Do you want to get cozy and warm housing, the temperature in which does not depend on the vagaries of the weather? Then you should insulate the walls outside with polystyrene foam. Don't know where to start and how to get started with this work? In this case, study this article - it will give you answers to your questions.

Insulation of external walls with foam plastic

Overview of the material

Before insulating a house with polystyrene foam, you need to find out which material is suitable for which structures. EPS is supplied to the trading floors of the construction market in the form of slabs of different densities and in bulk. Each option belongs to the group of polymers with a foamed structure.

The table presents a number of basic technical characteristics characteristic of the group of foam materials for home insulation.

| Parameter | Meaning | What is important for a builder |

| Density | 15-40 kg/cub.m | The low weight of a cubic meter of insulation is considered one of the main advantages. This is justified by the relatively insignificant load of the material on the load-bearing structures of the building, which practically does not limit the scope of application of PPS. |

| Thermal conductivity | 0.038-0.042 W/m*K | The values are close to the average compared to thermal insulation products, which are often used in construction. |

| Water absorption | 0,02 | Extruded polystyrene foam has an indicator as close as possible to zero. This justifies the use of the material as an independent and additional waterproofing layer. |

| Vapor permeability | 0,05 | A low coefficient indicates poor breathability of PPP. This property is important to take into account especially during interior work, as it affects the microclimate in the room. |

| Working temperature | -50-+75 degrees Celsius | Foams are synthetic in nature, so when heated they can release toxic substances. Therefore, insulation is rarely used indoors with high thermometer readings. |

| Operational period | 60 years (outside 20 to 40 years) | The time period can be reduced if the rules for installation and operation of materials are not followed. |

Extruded foam Source myremontnow.ru

Experts recommend paying attention to the chemical composition before purchasing polystyrene foam for insulation. It is desirable that it contains fire retardant additives and non-flammable carbon dioxide. This is justified by the fact that PPS is unstable to open fire. When purposefully igniting foam plastic, the effect of fire retardants may not be noticed, but in general, thanks to them, the fire takes longer.

The advantages of the material, in addition to good thermal insulation properties and water resistance, include noise absorption and inertness to corrosion and biological activity. Foam boards and granules are often used to improve the acoustic environment in a building. The material is also easy to cut, which is important for installation work. But it is worth considering that foamed polystyrene can crumble and cannot withstand mechanical load and is deformed.

PPP and dew point

Insulation tends to shift the dew point outward. Let's consider three design options without insulation and with insulation with polystyrene foam. In the absence of finishing, the walls are the only material that is located between spaces of different temperatures. Due to changes in thermometer readings, the following occurs:

- heat loss;

- condensation indoors;

- the operational life of the monolith or log house is reduced.

If the dew point in a log house without finishing is poorly calculated, then there is a possibility of condensation Source remontnik.ru

See also: Catalog of companies that specialize in insulating houses

When insulating walls internally, the dew point shifts towards the contact between the base and the PPS. Heat leakage is significantly reduced, but the issue of dampness remains. Because of this, there is an increased risk of the appearance and spread of mold, mildew, and bacteria.

The optimal solution is to insulate external walls with polystyrene foam. In this case, the dew point is closer to the surface on the front side of the structures. As a result, the risks of heat loss and condensation accumulation are minimized.

What do you need for work?

Before proceeding with the installation of foam plastic, the necessary materials and tools are purchased and prepared.

Materials:

- Styrofoam;

- Adhesive composition suitable for the material;

- Polyurethane foam;

- Dowels;

- Primer and plaster;

- Construction mesh for reinforcement;

- Starting bar.

Tools:

- Drill (it’s good if you have a mixer attachment);

- Notched trowel for applying adhesive;

- Regular spatulas;

- Construction knife;

- Container for diluting glue;

- Roulette;

- Level;

- Drill;

- Graters with teeth of various sizes.

It is important to purchase the “correct” polystyrene foam to insulate walls. To do this, its density should be about 25 kg per cubic meter

The thickness of the slabs should be at least 8 cm, most often 10 is used.

You can attach the foam with glue or dowels. But as practice shows, both are better. The pasted sheets are fixed in several places with nails for greater strength.

