A fireplace is the decoration and heart of any living room, and thanks to modern technologies, the owner of any home or apartment can become the happy owner of this piece of furniture. In the realities of today's life, you do not necessarily have to build a heavy brick structure with a chimney and pipe to enjoy the view of the fireplace. You can build a fireplace from plasterboard with your own hands and install an electric firebox inside with the effect of flames and even smoke - such a fireplace will be inexpensive and will decorate the room, and it’s not at all difficult to make if you carefully read this article!

Niche design options

The resulting portal also allows you to implement many interesting solutions:

- Installation of shelves. You can make removable or portable options.

- Placement of a painting or bas-relief. To achieve this, the space is made more open and the appropriate exterior decoration is selected.

- Illuminated glass insert device. To enhance the effect, a pattern is created on the base, which is illuminated in different shades.

- Installation of a mirror covering with decor in the form of electric candles.

The main thing is complete harmony with the style of the room; the fireplace should create an atmosphere of calm and set the mood for relaxation.

Decorating with plasterboard

Finishing a fireplace with plasterboard is one of the simplest and most budget-friendly options.

In order to carry out such a design, it is enough to simply sheathe a metal or wooden frame with sheets of this material. Its main advantages and features include:

- Low cost;

- Easy installation;

- Minimum time costs;

- Possibility of giving any shape;

- Light weight.

Direct assembly of the main frame

When compared with other furniture options, the TV niche has a separate assembly structure. The only similarity is that it has a main element and additional details of a special figure that have a formative function.

The assembly process itself is carried out as follows:

1. Installation of guide profiles. The most advantageous option for optimal load is 50 mm.

2. Approximately 4 rows of guides are nailed to the rough version of the plane, and in the case of continuous sheathing - to hidden plasterboard profiles.

3. An ordinary small podium is mounted at the foot.

4. If there are side columns, it is recommended to duplicate the guides, between which it is necessary to insert special jumpers of the required length; they will be the ones who will determine the depth of the excavation.

There are several profile connection options:

- with the help of bent wings”;

- use of “crab”;

- using a special insert that serves as a possible profile extension;

- The best option is cutters.

One more point should be taken into account: before sewing the frame, it is recommended to lay all the wires in the internal plane of the structure.

Two ways to make a false fireplace

We build a fireplace from plasterboard

To build a fireplace from plasterboard we will need:

- profiles;

- plasterboard sheets;

- self-tapping screws;

- screwdriver;

- glue;

- putty;

- decorative elements.

First, we create a drawing and calculate the volume of materials. When planning, you should remember that the appearance and dimensions of the future structure depend on the area of the room. You should not make a fireplace too large for a small room; it is better to install a corner false fireplace, which will also solve the problem of unused space.

Frame made of metal profiles

The location for the future fireplace has been chosen, now you can begin installation. To do this, we make markings on the wall and install a frame made of metal profiles. For stability, we connect the frame elements with transverse jumpers. We check the evenness of all edges of the finished frame with a level and proceed to cutting the drywall.

Next, we proceed to covering the frame with plasterboard. The screw caps should not stick out, so we recess them slightly. After assembling the structure, we seal the joints with putty. First of all, we process the seams, screw heads and corners. We prime everything on top.

Covering the frame with plasterboard

False fireplaces made of plasterboard can be painted or finished with other materials: tiles, artificial stone or stucco.

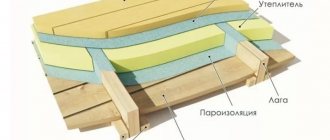

It is advisable to finish the inside walls of the portal with magnesite or foil thermal insulation

Pseudo-fireplace from old furniture

This option is considered the cheapest. It allows you to create a chic false fireplace from old unnecessary furniture. To work you will need:

- old wardrobe or sideboard;

- Sander;

- plywood sheets;

- jigsaw;

- putty;

- acrylic paint;

- decorative elements (stucco, stone).

