Ventilated facades make it possible not only to reconstruct a dilapidated building or to resolve issues with facades in new residential construction of high-rise buildings in Moscow and other megacities of Russia and the CIS countries, but also eliminate errors in the geometry of the building. The fastening system protects structures from the influence of the external environment. Our company has prepared the top 10 options for the most popular cladding, based on the practice of using suspended facade systems for more than 10 years in the installation, design and manufacture of these subsystems.

Façade system fastening units

Just as it is not easy for any new customer in construction to understand the abundance of systems used from different metal compositions and the type of fastening of various substructure frames: now there are more than 50 manufacturing plants on the market with official structures confirmed by testing and technical documentation.

However, not every manufacturer tries to think about the costs of the customer directly and solve the assigned tasks on time to quickly complete the project, all the more so it is necessary to have time to design everything, conduct a consultation and provide technical support to the client, and, if necessary, even make samples and stands.

A standard set of façade system components is a solution for the designer before designing the entire building as a whole and roof superstructures (which also need to be designed).

The situation with problem nodes is a standard task for an experienced engineer, which is solved together with the designer who directly developed the ATP album or together with the design team in the department of the Optima Facade company.

The problem is that for each building, the architect-designer is not guided by the available documentation (technical certificate) and fire expert documentation to develop the design and concept of the building; projects and AGR for facades with color layout of cladding are received without agreeing on the type of system and without any reference to the documentation of the Ministry of Construction or FAU-FCS, which then raises a number of questions from the customer from the series: how to implement this ventilated facade using technology?

Answers to these questions and approval (on the shore) of such a building will save any builder from unnecessary expenses or fire tests of the facade section on stands, and will complete the work on time without extra costs.

Air gap system design

A ventilated façade is a relatively new technology that is becoming increasingly widespread. The need to use this technology is due to a number of problems that owners of private and apartment buildings often face. Very often, moisture forms in load-bearing walls as a result of life activity inside residential premises. Cooking and cleaning cause moisture to accumulate inside the walls. Evaporation occurs under the influence of temperature differences. Such conditions lead to an increase in vapor concentration inside the walls. When steam turns into water, it begins to negatively affect the finishing material, which can be destroyed under the influence of moisture and dampness. The principle of a suspended ventilated façade is simple: its essence comes down to removing excess moisture. Thanks to the special air gap, air can easily circulate inside the walls. Continuous natural ventilation eliminates the possibility of problems.

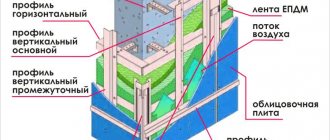

Schematically, the ventilation façade consists of the following key components:

- load-bearing base;

- substructure;

- sound insulation layer;

- thermal insulation layer;

- vapor-permeable membrane;

- ventilated gap;

- decorative finishing.

Each component is designed to perform its specific function.

Ventilated facade - 10 cladding options

To try and tell you about all the variations of cladding, not even a week is enough to complete the task: however, we will try to display in this article as briefly as possible about the most used cladding options and reveal 10 options for ventilated facades and convey the main essence of the advantages and disadvantages of each.

We will cover the most commonly used and affordable panels or slabs, sheet materials and the creation of galvanized metal cassettes from them, aluminum processing and much more in this article.

Frameless ventilation facade

Just as not every curtained façade is ventilated, not every ventilated façade is curtained; there is also a frameless variety. We are talking about a brick ventilated facade - a house made of any wall material is insulated with non-combustible thermal insulation and covered with facing brick through the ventilation gap, fixed with flexible connections or metal brackets. A brick ventilated facade is erected in two ways:

- at the stage of building the box - when pouring, the foundation is made taking into account the thickness of the multi-layer wall;

- around the house in use - if it is not possible to support a brick screen on the foundation, an additional cast is cast for it, less often it is supported on metal subsystems.

There are several variations of wall pie.

Negativ FORUMHOUSE Member

Approaching the process thoroughly, I would recommend considering several options for solving the facade for the case of an external cladding layer:

- ceramic block 440-500 mm, air gap 30-40 mm, facing brick 85-120 mm;

- solid brick 380 mm, insulation (mineral wool or foam glass), air gap 30-40 mm, ceramic brick 85-120 mm;

- GSB (gas silicate block) 375-400 mm, air gap 30-40 mm, face brick 85-120 mm.

The choice of a specific solution is determined by the complexity of the facade and the requirements for materials (ceramics, GSB, relation to insulation, etc.).

Porcelain stoneware slabs

Porcelain stoneware - (ceramic granite slabs, porcelain stoneware panels, products with a thickness of 4 to 16 mm) occupy the first line of our hit parade of facing materials and for good reason: a façade fastening system in Russia and the very first building in Moscow, according to confirmed information from the Russian Ministry of Construction The federation is determined specifically with the cladding based on this cladding panel.

By confirmed information, we mean the presence of a positive expert opinion on this type of facing materials on a stainless steel facade system (substructures made of corrosion-resistant steel of the Diat system)

* The fastening system involves installation on clamps or hidden fastening on a clamp with a cut of tiles of at least 10-14 mm in thickness.

Facade systems made of porcelain stoneware. The main pros and cons of assembling this cladding can only be determined by a detailed examination in the overall concept of facade design, usually by the following parameters according to the type of fastening of the porcelain tile ventilated facade :

- open mount

- imitation of hidden fastening*

- hidden mount

The type of fastening is determined based on the wishes of the designer of the existing building and the development of the facade in terms of the AGR (architectural urban planning solution) immediately before submitting the finished albums for approval to the architecture department with the project design at the approval stage. We will not describe the subtleties and complexities of this process, only the main aspects and legal points in this matter, which are:

- Development of a color solution for the facade

- Going through the building approval procedure at BTI

- Coordination of color scheme in “Moscomarchitecture”

Basic installation methods

All methods of fastening the finish to the base of the subsystem are divided into two categories - open and closed.

The first method assumes that some parts of the fasteners protrude outward:

- A clamp is a metal plate, most often made of galvanized or stainless steel. This method can be used for heavy finishing materials such as fiber cement or porcelain tiles. Clamps with spacers are the most successful and reliable modification of the product. If the clamps are made of galvanized steel, it is necessary to provide additional protection in the form of complete painting of the fastener.

