According to environmentalists, up to 40% of heat and electricity generated in the northern hemisphere is spent on heating residential, industrial and other facilities. For this reason, high-quality insulation of buildings brings tangible benefits in terms of financial savings and living comfort. One of the most popular heat insulators is polystyrene foam (expanded polystyrene, EPS).

Which polystyrene foam is better for insulating the outside of a house?

Which polystyrene foam is better for insulating the outside of a house? Let’s look at this question in detail.

Is polystyrene foam safe?

In Europe, PPP has been widely used for more than half a century. During this time, no material was found that would surpass foam plastic in terms of environmental friendliness, efficiency and thermal insulation characteristics. Europeans use PPS everywhere: as insulation for buildings and utility lines, packaging material for food products and any other goods.

Styrofoam

In Russia and the CIS countries there is a certain prejudice towards this material. It is based on information about the environmental friendliness and fire hazard of polystyrene foam. The veracity of this information can be verified using documents that contain the results of tests and examinations carried out in relation to the teaching staff.

The eco- and fire safety of this material is confirmed by many official researchers, including:

- Research Institute named after Erisman (expert opinion No. 03/PM8);

- State Institution “Republican Scientific and Practical Center of Hygiene” (Republic of Belarus);

- SP 12-101-98 (SNiP for construction heating engineering);

- Research Center for Fire Safety VNIIPO of the Ministry of Internal Affairs of the Russian Federation;

- According to the BREEM environmental safety scale, PPP is classified as class A +.

The products of each foam manufacturer must undergo a certification stage. The presence of an appropriate conclusion confirms the suitability of this material for use in everyday life, construction and for other purposes.

Certificates of Conformity

Certificates for foam plastic

Hygienic characteristics of products

You need to know: the most important information about the percentage of harmful substances and their list is on the back of the hygiene certificate, which is rarely paid attention to.

After reviewing the documentation, we can conclude that the opinion about the dangers of polystyrene foam is greatly exaggerated and is based not on facts, but on myths and rumors. If there are any doubts about the rationality of using this material, it is worth considering that it will be located not inside, but outside the premises, since the technology of insulation of the facade, and not living rooms, is being considered. Therefore, PPS can be safely chosen as the main heat insulator for the external walls of a house.

Foam plastic, test results according to GOST 15588-86

Expanded polystyrene (foam) is a panel material that occupies the highest positions in sales volumes

Pros and cons of foam plastic

The name “foam plastic” is used in everyday life as an abbreviation for expanded polystyrene. This material is designated by the abbreviations PPP or ESP. The first name is in Russian, the second is in English.

Polyfoam sheet

In the information from manufacturers and sellers of this material there is not a word about its shortcomings. Only the advantages are listed. And this is understandable, since the goal of the manufacturer and distributor is to sell the product, but polystyrene foam has been known to the consumer for more than half a century, and during this period a lot of information has accumulated on the practical use of PPS. This information is not so widely known, but is extremely important for the correct choice of material for facade insulation. There are application features and limitations that you need to be aware of.

The list of advantages of polystyrene foam includes such characteristics as:

- environmental friendliness;

- high-quality sound insulation;

- vapor permeability;

- counteraction to the development of pathogenic microorganisms, due to which fungus and mold do not form in the EPS.

Comparison of insulation materials

Comparative characteristics of thermal insulation materials

The fire safety of polystyrene foam is low, which is the main disadvantage of the material.

How PSB-S burns

Styrofoam and rodents

The advantages of this heat insulator include the statement that rodents ignore PPS and do not eat its granules as food. That's a moot point. You can find facts for and against.

The practice of using this material suggests that rodents do not eat PPS, but chew it with pleasure. Therefore, the only rational solution is to close the heat insulator as well as possible, that is, to block rodents’ access to it. This is a smart choice for a practical owner.

