Insulating the external walls of a house with polystyrene foam or extruded polystyrene foam is a classic method in construction that creates additional insulation and reduces heating costs.

But, despite the advantages, not everyone is happy with external wall insulation with polystyrene foam. Which is not surprising, because progress does not stand still; new, more advanced materials are appearing.

To make a choice, let's find out how extruded polystyrene foam differs from regular polystyrene foam and which one is of better quality.

Internal and external insulation

Before you start insulating the walls, you need to decide on the insulation method. Laying insulation outside or inside is an individual preference. Each method has its own advantages and disadvantages . The features of each insulation method must be studied at the time of building design.

Insulation from the inside

Internal wall insulation is characterized by the following features:

- the cost of insulation from the inside is less than that of external insulation;

- season and weather do not affect the choice of time for work;

- there is no need to build additional scaffolding for insulation work.

Negative factors for internal insulation are:

- significant reduction in living space;

- the outer wall is insulated from heating from the room;

- the likelihood of fungus forming inside the wall increases, since the dew point is formed precisely in the inner part of the structure;

- when the heating is turned off, the walls quickly cool down due to the low inertia of the insulation;

- the junction of the ceiling with the external wall cannot be equipped with insulation, which leads to the formation of cold bridges.

The method of insulating walls from the outside is more popular despite the fact that the cost of labor and materials for performing the work is significantly higher than the method of internal insulation.

Dew point

Insulation from outside

The advantage of insulating walls from the outside is:

- in winter and in cold weather, heat is retained in the wall for a long time;

- the design area of the room is preserved;

- external thermal insulation protects internal walls from dampness.

In addition, the external walls are additionally protected from weather conditions, which significantly increases the service life of the structure.

The main disadvantages of external thermal insulation of a structure are:

- restriction of work in accordance with weather conditions;

- increase in costs for materials used.

Which side of the wall to insulate with polystyrene foam?

It is advisable to insulate walls with expanded polystyrene from the outside, since the material does not allow air to pass through, which can lead to the formation of condensation inside the wall during internal insulation, and also inside the room the material can emit a specific odor.

Factors that influence the choice of material thickness

Insulating a house with expanded polystyrene from the outside eliminates the problem of condensation droplets forming inside the house. The dew point is always outside, since the wall of the house does not freeze.

The thickness of the slabs is selected based on the climate zone and air temperature in winter. Also taken into account are the type of walls, the number, location and size of windows, and the presence of a basement.

Advantages and disadvantages of expanded polystyrene

The polystyrene foam material is a porous, air-containing raw material , used in most cases as a heat-insulating material.

In industry, the material can also be used as electrical insulating and packaging material.

The material has become widely used due to its quality indicators:

- low level of water absorption;

- low thermal conductivity;

- ease;

- biological stability;

- durability;

- compressive strength;

- not affected by temperatures;

- ease of installation;

- low price of material.

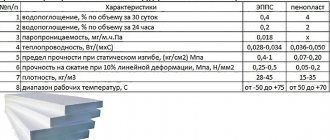

Comparison of insulation materials

Despite the impressive list of positive indicators, polystyrene foam has disadvantages that must be taken into account during installation:

- low sound insulation;

- instability to solvents and many chemicals;

- afraid of fire. When burned, it releases harmful toxic substances;

- poor resistance to ultraviolet radiation;

- easily susceptible to the influence of rodents and insects, which, by making holes in the material, provoke its destruction;

- low vapor permeability;

- fragility.

IMPORTANT!

Expanded polystyrene is sometimes compared in terms of characteristics and external indicators with another similar material - polystyrene foam.

However, the production technology of these materials is different : polystyrene foam is produced by extrusion, when the granules melt when combined into a single structure, polystyrene foam is produced by gluing granules with dry steam.

Specifications

Calculation rules

The size of the insulation layer will depend on the type of building (residential, non-residential, heated or not), type of foundation, climate zone, and thermal insulation system used. The calculation is carried out according to the method “Thermal protection of buildings” SP50.13330.2012.

There are many options for determining the thickness of foam plastic, but they are very complex. It is better to use the online calculator offered by construction sites. You can use the formula:

R= df/λ b +dу/λ p , where:

- df - foundation thickness;

- dу is the thickness of the insulation;

- λb is the thermal conductivity coefficient of the foundation material (concrete or others);

- λп — coefficient. thermal conductivity of the insulation (indicated on the packaging);

- R - heat transfer resistance (value from the table).