- Rivets are the most economically advantageous option and are extremely easy to work with. They are used more often when constructing a fiber cement board and a metal cassette.

The following are used as closed fasteners:

- Hidden clamp method, in which clamps fix the finishing material not from the outside, but in the end cuts;

- Holder strips are horizontal guides; slabs of finishing material are applied to them;

- Keil type anchors - in slabs (cassettes or panels) special drills are made in the corners into which expansion anchors are inserted. They are attached to agraphs, which are mounted on horizontal guides. These types of fasteners are very expensive.

- Slides are the components on which the hooks mounted on composite cassettes are attached.

Features of porcelain stoneware cladding

The features of porcelain stoneware are very important, because to determine the design from such a wonderful (albeit artificial and not natural) facing material, which is the device from its subsystem in our time. Its features are the maximum dimensions of the cladding up to 1200 mm * 600 mm, which is determined on the basis of the fire safety requirements of the Central Research Institute of Fire Resistance and the regulations on the non-combustibility of this material.

Porcelain tile panels (not to be confused with porcelain tile slabs) are undoubtedly a newer type of fastening of cladding material, which is more designer in its concept when installed on material subsystems, allowing the use of formats with thin-walled cladding on a frame with a length and width from 3500 mm* to 1500 mm.

Conclusions: A tile or panel made of porcelain stoneware is a modern and most importantly affordable material (compared to natural stone), has a more pronounced texture and low weight per m2, is an absolutely non-flammable material (flammability level NG) for buildings with structural hazards with maximum requirements (school , kindergarten, hospital) where the maximum guarantee of resistance to evacuation in case of fire is required.

The cost of a ventilated façade made of porcelain stoneware

| 1. | CERAMIC GRANITE TILES. Packing list for the horizontal-vertical system “Optima-Keramogranite” | Information: Project type 1 | |||||||||||

| Design data “Porcelain stoneware” (reserve, consumption) | |||||||||||||

| Square: | 1 m2 | S.K. 1.1 | 1,1 | sq.m. | |||||||||

| Building type: Residential building at the address: Moscow, st. Moscow (approx.) | System type: open mount | ||||||||||||

| № | Name | Unit change | Consumption rate | Qty | price per one. | Cost with poly. coated | |||||||

| p.p. | |||||||||||||

| 1 | Profile L-shape 40*40*1.2 | linear m | 1,52 | 1,67 | 45,40 ₽ | 75,91 ₽ | |||||||

| 2 | T-profile 60*30*1.2 | linear m | 1,44 | 1,58 | 99,00 ₽ | 140,98 ₽ | |||||||

| 3 | Z-shaped profile 40*20x20 1.2 | linear m | 0,18 | 0,20 | 45,40 ₽ | 8,99 ₽ | |||||||

| 4 | L-shaped bracket 70*L200 | PC | 2,22 | 2,44 | 29,00 ₽ | 70,82 ₽ | |||||||

| 5 | Anchor mountains galvanized 10*100 Rawlplug | PC | 2,22 | 2,44 | 16,00 ₽ | 39,07 ₽ | |||||||

| 6 | Paronite gasket | PC | 2,22 | 2,44 | 4,20 ₽ | 10,26 ₽ | |||||||

| 7 | Rivet 4.0x10 | PC | 10,0 | 11,0 | 2,20 ₽ | 24,20 ₽ | Visualization of tile fasteners: | ||||||

| 9 | Clamp 4-arm RAL stainless steel | PC | 2,78 | 3,06 | 12,00 ₽ | 36,70 ₽ | |||||||

| 10 | Clamp 2-arm RAL stainless steel | PC | 0,60 | 0,66 | 9,00 ₽ | 5,94 ₽ | |||||||

| 11 | Rivet 4.0*8 stainless | PC | 6,7 | 7,37 | 1,90 ₽ | 14,00 ₽ | |||||||

| Total m2: | Galvanized: | RUB 456.86 | Painted: + 14%: | RUB 545.79 | |||||||||

Variations of subsystems: As a fastening system, both the classic scheme of assembling the structure on visible stainless steel clamps, and the installation of porcelain stoneware using the adhesive chemical composition of the following assembly variations are suitable:

By frame type:

- Vertical design

- Horizontal-vertical system

- System in floor slabs (interfloor)

By metal type:

- Aluminum (type 1)

- Stainless (type 2)

- Galvanized with protective coating (type 3)

It is worth noting the choice of the convenience of the system before direct assembly on the facade and the speed of construction and installation work, because the whole process of recreating a new facade depends on this. Here it is worth highlighting the aluminum version of the fastening subsystem; it is quickly designed and inexpensive.

If we are talking about a highly aggressive environment, a maritime climate or a facility in transport tunnel systems, where safety is important and quality comes first, it is better to use a stainless steel type of construction at the expense of assembly speed (corrosion-resistant steel is more difficult to install, it takes longer to assemble components and carry out leveling work on the facade .

This is evidenced by the price cut and feedback from our marketing department for three years; we also turned to other specialists for advice, for example, blogger Pakhomov (NFS research at sites)

According to statistics, 45% of all ventilated facades are made on galvanized systems with a polymer (powder) coating, and the remaining 55% of structures are divided between aluminum and stainless steel structures in the following ratio:

System statistics: 30% aluminum systems, 10% stainless steel and 15% combined (galvanized and stainless steel systems), that is, the brackets are made of stainless steel, the panel clamps are also made of corrosion-resistant steel, the profile is galvanized and painted.

Fiber cement boards

If we are talking about quickly closing construction volumes and cutting cladding panels during the installation process, such an excellent type of cladding panels as fiber cement will help. The fact is that fiber cement boards have the property of durability and are quite conveniently mounted on a rivet with a wide side, both on vertical guides and on an interfloor or cross frame.

In fastening systems, a wider guide of at least 80 mm or more is used for ease of assembly and joining of plates, which makes it possible to comply with the installation flow chart and factory requirements, to comply with the correct assembly of the NFS and the manufacturer's warranty requirements. The structure can be mounted using simpler 40-50 mm guides, but in this case it will be necessary to carry out two-level punching of the guides at the junction of the slab, or violate the installation and the edge distance of the slab from the guide.

