Considering the level of real estate prices and its continuous growth, the construction of a frame house looks like a completely budgetary and realistic undertaking. In addition, anyone, even if they have not held anything heavier than a mouse in their hands, can do some of the work themselves. However, when building a house, you need to study many issues, including how to more effectively insulate it. In this article, the editors of Yanashl have prepared a review of the best insulation materials for 2022.

What you need to know

The insulation material should be chosen before construction begins. Selection errors, like savings, can be very costly. For a frame house, this is, in fact, the only barrier from the cold.

It is worth noting that more than half of such houses in our country are insulated with mineral wool or other materials based on it. Therefore, in our review we will mainly consider such insulation materials.

Mineral wool, first of all, is a convenient material, it is easy to transport, convenient to supply to a construction site and store, not to mention installation. It bends and cuts with any knife. In addition, it is a fairly environmentally friendly, lightweight and resistant to rotting and pests material.

Reasons for the popularity of mineral wool

Insulating a frame house with mineral wool is often chosen. The popularity of the material can be explained by several reasons:

- Mineral wool is endowed with high levels of noise and vapor barrier;

- Has excellent thermal conductivity;

- It is considered a non-flammable and environmentally friendly material;

- Has an ideal water absorption rate;

- Eliminates the formation of condensation.

The material cannot be called cheap. But by choosing it, the user has the opportunity to save on the purchase of a vapor barrier film or specially designed membrane materials.

What materials are used for wall insulation?

Today there is a huge range of insulation products on sale. If you are building a frame house made of wood, it is important for you to know about the vapor permeability coefficient (VP) of the insulation. This indicator will help you choose the most suitable material for you from the whole variety. The main criterion here is to choose an insulation whose vapor permeability is not lower than the wood used for the frame.

For the construction of frame houses in our country, softwood is mainly used, and its CP can be found in the table below:

| Material | KP |

| mg/(m h Pa) | |

| Extruded polystyrene foam | 0.013 |

| Polyurethane foam | 0.05 |

| Styrofoam | 0.23 |

| Expanded clay | 0.21 |

| Pine and spruce across the grain. | 0.32 |

| Ecowool | 0.32 |

| Mineral wool density 200 | 0.49 |

| Mineral wool density 50 | 0.6 |

| Reinforced concrete with a density of 2500 kg/m3. | 0.03 |

The table shows that it is better not to use some materials for insulation at all; their CP is much lower than wood, and the most suitable for this are mineral wool and ecowool.

Various compositions are used to produce mineral wool. Depending on the type of composition, its types are distinguished:

- Stone or basalt - created mainly from rocks. This type is distinguished by durability (does not lose its properties for more than 50 years), heat resistance (withstands heating of more than 1000 degrees). The insulation practically does not shrink and does not lose its geometric dimensions during the entire service period, and accordingly, cold bridges will not form in the walls. Another advantage of this cotton wool is its hydrophobicity. Water-repellent properties appear thanks to special additives. They do not allow moisture to penetrate inside the insulation and do not accumulate condensation. This insulation is produced in the form of slabs, which is very convenient for frame construction. The optimal density is considered to be 35 – 50 kg/m. Also, do not forget that when laying the slab should be 3-4 cm wider than the frame, this will avoid unnecessary gaps.

- Glass - created on the basis of fiberglass. Its properties are similar to stone, but it is made from the same materials that are used in glass production. The release form also differs; it is produced mainly in the form of rolls of different sizes. This material is often opposed by the fact that during installation it produces a lot of glass dust and it is necessary to work with it only in a respirator. This also repels potential buyers. However, in practice, if installed correctly and all certification conditions are met, glass wool is absolutely safe and does not pose a health risk. Due to its lightness and springy fibers, the material holds well in the frame. For denser installation, the material is cut into strips 15-20 cm wider.

- Slag insulation is now quite rarely found on a construction site. This is a cheap but short-lived material. Formed during the processing of blast furnace waste. Fragile, brittle and not environmentally friendly, a possible area of application is filling the foundations of courtyard buildings and sewers.

- Ecowool is the most modern of the materials presented. It is produced on the basis of cellulose with special additives that protect it from rotting and parasites. Superior to mineral wool in sound absorption (more than 2 times). Resistant to high temperatures, does not emit toxic substances when ignited. Recently, it has been increasingly used for insulation of residential and non-residential premises. The material does not get wet and prevents condensation. However, there are also disadvantages. The first and main one is that today it is one of the most expensive insulation materials, and also requires additional equipment during installation.