If desired, a starting profile profile is installed at the bottom of the wall, which serves to secure the position of the sheets and prevents them from sliding during installation. It also prevents damage to the foam by rodents, so if there is a problem with uninvited guests visiting, then it is better to use it.

External insulation technology

You can insulate walls with foam plastic on your own, since the technology for installing lightweight insulation is simple and does not require special skills or tools. However, before starting work, it is important to learn about the features that are associated with facades, internal walls and openings for windows and doors. There are also some nuances in subsequent finishing.

Preparatory stage

Any installation and repair work begins with preparing the base. It must be clean, “healthy” and, in the case of slab foam, even. The procedure at this stage looks like this:

- removal of old decorative coating;

- removing weak elements;

Peeling pieces of plaster must be removed Source krysha-expert.ru

- bridging cracks;

- “treatment” of affected areas (mold, mildew, rust) followed by prevention;

- priming of defects and repairs;

- treating the working surface with a primer;

- leveling the walls (differences of up to 1 cm per linear meter are acceptable) and forming corners.

Before insulating the facade with polystyrene foam, it is recommended to impregnate the dry and even base twice with a primer. In this case, for the second layer it is permissible to dilute the primer with water. The main thing is not to exceed 10%, so as not to reduce the quality of the original product.

Installation work

As a rule, to insulate vertical structures, craftsmen use a slab version of PPS. There is no need for lathing here, but the fastening must be combined. That is, first a special adhesive solution is applied and the position of the canvases is adjusted to create an even plane. To prevent the insulation from slipping, you must first secure a support strip under the first row. This can be a beam or a metal profile. If you lay the first row unevenly, then subsequently all the joints will turn out to be uneven.

Then, after the composition has hardened (after about three days), additional fixation is carried out with plastic dowels (“umbrellas” or “fungi”) with a wide cap.

Special dowels for insulation Source allegroimg.com

Preparing the wall surface

In order for the thermal insulation to be of high quality and last a long time, the surface to be insulated must be well prepared. This process is quite lengthy, and you will have to put in a lot of effort. But the result is worth the effort and time spent.

If you are insulating a new house, then you do not need to do some things.

#1. The first step is to remove everything from the external walls that could interfere with the work. These are drainpipes, ventilation grilles, air conditioners, spotlights and wires. If the brick house is old enough, then on its facade there may be decorations framing the cornices and windows. They will have to be sacrificed by carefully knocking them down.

#2. If there is plaster on the walls, we will check its strength by tapping the surface. We check all unevenness and slopes using a plumb line, rule or cord of sufficient length. We will mark all errors with chalk so as not to miss a single flaw. As a rule, upon inspection it turns out that the walls are far from ideal. Not only are they not very even, but in some places the plaster is held to its word of honor.

Do not undertake insulation if you discover these shortcomings. First, remove these pieces of plaster, and then work with a chisel, knocking down the concrete beads and excess mortar between the bricks.

#3. If the façade has been painted with oil paint, it cannot remain on it. In this case, you will have to peel off the paint. Because of this, the adhesive properties of the surface are reduced. Well, perhaps everyone knows that it is necessary to remove mold, grease and rust, as well as salt deposits.

#4. If there are large enough unevenness and cracks on the walls (more than 2 millimeters), then they must be primed. To do this, use a deep penetration primer using a special brush called a paint brush. It will allow you to do this work faster and more accurately. When the primer has dried well, you can apply cement putty for exterior use and fill the cracks.

#5. In the case where the unevenness is very large - more than 1.5 centimeters - we also prime them first. And then we put up beacons along which we apply the plaster composition.

#6. The walls are covered with a brick primer once, with cellular concrete 2 times. You can apply it with a large brush or roller.

Sometimes part of the communications is left on the surface of the wall, covering them with insulation. In order not to damage them when driving in dowels for fastening polystyrene foam, you need to draw up a detailed plan for their location.

PPS or EPPS

The starting raw material for the materials is polystyrene. The final product can vary greatly in density, hardness and structure. This is explained by the plate production technology:

- Foaming . Expanded polystyrene is characterized by lower weight due to the high air content in the pores and granules. The advantage is the low price, the disadvantage is that it retains heat worse with the same thickness of the slab.