Fiber cement manufacturing plants:

- LTM (Kaluga region, Balabanovo)

- LATONIT (Russia, Lato Plant, Mordovia, Chamzinsky district, Komsomolsky settlement.)

- ETERNIT (Europe, the Netherlands, Goor.)

- CEMBRIT (Finland, Mujala, Lohja, 45 km from Helsinki.)

- VIKOLOR (Russia, Volna Plant, Krasnoyarsk)

Each plant produces its own version of a large-format panel and differs in texture and method of processing and painting the panels based on market needs. As a rule, plain-painted matte and glossy slabs are supplied in sheets or cut into a certain size of panels, however, based on the technical specifications for the concept, sometimes it is better to order the material in sheets and cut directly on site.

Universal tips

We will not analyze the main structural elements and their purpose. All this is the topic of another article. You can read here or here. Let's consider the general rules and stages of installing a ventilated facade.

The main thing is that there will be examples, analysis of errors, requirements of supervisory authorities and step-by-step instructions so that you can install a ventilated facade with your own hands.

Before installing the NVF

According to the requirements of SNiP 12-03-2001, the site must be fenced and warning signs installed.

According to the PPR previously developed by the contractor for the ventilated facade, scaffolding or facade lifts are installed in accordance with the manufacturer’s instructions. The scaffolding is covered with a protective polymer mesh.

Scaffolding can be installed not only in the standard way - at the zero level, but also on the interfloor ceiling or on a supporting device mounted in the building opening.

At the site, the location of lighting, a warehouse, a workshop, and an open area for ground work are determined. Arrows are installed for vehicle movement.

One of the common mistakes at this stage is the delivery and storage of façade substructures or cladding elements together with aggressive chemical products, or even simply dumped in the dirt. The dirt in the modern city contains reagents and salt. Salt increases corrosion several tens of times.

Marking

Before starting marking work, we already hold in our hands a pre-developed project of a hinged ventilated facade and carry out all marking or installation work in strict accordance with it.

This stage begins with drawing control points for attaching brackets to them. First, mark the lower horizontal line and two extreme vertical lines along the facade of the building - on the right and left.

To correctly mark the extreme points, a level is used. Next, the remaining intermediate points are marked at the two extreme points using a laser level and tape measure. And so on, all other points along the facade of the building are marked.

How to install brackets?

Installation of brackets on the wall is carried out, as a rule, in vertical increments from 600 to 1200 mm, horizontally from 350 to 800 mm, retreating from the edge of the wall at least 100 mm to the axis of the bracket.

Before installing the bracket, you need to prepare a hole for the anchor. To do this, use a hammer drill to drill a hole 15 mm deeper than the length of the anchor. Directed compressed air is used to blow away dust.

Then use a mounting hammer to knock the dowel through the hole in the bracket and paronite gasket. The fastening will be more reliable if you use a washer with the anchor.

Paronite gasket is an integral part of the technology for installing ventilated facades; it cannot be abandoned under any circumstances. It serves to prevent the formation of cold bridges.

Important! The offset of the bracket is determined by the current unevenness of the wall and the thickness of the insulation. The ventilated gap must be at least 40 mm from the surface of the insulation to the cladding. We don't have straight walls. Therefore, on one facade there will be a need to use brackets of different extensions. For example, 150 and 180 mm.

Installation of a ventilated facade compensates for wall unevenness

Installation of thermal insulation and wind-hydroprotective membrane

First we prepare the holes for the dowel. You and I know that each insulation board must be secured with five dowels.

Cuts are made in the slab with a knife to fit it onto the brackets.

When installing a suspended ventilated facade, two-layer insulation is allowed. Moreover, the top layer must always be of high density - at least 80 kg/m3. The requirements for the bottom layer are softer, and it can have a density of at least 50 kg/m3.

Important! The second layer of insulation should be installed offset from the first. Thus, the gap between the slabs of the first layer will be completely covered by the blind second layer. Look at the picture, it will become clearer.

Installation of insulation boards is carried out from bottom to top and from left to right. The voids between the slabs are sealed with the same material.

A serious mistake at this stage is to install not stone wool as insulation, but any type of polystyrene. This is strictly prohibited! According to the technology, only mineral wool can be used as insulation when installing suspended ventilated facades.

The installation of a wind-hydroprotective membrane on a ventilated façade is designed to protect the insulation from blowing out fibers and moisture. Basalt wool is practically hygroscopic, and the very principle of a ventilated facade will not give moisture a chance to linger inside the air gap.

Insulation manufacturers have proposed an innovation. They deliberately compacted the top layer of insulation to a density of 120 kg/m3. Not the entire slab became so dense, but only the top half a centimeter. This surface is called cached. And protects the insulation from blowing out. Therefore, such insulation can be used without a windproof membrane.

If you use the usual type of non-cached insulation, then the membrane is an integral part of the structure and you must use it when installing curtain wall facades.

In the case of using a moisture-proof film, the insulation board is first secured with two dowels and only after covering with the film is secured with the rest provided for in the project. The film panels are installed with an overlap of 100 mm. The panels are connected at the seams using a construction stapler.

Installation of guides

The installation pattern of a ventilated façade will vary depending on the profiles oriented horizontally, vertically or crosswise. We will look at standard rules for attaching a vertical profile.

The profile can be attached to the bracket using rivets with a stainless core or stainless self-tapping screws.

Important! There cannot be any galvanized screws. This is a serious mistake. Fasteners for mounting ventilated facades can be either made of stainless steel only, or made of aluminum and stainless steel, if we are installing an aluminum system with rivets.

If you mount a ventilation façade from an aluminum system on galvanized screws, the attachment point will rot in a year or two. Because different metals: ferrous and non-ferrous enter into a chemical reaction with each other. It's called galvano steam. This is corrosion in simple words.

If you install a ventilated façade from a galvanized system using galvanized screws, the service life will be reduced to three years. And, most importantly, you will violate the ventilation facade installation technology. And the validity of the Technical Certificate for the system in this case will not apply to such “sharash installation”.

Each bracket must be attached to the profile with at least two rivets or self-tapping screws. And the supporting bracket is an aluminum system with four rivets.

