How to plaster walls without beacons

Do-it-yourself plastering of walls without beacons is a step-by-step cycle of interrelated work, including:

- preparing walls for plastering;

- calculation of the need for dry plaster or its components;

- purchasing materials and preparing tools;

- preparing the solution;

- applying plaster to the wall surface.

Alignment without beacons with other available options

Plastering using the manual method of application can be carried out with a special construction trowel.

When performing the plastering process, an automated, namely machine, method is also used. Thanks to its use, the mixture is used economically, since the solution is distributed evenly, however, this type of processing will require a special level of skill.

Methods and tools for plastering the wall surface can be different. Plastering surfaces without beacons requires experience and extreme care, experience in working with plaster, as well as strict adherence to the sequence and technique of work.

Preparatory work

Preparatory work for applying plaster without beacons is slightly different from similar work when working with guide profiles. This is due to the different status of the premises in which the work is carried out.

However, here too, to ensure a long service life of the plaster, it is necessary to perform a step-by-step cycle of operations:

- remove from the walls, if repairs are being carried out, wallpaper, paint or whitewash, as well as the old plaster layer (in newly built premises this stage is skipped);

- inspect the walls and, if necessary, carry out work to seal microcracks;

- embroider masonry seams in brick walls to create good adhesion of the mortar to the wall surface, and on concrete walls, so as not to attach the plaster mesh, make notches with a hammer and chisel or bush hammer;

- clean the surface from dust and dirt;

- apply two layers of penetrating primer (when purchasing a primer, you should pay attention to the type of wall - brick, concrete or aerated concrete).

Calculation of the required number of beacons and marking

The calculation of the required number of beacons can be carried out simultaneously with the marking.

- A vertical line is drawn along the wall from bottom to top. The line is drawn 30 cm from the corner and repeated on the other side of the wall.

- The distance between the lines is measured and divided by 1.5 meters (rule width = distance between beacons). The result obtained will indicate the required amount of available funds. In larger production facilities, a longer rule may be used. In accordance with this, the lines will have to be drawn every 2 or 2.5 meters.

- Each guide is ultimately shortened to be 30 cm shorter than the height of the ceiling.

- The wall is drawn with vertical lines with a distance between them of one and a half meters. At the ends of each line, at a distance of 15 cm from the floor and ceiling, holes for self-tapping screws are drilled.

- The screws are screwed in, and a thread is stretched horizontally between their heads.

- The level of the screw heads is leveled. In this case, the degree of collapse of the wall is taken into account. For example, if the blockage is 1.7 cm, to this you need to add the thickness of the beacon 0.6 cm and add another interval of half a centimeter. So the cap will be 2.8 cm from the original wall.

- The threads are stretched diagonally, the caps are additionally aligned.

- You need to draw a beacon along the resulting mesh, ideally which should barely touch the threads.

- The threads are removed.

- The wall is coated with a primer to improve adhesion.

Marking the alignment plane This rather complex and painstaking approach is used if the master does not have a laser level on which beacons can be easily and quickly installed.

A much easier approach to installing beacon preparation is to use the plastic adjustment system we wrote about above. The lugs are screw-mounted and adjusted with a level, plumb line or other auxiliary tools. If you also make a mistake in the proportions when diluting the solution, the mass may begin to slide down under its own weight, leaving sagging. It is even more difficult to work with cement plaster, which takes longer to dry than gypsum plaster. In this matter, everyone chooses for themselves at what distance to install beacons, depending on their skills and experience.

When placing beacons you need to correctly evaluate your plastering experience

Plaster

We suggest you familiarize yourself with: Beacons for drywall in a wooden house

Checking beacons

Since beacons are used to level the wall, they naturally must be level. Beacons are made of plastic material, be it aluminum alloy or plastic, so they can easily bend during transportation or storage. For the first time, you need to check the evenness of the beacons in the store.

- the entire surface of the lighthouse should lie on the floor;

- The edges should not bend upward;

- the beacon should be parallel to the profile.

After checking, you need to wrap the beacons with tape and carefully take them home.

The lighthouse must be level

The easiest way to install beacons is using a laser level, but not every home craftsman has such a device. Therefore, we suggest that you familiarize yourself with an alternative method of marking walls for the installation of beacon profiles.

