What is Penoplex

The modern building materials market offers a fairly wide range of insulation materials, where the so-called polystyrene foam group stands out. Their prominent representatives are standard polystyrene foam and the equally well-known extruded polystyrene foam, which is produced in slabs of different sizes. It is the latter that has gained particular popularity among builders for its high thermal qualities and other technical characteristics.

Everyone has heard the term “Penoplex”. Anyone who has already encountered thermal insulation measures knows that this is a type of extruded polystyrene foam. It's not a separate group, it's just a brand name. But it just so happened initially that consumers began to call almost all extruded polystyrene foam boards by this name. That is, it gradually became a household name. Although it should be noted that not all polystyrene panels are of the Penoplex brand.

Trademark "Penoplex" Source tr.skopelitissa.com

Let's start with the fact that the Russian company, under the same name "Penoplex", began producing products under this brand in 1998, taking as a basis the experience of foreign partners, but adding its own ideas and developments. The quality of the insulation was immediately highly appreciated by specialists and consumers, so production eventually ceased to meet the need. Today the company has eight factories that produce only thermal insulation boards.

The production process itself includes several stages:

- melting polystyrene

under the influence of high temperatures;

- addition

it contains special

reagents

, which form a gas inside the mass, distributed evenly throughout the entire volume; - gas rich mixture fed into extruder

, hence the name - extruded, in which a formed mass of frozen material in the form of a tape passes through the nozzles (slits);

- last cut into panels

required size.

The width of the slots determines the thickness of the material. Therefore, this parameter is set in advance, adjusted to the standards.

Production of foam insulation under the Penoplex brand Source pt.decorexpro.com

The most important thing is that the foamed mass consists of pores with a diameter of 0.1-0.3 mm, which are completely hermetically sealed from neighboring ones. It is this state of the material that maintains the high strength of products and high thermal characteristics.

Today, the manufacturer offers penoplex slabs of different densities and thicknesses, which are used for thermal insulation of various building structures and communication networks. And since the topic of our article concerns finishing a house with penoplex, we will consider those positions that are used specifically for insulating the facades of buildings and structures.

Today the company produces two types of insulation, which are used for thermal insulation of walls. These are “Penoplex-Comfort” and “Penoplex-Facade”. In appearance, both types are no different. It’s just that the façade variety has higher compressive strength and a higher fire resistance class due to the addition of fire-retardant components during the production process. Let’s compare: the compressive strength of Penoplex-Comfort is 0.18, and that of Penoplex-Facade is 0.2 MPa. Accordingly, the fire resistance class is G4 and G3.

Penoplex is a flammable material Source otoplenie-gid.ru

On our website you can get acquainted with the most popular projects of houses with and without finishing – from construction companies presented at the exhibition of houses “Low-Rise Country”.

And other technical characteristics that are the same for both types:

- density

: 25-35 kg/m³;

- limit strength

bending: 0.25 MPa;

- water absorption

: 0,4-0,5%;

- thermal conductivity

: 0.03 W/m K;

- soundproofing

: 41 dB;

- temperature

operation from -100C to +75C;

- standard sizes

: width 60 cm, length 120 cm, thickness varies from 20 to 60 mm in increments of 10 mm, then 80, 100, 120 and 150 mm.

It should be noted that penoplex boards are actually an ideal material, because they have fairly high compressive and bending strength, they have practically zero ability to absorb moisture, plus excellent thermal conductivity, which can be considered the most optimal. At the same time, the material does not react to the main types of solvents used in construction. But there are a number of materials in contact with which it decomposes. This:

- diesel fuel, gasoline, kerosene, etc. liquid fuel

;

- acetone and others solvents

ketone group;

- formaldehyde

, formaldehyde;

- complex ethers

(Not all);

- paints

oil based;

- tar

.

And, of course, a fairly long service life - at least 50 years. But taking into account the fact that the original insulation was purchased. Because many products have appeared on the market today that imitate penoplex, but do not meet its characteristics.