For convenience, the profile can be clamped with a clamp after you have leveled it. This will free up your hands and make installation of the ventilated façade more convenient.

Installation of window slopes and ebbs

Window slopes can be made of façade cladding material or painted galvanized steel. If facade cladding is used on slopes, you should know that there must be a backup galvanized box under the cladding in any case. In this case, such a box acts as a fire cutoff.

The requirements for a fire duct when installing a fire protection box can be reduced to three rules:

- It must be attached to the system.

- It must be attached to the frame.

- It must be attached to the base (wall).

If the slopes are not made of facing material, then the galvanized painted slopes will simultaneously act as a direct slope and a fire cutoff. In this case there will be no second duplicate box.

For framing window and door openings, complex finishing strips, slope strips with dimensions according to the design, or external corner strips (30x30, 50x50, 75x75 mm) are also used.

A window drain strip with dimensions according to the design is installed on the bottom of the window frame.

Installation of external corner

The corner areas of the building are always subject to close attention from the inspection authorities, and this is not without reason. Due to increased wind pressure, these areas have increased loads. Sometimes, in corner areas, based on the results of static calculations, a different profile is used, reinforced in comparison with the rest of the façade. Or a more frequent bracket spacing.

But, in addition, local strengthening of the structure is required. There are different options for reinforcement, more metal-intensive and less.

One of the options for strengthening the corner is the horizontal transverse connection of L-profiles at the outer corner of the building. Such reinforced elements are installed in 600 mm vertical increments along the entire surface of the external corners of the building. The picture shows a diagram. It is always easier to draw the desired knot than to explain it verbally.

How to install the cladding?

As already discussed at the beginning of the article, depending on the type of cladding, we attach it differently. We hang the cassettes using pins on carriages pre-installed on the profile. We attach the porcelain tiles to a clamp. And natural stone on a horizontal plank.

We will not cover the issue of fastening each type of cladding in a generalized article. To do this, follow the links at the beginning of the article to the necessary reviews.

Fiber cement subsystem design

- Bearing bracket, support bracket.

- Gasket, thermal break.

- Anchor with dowel (for wall base)

- Stud with washer and nut (for metal structures)

- Insulation, membrane. (with facade insulation)

- Profile, guide.

- Corner strip (external corner strips)

- EPDM tape 60 mm, 80 mm.

- Rivets 4.8*19-A2, 4.8*21-AL/A2 (for installing fiber cement)

- Stainless steel bushings

- Galvanized structure (polymer coated box)

- Left and right slopes.

- Low tides

- Parapet cover.

- Base strip (perforated strip)

Options for fastening a facade system made of fiber cement slabs allow you to repair a high-rise building with minimal time costs. The most popular solution for installing the system is the galvanized vertical T-shaped fastening subsystem “Optima” or a similar cross system with U-shaped and L-shaped profiles.

Variations by type:

- Stainless steel system

- Vertical or cross

- Interfloor in the ceiling

- Galvanized system

- In floor slabs

*The type of fastening of the fiber cement board and the selection (definition) of the facade system during assembly is taken on the basis of testing the fastening of anchors with dowels, concrete screws (new), and testing of disc dowels is also carried out, which are calculated together with insulation or insulation in two layers.

Fiber cement panels (Japanese panels)

Japanese building material manufacturers have developed more than 1,000 variations and textures for their panels from Japan. The advantage of this material is low flammability and light weight, and although low-flammable material is prohibited in schools and kindergartens, such panels are pleasing to the eye on low-rise facades or in fragments on high-rise residential buildings.

Mounting system type:

- For self-tapping screws

- For end clamps

- On glue

- On the picks

There are more than 4-5 types of installation options and this is not the limit, the fact is that the manufacturers of fiber cement panels have tried hard and opened more than 10 factories and brands for us in Japan. This implies the popularity of this panel in our market in Russia, but their panels are also used in Canada, America, and Europe.

It is worth noting the wide scale and simplicity of this type of material in the Optima ventilated facade systems, because we have been designing and installing Japanese panels for several years.

Trademarks fiber cement (Japan)

- Asahi

- Kmew

- Nichiha

- Konoshima

- Toray

Each plant has its own type of fastening and the thickness of the panels is from 12 to 20 mm. The Japanese initially developed the design of the assembly of the facade system for this type of fastening on a wooden frame, wooden beams and a device for the facade, but in this way they can install facades in real life in Russia We do not recommend federations to you.

It is much easier to mount fiber cement facades on a more affordable version of an L-shaped profile and make the structure less flammable in terms of the composition of the system and components, rather than experimenting with wooden blocks (which is logical*)

We do not recommend installing Japanese panels on a wooden frame structure, even if manufacturers of fiber cement panels from Japan argue with us and prove otherwise*

Composition of the fastening subsystem:

- Mounting bracket (50-380 mm)

- Gasket PON-B

- Guide 65*30 (oct. pp.)

- L-shaped profile (os.pp.)

- Starting clasp for federal target program*

- Klyammer Private under the Federal Target Program*

- Rivets 4*10 mm.

- Adjunctions

- Additional slope elements

- Parapet cover

*The photo shows the frame of the system in floor slabs with a weak base of foam block masonry. Such problems are solved by fastening brackets with a two-level assembly of brackets and reinforced guides, usually at least 1.5 and 2 mm.

When cutting panels into small sizes (making the facade in a checkerboard pattern), it is worth using a cross frame, which we did not indicate in the visualizations. This type of installation is always simpler in terms of profile placement; in this case, installation errors are minimal (you can always correct the profile placement)

Ventilated façade installation technology

The ventilated façade is installed in several stages.

Preparation - decorative and hanging elements are removed from the walls, the base must be clean, even (as far as possible to bring the subsystem into a plane), without peeling fragments. Wooden walls must be treated with an antiseptic; stone walls must be treated with a deep penetration primer with water-repellent properties.

Subsystem installation. The parameters of the subsystem depend on the type of insulation and the number of layers; the guides are mounted on self-tapping screws, dowel-nails, brackets, or other fasteners, based on the characteristics of the base. All elements of the wooden subsystem must be treated with fire and bioprotection. If necessary, a counter-lattice is placed on top of the subsystem.