Mice gnawed through the foam

Foam and ultraviolet

Manufacturers of polystyrene foam do not provide information that it is extremely unstable to ultraviolet radiation, and direct exposure to sunlight is especially harmful. The consumer is not informed that this type of radiation negatively affects the chemical stability of EPS and it begins to “age” intensively.

The fact is that polystyrene foam has a polymer structure, therefore, like any other polymer, it will gradually decompose. Ultraviolet light significantly accelerates this process.

Polystyrene foam does not like ultraviolet light

But this disadvantage of expanded polystyrene can be considered relative, since it is not difficult to eliminate the negative effects of UV: it is enough not to expose EPS to direct exposure to the sun. That is, when installing the thermal insulation layer of the facade, the foam must be covered with finishing material as quickly as possible.

About the soundproofing ability of PPS

Claims by PPP distributors that this material is a high-quality sound insulator are questionable. Owners of frame houses who have chosen foam plastic as insulation claim that it has extremely low noise absorption.

An example of soundproofing a ceiling using penoplex

If you think about it, this fact is quite understandable: more than 90% of PPS consists of air, which is an excellent heat accumulator and an equally excellent conductor of sound. Therefore, you should not hope that polystyrene foam will help reduce the degree of sound permeability of the walls of the house.

As the thickness of the foam blocks increases, the structure's ability to absorb noise increases

About the vapor permeability of foam

The low vapor permeability of expanded polystyrene in practice means that in the path of steam movement from inside the house to the outside, there will be an obstacle in the form of EPS sheets. The temperature outside is often lower than indoors. Therefore, the steam will inevitably condense, as a result of which drops of water will form at the junction of the insulation with the elements of the wall structure. This increases the risk of adjacent materials getting wet.

When deciding what is best to sheathe the outside of the house, do not forget to take into account the vapor permeability of the materials

There is only one way out: correct calculation of the dew point and the required thickness of the insulation, moving the dew point beyond its limits. A reasonable solution is to install a ventilated façade.

It should also be taken into account that the vapor transmission capacity of any heat insulator cannot be considered in isolation from the details of a specific design. It is necessary to take into account what the walls are made of, whether hydro- and vapor barrier is installed, how high the foundation is and other nuances.

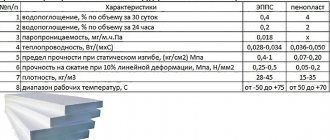

Main characteristics of teaching staff

Technical characteristics of extruded polystyrene foam boards

How to choose high-quality insulation in a large assortment on the market

- Ask the seller for a product certificate. The quality of the purchase must be confirmed not only visually, but also documented. Reliable manufacturers of building materials who value their reputation are always ready to provide the necessary quality certificates.

- Assess the storage conditions of the material where it is sold. For example, under the influence of the sun's rays, polystyrene foam may acquire a foreign odor, turn yellow, and its properties deteriorate.

- Examine the packaging. A quality product is marked; if the packaging material does not have the appropriate markings, then it is better to buy polystyrene foam elsewhere.

- Inspect the material granules. They should be uniform, approximately the same size, and evenly distributed across the sheet. If voids or peeling of granules are noticeable, then this is a sign of a low-quality product.

- Rate the sheets. Visually, they should be without bumps or deformations, and to the touch - soft and elastic. The rigidity of the sheets indicates that the production technology has not been followed.

- Don't chase the cheap. Polystyrene foam, purchased at a low price and initially pleasing with this fact, may later turn out to be worthless. Cheap material absorbs water, freezing and thawing between the granules, it destroys the foam.

There are more advantages to using polystyrene foam than disadvantages: it is inexpensive, easy to install and operate, and non-toxic. To enjoy the quality of your new insulation for longer than one season, you should carefully consider purchasing the material.

Classes and grades of foam plastic

Foam classes

There are only two classes of foam: pressed and non-pressed. From the names it is clear that these materials have different production methods. The first is made using pressing equipment, the second - by sintering at high temperatures. But this production line also uses pressing equipment. However, the classification is what it is.