The values of R, λ p, λ b are taken from the tables, the value of df is known, it remains to determine dу by substituting all the numbers into the formula:

dу = (R - dф/λb) x λп

The result is rounded. You can independently calculate both the thickness and width by substituting data from the tables (the values are determined for each value).

By dividing the areas of insulation and slabs, determine how many pieces are needed. In this case, 10-15% is added for adjustment. To protect the basement from the inside, use polystyrene foam no thicker than 3 cm.

Types of expanded polystyrene

Expanded polystyrene is classified according to the method of production of the material and the inclusion of various additives in it:

- pressed polystyrene foam . Produced by pressing;

- pressless polystyrene foam . Produced by removing moisture by drying and then foaming at high temperatures;

- extruded polystyrene. Not much different from pressless; an extruder is additionally used in production. The best and optimal option for thermal insulation of walls.

There are other types of polystyrene foam (extruded, autoclaved), but they are not used as insulation materials because they have different characteristics.

In addition to types of expanded polystyrene, there are also various types of insulation, such as:

- mineral wool;

- penofol;

- penoizol;

- penoplex;

- polyurethane foam.

Styrofoam harbors mice

And one more fact that needs to be pointed out when assessing the pros and cons of foam insulation is that mice breed in the material.

Expanded polystyrene is an ideal habitat for them, because it is warm and soft. Therefore, when insulating with polystyrene foam, block the access of mice. To do this, you can finish the places where rodents can enter with mineral wool, which mice do not like.

Therefore, although polystyrene foam has a number of positive qualities, we should not forget about its disadvantages. Therefore, it should be used thoughtfully and in accordance with all the technological features of the material.

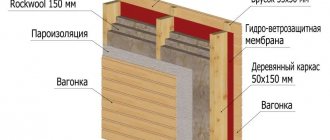

Wall pie when using insulation - polystyrene foam on the outside

A wall pie refers to layers of materials that are laid in a certain order, each of which performs its own functions to ensure a normal microclimate in the room.

When thermally insulating brick walls with polystyrene laid outside, the wall pie looks like this:

- interior plaster;

- outer wall;

- adhesive solution for gluing polystyrene foam;

- insulation (expanded polystyrene);

- adhesive solution for gluing the next layer;

- fiberglass mesh;

- adhesive composition;

- primer;

- finishing plaster.

NOTE!

When arranging a wall using polystyrene foam, it is necessary to lay the layers in strict sequence.

Internal and finishing plaster can be replaced with other finishing materials that are provided for in design solutions.

Wall cake "wet"

Installation of mesh on insulation

After 24 hours, take a sanding brush and level the surface of the foam. Even if after this the grater loses its functionality, you don’t have to throw it away: it is suitable for leveling the primer for plaster. Then a leveling mixture is prepared, onto which the mesh is glued. This is done from top to bottom, starting from the corners, using a serrated spatula.

Further actions:

- The mesh is stretched and rolled until it fits well on the material.

- If winters are harsh in a particular region, the walls need to be additionally insulated. To do this, take a special plastic corner with perforation or mount the mesh on the mortar. The work is carried out one day after installation.

- Fill the products with the mixture and rub it again a day later.

- To prevent the joint from sticking out, the edges are left free. They should overlap each other by two thirds, leaving one third free.

- After the mixture has hardened, the edges of the product are folded back, lubricated with the solution and placed on top of each other again, carefully punching it to the surface.

Issues of vapor barrier and waterproofing

An important requirement during the construction and improvement of a house is the correct implementation of all work to ensure ventilation and waterproofing, since it is the incorrect installation of these components that significantly reduces the performance of the structure.

When insulating walls with polystyrene, waterproofing is not needed . It should be taken into account that if there is a high passage of groundwater under the building, it is necessary to waterproof the basement and foundation.

Since polystyrene foam does not allow air and water to pass through, there is no need to lay a vapor barrier layer when insulating walls from the outside.

Wall insulation cake under siding

Useful advice from professionals

For high-quality insulation, it is recommended to listen to the advice of builders. The main ones:

- Insulation from the inside is carried out along the entire perimeter of the housing, and not just those walls that border the street.

- To prevent the formation of condensation and further problems with the insulation, care should be taken to ensure reliable ventilation. Air ducts are installed in the walls during the construction of a building or in the ceiling structure.

