7698 0 0

Savig June 15, 2017Specialization: master of interior finishing works. I am well versed in power tools for repair and construction. Formerly a teacher at a radio engineering college.

Self-tapping screws for drywall have several fundamental differences from similar products intended for wood or metal

Do you want to know how self-tapping screws for gypsum fiber board differ from similar fasteners designed to work with other materials? Then I propose to look into this issue together. The corresponding diagrams and photographs will help us with this.

Features of self-tapping screws

Self-tapping screws are fasteners that have a threaded rod and a head.

In appearance they resemble screws, but in their design features they differ significantly from them. But in colloquial speech, screws and self-tapping screws often mean the same product. In general, self-tapping screws practically do not differ from each other, however, each specific type of these products has its own individual characteristics. This is why self-tapping screws designed for gypsum fiber sheets (GVL) are not suitable for drywall, wood or metal.

Finishing

Refinement of the resulting surface can be carried out in various ways, but always after preliminary preparation:

- The joints between adjacent panels are sealed. To do this, the seam is treated with a primer and filled with elastic putty. If work is carried out in a recently erected building, then the areas are strengthened with reinforcing tape. This will avoid the formation of cracks in the future.

- The seams are rubbed down to level out possible unevenness.

- The surface is completely covered with primer and dried well.

All joints between sheets must be primed, after which they are reinforced with serpyanka and puttied with compounds with increased elasticity

You should know! It is rarely necessary to putty GVL, so further work is carried out much faster.

Decorative finishing is selected depending on the specific situation:

- The easiest way is to stick wallpaper. All varieties are suitable for this, but in the case of joining, the seams should be taped with a special tape, especially when choosing the paper version.

- Painting will require a lot more effort. For work, water-based compositions are purchased; the number of layers depends on the desired result.

- The surface can be tiled. This procedure is no different from standard wall finishing: the glue is applied with a notched trowel, installation is carried out 4-5 rows of elements at a time.

GVL is an excellent option for walls, as it provides a durable and reliable base that can be lined with various materials.

Properties of self-tapping screws for gypsum fiber boards

- Firstly, self-tapping products for gypsum plasterboard will definitely be made of steel in black, this is their signature color.

- Secondly, the diameter of the head of such self-tapping screws will be smaller than that of similar products, for example, intended for gypsum boards.

- Thirdly, self-tapping screws for gypsum fiber boards have a cone-shaped head, which gives the product countersinking capabilities. When screwing such a self-tapping screw, its countersinking head is completely recessed into the gypsum fiber, after which the part to be joined is rubbed with dry mixtures.

- Fourthly, these products are equipped with a two-start thread: one thread is located slightly lower, the other is slightly higher. This arrangement of turns eliminates the possibility of self-extrusion of the self-tapping screw from the gypsum plasterboard.

- Fifthly, the slot of such screws has a cross-shaped No. 2 (Philips classification).

In addition, self-tapping screws for GVL differ from their other “brothers” in the quality of the steel, the surface of which is oxidized. The tip of the rod is sharp, but does not have a drill. Such screws allow the use of automated tools such as screwdrivers. At the same time, the bit (attachment) for a screwdriver for this type of screws is also equipped with the PH2 marking (Philips classification). Self-tapping screws for GVL have notches on the screw head for countersinking.

Which ones to choose?

When choosing the type of fastener for gypsum boards, it is important to know:

- frame material (wood, metal, other);

- what exactly the fastener is intended for;

- how many layers will the plasterboard sheet be laid;

- operating conditions of the structure (indoors, outdoors, humidity level, etc.).

If you have to work in the “GKL-metal” system, then the fasteners are selected for working on metal - with “thick” threads. In the case of a wooden frame, the fasteners must have a wider thread pitch.

If you just need to fix the shelf on the drywall, then you can use a self-tapping screw with a butterfly dowel, equipped with a stop device that opens from the back and can withstand high loads.

For laying gypsum board sheets in 1 layer, the length of the fastener is 25 mm, in 2 layers – 35 mm. The thread thickness in both cases is 3.5 mm.

If a product made from gypsum plasterboard is to function at high levels of humidity, it is necessary to use moisture-resistant fasteners: alloyed or galvanized.