A fireplace can be made from old furniture

Remove the doors from an old cabinet or sideboard. Using a screwdriver and self-tapping screws, we cover the facade of the cabinet with plywood or plasterboard so that we get an imitation of the firebox and firewood. If the surface of the sideboard or cabinet is polished, then we process it with a grinding machine to roughen it. Next, we proceed to prime the walls, which, after drying, we putty and level. We paint the surface with acrylic paint and glue decorative elements. The corners can be trimmed with artificial stone or brick.

Now we make the combustion hole. To do this, place a yellow or red LED strip at the bottom of the firebox (along the perimeter) and lay out shells, pebbles or colored sand.

Detailed calculation of the dimensions of the future structure

The heating structure must function well, that is, the design, as well as all the necessary drawings, must fully comply with the established requirements. These can include the following:

Approximate dimensions of corner fireplace

- a corner fireplace should have excellent draft, which will further eliminate the occurrence of smoke in the room. Moreover, the draft should help light the fire easily and quickly;

- the heating structure itself must ensure uniform heating through high heat transfer;

- a fireplace that is not in use should not cause the building to cool down;

- A do-it-yourself corner fireplace is a fairly compact structure and will serve as an excellent addition to the interior.

To ensure maximum compliance with all qualities, correct calculations of the dimensions of the structure and its individual elements should be made.

Firebox

Section of a corner fireplace

Correctly selected dimensions of the firebox can provide not only a cozy interior, but also the necessary amount of heat. As a rule, its dimensions are calculated taking into account the total area of the room. The resulting value is divided by 50. The resulting value will be the estimated area of the firebox opening.

It is considered important to correctly calculate the depth of the fireplace, since the overall efficiency of the fireplace depends on this indicator. The estimated depth of the firebox should be approximately half of its total height.

If the dimensions are increased, the fireplace will not be able to provide the room with the required amount of heat, since the heat will immediately escape into the chimney, and in order to maintain the fire, a huge amount of fuel material (in this case, firewood) will be needed.

If a corner fireplace made of brick has a firebox whose depth is less than the required size relative to its height, then there is a high probability of heavy smoke in the room.

DIY corner fireplace - project

Chimney

Calculating the dimensions of the chimney is an equally important task - this is what determines the quality of draft. So, for this you need to find out the height and diameter of the chimney pipe

Often, the maximum acceptable proportion is considered to be the cross-section of the chimney, with a size of 1:10 of the total area of the firebox window. The total height of the chimney is at least 5 meters, but in some cases there is a need to raise it much higher.

Today, there are specially developed programs with which you can quickly perform the necessary calculations, competently draw up a project, create drawings of the future design, and the order of the fireplace can also be developed.

The final touch: fireplace decor

A decorative portal on the wall or in the corner of the room can be supplemented with candle flames by installing a bio-fireplace with real flames in the firebox or by placing a heater there, stylized as burning logs. In any case, an artificial hearth will look no worse than a real one, and can perform the functions of a decorative element in the interior even better. After all, to light a fire you will not need either wood or coal, which can stain the carpet or floor.

It is not enough to just build a fireplace with your own hands from plasterboard. It is also necessary to decorate the finished structure. A few photos will help you choose the desired design style and make a reliable frame suitable for a specific interior.

The sufficient strength of gypsum board allows you to decorate the hearth even with materials such as imitation wild stone and tiles. Tip: the easiest way is to buy ready-made stucco molding from polystyrene foam.

Fireplaces for a rustic-style interior (photo in Fig. 3) can be covered with light tiles that reproduce the surface of rocks. Before finishing, cover the surface of the gypsum board with putty for better adhesion of the tile adhesive. Installation of tiles is carried out according to general rules:

- stick the elements;

- dry;

- perform grouting and jointing (if necessary).

The tiles are fixed in the same way. For interiors in bourgeois style, you can find tiles that imitate tiles in trade organizations. Such fireplaces can be complemented with stucco molding painted in shades of paint on the tiles.

Interior products: polyurethane molding

The greatest scope for imagination is provided by the classic style. Polyurethane foam and plastic moldings, baseboards, and stucco moldings allow you to create masterpieces in the Rococo and Baroque styles, as in the photo (Fig. 4), turning your apartment into palace apartments. This design of fireplaces should be approached very responsibly, trying to combine the appearance of the hearth and other furnishings.