Penoplex-Comfort panels Source helpstroy.ru

Application in apartment buildings

Insulation of external walls from the inside with penoplex is usually required for residents of the upper floors of high-rise buildings. Basically, previously, there were rather lenient requirements for thermal protection of many storey buildings. This approach led to the formation of a huge number of residential buildings that did not meet the proper requirements for living in the winter. Therefore, today they require serious expenses for heating an apartment.

Installation of insulation indoors

Among such multi-storey buildings, it is worth highlighting panel buildings, where the thickness of the concrete wall is 30-50 cm. Such indicators of wall thickness are not acceptable in the Russian Federation. They are greatly underestimated and do not comply with building codes.

To comply with modern heating engineering requirements, it is recommended to build external walls of concrete with a minimum thickness of 4 m. Therefore, in the current situation, there is only one solution - insulation from the inside, since the administration will not give permission to make changes to the facade of the building in a small area of the building. Such changes to the design will spoil the appearance of the high-rise building. In addition, insulation of the walls of the upper floors cannot be done independently. Such construction work will require resorting to the expensive services of industrial climbers.

The principle of thermal insulation with penoplex

Sheathing a house with penoplex requires a special approach, taking into account the thickness of the slabs used. Therefore, first of all, it is necessary to understand the thickness of the thermal insulation layer.

Required thickness of Penoplex

So, it has already been indicated above what thickness this material is produced. This is a fairly wide range of sizes, which is not produced in vain. In order to determine this parameter specifically for your home, it is necessary to carry out a thermal engineering calculation. It is based on the requirements of SNiPs, which indicate that all layers separating the interior from the street must create a heat-protective barrier that would not let the outside temperature into the rooms. And this parameter should not be lower than that specified in SNiP.

The thickness of the insulation is selected based on the average winter temperature Source dovidkam.com

That is, each layer, and this is not only insulation, but also the wall itself, decoration, etc., are barriers that have some kind of protective properties. Some to a greater extent, some to a lesser extent, but each layer performs such a protective function. True, not everything is so simple here, so this calculation is carried out by specialists. In this case, there is no need to engage in amateur activities. The only thing we note is that the thickness of the insulation mainly depends on the region where the house is being built. The colder it is in the construction area, the thicker the thermal insulation layer should be.

On our website you can find contacts of construction companies that offer ]insulation and exterior finishing of private houses[/anchor]. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Facade insulation technologies

Today, there are two technological schemes for insulating facades: wet and ventilated. Let's look at each separately, but let's immediately note that the method of laying penoplex on the walls is identical. The technological schemes for installing the remaining building materials are simply different.

Tools used for work

The technology of insulating walls with penoplex from the outside does not present any difficulty, so it is quite possible to carry out all the work yourself, saving on turning to professional builders.

To complete this work you will need the following:

- High-quality penoplex.

- Foam glue or SSS glue (dry construction mixture).

- 6 dowels for each slab.

- Toothed and needle spatulas.

- Sandpaper or needle roller.

- Hammer.

- Fine-tooth hacksaw and steel knife.

- Drill or screwdriver.

- Starting bar.

- Reinforcing mesh.

- Primer.

- Finishing material.

Video description

And in the video we suggest looking at information about the thermal insulation material “Penoplex”, its advantages and disadvantages:

Wet technology

In fact, it turns out that the inside of the house wall is finished with plaster or putty mortar. From the outside it is treated with a primer if the wall structure is a reinforced concrete wall. If it is brick, then a certain layer of plaster is applied to it to level the surface as much as possible.

It is better to plaster brick walls Source hu.aviarydecor.com

It should be noted that polystyrene foam boards can only be laid on a flat surface with high strength. This is how you can guarantee their long service life. Therefore, the surface of the facade must be leveled and all defects repaired. And even if it has already been used, for example, it was plastered and painted, then it is better to get rid of the paint and check the plaster and, if necessary, level it.