Expanded polystyrene suspension pressless

Which class the foam belongs to can be determined visually. Bespressovy is a complex of fairly firmly glued round and oval granules. The structure of this material is porous, the strength depends on the density.

Pressed polystyrene foam

Pressed sheet has the appearance of a fairly smooth sheet, the density of which varies and depends on the brand of the product. This material has excellent technical and performance characteristics.

Foam brands

Foam brands

Polystyrene foam produced using the non-press method is designated by the abbreviation PSB. Press - PS. The product name may also contain other letters, each of which indicates a feature of this product.

- A – the canvas has the correct geometric shape of a parallelepiped and a smooth edge;

- B – the edge of the product has an L-shaped cut;

- P – cutting of the blades is done with a hot string;

- F - façade or made using special forms;

- C – self-extinguishing;

- N – the product is suitable for external use.

The numbers in the name of the PPP indicate its density.

Brands of pressless foam

PSB-15

The most inexpensive product with a high degree of fragility. Used as a thermal insulation and packaging material, it crumbles easily and has low hygroscopicity. Traditionally used for insulating balconies and loggias, country houses, containers and outbuildings.

Foam plastic PSB S-15

PSB-25

Foam plastic of different brands

This brand of foam plastic is often supplemented with the letter “F”, so the material is recommended for insulating facades. Due to its higher density than PSB-15, it is used for the manufacture of landscape and interior decorative elements.

PSB-35

Expanded polystyrene PSB-S-35

A universal material with a wide range of applications. It is used for insulation of utilities, heat and gas mains, production equipment, thermal insulation of roofs and attics. Involved in the production of multilayer panels (including reinforced concrete) as a thermal insulation gasket.

PSB-50

Characteristics of polystyrene foam PSB-S 50

This material has the highest density among non-press foams. Demanded as a heat and sound insulator for objects of any purpose. It is able to provide high-quality protection from the cold, therefore it is used in the construction of underground communications, garages and parking lots, and in road construction.

Characteristics of brands of pressless foam.

| Index | PSB-15 | PSB-25 | PSB-35 | PSB-50 |

| Compressive strength at 10% strain (MPa) | 0,04 | 0,08 | 0,14 | 0,18 |

| Density (kg/m3) | 15,0 | 15,1-25,0 | 25,1-35,0 | 35,1-50,0 |

| Thermal conductivity (W/mK) | 0,1 | 0,43 | 0,38 | 0,38 |

| Water absorption during the day in% of the total volume | 4 | 3 | 2 | 2 |

Pressed foam brands

Durable and rigid press (tile) foam is a closed-cell plastic. It is a radiotransparent material. It has found wide application in all sectors of industry and agriculture. PVC foams, which contain polyvinyl chloride resin, are produced using the pressing method.

Brands PS-1, PS-2, PS-3, PS-4.

They have a closed-porous structure, the degree of hygroscopicity is close to 0. They are extremely resistant to atmospheric influences. Self-extinguishing, petrol and oil resistant.

High-hardness foam PS-1-350

PS-1-150

They are used in radio electronics as a material that is unstable to electrical breakdown, as well as for the manufacture of containers and floats for aggressive liquids.

For insulation of building facades, pressless foam plastics of different densities are in demand. In order to buy truly high-quality material, you need to know how you can independently check the information of the manufacturer and seller.

Polystyrene foam of increased hardness PS-4-40

Among the largest Russian producers of foam plastic are the following companies:

- "Styroplast" (Chekhov);

- "Omegaplast" (Moscow);

- "Gamma Center" (Kolomna);

- "Kavminprom" (Mineralnye Vody);

- "Stavpolyester" (Stavropol);

- "Rosplast" (Moscow).

Prices for various brands of polystyrene foam

Styrofoam

What density is needed?