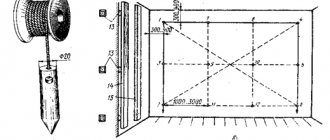

When installing using this method, it is important to take into account that the fasteners for the lace are installed at a distance of approximately 150 mm from the floor and ceiling, and 300 mm from the corners

- On the wall, level, straight vertical lines are drawn at the corners of the wall with the indicated indentation.

- At the top and bottom points of the lines, holes are prepared into which dowels are driven and screws are screwed in.

- The depth of the upper and lower screws is adjusted by a plumb line or level so that a vertical is obtained, under which the remaining screws are screwed along the line to the appropriate depth.

- Vertical lines are drawn along the remaining section of the wall in increments of 1000-2000 mm, depending on which rule will be used.

- Horizontal threads are stretched between the screwed-in screws, and at the intersections with the other vertical lines, holes are also drilled and self-tapping screws are screwed in.

- The screw heads must be located strictly in a straight line, since vertical beacons should not bend.

- After pulling the cord, all the unevenness of the wall and the approximate average thickness of the plastering will be clearly visible.

Calculation of material requirements

At first glance, calculating the need for mortar components or dry plaster mixtures is not very difficult. Multiply the area of the wall by the thickness of the plaster layer, take into account losses of 10-15% and, using construction tables, calculate the amount of cement and sand required for the work.

If you buy ready-made mixtures, then the packaging shows their consumption per 1 m2 with a layer thickness of 10 mm. Which also does not cause difficulties in calculations.

- Problems arise when determining the thickness of the plaster layer. When hanging a wall to install beacons, a large number of measurements are used to determine the average thickness of the plaster. It is impossible to carry out such work here, since the plane of the plaster is not formed.

- Experienced craftsmen get out of this situation simply: using a level and an even long board (slat) as a rule, they find the maximum deviation of the wall from the vertical. This figure is divided by two and 4 mm is added. The result is the approximate thickness of the plaster layer.

- For those who want to more accurately know the solution consumption, we recommend hanging the wall.

Marking

It is important to determine exactly where to place beacons. Not only the correct alignment geometry, but also the evenness of the walls depends on the correct markings

The marking process is called wall hanging. Performing it is not as difficult as it might seem at first glance. All you need is knowledge of a school geometry course. Stages of work:

- First you need to determine the evenness of the wall. To do this, apply a long rule to different sections of the wall alternately, marking the protruding places or depressions with different colors. For example, green chalk can be used to mark bulges, and blue chalk can be used to mark depressions.

- Measure down 2 m from the top of the wall. It is best to take measurements at the junction of two walls in the corner. Use a laser level to line up the horizontal line. Then measure 2 m up from the line adjacent to the floor and also build a horizontal line.

- Measure 10 cm from the corner joints along the upper horizontal line. Drill holes in these places and install screws in them.

There is an easy way to build straight verticals. A plumb line is used for this. A cord with a plumb line is attached to the upper screw and lowered until the distance from the floor is 3-4 cm. As soon as the plumb line stops oscillating, mark points on the lower horizontal line. Holes are also drilled here and screws are installed. Next, measure 10 cm from each screw and drill holes again, installing the screws. The outermost lighthouses will be located here. The distance between the locations of the outer beacons should be divided into several approximately equal parts about 1-1.3 m in length

Please note that it is better to plot the points along the upper horizontal line, and mark the corresponding points on the lower horizontal line using a plumb line. Drill holes at each of the new points and insert screws. If there is a door or window opening in the wall, then you need to retreat 10-15 cm from it on each side

Additional beacons will be installed here. Be sure to determine the evenness of the door or window opening using a level or plumb line. Even if the opening is level, it is still better to determine the verticals with a plumb line.

Now stretch the fishing line between the outer screws along the perimeter and diagonally. Next, screw in the screws until the line lightly touches the protruding area. Diagonal lines should touch slightly, be at the same level, and lie in the same plane. Next, all the screws that determine the position of the beacons are unscrewed until they lightly touch the fishing line

It is important that they lightly touch, and do not rest against the fishing line. This is how the thickness of the plaster layer is indicated.

Make sure that the screws lag behind the wall at a distance no less than the height of the selected beacons. If this is not the case, then adjust the position by unscrewing all the screws to an equal distance.

Materials and tools

Leveling walls without beacons usually requires purchasing the necessary materials and providing workers with tools and equipment.