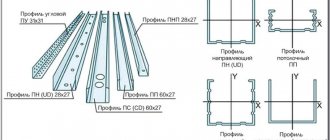

For work, the so-called “bugs” in everyday life may be useful - shortened screws with a drill, used to fasten the profile. The profile is fixed directly to the wall or ceiling using anchor screws and dowels.

The consumption of fasteners directly depends on the quality of the screws, which is important to consider when choosing them:

- In appearance, the self-tapping screws should be of the same size, with uniform threads, and not have any thickening or bending, which reduces its strength.

- The slotted hole must be clear and located strictly in the center of the screw head. Various types of bulges and bulges are a technological defect. A low-tech slot affects the quality of installation and can deform the screwdriver attachment.

- In color, the entire batch of self-tapping screws should be a uniform dark or grayish-black shade, which indicates good quality when phosphating or oxidizing products. Otherwise, an increase in humidity leads to the appearance of rusty stains, for example, under wallpaper, the removal of which is extremely difficult.

Product options

Self-tapping screws for gypsum fiber sheets are available in packs of 1,000 to 20,000 pieces. Their diameter is standard and is 3.9 mm. This makes it easy to mask the screw heads. So, the following sizes are available for sale:

- 3.9x19 (length 18.2-19.8 mm, diameter 3.76-4.01);

- 3.9x25 (length 24.2-25.8 mm, diameter 3.76-4.01);

- 3.9x30 (length 28.7-31.3 mm, diameter 3.76-4.01);

- 3.9x35 (length 33.7-36.3 mm, diameter 3.76-4.01);

- 3.9x45 (length 43.7-46.3 mm, diameter 3.76-4.01).

As a rule, to connect two gypsum fiber sheets together, it is recommended to use self-tapping screws measuring 3.9x19. The thickness of the gypsum fiber sheet does not exceed 10 mm, so the tip of such a self-tapping screw will not come out. In the case of fastening sections to other materials, you should be guided by the situation; extended fasteners may be required.

How many screws are needed per sheet?

Thus, about 13 - 18 pieces are required per square meter.

In general, in order to estimate the required number of screws for fastening brackets (direct hangers) to the supporting profiles, it should be taken into account that a prerequisite for proper fastening is four screws per fastening (2 on each side). And at the same time, for a more reliable connection of metal elements, the screws must have a flat head. Also, the general rule for correct fastening requires that the length of the screw be at least 10 mm greater than the thickness of the connection.

Scope of application of self-tapping screws for gypsum fiber boards

Self-tapping screws for gypsum plasterboard, as is already becoming clear, have found their application when working with moisture-resistant gypsum fiber sheets. Their design features guarantee reliable fastening of gypsum fiber to surfaces made of any materials. Such self-tapping screws are needed both for finishing (for example, wall cladding) and for construction work (construction of a false wall in a bathroom).

Also, these self-tapping screws guarantee a strong connection when installing gypsum fiber boards on two and three-level ceilings. Fastening with other types of screws does not guarantee the integrity of the gypsum fiber sheet around the rod, which means it can cause the screw to fall out of its seat.

Material consumption

Having answered the question of how many screws per sheet of drywall are required when working with a wall or ceiling, you can immediately buy the required amount of fasteners. Thanks to correct calculations, there won’t be a lot of extra screws left and you won’t have to go for them twice.

It is impossible to say the exact consumption of self-tapping screws per 1m2 of drywall. It's all about the distance between the fasteners. The metal frame to which the gypsum board is attached also plays an important role. After all, if there are a lot of jumpers in it, then more screws will be needed. On average, drywall is fastened with self-tapping screws in increments of 15-30 cm for the wall and ceiling. On the ceiling, the pitch is the same if lighter ceiling plasterboard is used.

So, how many screws do you need for a sheet of drywall on the wall and ceiling? On average, about 120 pieces, if we are talking about a standard sheet of 1.2x2.5 meters. From this we conclude that 40 screws are needed per 1 square meter. This is an average of the consumption of a step of 20 cm and the presence of jumpers with a step of 40 cm.