To insulate a house, foam plastic of different densities is used, depending on what goals are being pursued and what specifically needs to be insulated. So, to insulate the walls from the outside, it is better to opt for polystyrene foam with a density of 25 kg/m³ ; if you need to insulate the floor, then use denser slabs - 35 kg/m³ ; the same material is also used for roofing. But to insulate walls from the inside, it is better to choose polystyrene foam with a density of 15 kg/m³ .

It is better not to use foam plastic with a density of 15 kg/m³ for insulating external walls. Of course, this is not prohibited, but its durability, strength and reliability will be in question, which is easy to check yourself, because you just need to compress the material. As a result, you can get less durable insulation, and in terms of thermal insulation, such foam is inferior to its denser counterpart. But it is worth noting that such material can be used to insulate non-permanent structures: stalls, small shops, warehouses. Also, foam plastic with a density of 15 kg/m³ can be used to insulate some parts of the facade that are adjacent to the house, but do not require serious insulation: veranda, technical buildings, open balconies.

Foam plastic with a density of 35 kg/m³ is used extremely rarely for wall insulation: it copes with its tasks perfectly, but has a high price. In some cases, by the way, when thermal insulation properties are especially important, it is more profitable to use a thinner sheet of denser foam than medium-density foam of double thickness. But in most cases, it is the material with a density of 25 kg/m³ that is in highest demand.

Rules for choosing polystyrene foam for facade insulation

PSB-S-25 foam is best suited for façade insulation. There are several reasons for this:

- this material has sufficient density and strength for installation on any supporting base;

- has a degree of thermal conductivity low enough to prevent heat loss from the interior;

- is light in weight;

- easy to transport;

- is characterized by low cost;

- self-extinguishing;

- durable.

Foam plastic for facade insulation

The most important indicator of the quality of PPP is density. It depends on the production method and the characteristics of the foam granules. During sintering, polystyrene foam granules swell; when pressed, they stick together. The stronger the pressing, the tighter the granules adhere to each other. The degree of thermal conductivity and vapor permeability of the product at the outlet directly depends on this.

What's bad about low-density foam?

With a low density of EPS, its structure is relatively loose, since the distance between the granules is significant. These gaps are the reason for the good vapor permeability of the material. But the polystyrene foam granules themselves, due to their higher density than the air between them, allow steam to pass through much worse.

This leads to the accumulation of moisture inside the insulation, which is removed more slowly than required. As a result, the plaster applied to the foam will attract moisture and gradually deteriorate. The same can be said about other materials adjacent to the insulation, or located next to it. Therefore, it is so important to make sure that the foam purchased in the store is of sufficiently high density.

What is sold under the brand name PSB-25

The high demand for polystyrene foam has led to the emergence of a large number of large and small manufacturers and distributors of polystyrene foam on the market. They all understand that this material is chosen as insulation primarily due to its low price. This fact, coupled with high competition, forces manufacturers to win back their market segment by reducing prices, which cannot but affect the quality of their products.

For this reason, the situation on the market is such that under the PSB-25 brand they sell products whose quality does not stand up to criticism. This also applies to foam plastics of other popular brands.

Video - Polystyrene foam PSB-S 25 TU and foam plastic PSB-S 35 TU

It is important to know: for many years, the production of polystyrene foam has not been standardized by GOST to the extent necessary. Each enterprise that manufactures PPP develops its own technical specifications (TS) regulating the technological process. This gives the owner of the enterprise freedom of action, and he has every right not to comply with previously adopted standards.

Foam production diagram

The need to reduce the price of the finished product forces the manufacturer to reduce the cost of the material. GOST according to PSB-25 allows the production of a product with a density of 15 to 25 kg/m3 under this brand.

This has led to the fact that building materials stores under the PSB-25 brand offer foam plastic, the density of which is significantly lower than 25 kg/m3. But, as mentioned above, this is not consumer deception. This is permitted by the standards body.

How to find out the density of foam plastic

How to determine the density of foam plastic

The density of PPS is calculated as follows: 1 m3 of this material is weighed. The resulting value is an indicator of density. That is, 1 m3 of PSB-25 should weigh 25 kg. In practice this is extremely rare.