Depending on whether you plan to use the fireplace as a decorative element, or whether you want to receive some heat from it on winter evenings, it’s up to you to decide, but you can choose to imitate different types of flames. The portal looks elegant, in the firebox where the bio-fireplace is installed. Such design will 100% comply with fire safety rules.

How to light a fire in a fireplace?

You will probably think that lighting a fireplace is the easiest task - throw in a couple of branches, papers, bring a match and here it is - beauty. In reality, everything turns out differently. The first fire can tell you a lot.

After manual construction, if you suddenly doubt the effectiveness of your miracle fireplace, call a specialist to the site for an assessment and initial heating

Otherwise, there may be a strong risk of ignition if installed incorrectly, as in the 2016 American film “Manchester by the Sea,” where the main character inadvertently burned down the entire house by throwing in a couple of extra firewood. There are other pitfalls that may emerge after a short time

Still from the film Manchester by the Sea (Manchester by the Sea) burning house

There is no need to rush things when it comes to the finish line. Your efforts may be ineffective, so read one of our articles in advance on how to properly light a fireplace.

In conclusion, check out this funny video of a Dalmatian and a horse having fun against the backdrop of enchanting flames - relaxation is guaranteed.

https://youtube.com/watch?v=UTxsZn7ZVkg

Cladding the fireplace insert: choosing suitable materials and familiarizing yourself with the basic rules

05/04/2017 4889 Pechnik (Moscow)

Cladding a fireplace insert requires a correct and professional approach. This is primarily due to the fact that not all materials are suitable for finishing both the hearth and the portal itself.

Equally important is compliance with the basic requirements and rules for the facing work performed. In order to become familiar with these criteria, we suggest watching the video in this article or reading the following materials in a clear and accessible presentation.

Step-by-step instructions for making your own from plasterboard

Creating a portal for a fireplace from plasterboard with your own hands is not a difficult, creative, and interesting task. Materials for it are sold in almost all construction stores; tools can be bought or rented.

A plasterboard fireplace is a portal in the shape of a real hearth, but the structure remains hollow inside.

Deciding on the interior design

At the very beginning, it is recommended to decide on the design of the structure - the object should optimally fit into the existing interior design. It will be a “antique” fireplace decorated with stucco or covered with silver paint in a high-tech style, a simple minimalist design in white color or covered with imitation brick in a loft style. Sometimes the object is lined with flexible artificial stone, or covered with a film to imitate marble, granite, onyx and other stones.

In appearance, such a portal, with appropriate finishing, is no different from a traditional solid fireplace.

Choosing a suitable location

The fireplace can be installed in any convenient location. A niche in the wall, a free corner, just an empty, flat wall or a large protrusion (at least a meter wide) on it is suitable for it. The product is hung from the wall, placed in the middle of the room, and mounted on a pedestal. The installation site is leveled and freed from all unnecessary things.

Drywall frames are used for arranging decorative portals and for placing an electric or bio-fireplace inside the structure.

We make drawings with dimensions

After creating a preliminary sketch, you need to depict the view of the hearth from different sides to determine what details are needed. Afterwards, full-size drawings are transferred directly to the material.

Building a decorative or conventional portal for a fireplace with your own hands is a fairly simple technological process.

We create a full-fledged project, layout

For a more accurate idea of what the finished fireplace will look like, a miniature mock-up is created. Any scale is acceptable - one to three, one to five, one to eight, etc. The project notes the overall dimensions, thickness of parts, cut of the internal part and other important points.

A frame is erected from a metal profile or wooden blocks, and the top is covered with plasterboard according to the pattern of the structure.

Necessary tools, materials

To work you will need:

- screwdriver;

- perforator;

- ruler;

- iron tape measure;

- square;

- building level;

- a simple pencil;

- jigsaw;

- sheet of drywall;

- metal guides;

- self-tapping screws;

- PVA glue;

- putty;

- finishing coating.

Tools you will need for your work.