After the applied plaster layer has dried, it is primed in order to strengthen the outer thin layer. This is done specifically so that the plaster does not crumble under the influence of loads from other applied materials.

The next layer is the adhesive composition on which Penoplex slabs are laid. A very important point. The adhesive composition can only be applied to a dry surface. Therefore, you will have to wait until the plaster dries. And this may take more than a dozen days. In this case, there is no need to rush.

Primer of a plastered facade Source gidpokraske.ru

This might be interesting!

In the article at the following link, read about the features of penoplex.

While the plaster is drying, you can install the embedded parts, with the help of which various devices will be attached. For example, a drainage system, antennas, lamps, window grilles and other accessories for the exterior of the house. It is recommended to treat those parts of the fasteners that will be inside the heat-insulating layer with protective compounds, for example, paint (not oil-based).

So, the wall is ready for insulation. A horizontal line is drawn on it at the very bottom, as the starting point in the installation of penoplex. The so-called starting profile made of galvanized steel is attached exactly along the line to the wall with self-tapping screws. Its purpose:

- become basis

for insulation boards, that is, the first row of thermal insulation will rest on it;

- He levels out

horizontal panels;

- protects

thermal insulation material

from moisture

, insects and rodents from the bottom end, which will not be protected by plaster.

Note that the level at which the installation of the bottom row begins is set 20-30 cm below the level of laying the floor inside the house. In this way, 100% thermal protection of rooms is achieved. And one moment. The width of the profile flange should be equal to the thickness of the foam boards used: no more, no less.

Installation of a starting profile for penoplex Source strhouse.ru

Everything is ready, you can proceed to the installation of Penoplex. To do this, an adhesive composition is applied to the wall, onto which the first row of insulation is laid exactly according to the starting profile. Please note that the plates themselves have connecting grooves in their design. That is, a seamless thermal insulation coating is formed on the surface of the wall.

The second row of penoplex is mounted offset by half the panel. This is done so that the seams between the joined elements do not coincide vertically. In this way, maximum strength of the laid material is achieved. The third row is mounted in exactly the same way, only relative to the second. And in this way the entire height of the walls.

You can start installing panels from the corner of the house. But in areas where door and window openings are located, installation begins from them, filling along the perimeter. To do this, you will have to cut some of the slabs to fit the shape and size of the openings. This is easy to do with a regular saw or hacksaw.

Recommendations for insulating walls made of various materials

Rules for insulating concrete walls:

- before proceeding with the installation of thermal insulation, you need to treat the surface with antiseptic compounds;

- You cannot lay insulation in a specific area, this must be done over the entire area of the building;

- concrete is not resistant to moisture, so the installation of a waterproofing membrane is necessary.

Rules for insulating a wooden house:

It is important to know!

The most important rule for thermal insulation of a building made of any material is compliance with the stages and installation technology. The work is quite difficult, so it is better to entrust this task to professionals.

As it became clear, there are many types of insulation for facades. Penoplex is considered one of the most modern and effective. It has impressive performance characteristics and a long service life. However, it is important to consider that this can only be achieved if the installation work is carried out in accordance with all rules, regulations and requirements.

Video description

The video shows how Penoplex panels can be cut:

This might be interesting!

In the article at the following link, read about roof insulation with penoplex.

Scraps can also be used, but it is better if the insulation is carried out in large slabs. Scraps are often placed in the corners of a building, because the length of the building cannot always be covered with solid insulation panels. But there is one caveat - you cannot install pieces less than 20 cm wide in the corners of the walls.

Installation of insulation with glue Source meiers.info

It is clear that trimming will lead to the removal of connecting ends on pieces. That is, adjacent slabs will be joined with a small gap, no matter how hard the craftsmen try to cut exactly along the drawn line. And gaps and cracks are cold bridges. This problem is being solved today with the help of a special foam type sealant. This material is very similar to polyurethane foam. But it is white and does not expand in air.