The most common situation is that foam plastic with a density of 16.1-16.5 kg/m3 is sold under this brand. You can check the density of the sample directly at the retail outlet where it is purchased.

As a rule, all building materials stores or market pavilions are equipped with equipment for weighing goods. It is necessary to take a sheet of foam plastic of the required thickness and calculate its volume. To do this, multiply the length of the canvas by its width and height (thickness). Then you need to find out the weight of this sheet and divide the resulting value by the volume indicator.

Example calculation for a sheet 2 m long, 1 m wide, 2.5 cm thick:

- calculate the volume of the sheet: 2 m x 1 m x 0.025 m = 0.05 m3;

- weigh the sheet;

- divide the weight by the volume.

Calculations can be done using a calculator, which is available on any mobile phone. This approach will help you buy the insulation that will serve flawlessly for many years.

Video - How to determine the density of foam plastic

Extruded polystyrene foam

A facade made of extruded polystyrene foam is the right choice for finishing and insulation. Since the material itself has higher density characteristics than PSB-50. Brands such as Penoplex, Technoplex, Ursa are represented on the Russian construction market.

All of them are of high quality, although they have their own characteristics. For example, Technoplex brand products add graphite to the canvas to increase density, due to which the canvas comes out grayish. Sheets from Penoplex have a specific bright, carrot shade. And the product of the Ursa company has a beige color. The quality parameters are the same for everyone, the only thing is that the dimensions of the expanded polystyrene sheet may vary.

Technology of facade insulation with foam plastic

Polystyrene foam can be fixed to the wall of a house in two ways: glued and glueless. The use of the first installation option is justified if the load-bearing surface is smooth and does not have significant flaws. This situation often occurs in new buildings. Therefore, if possible, use the PPS gluing technology. It is much simpler and more convenient than the glueless installation method.

Facade insulation, diagram

Step-by-step installation of foam plastic

Stages of façade insulation with polystyrene foam using the adhesive method

Step 1. Dust removal and strengthening of the base.

This is done by applying a deep penetration primer using a brush or roller.

Step 2. Marking and fastening the base profile.

Fastening the plinth profile

Option for fastening profile corners at 45 degrees using a plate and self-tapping screws

The base profile is attached to the bottom of the walls along the entire perimeter of the building. It will act as a support for the foam boards.

Step 3. Preparation of the adhesive composition.

Use dry adhesive mixtures. Experts recommend simultaneously purchasing reinforcing compounds from the same manufacturer. They (compositions) are applied to a mesh reinforced over PPS, which is necessary if plastering of the facade or other type of finishing is planned, the installation of which requires a cement-sand mortar.

The following adhesive mixtures can be used: Cerisit CT83, Kreisel 210, Master Termol, SOUDATHERM, Bitumast.

Cerisit CT83

Kreisel 210 Adhesive for polystyrene foam boards

Foam adhesive for expanded polystyrene and polystyrene foam “Soudal” Soudatherm

Step 4. Applying the solution to EPS boards.

Applying glue to foam plastic

Leveling the glue with a spatula

The solution is applied in two ways: along the perimeter of the canvas and in its middle, at 5 points (in the corners and in the middle). The thickness of the layer depends on the type of glue. On average, it is 0.5-1 cm.

Example of applying adhesive foam

Step 5 . Gluing slabs.

Bonding boards

The PPS sheet is installed on the base profile and pressed against the wall. Hold in this position for several seconds (refer to the adhesive mixture manufacturer's instructions). Excess glue is removed with a spatula.

The sheets are fixed with dowel mushrooms.

Laying foam for insulation

Secure the foam boards with dowel mushrooms

Hammering a nail into a dowel

Seal the seams between the plates with foam

Step 6. Applying adhesive and gluing the reinforcing mesh.

Reinforcing mesh for foam plaster. Photo

Attach the mesh and cut off the excess

Step 7 . Applying a reinforcing solution to the mesh. Leveling the solution.