- To secure polystyrene foam boards, it is recommended to use mushroom dowels with plastic rods.

- According to reviews from builders, double-layer insulation with thin slabs of polyurethane foam on the outside is preferable to single thick insulation.

Simple tips will help you avoid making mistakes when insulating your home.

It is up to the owner to decide which polystyrene foam is best for insulating a house made of timber or brick. Each type has a number of advantages, for which professionals value it. The material is durable, lightweight, provides high-quality insulation and is affordable. With proper installation, the results will last for decades.

Sealing cracks and preparing sheathing

Installing polystyrene foam on the sheathing is the most labor-intensive process among the insulation options. Most often, sheathing is done in the case of finishing siding.

Sealing cracks

If you plan to install siding on the wall of a house made of beams, you must first seal the seams properly, clean the surface of dust and debris, and seal the cracks with sealants, polyurethane foam, or a mixture of sawdust and PVA.

If the wall is concrete, brick or foam blocks, then the cracks in such houses are cleaned of sand, treated with a primer, then sealed as follows :

- if there is a small gap . Using a prepared mixture of cement and sand with the addition of PVA, seal the gap with a spatula;

- if the gap is medium in size . Make holes for dowels at a distance of 20 cm. Using screws and washers, pull the metal mesh over the gap and seal it, pressing it into the mesh with plaster. Next apply the finishing layer;

- for a large crack . Seal the gap with polyurethane foam, cut off any irregularities and seal it with two layers of plaster.

Large cracks can be repaired using anchors:

- knock down the plaster, seal the cracks with polyurethane foam;

- install a channel in the opening and attach a reinforcing mesh to it;

- you can use staples made of reinforcing mesh;

- apply plaster;

- putty.

Sealing cracks

When the wall is prepared for laying insulation, you can install the sheathing.

Preparing the sheathing

The sheathing for siding can be made from metal profiles and wooden beams . In humid climates, it is advisable to install metal slats.

Before you begin installing the sheathing, you should determine the location of the siding:

- with horizontal siding . The beam or metal profile is installed perpendicularly;

- with vertical siding . Frame boards or metal profiles are installed in a horizontal position.

The pitch of the sheathing is determined by the width of the polystyrene foam sheet: in width it should fit tightly between the sheathing slats and not form gaps.

The order of work is determined in steps:

- treat the wall with special mastic;

- frame boards are secured around the entire perimeter of the walls using galvanized screws and plastic dowels;

- if holes form between the timber and the wall, these gaps are sealed with pieces of polystyrene foam by gluing them to the wall.

When the sheathing is installed, then proceed to the installation of polystyrene foam panels.

CAREFULLY!

If the sheathing is made of wood, the boards must be pre-treated with antiseptic agents.

Lathing does not require special skills, but it should be noted that the choice of materials should be made based on climate conditions.

Lathing for siding

Wooden sheathing

Myth - Insulating a façade is expensive

If you decide that it is absolutely necessary to insulate the facade and there is no return to your decision, the time will come to purchase materials. In order to cover the entire house, you will need relatively large amounts of money.

To reduce heating costs, many owners of houses and apartments are thinking about insulation. One of the possible options is insulating the facade with polystyrene foam (PPS or EPS). The work is not the easiest, but you can do it with your own hands. It is important to know the technology. We will talk about it in detail further.

Proper insulation of the facade with polystyrene foam will give good results

Technology of wall insulation with polystyrene from the outside

Before you begin insulating the wall with polystyrene foam, you should dismantle the gutters, decorative elements, clean and prime the wall. Next, insulate the sills and window slopes.

Now let's talk about the thickness of polystyrene foam.

NOTE!

When insulating walls with extruded polystyrene, sheets are used whose thickness ranges from 80 to 100 mm or more.

You can also use thinner sheets 30-40 mm thick if they are laid in two layers.

Let's start installing insulation on the walls with our own hands:

- a profile is installed at the bottom of the wall to hold polystyrene foam;

- the adhesive mixture is applied to the wall over the entire area in spots and onto the insulation sheet (amply on the center and edges of the sheet);

- tightly attach the sheet for gluing to the wall;

- Use dowels to secure the panel so that the dowel penetrates the wall at least 50 mm. The dowels are placed in the center of the panel and at the joints. It is recommended to use plastic nails;

- if gaps form (up to 2 cm), then they are sealed with polyurethane foam , if the gaps are larger, then they are first sealed with pieces of insulation, and then foamed. Excess foam is cut off;

- The heads of plastic nails are cleaned and puttied.