I would like to add that the adhesive composition is not the only option for attaching foam boards to the wall. Usually craftsmen add one more fastener, which ensures maximum strength of the connection between the insulation and the wall. This is a plastic dowel-nail with a wide mushroom-shaped cap. It is driven into prepared holes, which are drilled between the laid slabs of heat-insulating material or directly into the slabs themselves. The only thing you need to pay attention to is the length of the fastener. It should be 45-50 mm greater than the thickness of the foam boards used.

Fastening panels of thermal insulation material with dowels and nails Source vse-postroim-sami.ru

So, the wall is finished with panels, all that remains is to plaster the facade. The plaster mortar itself will not adhere to the flat surface of the insulation. Therefore, a plaster synthetic mesh is first laid on it and secured with screws or staples from a stapler. And a layer of plaster is already applied to it.

Insulation from the inside: advantages and disadvantages

Unfortunately, insulating walls from inside the house has more disadvantages than advantages. And they, admittedly, are quite significant. One of the main disadvantages is ignoring the requirements of heating engineering. And it says that any heat insulator must be attached on the cold air side. And if you act differently, then the dew point (the place where condensation accumulates) moves into the thickness of the walls and creates the preconditions for the rapid destruction of the structure. In addition, the disadvantages include the following:

- Relatively complex and expensive construction work;

- Significant reduction in usable area of rooms.

Shift of the dew point deeper into the wall

If there is no other solution to the problem and the only solution is to insulate the walls from the inside with penoplex, then you need to be prepared for the negative consequences listed above. But there are cases when it is not possible to use other options. Such situations include the following.

Video description

The video shows the technology of insulating the facade of a house with Penoplex panels:

This might be interesting!

In the article at the following link, read about the technology of foundation insulation with penoplex.

Let us add that wet technologies include any finishing operations that use adhesives. For example, cladding with bricks or slabs, installation of decorative panels of various types, and so on.

Penoplex for brick cladding Source hi.decorexpro.com

Ventilated technology

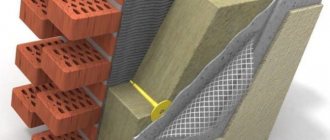

This method of facade insulation differs from the previous one in that a so-called ventilated facade is mounted on the wall itself. Essentially, it is a frame structure on which slab or panel finishing material is installed. And between the finishing and the wall, penoplex is laid in the same way as in the plastering technology.

Ventilated facade with foam boards. Source 2gis.ru

Here is the sequence of construction operations:

- Preparation

walls: repair and primer;

- application

vertical lines for direct hangers;

- installation

metal profiles made of galvanized steel or wooden blocks, with the help of which the frame is assembled on the wall;

- the distance between the frame and the wall should be 5 cm more

the thickness of the insulation used, this gap will serve as façade ventilation, hence the name of this structure;

- carry out installation of slabs

penoplex, for this purpose, slots are made in them, into which the antennae of direct suspensions are inserted, then these slots are filled with foam sealant;

- technology

installation of panels is exactly the same as in the previous case;

- the frame is assembled

with mounting on hangers, profiles or bars are installed vertically in one plane and connected to each other by crossbars, that is, a lattice structure is formed on the wall;

- mounted on the frame façade cladding

.

How to insulate a facade, popular technologies

To insulate a house, you can use the “wet facade” technology. It bears this name because during the work process liquid construction compounds are used that require drying.

How insulation is performed:

- Cleaning and surface preparation.

- Applying an adhesive layer (maximum 3 cm).

- Installation of thermal insulation.

- Applying a second adhesive layer.

- Installation of reinforcing mesh.

- Applying plaster.

- Padding.

- Painting.

Another popular technology is the ventilated facade. Its peculiarity is that work is carried out much faster than with previous technology. This is due to the fact that installation does not involve the use of so-called “wet” compounds, between the application of which a certain time must pass. When choosing a ventilated facade, you can begin subsequent installation stages immediately after completing the previous one.

For fastening, not glue is used, but disc-shaped dowels and anchors. This technology is durable and has good resistance to external influences. You can choose any materials for exterior finishing.