Preparation, marking

Before installation begins, the installation site is marked, indicating the location of the support strips, top shelf, and extreme side points. Average dimensions of a pseudo-hearth for a room with an area of 10-16 square meters. m.: height 770-90 cm, width 100-120 cm, depth 25-45 cm.

The thickness of the drywall is selected based on the required load-bearing load.

Frame assembly, installation

Installation of the product begins with the installation of pedestal supports. Later, horizontal jumpers are attached to it. Afterwards the main part is installed

It is important to maintain the parallelism of the supporting parts with each other - otherwise the distortion of the structure is inevitable

Drywall is the basis for any finishing material.

We make the arch of the fireplace chamber

The “insides” of the fireplace structure are assembled separately. If the portal is arched, to create it you will need flexible perforated profiles that are laid along the contour of the already cut parts.

Heat-resistant plasterboard is an excellent material for bio- and electric fireplaces.

Sheathing

After installing the frame, the fireplace is covered with plasterboard. Self-tapping screws are used for this - they should be screwed in so that the caps are slightly buried in the material and can be easily puttyed, completely hidden from view. On such a flat surface it is easy to apply a finishing coating and glue three-dimensional props.

The shape of the portal depends on the chosen design style.

Portal cladding

It is possible to finish a plasterboard structure with a variety of materials. These are ceramic tiles, various paints, decorative plaster, self-adhesive films with images of bricks or fancy designs. All kinds of ornaments and hand painting are also acceptable.

The advantage of decorative and electric fireplaces is that their construction does not require paperwork for a building permit.

Briefly about fireboxes

Conventionally, they can be divided into two large groups:

- Functional: open, closed. According to the material of manufacture, steel or cast iron, brick. Such equipment requires additional fireproof protection of walls and floors.

- False fireplaces. Instead of a real firebox, screens with imitation flames of fire are used. For such devices, chimneys are not installed, but an electrical supply is required.

There are no restrictions on the shape of the portal (fireplace facade): rectangular, complex geometric shapes, radius, corner. For every taste and color. It should be noted that finishing a fireplace with plasterboard with your own hands is a process of preparing a rough base for the finishing cladding.

Portal for an electric fireplace made of plasterboard

In order to make a beautiful portal from plasterboard, you need to carry out all your actions clearly according to this list:

- We purchase an electric fireplace and measure its dimensions.

- We determine the place where the future fireplace will be located.

- We make a drawing with images of the frame and appearance of the fireplace.

- We make markings on the walls and floor.

- According to the drawing (dimensions), we cut the metal U-shaped profile (UD or CD) into pieces and assemble the frame using self-tapping screws, starting from the support frame near the wall.

- We check the correctness of the lines with a building level and a tape measure (diagonals).

- We mark and cut the sheets of drywall and use self-tapping screws to attach them to the finished frame in two layers.

- In a similar way, we assemble the base of the future fireplace portal and the mantelpiece from plasterboard and a metal profile.

- We attach the mantelpiece and the base with screws and glue (or silicone).

- We putty all the joints and holes in two or three layers, smooth out the unevenness with an abrasive mesh until absolutely smooth surfaces are obtained.

- We putty the surface and start decorating the portal using self-adhesive film, paint, gypsum stucco elements, decorative plaster or other materials necessary to create the stylistic design of the fireplace portal.

Finishing the fireplace portal with artificial stone

Artificial stones have a number of advantages. The appearance can imitate granite, malachite, sandstone, marble and other natural stones. Artificial stones are divided into three groups: porcelain stoneware, agglomerates and colored concrete stones.

The process of finishing a fireplace with decorative stone

Before purchasing material for constructing a fireplace portal, you should pay attention to:

- the thickness of the purchased stones (this affects the dimensions of the finished structure);

- frost resistance and percentage of water absorption;

- repeatability of elements (optimally 3 m2).

Preparation stages:

- We create a sketch of the future portal, drawing all the elements and taking into account the color scheme.

- Open several packages and mix them. Clean the side of the stone that will come into contact with the adhesive mixture and the wall with a wire brush.