Insulation. When laid sideways between the guides, stone wool does not require additional fixation; when installed directly on the walls, it is attached mechanically using plastic dowels. Regardless of the type of wall material, no membranes or films are placed under the insulation.

Hydrowind protection. Stone wool with a density of 90 kg/m³ does not require a protective membrane; looser thermal insulation is recommended to be protected from exposure to water and wind. If the facing screen is permeable (ceramic granite, wood using the slot method), cover any insulation, regardless of density.

Facing. Fixation to the subsystem is carried out according to the manufacturer's instructions, usually this is fastening with self-tapping screws with a backlash in a hidden position, but open fastening is also possible, followed by putty and painting of the caps.

Vector FORUMHOUSE Member

I cut the beam myself from a 50 mm board using a manual circular saw with a disc offset of 70 mm, impregnate it, the first beam is a vertical corner beam. Next, I press the next one to it with clamps, through a spacer (a piece of the same timber 590 mm long), a long lever clamp, 2 - 3 pieces per wall 5 m high. Then I drill through the beam into the KBB with a hammer drill, trying to get between the top of the block and the horizontal seam. The only fastening element that I was able to find for mounting the timber on the KBB was a metal frame dowel (approximately 120 mm). Everything else either doesn’t hold up or is prohibitively expensive.

When the first row of sheathing is ready, I lay in insulation, fix it in a lightweight polypropylene tape, with a stapler (I bought a 3000 m roll) so that it doesn’t blow away - I work alone. The next row from bottom to top uses serious yellow self-tapping screws; I made the drill of different diameters so that the self-tapping screw would pass through the outer beam freely. I repeat all operations. Then a wind and moisture protective membrane, a vertical sheathing made of 30 mm boards with a pitch convenient for installing OSB.

On the OSB there will be flexible facade tiles imitating brick - the ventilated facade is a dynamic base, and such an elastic material is able to withstand some deformations without damage to tightness and appearance. Similar examples already exist on our portal.

Metal cassettes for facades

The section of façade cladding panels made of galvanized steel, aluminum sheet, copper and bronze occupies a large market segment in the façade fastening systems. The fact is that metal processing and modern equipment for laser cutting and processing of sheet materials are rapidly moving forward, and our equipment at the Optima Facade company is constantly being modernized.

List of company equipment:

- Laser punching machine

- Dorma bending machine

- Automatic guillotine

- Painting line (6 meters)

- Punching camp

Any solutions for cassettes of closed or open mounting type with laser cutting and automatic feeding, bending equipment allows us to produce metal cassettes with different radii and rolling (columns, entrance groups, complex geometric products.)

In addition to standard cassettes made of galvanized steel, we produce the following type of metal cassettes:

- Perforated metal cassettes

- Steel cassettes

- Copper products

- Bronze products

- Closed cassette type

- Multi-level architectural decors

- Additional elements

Cost of metal cassette subsystem per m2

| Estimate | Metal cassettes Calculation table for components of a ventilated facade made of metal cassettes | ||||||||||||||||||||||||||

| p.p. | Name | Unit change | Consumption | Qty | Stock m2 | Cost pcs | Cost of the set (m2) | Design visualization | |||||||||||||||||||

| 1 | Profile L-shape 40*40*1.2 | linear m | 0,75 | 0,83 | 45,40 ₽ | 87,46 ₽ | |||||||||||||||||||||

| 2 | Vertical profile.. 60*40*1.2 | linear m | 1,10 | 1,21 | 94,58 ₽ | 114,44 ₽ | |||||||||||||||||||||

| 3 | Profile image VU external corner | linear m | 0,18 | 0,20 | 195,00 ₽ | 38,61 ₽ | |||||||||||||||||||||

| 4 | L-shaped bracket 50L-150 | PC | 2,22 | 2,44 | 25,70 ₽ | 62,76 ₽ | |||||||||||||||||||||

| 5 | Anchor 10*100 | PC | 2,22 | 2,44 | 16,00 ₽ | 39,07 ₽ | |||||||||||||||||||||

| 6 | Paronite gasket | PC | 2,22 | 2,44 | 4,20 ₽ | 10,26 ₽ | |||||||||||||||||||||

| 7 | Rivet 4.0x10 | PC | 10,0 | 11,0 | 2,20 ₽ | 24,20 ₽ | |||||||||||||||||||||

| 9 | EPDM screws | PC | 3,50 | 3,85 | 1,90 ₽ | 7,32 ₽ | |||||||||||||||||||||

| 10 | Plank start | PC | 0,50 | 0,50 | 0,75 ₽ | 0,38 ₽ | |||||||||||||||||||||

| 11 | Rivet 4.0*8 stainless | PC | 6,7 | 7,37 | 2,00 ₽ | 14,74 ₽ | |||||||||||||||||||||

| estimate | Price m2: | Type: Galvanized: | 389,22 ₽ | ||||||||||||||||||||||||

Composite panels

Initially, sheet composite panels “Alucobond” were called composite materials, and the name of the material itself was blurred and did not “appear” in the design of various buildings. The beginning of the existence of this wonderful material could be noticed with the arrival in our country of high-rise construction of shopping centers and “skyscrapers” of the type: Federation Tower, Moscow City, and similar high-rises where this material was used.

Advantages of composite cassettes:

- Affordable price

- Quick installation

- Easy design to size

- Can be perforated

Included:

- Recreating geometric shapes

- Production of decors

- Filing of ceilings (openings, slopes, canopies)

- Advertising structures and signs

The design and everyday use of this material in the arrangement of shops and supermarkets, gas stations and interior decoration everywhere allows you to quickly complete the assigned tasks. As a rule, the upper part of the composite sheet allows not only to produce cassettes in any color according to the “RAL” catalog, but also to solve problems with textures like wood, copper, mirror texture, bronze, etc.

The photo shows installation on a U-shaped aluminum guide.

Unlike HPL panels, a composite sheet lends itself perfectly to bending and milling of the material, both in production using an industrial router or laser, and in artisanal conditions (on site with a hand router). What’s more, we have more than once carried out simple framing work without equipment, if you do the work responsibly and slowly, it is possible to complete a small volume of composite cassettes using auxiliary tools.