- Extrusion . EPPS has less moisture-absorbing ability and higher density, strength and hardness. With identical sheet thickness, the thermal conductivity is lower. Against the background of the advantages, only one disadvantage stands out in the group of materials - high cost.

Craftsmen also note the low adhesion of extruded insulation due to the dense and smooth surface. To improve the situation, the boards are passed with a float or a needle roller (with metal spikes) to bend the drywall. Also, such products are characterized by a stepped shape of the mounting edges. This is a practical approach from manufacturers, thanks to which there are no cold bridges and the joints between individual sheets are strengthened.

Production line for extruded polystyrene foam Source ros-tenders.ru

Where can I use it?

A universal material that can be used to insulate any surface:

- Roofs and walls.

- Floor and plinth.

- Industrial buildings and residential buildings.

This is one of the simplest methods of insulation, which is why many people use foam plastic. The house will become comfortable and warm, and the insulation itself is very reliable. The installation work itself and the material are inexpensive, so if you wish, you can hire a team of workers for these purposes.

To insulate walls, foam sheets are more often used, and crumbs or balls are used for the roof. The floor and base are often insulated with extruded polystyrene foam.

Briefly about the main thing

Foam plastic is actively used as insulation for walls due to its lightness, low thermal conductivity and relatively low cost.

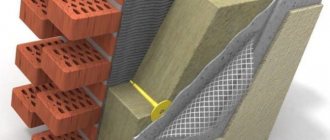

The technology for installing PPS and EPS boards includes preliminary leveling of the working base, gluing the sheets and then fixing them on special dowels. If necessary, the joints are filled with low-expansion polyurethane foam.

It is considered more practical to use two-layer insulation with overlapping seams of the previous one. The slabs are shifted to the side in a row.

Before painting, it is enough to prime the finished coating after filling the voids and recesses from the fasteners.

Before plastering and cladding, polystyrene foam is reinforced with fiberglass mesh, which is attached to a special adhesive for polymer materials.

The ventilation facade is made with a layer of waterproofing membrane.

Ratings 0

We attach the starting profile

Having studied the project, we calculate the location of the lower border of the walls, which should be insulated with foam plastic. Now we take a hydraulic level, measuring this boundary at all external and internal corners of the house. We pull the cord along these points. It is along this line that we have to install the starting profile on which the bottom row of slabs of heat-insulating material will be supported. Otherwise, until the glue dries, the slabs may move.

We select the size of the starting strip according to the width of our heat insulator. We fasten it with six-millimeter dowel nails, placing them every 30 or 35 centimeters. The expansion element for the dowels is driven nails, onto which washers should be placed. The joints of the starting strip at the corners of the house are made either with an oblique cut or using a corner connector.

To prevent temperature fluctuations from deforming the structure, we place plastic connecting elements at the ends between the base profiles. Overlapping profiles are not permitted.

To be on the safe side, check the level of fastening of the starting profile.

The optimal way to attach insulation to the wall from inside the house

The most convenient and less expensive method of fastening is fastening with glue. The possibility of abandoning the mechanical method was discussed above - small areas and the absence of unfavorable climatic factors.

This work can be carried out in several steps over two days:

Preparing the wall surface. The quality of the entire work depends on the basis on which the insulating material rests. The quality of surface preparation determines how firmly the foam will stick to the wall and how much glue will be needed to attach the sheets.

The wall must be carefully leveled and primed. The surface of the foam, on the contrary, should be rough for better adhesion to the glue. Selection of the optimal glue for attaching sheets of foam to the wall. Dry glue mixture or polyurethane foam glue?

It all depends on the skills at work. It takes much more time to properly prepare glue from a dry mixture, and the quality and consistency of the glue must be constantly monitored. Laying insulation sheets using polyurethane foam is faster and the adhesion is better.

But the complexity of preparing glue and the long duration of the work itself are compensated by the absence of errors with little experience in this field. Foam dries faster and requires experience and skill from the master. An important factor is that polyurethane glue in cylinders is much more expensive, and the quality of adhesion for glue made from a dry mixture is not much lower.

The glue is applied to the foam sheet using a notched trowel evenly over the entire surface in a layer of about 1 cm.

The sheets are glued to the wall starting from the bottom to avoid slipping while the glue dries. It is advisable to arrange the foam sheets in a checkerboard pattern, as when laying bricks. This way the whole structure will be more stable.