Materials. For cement-sand mortar you need to buy:

- Portland cement M400 (ready-made dry mixes);

- river sand (fine-grained), washed from clay;

- fiberglass fiber to prevent cracking of the plaster;

- deep penetration primer (Ceresit CT 16, Condor, Alpina Primer);

- PVA glue to speed up the hydration process or liquid soap to slow it down (it is recommended to add soap to the first batches - lack of experience can lead to the setting of the solution that has not yet been developed).

You will also need water.

Tools and accessories. The work cannot be completed without tools and devices.

You will need:

- portable platform or stepladder;

- homemade metal trough for mixing mortar for 4-5 buckets;

- garden hoe - it’s convenient for stirring the solution;

- long flat board or rule 2-2.5 m;

- primer cuvette;

- roller or brush for applying primer;

- hammer;

- chisel;

- plumb line;

- spirit level (bubble level);

- plasterer's set (includes trowel, falcon, trowel, float, trowel and set of spatulas).

Installing profiles

Now everything is ready for mounting. For further work, you can use plastic beacons for plaster or metal products. Their fixation is performed in different ways. Before installing beacons under the plaster, you need to prepare a solution. Metal products are attached specifically to the plaster. It is applied along one line in small portions, after which the profile is recessed into the plaster to the desired size (stand flush with the screw heads). When all the profiles are level, you can unscrew the screws. But the plastic plaster beacon is installed on special fasteners.

You will learn more about how to install beacons for plaster using fasteners in this video.

A relatively new method is plastering on string beacons. The following video will show you how to do this:

Preparation of plaster mortar When the beacons are set, you can start mixing the mortar. Gypsum plaster mixtures are sold dry or ready-made. To work, you need to mix the dry mixture with water, and just open the finished solution and start working. As for the cement composition, it is made by hand. The creation is as follows:

- Cement M400 or higher is mixed with sand. Proportion 1:3.

- A little water is added to the mixture and the contents are mixed.

- The solution is brought to the state of thick sour cream and you can begin to plaster on the beacons.

Note! For plasticity and good adhesion, water is mixed with PVA glue. The fact is that ready-made mixtures already contain plasticizers and additives that improve plaster

Basic techniques for plastering without beacons

Every professional plasterer knows how to level walls without beacons. Moreover, each of them has their own favorite method (experts count 4 methods).

- First. When applying primer, three horizontal strips of mortar are laid out along the entire length of the wall: one in the center, the other at a height of 10-20 cm from the floor, and the third along the top of the wall. Using a rule and a spirit level (bubble level), the future plane of the plaster is formed with a trowel.

The result is something similar to mortar beacons - in the language of professionals they are called landmarks. It is impossible to achieve high accuracy using this method, but the process is accelerated and the result is a fairly flat wall surface.

Work is carried out after the landmarks have completely dried. To speed up the process of hydration of the plaster, craftsmen add gypsum to the solution (only for guidelines, and not for the entire plaster) (1-2 trowels per bucket of cement-sand mixture) - improvised beacons will be ready for further work in 30-40 minutes.

- Second. Along the edges of the wall, at a distance of 5-10 cm from the corner, three holes are drilled for dowels: at the top, bottom and in the middle. Self-tapping screws are screwed into them so that their heads protrude from the wall by 5-6 mm.

Using a plumb line, each row of screws is brought into one plane, after which three strings of fishing line are pulled between the screws. These strings serve as guides when applying the second layer of plaster - primer.

- Third. The most popular method is working with an “eye meter”. Let's see how to properly plaster walls without beacons with a cement-sand mixture.

Grouting plaster

After 6-8 hours, when the third layer has set, we begin grouting the plaster. To do this, the surface is poured with water from a ladle. Using a grater and circular movements, rub the surface until it is velvety.

The surface intended for tile or stone cladding does not need to be rubbed down.

During the drying process of the plaster, it is necessary to exclude the possibility of drafts and ensure constant humidity and temperature in the room. In hot weather, to prevent cracking, it is recommended to periodically wet the entire wall with water. After a few days, the plastered surface is ready for finishing.

How to plaster using the rule without beacons

Method No. 1

Plastering walls with your own hands without beacons can be done using rules for leveling the slats. After filling the area with mortar, using a spatula, placing a rule strip on the edge of the base, guide it along the wall, leveling it to scrape. At the same time, more mixture remains in the recesses, while its amount is minimal on the protrusions.