Cons of composite material

- Is a low-flammable material

- Not homogeneous material

- Requires professional milling

- Average cost compared to other cassettes

- Cost of fastening subsystem

- Requires design

In general, this material has more advantages than disadvantages. Of course, it is impossible to install composite cassettes in schools and kindergartens, since this is prohibited by fire expert opinions. It is also worth noting this material in wall and interior decoration, for advertising purposes and in design.

Thermal insulation, wind protection and waterproofing

The choice of thermal insulation material must correspond to certain properties and characteristics:

- The vapor permeability of the insulation should be the same as that of the walls of the house.

- Minimal heat loss.

- Good sound insulation.

- Water-repellent qualities.

Therefore, polyurethane foam, polystyrene foam, mineral or basalt wool are suitable for insulating ventilated facades.

Expanded polystyrene and polyurethane foam have the same characteristics:

- do not lose their quality properties under the influence of weather conditions;

- moisture resistant;

- high heat and sound insulation;

- do not shrink over time;

Among the disadvantages are:

- low vapor permeability;

- high cost.

In terms of quality characteristics, mineral or basalt wool is most suitable for insulating ventilated facades. They are low cost, light weight and allow steam to pass through well. Among the disadvantages is rapid caking of the material, which leads to the formation of cold bridges.

Important! Basalt slabs have a long service life.

If the choice fell on cotton wool to insulate the ventilation façade, then you should consider:

- Product density. In order for the material to last for many years, it must have a high density. Otherwise, the absorption of moisture and steam will lead to the destruction of mineral or basalt wool.

- Building height. When building multi-storey buildings, you should choose high-quality and dense insulation. This will prevent the cotton from being blown away by air currents.

- Climate. In places with high humidity, cotton wool is not the best insulation.

Note! Mineral and basalt wool can only support its own weight; air currents passing through it erode moisture and small particles of wool. This significantly reduces the service life of the product.

Waterproofing films or membranes are used as a waterproofing and windproof material for a ventilated façade. Their purpose is to protect thermal insulation from precipitation and wind, as well as to remove moisture.

Composite panels price

| Composite cassettes | Visualization | ||||

| Aluminum composite system vertical | |||||

| Calculation of the cost of work and materials for the installation of Optima composite panels | |||||

| Installation | |||||

| Name of works | Qty | Consumption | Cost per unit change | Price | |

| Installation of composite panels with an aluminum subsystem. | 1 | m2 | 1850 | 1 850,00 ₽ | |

| Total: | 1 850,00 ₽ | ||||

| Support bracket KN-100 | 0,9 | 0,9 | 76 | 68,03 ₽ | |

| Support bracket KN-100 | 2,1 | 2,1 | 55 | 115,50 ₽ | |

| Taurus profile 50*70*1.7 mm. Aluminum T-70 | 2,25 | 2,25 | 174 | 391,50 ₽ | |

| Component material | |||||

| Name and size | Qty | units from. | Cost per unit change | Price | |

| Consumables for installation of composite panels | 1 | m2. | 150 | 150,00 ₽ | |

| Fasteners for the fastening subsystem (hook and slide) | 1 | m2. | 520 | 520,00 ₽ | |

| RAL composite panel (*Any color according to the project) | 1 | m2. | 1020 | 1 020,00 ₽ | |

| Transport costs and assembly. | 1 | PC. | Around Moscow. | 3 000,00 ₽ | |

| Total: | 4 690,00 ₽ | ||||

| The total cost of work and materials with delivery per m2 is: | 6 540,00 ₽ | ||||

A natural stone

In the system of fastening ventilated facades, natural stone with installation work in the end cut of the stone plays an important role in the finishing of both the main plane of the facade (ordinary zone) and the finishing of the base or entrance lobbies. The fact is that there are three ways to install it on the subsystem, and three types of fastening.

Stone fastening options

- Stone pin fastening

- End cut

- Kayla

System mounting type:

- Vertical

- Horizontal-vertical

- Interfloor

Stone Design

- According to drawings and plans

- By geodesy

- Combined

Any type of fastening is based on a static calculation of the system, and is selected based on the weight per m2 of the system cladding. Complex architectural forms of stone are established based on the design solutions of the building and its geometry.

Concrete tiles

In 2012, the opportunity arose to develop a system for fastening concrete tiles and to develop a system for fastening these facing materials.

The simplicity and reliability of these concrete tile systems is the texture and uniqueness of color rendering compared to the brick cladding format. The system and substructure for fastening the tiles is located on load-bearing starting and row strips under the concrete tiles and allows for competent and high-quality installation of units due to a special clamp (tile fixer)

The system includes:

- Console carrier

- Starter strip for tiles

- In-line tire

- Console gasket

- Horizontal insert

- Guide 65*30*1.2 mm. (C-shaped)

- External corner plank.

- L-shaped corner element

Selection of facing materials for ventilation facades

When choosing a facing material, several factors are taken into account:

- Design is the most fundamental factor! Choose the material, texture and color - such that you like it.

- Operating conditions - it is necessary to take into account weather conditions and climatic load on the facing material.

Ventilated facades made of porcelain stoneware

They are characterized by good durability of the cladding material. The variety of types of porcelain tiles is provided by various surface treatment methods (matte, polished, embossed) and colors. Ventilated facades made of porcelain stoneware are one of the most popular today.

More details

Ventilated facades made of fiber cement boards

The basis of fiber cement boards is cement, reinforcing fibers and mineral fillers. This composition makes the facing tiles strong, non-flammable, resistant to all external influences and relatively inexpensive. Fiber cement slabs are distinguished by a wide variety of textures and the ability to be painted in all RAL colors. Fiber cement ventilated facades provide an unlimited choice of design solutions.

More details

Ventilated facades made of metal elements

Such ventilated facades are distinguished by their simplicity and speed of installation, lightness of construction and a wide choice of colors. Metal siding, corrugated sheeting and metal cassettes are used as facing elements. The attractive but ascetic appearance of the metal-clad facade, coupled with its inexpensive cost, has made it one of the most popular in industrial construction. This system of curtain facades is installed on the walls of warehouses, workshops and production facilities.

More details

Ventilated stone facades

For those who love natural patterns, this facade system is most suitable. On the subsystem of this ventilation facade, you can attach slabs of natural stone of strong, medium-strength, as well as agglomerate granite slabs - artificially created slabs from natural granite chips. The subsystem of a ventilated facade made of natural stone uses special tires, which provides additional opportunities for reliable fastening of heavy stones.