After installing the insulation, a reinforcing mesh is applied to the façade . You should cut strips of mesh at the corners and slopes and glue them with a spatula using an adhesive composition. An adhesive composition is applied to the mesh along the wall so that it penetrates 0.1 cm through the mesh onto the polystyrene foam. If an overlap occurs, separate strips of mesh are placed on it and additionally glued.

Sectional view of the device

Fastening slabs with dowels

Application of assembly adhesive

After the surface has completely dried, it is leveled with fine granulation sandpaper.

Next, the surface of the walls is covered with putty and a finishing decorative coating . External insulation with polystyrene foam, when installed correctly, will provide comfort and warmth in the house.

Surface priming

The choice of primer depends on the scope of the intended work. The best choice would be products with deep penetration. When planning to prime, you need to run your hand along the wall with slight resistance. If it is dusty after this, the wall must be thoroughly washed and dried. You can reapply the primer after a day. A white coating indicates the presence of mineral deposits that occur during weathering of the top layer.

If there is a white coating, the surfaces are treated with a stiff wire brush. Now you can apply the primer. Concrete and brick walls with deep erosion leave a gray, brown or red coating on the hand. Such walls are treated with a metal cord brush until the wall has a smooth surface and integrity. To remove the damaged top layer, you can use a hammer drill with a chisel, after which the wall is rubbed with cement putty on concrete until completely level.

Common mistakes

When installing extruded polystyrene foam with their own hands, builders often make the same mistakes. The most common of them is an incompletely leveled wall surface. For this reason, the slab may lie unevenly.

Applying glue in the central part of the slab is also a common mistake. This causes the corners to bend outward over time.

The absence of reinforcing mesh when applying plaster is also unacceptable. Because of this, the surface becomes covered with cracks.

Insufficient insulation of the seams located between the plates contributes to the formation of the notorious cold bridges. There is an opinion that the thermal insulation of houses made of aerated concrete leads to a violation of the vapor barrier of the premises and the formation of mold. This is quite possible if the installation of insulation was carried out without observing important conventions.

As you can see, all work takes place without any problems. They are easy and easy to understand, even for beginners in the field of construction. When using extruded polystyrene foam, reinforcement of the structure on an additional basis is not required.

The insulation holds well thanks to the adhesive solution, finishing materials and sheathing. As for ventilation, a slight air gap is formed in the area between the insulation and the wall. The insulation can be finished on top with sheets of plasterboard. They are later painted and covered with panels.

Working with the foundation

Expanded polystyrene is successfully used in private housing construction. It is used to sheathe walls and attic floors. The base plays a dominant role in the home. That is why it is necessary to primarily consider insulating the foundation with extruded polystyrene foam.

This zone accounts for 15% of the heat loss of the structure as a whole. A very impressive parameter to urgently take measures to prevent the problem.

The use of the material has its own conditions. When working with the vertical area of the structure, the slabs are laid to the freezing depth of the soil, but no more. In the corner part of the foundation, the thermal insulation has a thickness of 1.5 r. more. External or internal insulation of a frame house with polystyrene foam is the most effective and justified option. Insulation from the inside also requires its own nuances.

In case 2, the width of the thermal insulation material around the perimeter must be no less than the soil freezing level, at the same time, the horizontal type layer must be thicker than the vertical thermal insulation. Such insulation of your own frame house from the outside with polystyrene foam helps to move the cold in the gravel bed.

Expanded polystyrene should be located with a slope of the blind area of 2% or more relative to the building. In one case, thermal insulation is glued to the surface of the walls using a special composition. No solvents are required. Another method is to mechanically fix the polystyrene foam. To do this, you will have to start arranging the finishing layer.

How the insulation is fixed:

- Begin gluing the slabs along the line from bottom to top, adhering to the horizontal orientation of the rows;

- The material is fixed to the surface of the walls, which is covered with waterproofing, using glue;

- Mechanical fastening when insulating the base of a house from the outside is unacceptable. The following rows are equal to the previous ones. The heat insulation slabs must have the same dimensions;

- The adhesive used for work should not contain any solvent. This composition itself is applied only to bitumen that has a dry surface. For maximum reliability of fixation, dowels are used with the exception of the recessed part of the building.