After the composition has set, final leveling is performed with a spatula, applying a thin layer of the mixture. This method is used to level small areas or fairly flat surfaces.

If the wall is completely leveled, the length of the rule should be equal to the height of the room or be comparable to it.

Method No. 2

Another leveling method is to double pass. Apply a relatively even, fairly thin layer of the composition with a wide spatula, level it with a horizontal rule (movement from bottom to top).

The second pass on the dried wall is performed in the same way, but the rule is placed vertically and carried out horizontally, leveling the layer of solution.

Method No. 3

- Now a little about how to plaster a wall if its middle is not visible (there is no point in leveling it carefully), but the corners and the surface adjacent to them are visible. This is done using a rule and a wide spatula. A spatula with a medium-sized spatula is needed to apply the solution to a wide one. Make a plaster mixture of medium viscosity.

- Using a wide spatula, apply a strip of triangular cross-section mortar to the edge of the wall adjacent to the corner, without laying the corner itself (thicker towards the corner, towards the center of the wall). The movement of the spatula should be horizontal relative to the angle. To prevent the layer of mortar strip from being pulled behind the rule, the tip of the spatula is drawn from top to bottom along the corner, as a result of which the mortar near the corner is pressed much closer to the base.

- Having placed the rule at the corner, move it horizontally in a zigzag motion towards the center of the wall. In this case, the mortar is cut off, and a kind of beacon is formed from the mortar at the edge of the wall. The edge of this “beacon” farthest from the corner is smoothed with a horizontal movement of a wide spatula.

- When the entire wall is bordered with such beacons and their solution has set, begin applying the leveling solution. It is also applied with a wide spatula, making a wide strip along the beacon. Leaning the rule with one end on the beacon (perpendicular to it), the other on the wall, cut off the excess mixture in the same way as when leveling with real beacons.

- The corner is covered by applying the solution with a small spatula and leveled using a rule along the already leveled plane.

Stage 3 – apply the solution to the wall

There is a slight difference in leveling walls without beacons using gypsum and cement materials. We will consider both the first and second options.

Working with gypsum mixture

Applying the gypsum mixture is easier. We have already completed all the preparatory work, all that remains is to plaster the wall without beacons. All work is done with a wide spatula. Using a narrow spatula, the solution is applied to areas of the wall with unevenness. All this is equalized using a rule. In addition, it is recommended to immediately install metal corners on the outer corners. A level is used in this work. The corners are fixed with plaster.

The gypsum composition allows you to apply a thin layer to the surface in order to protect it and make it visually beautiful. Work starts from the corner, from bottom to top. Using a narrow spatula, the plaster is applied to a wide spatula, and then transferred to the wall. An even layer is made by holding the spatula at a certain angle. The first layer is a primer. It allows you to fill all the voids. Using the rule, the evenness of the layer is checked and the mixture is added if necessary. The second layer is done in the same way as the first, the whole process is controlled by a rule in order to obtain a flat surface. It remains to perform the last layer - smoothing. This is easy to do, and little plaster is required. The output is a flat and smooth surface. All that remains is to go over the surface with a grater.

Work with cement mixture

- If you are treating a concrete wall, then before plastering without beacons, it is better to moisten it. Concrete absorbs moisture. And since the cement mixture contains water, after application the layer may crack and lag behind. Then the sequence is like this:

- Using a trowel or ladle, the mixture is thrown onto 1 m2 of wall.

- Using a grater, the solution is leveled over the surface. The thickness of the first layer is from 5 to 7 mm.

- Move the grater in different directions.

- After processing the first section, a second one is thrown on and the work is repeated. Direction – from bottom to top.

- There is no need to perfectly level the layer so that it is rough and adheres to the second layer.

- After the first layer has dried, apply the rule over the wall. It will remove cement deposits.

- The second layer of plaster is applied according to the same scheme, only the composition is not thrown onto it, but transferred with a grater. This will smooth out the solution more.

- After setting, the wall is checked for evenness using the rule.

- The layer dries within 3 hours.

- The last layer is the thinnest. It smooths out all the unevenness and roughness. The solution becomes liquid. Using a ladle from above, the wall is poured with plaster, after which it is leveled in a circular motion with a trowel. The layer will dry from 5 to 8 hours, and then it needs to be grouted.

How to prepare the surface with your own hands?

Attention

All work related to surface preparation is carried out to strengthen the further adhesion of the wall and the mortar. The durability of the wall plastering work will depend on such actions. The main task of plastering is to level the wall horizontally and vertically.