It is worth mentioning that there are three options for installing ecowool:

- Dry – using special equipment, dry material is blown into prepared areas using air, these can be attics, interfloor ceilings, as well as the internal surfaces of roofs and floors.

- Wet – material mixed with water is sprayed onto the walls. When dry, a dense layer is obtained, which can be sewn up with finishing and decorative elements. At the same time, the cotton wool does not shrink in any way and does not generate dust during installation.

- Adhesive - used when you need to insulate the inner surface of a metal or reinforced concrete wall. The glue increases adhesion, and due to the fact that a fairly dense composition is obtained, it does not require additional covering.

Independent production of thermal protection

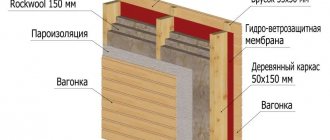

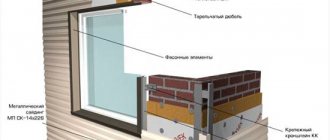

Insulating a frame house with mineral wool, namely its step-by-step scheme, will necessarily require the installation of a protective layer from moisture - waterproofing. This is necessary in order to prevent double-sided locking of moisture. Due to its removal to the outside, the walls will get wet and deteriorate.

Waterproofing

The first step will be measuring the dimensions of the surface and cutting the waterproofing material. The material is secured to the posts with a construction stapler. In this case, you need to ensure that the fastening strength is maximum, the frame is completely sheathed around the perimeter. The material should be laid using the overlapping method, the layers should overlap each other by approximately 10 cm.

Vapor barrier

This scope of work is absolutely necessary if hydrophobic materials or those that neutrally tolerate any contact with moisture are used for thermal protection. In addition to them, the so-called cake may also consist of other materials that are more sensitive to getting wet. It would be correct to choose (for internal and external thermal protection) foamed polyethylene or a special film. They are also attached to the racks, this will ensure a good seal to the insulation.

Important note! Wrapping heat insulation blocks in film is a gross violation of the standard method of arranging thermal protection. Until all areas of the frame, without exception, are covered from getting wet, the work cannot be considered complete.

Only after this will it be possible to safely begin work on laying the filler, strictly observing safety regulations.

Stitching

This is the final stage of thermal protection production. For internal surfaces, plasterboard sheets and particle boards remain unrivaled. GCR is best used in cases where the frame is perfectly flat. OSB, due to its rigidity, can be used in the presence of small irregularities. Then you can do the finishing touches.

What to choose

All the described materials have their advantages and disadvantages, however, when choosing, it is also necessary to take into account the characteristics of the insulated room. Complexity of installation, availability of appropriate qualified workers. Under no circumstances should you violate the technology for laying this or that material, as this can lead to a lack of heat in your home, and identifying and eliminating such defects may require much greater resources.

If your choice is between basalt blocks and ecowool, take into account the availability of qualified installers with special equipment; if you don’t find them, it’s better to use a simpler material - basalt blocks.

Vapor barrier as an important component of an insulated structure

Without taking into account the finishing - from the facade and interior (internal) - the wall of an insulated frame house consists of 5 layers. 3 of them have already been mentioned - insulation and cladding on the outside and inside. Other required layers: waterproofing - laid between the insulation and the outer (street side) cladding, vapor barrier - located between the cladding on the interior side and a layer of cotton wool. The main function of the waterproofing layer is to prevent sedimentary moisture and strong external winds.

The vapor barrier membrane has a special purpose. This two-layer non-woven material prevents vapors from warm living spaces from entering the laid insulation material. As a result, condensation does not form and the heat insulator continues to perform its function without loss of properties or changes in geometry. Also, load-bearing structures do not suffer from condensation, the service life of which is definitely increased.

Scheme of operation of a vapor barrier membrane

Important! The vapor barrier material must be correctly oriented during installation, making sure to read the manufacturer’s instructions.

The membrane works on the principle: the first fleecy layer absorbs moisture vapor and evaporates it; the second (water- and vapor-tight) – prevents moisture from reaching the insulating layer.

More details about vapor barrier in the video:

Wind and steam protection

No matter how hard insulation manufacturers try to endow their products with hydrophobic properties, no one will be able to get away from condensation, temperature changes, weather phenomena and other sources of dampness. To minimize the negative impact of dampness on heat-saving material, vapor barrier and wind protection are used.