Gaps should be minimal. If foam is used, glue is applied around the perimeter of the sheet at a short distance from the edge and in the center. After gluing, the gaps between the sheets are filled with the same glue and puttied.

After the glue has dried, mastic is applied to the insulation and a reinforcing mesh is laid on it. The mesh should be recessed in a layer of mastic, this will give greater stability to the entire structure and will facilitate further work on the wall. The use of mastic and reinforcing mesh further strengthens the entire structure on the wall.

Plastering does not relate to the process of attaching polystyrene foam to the wall, but this is the logical completeness of the entire process. For all the work you will need: The polystyrene foam sheets themselves of the required area. A dry adhesive mixture at the rate of 3 kg per 1 m2 of wall area. 1 bag contains 25 kg of dry mixture. If you decide to use foam, 1 bottle replaces one bag of dry glue. Reinforcing mesh, mastic (consumption of the finished mixture is 2-3 kg per 1 m2). Spatula, trowel, level and a classic set of home craftsman tools (hammer, screwdriver, knife, ruler , compass, masking tape). An electric drill, if you are planning to fasten with dowels. The use of polystyrene foam for home insulation has its supporters and opponents.

Modern developments of this material make it possible to use it for residential premises without fear of adverse effects on health. Lightness, environmental friendliness and fire safety in addition to ease of installation make this material very competitive in construction and repair. Ivan Publitorov Insulating a house is an important issue for its owner. One of the most popular materials used for insulation and additional sound insulation is polystyrene foam. It is reliable and effective, does not put additional load on the walls. If the decision is made to use it, then the home owner is faced with the question of how to attach the foam to the wall, what kind of fastening to use in order to get a reliable, strong structure.

Foam plastic and penoplex are the most popular materials for insulation and sound insulation of house walls, because... they are practical and inexpensive.

Common mistakes

When installing extruded polystyrene foam with your own hands, frequent mistakes are made. Knowing about them, you can avoid repetition of ridiculous situations. Below are the most common:

- The surface of the walls is not completely leveled. Therefore, the slab lies unevenly;

- The glue is applied to the center of the slab, the corners will bend outward over time;

- Plaster without a reinforcing mesh will lead to cracking of the surface;

- Poor insulation of the seams between the plates will lead to the formation of cold bridges;

- There is an opinion that the thermal insulation of a house made of aerated concrete will lead to the disruption of the vapor barrier of the premises and the possible formation of mold.

Only correct and competent installation of insulation in compliance with many conventions can benefit both the person and the entire building. This should be remembered!

Which polystyrene foam should I choose for external thermal insulation?

types of foam are currently produced :

- PBS-S-15. It has the lowest density and is used on secondary objects.

- PBS-S-25. The most used material has optimal characteristics and price.

- PBS-S-35. Material used for insulation and waterproofing of underground structures - foundations, plinths.

- PBS-S-50. The densest type used at critical facilities with difficult operating conditions.

IMPORTANT!

The declared density of the material often does not correspond to the actual one , therefore, when purchasing material, it is better to play it safe and buy a denser one.

In addition, there are modified foam samples - for example, extruded polystyrene foam (EPS). It has higher strength and does not crumble. At the same time, it is flammable and has lower vapor permeability than conventional foam. In addition, it is more expensive, which somewhat limits its scope of application.

Corner Facade Decorative Pilasters

Finishing the corners of the facade of a house with foam plastic is one of the most important components of the overall decor of external walls. Corner pilasters are a classic, effective technique to significantly transform the overall appearance of the facade of a house.

Unlike barefoot pilasters, they have a solid, continuous shape, which visually increases the height of the building. The classic pilaster includes a rectangular element with slots - flutes along the entire length of the architectural element. The upper part is completed with a shaped element with a 45º cut from any appropriate profile.

Classic corner pilaster – Exterior decoration of house corners

The finishing of the corners of the facade with classical pilasters is made by two elements - the body of the pilasters. With a required width of 50 cm, decorative elements No. 1860 and No. 1865 are used. As you can see, one element has a width of 50 cm, and the other 45 cm. The difference in the dimensions of the body of the pilasters is due to the ease of installation and the thickness of the elements themselves. We offer two common pilaster width sizes: 50 cm and 31 cm.