Preparing the surface for plaster may vary in steps. Everything will depend on what the wall is made of (brick, wood, etc.). You will also need to resort to actions to check the curvature of the walls. A scale or other tools are suitable here.

Prepare tools:

- Putty knife. It is with them that the solution of plaster and putty is applied.

- A brush with needles to clean the surface from dirt.

- A hammer used to knock down coverings that have become unusable.

- Before work, you need to make sure that the windows are glazed and the door frames are installed.

Actions:

- Measurement of the treated coating.

- It all starts with cleaning the walls from the old coating (why do you need to clean old plaster and how to quickly remove it?). Here you will need a hammer, spatula and brush. If you hear a muffled sound, it means the old material has fallen behind. It needs to be removed.

- Dismantling switches and sockets.

- Fill small cracks with plaster mixture three days before leveling the surface (how to seal holes and cracks on the wall and ceiling?).

- If the surface is wooden, then it needs to be sheathed with slats or shingles. There is nothing you can do with the brickwork. The plaster will cling to the seams between the bricks.

- Unevenness can also be removed using a mesh. Treat the entire surface with a primer.

Preparing the walls

Preparation involves removing old finishes, loose parts, dirt and dust. Depending on the materials for each type of surface, certain work must be carried out:

- In brickwork, it is better to deepen the seams by 1–2 cm.

- You need to make notches on the concrete surface, for which a file and a hammer are suitable.

- Large protrusions must be knocked down, since they will require more plaster mortar to be used, and cracks will need to be repaired.

- The solution can be applied to wooden walls only after installing wooden shingles on them at an angle or a plaster mesh with cells no larger than 4 cm. If there is mold, the surface must be treated with antiseptics.

Important! Regardless of the material, it is necessary to treat the walls with a primer, first removing oil stains, dirt and dust.

- Where surfaces meet the floor, you will need to remove all debris so that you can collect and reuse the solution.

- After applying and drying the primer, use the rule to identify areas with indentations and mark them with a pencil. This also applies to the floor plinth and ceiling areas.

Tips for Newbies

Advice

Quality work depends on the mixture. It is necessary to mix the solution correctly.

Every beginner must adhere to an action plan:

- Water is poured into the container, then 6-8 trowels of the finished mixture are poured. Using a construction mixer, mix everything thoroughly.

- The other part of the mixture is added gradually and mixed well during the process. This will avoid the formation of lumps.

- Wait three minutes and repeat mixing.

- Before you get to work, pay attention to advice from experts:

- It is not recommended to treat walls that are too smooth at one time.

- The smooth surface is treated using a plaster mesh.

- It is not advisable to apply the prepared solution onto walls that are too wet or dry.

- Use a trowel to remove excess compound from the lines.

- The mixture for plaster should not be liquid, thick or dry (how to dilute the mixture correctly?).

- You can repair walls using putty yourself, without having extensive experience in installation. The main thing here is to follow all the rules and listen to the advice of experts. Only in this case can you get a good result. With careful attention, even beginners will succeed.

Stage 2 – prepare the solution solution

All you have to do is open the finished plaster and start working. The dry one will have to be cooked. For mixing you will need a bucket of water into which the plaster is added. At the same time, the contents are mixed with a mixer. The instructions indicate the proportions and sequence of work. The mixture should have a paste-like consistency.

Subtlety! When the solution is mixed, it should be left for 5-10 minutes, and then mixed again. So it will “get there” and be perfect.

You should not mix a lot of solution at a time, as it has its own “lifetime”. During this time, the entire mixture must be applied to the wall.

List of the most popular plaster mixtures

Instead of cement and sifted sand, you can use ready-made plaster mixtures. Interestingly, many craftsmen use tile adhesive at the first stage to create the base, and apply the second and third layers with a solution of ABS mixtures.

There are several types of ready-to-use plaster mixtures:

- Cement-sand mixture - diluted with water, considered the cheapest option for use in these types of work;

- Cement-lime mixture - made using slaked lime, which allows you to maintain clean indoor air (lime kills bacteria). In addition, this mixture has the property of taking both paste and semi-liquid form, therefore it is used for leveling walls in the second and third stages. It has an average price among analogues.