Everything is very individual and depends on the type of structure, so the consumption of screws per sheet of drywall may vary. In any case, you can buy the required quantity, because they are sold in 1000 pieces and 500 pieces, 250 pieces and 50 pieces. You don’t have to take prepackaged fasteners in a box, because you can buy them individually and even by weight.

Dowels for self-tapping screws for GVL

Special dowels for self-tapping screws under gypsum plasterboard must be used when something needs to be screwed to gypsum fiber. These dowels are available in several standard versions.

Dowel "Butterfly"

These are the most common dowels for self-tapping screws under gypsum plasterboard. They were nicknamed “butterflies” for the shape they acquire after twisting. They are made of polypropylene and are necessary for mounting lighting fixtures, mounting switches, fixing electrical wiring, fastening cornices and baseboards, the thickness of which does not exceed 12 mm.

In a word, butterfly dowels are designed for hanging structures that are not very heavy. The main advantages of these products are the ease and smoothness of screw tightening and the ability to remove the fastener. The disadvantages of dowels of this type include the impossibility of using them in conditions of limited space on the back side of the gypsum plasterboard and the inevitable preliminary drilling of a through hole.

Dowel Driva

They are conical rods, hollow inside. Equipped with screw thread. The diameter can vary from 12 to 15 mm. The head of such dowels is equipped with a cross-shaped hole for a Phillips screwdriver. The main advantages of this type of dowels are the following:

- there is no need to pre-drill a through hole;

- there is no need for free space behind the gypsum fiber sheet;

- You can dismantle screwed sheets.

No disadvantages have yet been identified for this type of dowels.

Dowel Molly

The basis of this type of product is a bushing that has longitudinal slots with a nut on one edge and a flat cap with teeth on the other. Externally, such a dowel resembles an expansion anchor bolt. Its advantage is that it can withstand fairly high loads, but its disadvantage is the impossibility of operation in the case of limited space on the back side of the gypsum line.

Dowel "Umbrella"

Externally, it is a threaded rod with a nut equipped with two spring-loaded legs, open almost 180 degrees. Such dowels are needed when attaching chandeliers and lamps to the ceiling. It has one undeniable advantage - easy removal, since the rod is simply unscrewed from the nut, and the rest of the fastener is removed with pliers. The disadvantages of such a dowel include poor resistance to vertical loads, as well as the need for preliminary drilling of a through hole.

Tips and tricks

The consumption of self-tapping screws per 1 m2 of gypsum board sheet depends on the optimal pitch size, which is selected based on the following features:

- practice shows that a medium-strength structure has a pitch norm of 300-350 mm (distance between holes);

- to strengthen the plasterboard structure, the distance between the holes can be slightly reduced, sometimes up to 100 mm;

- The self-tapping screw should not be brought closer to the edge of the sheet by less than 10mm to avoid chipping.

When working with a reinforced profile (for example, 2 mm thick), self-tapping screws with a drill should be used, which will eliminate the additional operation of pre-drilling and significantly reduce the work time.

To hang various interior elements, it is better to use a “butterfly” dowel, which, after installation, opens up and forms a reliable stop. Installation of such a dowel is carried out as follows: a hole is drilled in the wall with a diameter equal to the diameter of the dowel, 5 mm longer than the fastener. After cleaning the hole, the dowel is inserted and then the fasteners are installed. One such “butterfly” can support up to twenty-five kilograms of weight.

For working with wood, self-tapping screws, usually 24 mm long, are used. For a metal frame, experts recommend using self-tapping screws with a small head, since they are more convenient to hide under the trim.

After marking, it is recommended to pre-drill the hole with a thin drill no more than 3 mm deep. In the future, this ensures high-quality and reliable fastening.

It is recommended to install gypsum boards to the ceiling profile using a special attachment that limits the drilling depth to the specified size. The head of the finally screwed in screw should be located flush with the surface of the sheet.

With a multilayer structure, to increase its rigidity, elongated self-tapping screws are used, which are installed more often - in increments of 200-400 mm.

You can learn how to properly screw screws into drywall in the video below.

Plasterboard structures are widely used in the renovation and redevelopment of apartments. These are walls, suspended ceilings, niches and partitions, boxes and decorative fireplaces. For high-quality assembly, reliable fasteners are required, so it is important to choose the right screws for fixing the profile under the drywall.