problems during or after installation work.

Installation of insulation

In the option of placing siding with insulation, slabs of selected materials are placed close to each other without additional gaps. If several layers of the protective layer are made, the slabs are installed with joints spaced apart. On the outside there is a windproof membrane film and all layers are fastened using disc-shaped dowel-nails. When installing this element, it is important to maintain the distance between the insulation and the siding, which should be within 25–30 mm.

Benefits of metal siding

You can fasten metal siding yourself, thanks to the simplicity of installation technology, but there are also other characteristics:

- Excellent durability.

- Tolerates temperature changes well.

- Possibility to choose from a wide range of colors.

- Environmental Safety.

- Fire resistance.

- Long quality guarantee period.

- Ease of installation.

- Easy maintenance.

The purchase and installation of metal siding is several orders of magnitude more expensive than vinyl, but this material is much stronger.

Physical characteristics of coatings

Material characteristics

| Coating | Polyester, polyester | Matte polyester | Plastisol | Pural | PVDF |

| Isosurface | flat | flat | extrusion | flat | flat |

| Covering layer thickness, microns | 26 | 36 | 205 | 49 | 28 |

| Primer, microns | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 |

| Thickness of the protective varnish layer, microns | 13-15 | 13-15 | 13-15 | 13-15 | 13-15 |

| Maximum possible operating temperature, °C | +125 | +125 | +60-85 | +125 | +125 |

| Minimum processing temperature, °C | -10 | -10 | -10 | -15 | -10 |

| Minimum bend radius | 3хt | 3хt | 0хt | 1хt | 1хt |

| Resistant to fading | **** | **** | *** | **** | **** |

| Resistance to fur. influences | *** | *** | ***** | **** | **** |

| Corrosion resistance | *** | **** | ***** | ***** | **** |

| Ability to withstand harsh weather conditions | *** | **** | ** | *** | ***** |

Installation of cladding

Installation of cladding

This event begins with the placement of the starting strip, which is the beginning and starting point for the subsequent installation of siding panels. When fixing it, it is important to use a building level and carefully measure every millimeter, since the slightest deviation from the vertical can subsequently lead to curvature of the entire facing surface.

Wood-look metal siding

We fasten the sheets using metal brackets, screws and self-tapping screws, depending on the available consumables. When placing the panels, they should not be installed tightly relative to each other, but a gap of 2–3 mm should be left, which will ensure subsequent adjustment of the installed surfaces.

As a rule, installation of “block house” siding begins from the center, gradually moving to the corners of the structure. At the points of contact, intermediate strips are installed, as well as external and internal corners. At the end, the finishing strip is fixed, and the overall facade of the house becomes similar to a “natural log house”.

As you can see, installing metal siding under a log is an effective and relatively affordable way to create a unique insulated and aesthetic facade. If all operations are carried out correctly, this material will function for a significant period of time and protect your home from the harmful effects of the external environment.

Specifications

If you look at a metal siding panel in cross-section, the metal siding structure will look like a multi-layer cake. The inside is galvanized steel, coated with an anti-corrosion layer and then a primer. The panel is covered with a polymer layer on top and with protective paint on the inside. Panel thickness up to 1 mm. Metal siding panels have latched locks, which make the assembly of metal siding much easier. The panels can be perforated, i.e. with holes for nails, or smooth. In the latter case, the holes must be drilled on site. The boxes with panels include instructions for metal siding, which will help you figure out how to attach metal siding.