- Gypsum plaster is the most expensive consumable material for leveling walls, so it is usually used only for the third layer, sometimes on the second. The price is very high, but the properties of gypsum allow you to create a perfectly flat surface. You can’t do without it at the finishing stage - it’s better than others at repairing all the defects found during the grouting of the last layer.

Plaster mixtures in dry powder form are packaged in paper bags with double protection. Usually the weight of one package is 25 kg, but there are packages of 1, 5, 10 and 20 kilograms.

Tip: You should not buy a large amount of putty at once; perhaps you can save money and apply a little plaster on each layer. It is better to purchase mixtures as needed. Take a couple of packages of a certain mixture and test how it sets, whether it fits well on the wall, how strong the base is. If one type of putty does not suit you, then you can buy another and finish the job you started with a higher quality material.

The most popular brands of ready-to-use dry plaster mixtures:

- Knauf

- Rotband

- Ceresit

- Teplon

You should not purchase putty from little-known manufacturers, because its properties may not meet your needs. “Knauf” is deservedly considered the best mixture, although it is expensive; this putty has no competitors.

Russian manufacturers also make good mixtures at a low price. The following good putties have proven themselves: “Yunis”, “Volma”, “Kreps”, “Osnovit”, “Teplon”. The quality of these mixtures is not inferior to foreign analogues, but remains the best on the market.

Plastering without beacons. Possible applications

Having some experience in the construction and renovation of premises, guided by the advice of professionals, applying plaster to walls without markers can serve as an economical way to renovate a room, significantly reducing the cost of building materials.

In conditions where there are complex communications that interfere with the installation of beacons, or a narrow space, plastering the surface without beacons becomes a necessity.

Plastering without beacons is appropriate if the wall does not have obvious irregularities.

This type of work is also applicable for walls that are initially smooth - for covering with plasterboard, or that do not require ideal smoothness - in a utility room, garage, or as a layer for further finishing.

Advantages of plastering without beacons:

- there is no installation of landmarks;

- there is no need to wait for the solution to harden to fix them;

- reduces the consumption of plaster solution, allowing a layer of less than 1.5 cm to be applied.

However, it will require a more in-depth understanding of the process and sequence of actions to create a level surface, the correct set of tools, as well as an objective ability to visually assess the satisfactory condition of each stage of the work performed.

How to plaster walls without beacons when the wall is collapsed?

Here, the lines drawn on the floor, walls and ceiling, limiting the surface of the plaster, come to the aid of the eye. The correct algorithm of work is as follows:

- Using a rule or a long, even board, find the place that protrudes into the room against the wall;

- Having retreated 5 mm from it, a line is drawn parallel to the wall, which continues on the floor, the next wall and the ceiling;

- The first stage of plastering work is carried out - spraying;

- After the spray has dried, primer is applied, where the drawn line acts as a guide;

- A small area is plastered, then the next one, and so on in a circle. The surface is controlled by a rule and a spirit level. After the plaster strip is looped, the next part of the wall is plastered. The reference point is no longer the drawn strip, but the plane formed by the plaster.

Work should be completed in the center of the wall. The technology for applying the plaster layer is identical to that given above (see point 3). Note that there are no differences in plastering walls with gypsum and cement mortar.

Liquid wallpaper application technology

The principle of working with liquid wallpaper is very similar to the technology of surface putty, so the phrase “glue liquid wallpaper” is not accurate. The prepared mass is applied to the wall in small portions and distributed over the selected area in an even layer.

However, applying liquid wallpaper to the wall has its own nuances:

- It is undesirable to work “in sections”. The fact is that the joints between finishing areas made at different times are quite noticeable. It is advisable to select a fragment from corner to corner or between protruding elements and finish it at a time;

- Accordingly, it is necessary to mix at one time the portion required for a given wall/ceiling area. It is better to knead with a small reserve; the unused mass is evenly distributed when kneading the next portion in the prepared raw materials. If the components of liquid wallpaper are supplied in different packages, they should first be mixed dry and then water should be added. If you plan to “dilute” the composition with glitters or dyes in addition to the existing decor, they are added to water, which, after dissolving (mixing), is poured into the main mixture;

- a large number of decorative inclusions makes it difficult to distribute liquid wallpaper evenly. Materials with long fibers are especially difficult. After the initial distribution, it is necessary to smooth the fibers, creating a certain pattern or simply a flat surface;

- The initial application of the liquid mixture is carried out using a wide spatula, the final smoothing is done with a roller or spatula, you can also use paint brushes. To form the relief (if provided), tools for sculptural work are used - palette knives.