- Using a brush or roller, apply acrylic primer to the cleaned surface of the stones.

Styling:

- We lay out the design on the floor according to the sketch (for cutting we use a grinder with a cutting wheel).

- Using a brush, moisten the surface of the fireplace and stones.

- We start laying from the top corner, initially using whole elements and taking into account the thickness of the seams. The rows alternate larger stones with smaller ones. Accordingly, elements of smaller thickness are chosen for the upper rows, and greater thickness for the lower ones.

- We carry the adhesive solution and level it with a spatula. We maintain a layer of about five millimeters.

- We press the stone to the surface and slightly scroll in different directions.

If necessary, we make jointing and apply paint and a protective coating to the front part of the masonry.

We use a tin profile

Tin profiles are easily attached at intersections in one plane. The elements are connected using small self-tapping screws using a screwdriver or similar attachment on a drill or screwdriver. When making plaster fireplaces using tin profiles, evaluate your metal handling skills. Bends or breaks in the profile are made along the line of cuts in the side flanges. They should be made with an angle cutting machine with a metal cutting disk installed on it. You can use a jigsaw with a metal file.

All cuts are made in clearly marked places to ensure that the front side of the profile is bent or folded exactly in the required place. When assembling a fireplace from plasterboard with your own hands, you will have to stock up on marking tools:

- square

- building level

- tape measure, construction ruler or laser tape measure

- construction marker for making marks and lines

The main requirement for the results of the work is that all surfaces must present a perfect plane.

Having completed the frame, we begin to create the surface. It is necessary to install sheets of drywall on the future fireplace. They are cut according to the configuration of the plane being closed. For pruning, you can use a construction knife, a hacksaw with fine teeth, or a cutting machine. The material cuts and breaks very easily. It is enough to draw a fault line and gently press along it along the loose side of the sheet. Drywall is attached to the frame with self-tapping screws, the length of which is about a centimeter greater than the thickness of the sheet and a diameter of about five millimeters.

After installing the sheets, you can putty the joints and seams using putty tape. This is not necessary if the surface is not subsequently painted or covered with film. Attention should be paid to careful alignment of the ends of the sheets facing intersecting planes. Do not forget that the lining of the fireplace insert with plasterboard should not be continuous, since electrical appliances installed in it need to remove heat. It is necessary to leave ventilation holes at the top of the structure.

The influence of a plasterboard fireplace on the layout

At the same time, the decision to install a fireplace in your apartment should not be taken lightly. Wrong decisions will turn advantages into disadvantages, and an unnecessary pretentious shelf for trash and dust will be piled up in the corner. Therefore, we have prepared information on how to make a fireplace from plasterboard, in order to expand your design horizons.

First, you should carefully consider the changes in layout that the fireplace will cause and choose a suitable location. Based on your conclusions, think about the shape and appearance that you would like to see.

The simple design of plasterboard fireplaces reveals the limitless possibilities of this material. Don't get hung up on grave granite, the brick splendor of old England fences, or marble covered in bronze to look like gold. There are many other stylistic choices that can be fun to explore.

Simulated fire vs natural flame

The home comfort industry offers several options for simulating live fire with varying degrees of authenticity. From a full-fledged picture of a fire to an almost completely identical process of burning birch logs with smoke and flame. The dimensions and characteristics of the selected equipment will allow you to determine the dimensions of the plasterboard fireplace required for installation.

1 - electric fireplace; 2 — imitation of fire; 3 - portal decor

This is much better than the real soot, soot, firewood and drafts of a real fireplace. The question of choice is only the amount you are willing to pay for it and the goals you want to achieve. An electric fireplace, or combustion simulator, is that part of the structure that will have to be purchased ready-made. You won’t be able to make it yourself, and there’s no point in experimenting. But decorating an electric fireplace with your own hands will allow you to show creativity.