More details

Ventilated composite facades

The aluminum-composite panel is characterized by a high level of strength, low weight and good flexibility, which makes it possible to cladding the facades of buildings with the most complex architecture. The fastening systems for composite ventilation facades include special holders that allow you to easily and securely mount cassettes on metal profiles.

More details

Ventilated facades made of volumetric terracotta ceramics

Terracotta is ceramic products made from a colored clay mass that is fired in a special way. Depending on the annealing method, terracotta ceramics acquires different textures (fine, coarse-grained, with complete or partial polishing, etc.) and different colors (shades of black, red-brown, light brown). A number of advantages make terracotta panels quite popular - this material is fireproof, has high levels of noise insulation and thermal conductivity, is not afraid of frost and moisture, is environmentally friendly, and durable. The ability to self-clean attracts those who do not have time to keep the façade clean.

The variety of colors of facades made of terracotta ceramics is achieved by using clay from different deposits, the method of annealing and mixing masses of different colors. In this way, not only a variety of natural shades are obtained, but also unique surface textures. All this, taken together, creates inimitable visual overflows depending on the angle of incidence of sunlight.

More details

Ventilated facades made of HPL panels

Facade HPL panels are a new generation material, which is characterized by sufficient lightness, high rigidity and resistance to shock and vibration. Such properties allow the use of large format panels and their installation without rigging equipment. Thanks to the strongest bond between the layers, the HPL façade perfectly withstands temperature changes from -60 to +80 degrees Celsius and is resistant to chemical and solar exposure.

Installation of HPL facades is very simple, and the presence of a wide range of textures, colors, visible and invisible fastening systems allows you to realize a wide variety of design ideas.

More details

Ventilated facades made of fiber cement siding

High-tech non-flammable fiber cement panels for facade finishing are produced in factories in Japan. True works of art that imitate natural materials are fiber cement slabs with various types of coatings, textures and colors.

Japanese fiber cement siding has unique properties that help maintain the original texture and color for a long time. Protection and durability of the color layer is achieved through a thin ceramic coating applied to the surface of fiber cement siding. A ventilated facade made of fiber cement panels provides a large number of possibilities in the execution of design solutions.

More details

Ventilated brick-like facades

Brick-like clinker tiles have the highest strength and give the facade a beautiful, clearly defined pattern of ideal brickwork. Made from natural raw materials, it has an extremely low moisture absorption coefficient, extreme frost resistance and a high degree of ultraviolet resistance.

More details

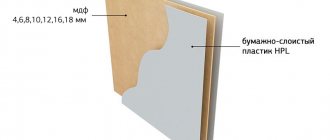

HPL panels

This type of cladding panels (laminated plastic) or HPL panel allows you to create a façade using an original color palette that differs from the standard cladding of a façade system. On facades, only a low-flammable version of panels marked FR+ (Low-flammable plastic) is used.

When decorating the inside of a building, this material is also used to decorate the panels with a flammable composition; it is also customary to make kitchen facades from this material.

Installing laminated plastic on a ventilation facade subsystem is no different from installing any laminated material on a rivet. And if we are talking about hidden fastening of this material, it is worth noting the complexity, because installation on stainless steel picks increases the cost, requires care during assembly, and requires special equipment for drilling and “jewelry” work.

HPL installation can be:

- Open rivet fastening

- Hidden piping mount

- Installation with adhesive composition

How to choose insulation

The main goal of thermal insulation of facades is to reduce heat loss. One of the criteria for choosing insulation is the thermal conductivity indicator. The lower the thermal conductivity, the higher the ability of the material to prevent heat loss through the walls.

To insulate the facade of a building, the following are used:

- mineral wool slabs, medium and high density;

- materials based on polystyrene foam (Penoplex and similar in composition and density).

Time has shown that stone wool is most widely used as insulation for ventilated facades.

. Mineral wool insulation has a number of properties that are difficult to neglect: fire resistance (fire safety), resistance to aggressive environments, environmental friendliness and adequate cost.

Insulation based on polystyrene foam is slightly more expensive

, but they also have a number of advantages:

- their installation is much simpler - both disc-shaped and ordinary dowels can be used as fasteners.

- expanded polystyrene has less weight - this has a positive effect on the speed of installation at high altitudes.

When choosing insulation for a facade, consider not only the cost and ease of installation - the manufacturer is of no small importance! Only proven brands are guaranteed to provide you with high-quality insulation

.

Clinker for grouting

Subsystems for fastening clinker for grouting are carried out with installation on a strip for grouting, where the clinker material is mounted supported by a strip, which forms the necessary gap for the composition of the grout mixture, and the strip itself is installed on a vertical or interfloor fastening subsystem.

In this type of fastening, it does not make sense to install a cross fastening frame, but it is worth taking care of the reliability and static calculation of the system, since the weight of the facing material together with the grout has sufficient loads.

Subsystem frame composition:

- Reinforced bracket

- Pad

- Vertical profile T-65*30*1.2

- Angle profile UP-300*300

- Starting grout strip

- Row plank

- Rivet 4*10

- Additional elements

Clinker without grout

Clinker without grouting, with the help of its design and, of course, a strip that is mounted at the end of the clinker. allows you to perform clinker installation work using mechanical fastening (without chemical composition)

The technology for installing on a galvanized steel strip with a polymer coating came to us from the method of installing natural stone. Only if in natural stones it is necessary to cut the end in order to reliably install the subsystem, then in clinker this task is solved by means of a special row and starting strip.

We decided to highlight the key points in the cost of the subsystem for clinker without grouting and came to the conclusion that the cost depends on factors not only the cost of fastening elements, but also the base of the facade itself.