Pros and cons of finishing

To do without beacons, the slats of which have their own height and do not allow a layer to be placed below the profile, means:

- do not increase the volume of plaster mortar unnecessarily;

- do not waste time on marking and installing profiles, dismantling them and sealing the resulting grooves;

- gain time on the drying speed of the coating.

These are the advantages of leveling walls with plaster without beacons.

The disadvantages include the complexity of the technology for beginners, as well as the fact that achieving perfect evenness using these methods is not always possible.

We display the remaining beacons

Next, we install the remaining beacons, in this case 2 more pieces. We measure and cut to size, taking into account that the height of the ceiling can be different, so you should not focus on one size, but measure each beacon.

Having measured and cut off the beacons, we throw in piles of mortar, guided by the drawn lines and “laces”. With “laces” it is more convenient to apply the solution, because you can immediately see where and how much of it should be applied.

Having made slides for one lighthouse, we put it on the solution. If the “laces” are well tensioned and the beacon is level, you can practically not use the rule, placing the beacon strictly under the “laces” so that they do not stretch, but only slightly touch the beacon. Having placed the beacon, we grease it around the edges, fixing it on the slides of the solution. Still, let’s check the correct installation by carefully applying the rule to the beacon and to the laces. If all is well, we set up the next beacon.

We wait until everything is dry, check that the installation is correct and remove the laces by unscrewing the screws. Next comes the turn of plastering the beacons. This process is described in the → corresponding article on the site, and this article can be completed here. Good luck!

Leave your tips below too. Subscribe to our newsletter. Good luck to you and good luck to your family!

Rules for applying plaster to different surfaces

Plaster mixtures sold on the market today are suitable for use on any surface. The main thing is not to forget to use fiberglass fiber, it will significantly strengthen the layers and help bind them to each other. You should also use a high-quality deep penetration primer when working with any surface.

Experts give the following tips for working with various walls:

- When leveling a gypsum wall, it is necessary to pre-coat it with a primer, preferably in two layers.

- to a concrete wall because it itself is flat. To set the plaster, notches are made on the surface of the concrete.

- When working with foam block , you need to first foam the voids or cover them with mortar; for leveling it is better to use gypsum putties, but a high-quality cement mixture is also quite suitable. When working with foam concrete, you need to constantly wet the surface you are leveling.

- Monolithic walls are sufficiently well primed.

- A wooden wall can only be plastered with cement-lime mixtures, provided that lathing is installed, since wood does not hold the mortar on itself well.

- Particularly difficult can be caused by brick walls that are folded incorrectly - in this case, blockages in the walls may occur, which can be eliminated by applying a thick layer of mortar. You need to level the blocked walls at the first stage, using a plumb line and applying such an amount of plaster that will allow you to level the blockage.

You can hang a plumb line at a certain distance and measure the distance to it with a tape measure, as in the photo above. This will simplify the process and help create a smooth surface on the wall, even if it is cluttered or crooked.

Leveling the applied mortar over the wall surface using a trowel

The primer application stage requires maximum care, since it is at this stage that the evenness of the wall surface is formed. There is no need to rush - usually work is carried out in small sections, bringing them to maximum perfection. These same areas, by the way, will become an excellent guide when moving to the next fragment, and thus a single surface will be maintained, without fractures or curvatures.

By the way, a logical question arises - what can you generally focus on when leveling a wall? For craftsmen with extensive experience, a well-calibrated eye is often enough, especially if the wall itself is flat and does not have significant level differences. But even in this case, of course, constant monitoring is carried out using the rules and the construction level.

Even before starting work, the master usually estimates which sections of the wall are the most collapsed and, therefore, will require thickening of the plaster layer at the stage of applying primer. They do it differently - they lay out horizontal strips of mortar (for example, three rows, closer to the floor, towards the ceiling, and one in the center), and then use a spatula to trim their surface, controlling using the rule and the building level so that they together set the required plane walls. Excessive precision is not required here, but you still get a certain semblance of solution beacons, which in this case, it would probably be more appropriate to call “landmarks.” Such landmarks can also be “scattered” along the wall in the form of slides with a leveled flat top.

To form such landmarks, you can use the same plaster mortar, but in order not to prolong the time waiting for hardening, it is recommended to add a little alabaster to this portion of the mortar (about half a plaster ladle per bucket of mortar). Such slides on the wall will be ready for further work in half an hour.