- vapor-tight;

- low sound insulation index;

- breaks down at high temperature (800C);

- is destroyed upon contact with organic solvents;

- not suitable for insulating multi-storey buildings.

Advantages and disadvantages of expanded polystyrene

The polystyrene foam material is a porous, air-containing raw material , used in most cases as a heat-insulating material.

In industry, the material can also be used as electrical insulating and packaging material.

The material has become widely used due to its quality indicators:

- low level of water absorption;

- low thermal conductivity;

- ease;

- biological stability;

- durability;

- compressive strength;

- not affected by temperatures;

- ease of installation;

- low price of material.

Comparison of insulation materials

Despite the impressive list of positive indicators, polystyrene foam has disadvantages that must be taken into account during installation:

- low sound insulation;

- instability to solvents and many chemicals;

- afraid of fire. When burned, it releases harmful toxic substances;

- poor resistance to ultraviolet radiation;

- easily susceptible to the influence of rodents and insects, which, by making holes in the material, provoke its destruction;

- low vapor permeability;

- fragility.

IMPORTANT!

Expanded polystyrene is sometimes compared in terms of characteristics and external indicators with another similar material - polystyrene foam.

However, the production technology of these materials is different : polystyrene foam is produced by extrusion, when the granules melt when combined into a single structure, polystyrene foam is produced by gluing granules with dry steam.

Specifications

Decorating a house with polystyrene foam: covering the ceiling and corners, using the material as a decorative element

Construction foam is a universal material. It is used as insulation, cladding, and products made from it play the role of decorative elements. At the same time, the price of such products is low, and any of us can purchase them.

Foamed plastic is an inexpensive and versatile material.

Ceiling tiles

Foam tiles on the ceiling.

Foam boards will be a good solution for inexpensive and aesthetically pleasing ceiling finishing. If they are glued without seams, the coating will look like a tension analogue.

Finishing the ceiling with foam tiles has a number of advantages.

- The coating is not afraid of prolonged exposure to moisture. Based on this, it can be installed in damp areas - in the kitchen, toilet, bathroom.

- Possibility of spot replacement or repair. If one or more slabs come off, you can always glue them back.

- This type of cladding is usually done on your own, because... its installation is simple, and the slabs are easy to process and cut.

- The cost of the material is low.

- The coating is easy to care for - it only needs to be wiped with a damp cloth from time to time.

Gluing the material is very simple.

Note! The instructions prohibit cleaning the finish with compounds containing solvents or gasoline. Polystyrene foam is not resistant to such substances.

- Ceiling tiles made of this material weigh almost nothing. Therefore, they do not create loads on the floors.

However, polystyrene foam also has some disadvantages.

- It is not resistant to thermal influences. Therefore, it is not recommended to install tiles close to incandescent lamps or lighting fixtures in which the bulbs point upward. The distance between them and the coating should be at least 20 cm.

- Foam cladding is easy to damage. However, in the case of a ceiling this is unlikely to happen.

- When exposed to direct sunlight, the material fades and turns yellow over time.

Installation followed by plastering (wet facade)

This method of thermal insulation of a wall outside a room is the simplest and most “low-cost” in financial terms. Insulation is carried out with expanded polystyrene, fixation in the same way as when facing with siding - fungi - umbrellas. The difference is that in this case the installation of a sub-cladding system is not required, and the insulation is additionally fixed with an adhesive mixture. This allows you to firmly fix it to the surface.

Having secured the thermal insulation over the entire required area and reinforced it with mesh, you can begin cladding the facade. This is done in three ways:

- Decorative facade plaster;

- Painting with water dispersion paint;

- Decorative plaster followed by painting the facade.

Mounting methods

In order for the insulation to fulfill its intended purpose, it must be properly secured to the base. Professional craftsmen use several methods to attach foam:

For the adhesive composition.

This option is suitable if the insulation will not be used as a basis for heavy finishing material. Using fasteners. A more reliable method, but also suitable for spruce on foam plastic, it is planned to install heavy decorative trim. A combination of the first and second options. The use of glue and dowels allows for the most reliable fixation.

But before you start installing polystyrene foam, you must prepare the base and all the necessary materials.