Applying plaster

Plastering on foam plastic

Plastered surface

Step 8. Applying finishing primer.

Glue-free technology for insulating facades with foam plastic involves fastening PPS boards to dowel-nails with a wide head (umbrella).

The mushrooms should be approximately twice as long as the thickness of the foam.

The work technique is as follows:

- Through the slab laid on the base profile, holes are drilled in the wall. Fasteners are made at 5 points: in the middle and corners of the sheet;

- drive in dowel nails.

Using a hammer drill, we drill a hole a little deeper than the length of the fungus, insert it and hammer in a plastic nail, so that the entire fungus sinks a little into the foam.

Installation of dowel-umbrella for facade insulation

Otherwise, all stages of the foam installation work are similar. If a ventilated facade is being installed, reinforcement of the slabs is not required. In this case, a frame of wooden bars or a metal profile is built on top of the insulation.

Prices for Ceresit glue

Ceresit glue

Video - Fire safety of polystyrene foam

Thickness

Foam thickness is a parameter that should be chosen based on an individual set of factors: wall thickness, wall material, climatic conditions, etc. That is why it is impossible to say that a 5 cm thick layer of polystyrene foam is suitable for absolutely everyone, although this is the material most often used for insulating apartment buildings in the temperate zone.

Everyone will be able to calculate the required insulation thickness using the tables below. So, let's say you live in a house whose walls consist of two rows of bricks. The heat transfer resistance will be 0.405 m²*°C/W. Considering that the thickness of the walls is 54 cm. At the same time, the standard value, for example, for Moscow is 3.16 m2*0C/W, the difference is 2.755 m2*C/W, and this is exactly what needs to be compensated for with insulation, the thermal conductivity coefficient of which in our case is 0.031 W /m*°С. It turns out that the thickness of the insulation will be equal to 0.031 * 2.755 = 0.085 m, which is 8.5 cm.

What is better to insulate with mineral wool?

- For wooden houses you don’t have to choose which is better - polystyrene foam or mineral wool. “Breathing” wooden walls cannot be insulated with foam plastic - this will negate their beneficial properties. Therefore, they are insulated with mineral wool. And in buildings built from other materials, partitions, floors, ceilings, and ceilings are sheathed with mineral wool. If external walls are insulated, then a ventilated façade of a suspended type is made. Vapor barrier membranes are an integral part of this design.

- Mineral wool is used to insulate attics, attics and floors of houses, and pitched roofs. At the same time, be sure to leave space for ventilation.

- Brick houses with a small number of floors, in which the middle thermal insulation layer is mineral wool. It is also used for three-layer panels made of concrete, reinforced concrete, as well as sandwich panels in a metal shell.

- They are used in places where it is necessary to provide good protection from very hot objects, since basalt wool can withstand temperatures up to 1000 0C.

- Frame buildings of any type are best insulated with mineral wool. In addition, it is also used for sound insulation. Moreover, this material is well suited for horizontal, vertical, and curved surfaces.

- Mineral fiber wool, produced in the form of soft slabs, can be used to wrap heat, water and gas pipes. It is also used to insulate industrial equipment in enterprises.

Features of the heat insulator

The production of penoplex for wall insulation includes the following technological operations:

- Granules of the material are loaded into an extruder, where they are heated to 130-140°C;

- Foaming agents – porophores – are added to the portion;

- The thickened mass is squeezed out of the extruder onto a conveyor belt, after which it is cut into dimensional slabs;

The mixture of semi-finished penoplex for external wall insulation consists not only of polystyrene foam and foaming agents - it also contains antioxidants designed to prevent thermal oxidation during processing and damage to the integrity of the insulation during operation, fire retardants to increase fire resistance, as well as antistatic, light-stabilizing and modifying additives that protect thermal insulation material from the influence of external factors.