We invite you to consider the price table in detail:

Cost calculator for a clinker tile facade:

| No. P/P | Name | Unit change | Quantity per 1 sq.m. | Unit cost RUR | Cost of 1 sq.m. rub. | ||||

| Load-bearing system with polymer coating in the floors | |||||||||

| 1 | KN1TsP-200 Bracket + polymer | PC | 2,2 | 58.00 rub. | 127,60 ₽ | ||||

| 3 | T4 45 Paronit | PC | 2,2 | RUR 3.91 | 8,60 ₽ | ||||

| 4 | PV1TSP-3000 Vertical T-shaped profile 80 D-3000 | PC. | 0,10 | RUB 450.00 | 45,00 ₽ | ||||

| 5 | PU3TsP-3000 L-shaped corner profile D-3000 | PC. | 0,03 | RUB 280.00 | 8,40 ₽ | ||||

| 4 | PV5.1 KTsP-3300 C-shaped interfloor vertical profile (for porcelain stoneware) 9x60x70x60x9 D-3300+polymer | PC. | 0,58 | RUB 775.50 | 449,79 ₽ | ||||

| 4 | PS kTsP Docking profile (for clinker) 9x27x66x27x9 L=300+polymer | PC. | 1,2 | RUR 87.00 | 104,40 ₽ | ||||

| 6 | PRK Row shelf for clinker, D=1200 mm, t=1.2mm, stainless steel. steel | p.m. | 3,16 | RUB 237.93 | 751,86 ₽ | ||||

| 7 | PSK Starting shelf under stone, D=1200 mm, t=1.2mm, stainless steel. steel | p.m. | 0,28 | RUR 222.48 | 62,29 ₽ | ||||

| 8 | PFK Stone-like finishing shelf, D=1200 mm, t=1.2mm, stainless steel. steel | p.m. | 0,28 | 166.95 rub. | 46,75 ₽ | ||||

| Calculation of clinker subsystem (m2) | Total cost of the subsystem | RUB 1,654.69 | |||||||

Tools and inventory

| Name: | Specifications: | Purpose: |

| Scaffolding | The height and length of the scaffolding is according to the passport. Standard load - 200 kgf/m | For installation work at a specific building level |

| Facade lift or cradle | The length of the working floor is 4 m. Load capacity - 300kg. Lifting height up to 150 m. | For installation work at a specific building level |

| Laser level | Measurement accuracy 0.1 mm/m | Height measurement |

| Spirit level | Length 1500mm, measurement accuracy 0.5 mm/m. | Checking horizontal planes |

| Plumb line, cord | The weight of the plumb line is no more than 0.4 kg, length 98 m. Cord length – 5 m, diameter 3 mm. | Delineation of grips, checking verticality |

| Laser level | Measurement accuracy 0.1 mm/m | Checking horizontal planes |

| Hammer or drill | The maximum diameter of the drill (punch) is 20 mm. | Drilling holes in the wall |

| Steel tape measure | Length 20 m, Weight 0.35 kg | Measuring linear dimensions |

| Manual impact wrench | Tightening torque 12.5 kgf.m | Screwing/unscrewing nuts and bolts |

| Lever head | Reversible lever | Screwing in/unscrewing screws and bolts |

| Electric drill with screw | Power consumption 800 W, maximum drilling diameter 20 mm. | Drilling holes and tightening screws |

| Battery rivet gun | Riveting force 85 kgf, working stroke 20 mm, weight with battery 2.2 kg | Installation of blind rivets |

| Riveting pliers | Rivet diameter up to 6mm | Installation of rivets |

| Protective mesh for scaffolding | Protection against falling objects from scaffolding heights |

Facade design

We offer to order from our company a complete set of facade systems and the development of design documentation for hinged ventilated facades with an air gap. We provide a full range of works on ventilated facades (facade systems) and also carry out supervision of installation, geodetic survey of the facade with detailed references of the building to drawings and components. The work should be divided at the approval stage based on the needs of your building:

- Development of a building color passport

- Implementation of architectural solutions

- Design project

- Development of constructive solutions

- Wiring diagrams

- Static calculation

- Specification

Components of a curtain wall substructure

The elements of the subsystem for a ventilated facade are:

- Profile

- Brackets

- Trim fastening details

The fastening elements of the ventilation façade are various products. In order for the fastening to be reliable and durable, it is necessary to give preference to quality products. All components together become the basis of a frame for a ventilated facade, onto which facing materials are subsequently installed. The key task of the substructure for ventilated facades is to firmly fix the finishing elements so that an air gap is formed between the finishing and the heat-insulating layer. The frame system makes it possible to create reliable and high-quality facades with a long service life. The ventilated facade must have reliable fastening. A very important component of the ventilation facade is a layer of thermal insulation, which protects the walls from freezing and gusts of cold air. Thanks to the ventilation gap, the formation of deformations is excluded. This technique will ensure a long service life of the entire ventilated façade structure. Reliable and high-quality thermal insulation prevents the penetration of extraneous sounds and cold air from the external environment. A vapor-permeable membrane is also an important component of the ventilation façade. When purchasing materials, you should pay attention to the manufacturer, country of production and expiration date.

Cost of design work:

The price did not include materials related to such work on the design of complex architectural elements made of glass fiber reinforced concrete and fiber reinforced concrete embedded parts. We propose to separately request the cost of this type of façade stucco molding and calculate the design work according to your request.

The composition of glass fiber reinforced concrete includes:

- Cornices

- Friezes

- Architraves

- Balustrades

- Columns

- Window frames

- Pilasters and rustications

Optima Facade company services

- Carrying out full-scale testing of fasteners

- Geodesy and facade binding (2D development, 3D model)

- Manufacturing of facing materials

- Production of ventilated facade systems

- Installation work

- Supervised installation

- PPR facade project

- ASR façade project

- Manufacturing of perforated baskets

- Laser cutting, milling, rolling

- Manufacturing of additional system elements

- Sales of insulation and thermal insulation

Our experience in the facade market for more than 10 years allows us to optimize our work to complete any complex task in a short time. We offer only informed decisions and are responsible for the project developed by our company.

Modern equipment for processing natural stone, production facilities for rolling and bending stainless or galvanized steel, allows us to provide comprehensive turnkey support for construction projects, deliver products on the second day after ordering, or provide the opportunity to pick up ready-made system kits from a warehouse in Moscow.

Portfolio

Porcelain tile facade of the Tikhoretsky shopping center

Facade area – 855 m2

Work completion time: 60 calendar days

Ventilated facade of the school “Integration XXI Century”

Facade area – 700 m2

Work completion time: 50 calendar days