Vapor barrier is used to protect against moisture and vapors coming from inside. The effectiveness of the entire insulation largely depends on the quality and correct installation of this shelter.

External protection is also important. Although it does not look impressive in appearance, all these materials together give the desired result.

The final choice of insulation will remain with the owner of the house, and in order not to be disappointed in the result obtained, it is worth studying all the main characteristics of the best insulation materials on the market. The right material will make your home warm and energy efficient.

Features of floor insulation

The specifics of floor insulation in a frame house are determined by the type of base. Many structures are built on a pile-screw foundation.

If the building is at a height and you can climb under the base, then a waterproofing film is secured under the logs, and then the lower cladding boards are installed. They are nailed closely or in increments of 40 cm. Such material will keep the mineral wool boards and waterproofing film from falling down.

The thickness of the floor insulation should be 15 cm.

If getting into this part is problematic, then boards are attached under the joists, and then a waterproofing film is installed.

The optimal insulation thickness is 15 cm. Each successive layer of slabs overlaps the joints and has an overlap of 20 cm.

A vapor barrier is installed on top of the insulator and the log, which is fixed with 2-sided tape. Plywood sheets, OSB boards or boards are laid on the wall, which are used as a basis for finishing.

Rating of the best insulation for frame houses for 2022

HeatKnauf for cottage

Dimensions: 1230*610*50 mm, 16 slabs per package, packaging is designed for an area of 9 m2.

It is produced in the form of slabs with a thickness of 50 and 100 mm, which allows you to most conveniently and accurately select it for the required structure of the house. Suitable for protecting your home from cold and noise, it has water-repellent properties.

Average price: 869 rub. per package.

HeatKnauf for cottage

Advantages:

- high quality;

- ease of installation;

- does not prick and does not generate dust.

Flaws:

- high price.

Rockwool Light Butts EXTRA

Dimensions: 1000*600*50 mm, 8 slabs per package, packaging designed for an area of 4.8 m2, density 45 kg/m3.

A universal solution for insulating a residential building, outbuilding or production workshop, it is even suitable for insulating children's and medical institutions. Made from stone wool. They have high density. It is a new product in the ROCKWOOL product line.

Average price: 530 rub. per package.

Rockwool Light Butts EXTRA

Advantages:

- easy to handle and install;

- excellent insulating properties;

- doesn't crumble.

Flaws:

- does not restore shape;

- The sheets in the package have different thicknesses.

TechnoNIKOL Technoblock Standard

Dimensions: 1200*600*50 mm, 8 slabs per package, packaging designed for an area of 5.6 m2.

Non-flammable, hydrophobic material made of mineral wool based on basalt. Can be used for insulating walls of various masonry and frames with different finishing options.

Average price: 640 rub. per package.

TechnoNIKOL Technoblock Standard

Advantages:

- acceptable price;

- always available in retail outlets.

Flaws:

- poor packaging quality;

- crumbles;

- sheets have different densities.

Ecoroll Extra Plate 037 aquastatik

Dimensions: 1230*610*50 mm, 16 slabs per package, packaging designed for an area of 12 m2.

Russian production. Optimal combination of price and thermal conductivity of the material. Treated with a special impregnation that allows you to cope with environmental influences, prevents getting wet and prevents shrinkage. Excellent for insulating attics, interfloor ceilings and walls. It can be used as insulation for attics and roofs.

Average price: 790 rub. per package.

Ecoroll Extra Plate 037 aquastatik

Advantages:

- price-quality ratio;

- environmentally friendly;

- easy.

Flaws:

- weak density;

- low sound insulation.

Isover Warm home – Stove

Dimensions: 1170*610*50 mm, package contains 7 slabs, package is designed for an area of 4.97 m2.

Quartz-based mineral wool slab. The material contains natural components such as soda, quartz and limestone. Certified for the construction of kindergartens and hospitals. Has high safety indicators for humans and the environment. Optimal for protecting residential premises from cold and noise with one product.

Average price: 700 rub. per package.

Isover Warm home – Stove

Advantages:

- convenient for transportation;

- easy to install;

- good thermal insulation properties.

Flaws:

- afraid of moisture;

- dusty;

- You cannot work without additional protection.