The main positive parameters of the material:

- Low moisture absorption of expanded polystyrene is the main advantage;

- The minimum coefficient of thermal conductivity, which allows, when calculating the thickness, to choose thin slabs;

- High vapor permeability of penoplex: a 20 mm thick slab replaces one layer of roofing material, but at the same time also insulates the working surface;

- High compressive strength and other mechanical loads. The extrusion method in the production of thermal insulation allows the cells of the material to be evenly distributed, improving the quality of density and strength;

- Easy and quick installation of insulation due to its low weight and good density;

- Long service life of extruded foam – up to 50 years;

- Excellent sound insulation and minimal chemical activity.

Penoplex size range:

- Slab length – from 120 to 240 cm;

- Slab width – 60 cm;

- Thickness – from 2.0 to 12.0 cm.

Disadvantages of extruded foam:

- Flammability of groups G3-G4, formation of toxic smoke during fire;

- Polymer additives in the composition of the material can evaporate toxic substances when exposed to sunlight. Therefore, the optimal use of penoplex is external, for example, insulation of brickwork;

- Petroleum products and some organic substances can deform penoplex, the thickness of which can be any. These are substances such as: formaldehyde and formalin, acetone and methyl ethyl ketone; liquids containing ethyl, benzene components, polyester resins, synthetic paints and fuels and lubricants.

Thermal conductivity properties determine the quality of penoplex insulation. The higher the thermal conductivity coefficient, the fewer centimeters the layer of insulating material will be. Laying the insulator from the inside or outside depends on the characteristics of vapor permeability and strength (density). You can compare the parameters of popular materials for insulating floors and other surfaces by studying the data in the table:

From the table it is clear that foam plastic thermal insulation has an average thermal conductivity value, which is slightly less than that of polyurethane foam, mastics and roll materials. But you can choose penoplex only because the layer of such liquid insulation does not have joints and seams, like slab insulation, no matter how many layers are applied to the surface.

How to fix a faucet with a cartridge

Most often, faucets with one lever are installed in the bathroom or kitchen. They are also called flag or single-lever. A special device, a cartridge, is responsible for opening/closing the water in it, which is why they are also called cartridge ones.

There are two plates with holes inside the cartridge. The lower one is fixed rigidly, and the upper one is movable. A rod is attached to it, and it, in turn, is attached to the handle. By turning the handle, we move the rod, and it moves the movable plate, which opens/closes the water and changes its pressure.

If there are problems with such a faucet, it can only be repaired by replacing the cartridge. The main problem with them is that they start to leak - water oozes or drips from under the handle. To repair a leaking or dripping cartridge faucet, you need to replace the cartridge. The only way.

Replacing the cartridge

The first step is to turn off the water, then remove the handle. To do this, first remove the colored plug - it covers the screw. After unscrewing the screw, pull the handle up, separating it from the stem. After the handle is removed, unscrew the pressure ring - it holds the cartridge. Now all that remains is to take it out.

Then, along with the cartridge, you need to go to the store or market and buy exactly the same one. The new one must match in size, the holes in its lower part must have the same shape and location. Basically, you need to find an exact copy.

How to disassemble a faucet with a cartridge

Assembly occurs in reverse order:

- place the cartridge (strictly vertically, twisting it a little around its axis so that the protrusions in the body fit into the recesses on the cartridge),

- tighten the clamping nut;

- install the handle;

- screw in the fixing screw;

- insert the plug.

An initial check can be done after the pressure ring has been installed. You can turn on the water and check if the tap is now flowing.

If the water flow becomes too weak

Most modern faucets are equipped with a mesh on the spout that traps solid particles that may be contained in the water supply. If the stream of water gradually becomes less elastic, and the pressure on other taps does not change, the reason is that this very mesh is clogged. In this case, you can fix the faucet in a couple of minutes.

Need to clean the mesh

Unscrew the nut with the mesh, which is located at the end of the spout. Rinse it, clean out clogged holes (you can use a needle or an old toothbrush). Place the cleaned mesh in place.