The second plastering has given the wall an even plane, but the surface is still not level enough - it may have many small flaws, roughness, stripes left by the edges of the rule or trowel. All this will be removed during the third stage, which is called differently - “washing”, “grouting”, “smoothing”, etc.

Plaster with cement-sand mixture

Plastering walls with cement mortar requires certain skills

To perform the work, you need to prepare the following tool:

- 2 m rule;

- level;

- container for mixing the solution;

- 2 buckets;

- plaster ladle;

- Master OK;

- foam grater.

What solutions can be used

Nowadays you can buy any material you like. The only question will be the quality and price of the product.

Solutions are cement-based; gypsum-based solutions are also suitable. Gypsum has its own nuances. Reviews say that it hardens quickly and does not allow defects to be corrected. This solution can be used if you have experience in plastering work. If you still decide to work with this composition, then you need to prepare the solution in small portions in order to have time to apply it to the surface.

There are universal solutions, they have a mixed base. Such mixtures are perfect for beginners in this difficult task. It is possible to purchase a dry mixture, to which you need to add water before use. You can also buy a ready-to-use solution. This option will significantly save time on finishing work, as noted by reviews.

The mixture from. has proven itself well on the market. Its main advantage is cost-effectiveness. 30 kg of this product requires 20 liters of water. The solution hardens after 20 minutes. Consumption per 10 square meters is a maximum of 9 kg, which significantly saves the buyer’s budget.

Laying the first layer

Leveling walls without beacons begins with the installation of a preparatory or rough layer, which serves to adhere the surface to subsequent layers of plaster.

Before starting, you need to wet the wall with water. Then, using a trowel (trowel) or a plaster ladle, apply even portions of the mortar onto the surface with sharp movements, starting from the floor.

Check the level of the wall. If there is a distortion in one place, a thicker layer of plaster is applied.

Using a grater, lightly level the solution, without achieving excessive evenness.

Leveling stages without resorting to the use of beacons

You should start by priming the walls. Next, you need to take the rule and walk around the corners. The indentations are revealed, the outline is outlined with a pencil. It is important to check the floor skirting boards and joints.

The next step is to prepare the solution using a drill. The layers should be thin, so you should mix a small amount of solution at a time. It is used within the first 25 minutes after mixing. Further stirring is impractical, as the solution thickens and dries out. It is not subject to further use.

How to level walls using the rule without beacons further? After application, the walls are treated with the rule, the surface becomes smooth.

You can level the walls with “Rotband” without beacons, as with a regular homemade mixture. The techniques are similar, but the drying time of the layers will be reduced. Each layer will take about an hour to dry.

Applying putty

It is best to carry out this operation in two steps: first apply the base, rough layer, and then finish with the finishing one. This will take significantly more time, but it will be easier to create a good surface. First, they put on a rough layer and it is smoothed so that it does not reach the top of the beacons by 4 - 5 millimeters. When all the space between the profiles is filled, the mixture is allowed to dry completely, after which it is primed.

The resulting surface will be very far from the desired look and there is still quite a lot of work left to do. The second layer of putty is less thick and is applied more carefully. The thickness of the applied composition should be slightly greater than the thickness of the installed beacons. When leveling according to the rule, all excess will simply be cut off. The plane should be leveled by pressing the rule tightly against the beacons, moving it from bottom to top. Excess mixture collected on the instrument. Always remove cleanly with a cloth.

When this stage is finished, you need to wait a little until everything dries, then apply a primer and the thinnest one - the finishing layer of mortar, which will completely level everything. With this approach, even a not very experienced master can achieve good results. If you plan to paint the wall, you won’t be able to do without finishing leveling, however, if you need to simply get a flat base for wallpapering, you can eliminate the finishing stage of the work - the wallpaper will hide the small remaining flaws.

Finishing layer

After grouting the primer layer, small irregularities, stripes and roughness may remain on the surface. Defects are eliminated by finishing grouting.

This stage is started when the previous layer has set, but has not completely hardened.

The semi-liquid solution is gradually applied to the entire wall in a layer of up to two millimeters, and carefully rubbed into the surface with a grater in a circular motion.

Particular attention must be paid to the uniformity of the plaster mixture, since large particles of sand or debris can leave grooves and stripes when grouting.