IZOVOL Izobel

Dimensions: 1000*600*50 mm, 8 slabs per package, packaging designed for an area of 4.8 m2.

Natural insulation of economy class, made of basalt. Available in slabs of thickness 50, 75 and 100 mm. Melting point is over 1100 degrees. It compares favorably with its competitors due to its thermal insulation properties, good sound absorption and durability. It is recommended to insulate only horizontal or inclined unloaded structures.

Average price: 365 rub. per package.

IZOVOL Izobel

Advantages:

- optimal in price;

- holds geometry;

- durable to the touch;

- does not burn.

Flaws:

- difficult to cut;

- crumbles easily.

Paroc Extra

Dimensions: 1220*610*50 mm, 16 slabs per package, packaging designed for an area of 11.91 m2.

A universal building slab made of basalt, capable of withstanding high heating temperatures. During operation, it does not lose its heat and sound insulation qualities, and also does not lose its geometric characteristics. The density of the slab allows you to preserve the body even in the harshest winters. Recommended for insulating walls, ceilings and floors in residential and non-residential premises, balconies, baths, saunas.

Average price: 1150 rub. per package.

Paroc Extra[

Advantages:

- high quality material;

- wide range of applications.

Flaws:

- high price;

- requires additional protective measures.

Insulation Izomin Light

Dimensions: 1200*600*100 mm, 4 slabs per package, packaging designed for an area of 2.88 m2, density 27 kg/m3.

Mineral wool slabs containing basalt fiber are made from rocks. The composition also includes additional additives that bind basalt fibers, impart hydrophobic properties and allow them to maintain their shape for a long time. It is a universal insulation material for non-load-bearing structures (floors with joists, beam ceilings, interior floors and walls). The melting point is above 400 degrees, the estimated service life is 50 years.

Average price: 325 rub. per package.

Insulation Izomin Light

Advantages:

- long service life;

- affordable price;

- high density.

Flaws:

- difficulty of installation due to density;

- a rare guest in stores.

Hotrock Acoustic

Dimensions: 1200*600*50 mm, 8 slabs per package, packaging is designed for an area of 5.76 m2,

Leader in sound insulation performance. Airborne noise protection index – 53 dB (according to tests of the Research Institute of Construction Physics). Ideal for insulating attic roofs, floors, frame walls. It is used as sound insulation for internal partitions of office, industrial and residential premises. Produced in thicknesses of 50 and 100 mm, density - from 6 to 44 kg/m3.

Average price: 545 rub. per package.

Hotrock Acoustic

Advantages:

- leader in terms of sound insulation among all mineral insulation materials;

- very dense material;

- doesn't crumble.

Flaw:

- produced in limited quantities;

- not sold in online stores.

Euroizol ECO 30

Dimensions: 1000*600*50 mm, 8 slabs per package, packaging designed for an area of 4.8 m2,

Stone basalt wool. Due to the use of modern technologies in production, it has high thermal protection and does not accumulate moisture. Thanks to the balanced pricing policy of the manufacturer, it has a competitive advantage in the market in terms of price-quality ratio. Certified for industrial and civil construction.

Average price: 359 rub. per package.

Euroizol ECO 30

Advantages:

- affordable price;

- high thermal conductivity coefficient;

- easy to cut and install.

Flaws:

- does not hold its geometric shape well;

- It is most effective only in a horizontal position.

Results

The density of mineral wool for walls and roofs must be at least 55 kg/m. cube, and for horizontal floors 35 kg/m is enough. cube For work, you can use both stone wool and glass wool. In any case, the insulation is protected by films. The first, main task is to prevent steam from entering the mineral wool. For this purpose, a vapor barrier is laid between the warm room and the insulation. The second, no less important task is to allow the steam that has leaked out to leave the insulation pie. To do this, the walls are covered with a wind barrier, and the roof, floor and ceiling are covered with a diffusion membrane. The use of membranes on horizontal floors (except the roof) is more of a recommended measure than a mandatory one.

Required Tools

You don't need anything special. Everything that the owner has in the kit is suitable for installing mineral wool. Although some tools may not be at hand. Then we rent it or borrow it from someone.

- Impregnation for wooden elements.

- Roller or brush for applying impregnation.

- Hammer or screwdriver.

- Chisel.

- Nail puller.

- Jigsaw with blades for transverse and longitudinal cuts.

- Construction knife - for cutting insulation.

- Wood saw.