Start of installation work

The experience of using plasterboard in interior decoration can be expanded to interior elements. Making fireplaces of the desired appearance with your own hands is a completely feasible task. Make a drawing and put the main dimensions on it. Many people neglect this stage, making a big mistake at the very beginning of the matter. Three sets of work are conventionally distinguished:

- frame manufacturing

- covering the fireplace with plasterboard

- finishing

The frame can be assembled from a tin U- and L-shaped profile or from wood. It is difficult to say which is preferable; it all depends on the dominant skills of the performer. The advantage of tin can be considered that it allows you to easily reproduce a broken and even bent surface.

Finishing

For final cladding, the plasterboard base is prepared as follows:

- The screw caps are covered with putty. The composition should be selected for aggressive environments with elevated temperatures.

- After hardening, the excess is removed with a spatula or special masking paper/sandpaper.

- At the end, the surface is completely puttied, sanded, and primed. The plasterboard finish on the fireplace insert matched the finishing lining.

GCR is a universal material, so porcelain stoneware, gypsum, clinker tiles, natural stone and others can be used as a finishing coating. The finish is selected to match the style of the interior.

An interesting solution is porcelain stoneware. The modern market offers this tile with an imitation of any other finishing material - marble, granite, wood. Moreover, the canvases can also have a texture similar to natural fibers.

Finishing a fireplace with plasterboard with your own hands is a simple process, but it has a number of subtleties. False fireplaces do not require thermal insulation or a solid foundation. It’s enough to just build a plasterboard portal and choose the appropriate finish. In the case of functioning furnaces, it is recommended to contact professionals who will perform high-quality installation, which will ensure the reliability of the equipment and fire safety.

Useful tips from professionals

Construction of a box for a decorative portal requires patience and some skills; at the first stage, advice from professionals will be useful. The most interesting and artistic part of the work is the finishing of the front part.

The traditional way of decoration is wallpapering. Wallpaper hides surface unevenness well, and one layer of putty is enough. The wallpaper is selected to match the tone of the walls from one collection, using a border with an ornament to decorate the facade. The option of covering the box and walls with the same trellises looks good only in fashionable, stylish interiors - Scandinavian, minimalism, hi-tech. In this case, it is better to prefer monochromatic colors. A fireplace covered with floral wallpaper or with monograms looks out of place.

Making a drawing

The next stage is the creation of the project. In principle, there is no project here as such, you just need to sketch out a sketch in which the shape of the fireplace will be clearly visible. Don’t forget to put the dimensions of the future structure on paper. This will definitely come in handy when you have to transfer the dimensions into reality.

But here you will be faced with the question, what kind of fireplace do you want to see in your apartment? If you have not yet presented it, and you are having difficulties with this, then we recommend looking at photos of fireplaces in apartments, which are posted in large numbers on the Internet. At this stage, you just need to find the form option that suits you

Don't pay attention to the finishing, you'll deal with that later.

If the choice is made, then the form can be transferred to paper. Now align the dimensions of the portal with the dimensions of the room and the wall near which it will be built. Everything should be harmonious. Although there are no strict restrictions in this regard. You can make the fireplace high but narrow, or low but wide. The choice is huge, so go for it.

Construction technology

Work structure

Some stores provide ready-made portal layouts that do not require lengthy installation or repair work. However, such solutions are quite one-sided and do not allow imagination to unfold, contributing to the creation of a typical fireplace that is unlikely to please the eye. An alternative to buying angular and not very beautiful prefabricated structures is to build a full-fledged portal yourself. However, for this it is necessary not only to have some practical skills in working with materials, but also to have spatial thinking.

The structure of work to create such an object is as follows:

- preparatory work;

- collection of tools;

- construction of the frame;

- portal cladding;

- decoration.

The above steps are an integral part of constructing a portal with your own hands from plasterboard. Today, such a solution is one of the best, since it does not involve large material costs and does not require much time.

The key feature of construction work is preparation aimed at creating optimal conditions for the construction of the facility. In the case of our construction, it is based on the following:

- determining the location for installing the fireplace;

- clearing the area, preparing surfaces;

- creation of a basic construction plan.

We decide on the place where the portal will stand.

Based on these principles, building a full-fledged portal for an electric fireplace will not be difficult. At the very beginning, you should decide on the location of the fireplace system. Choosing it is not as difficult as when building a full-fledged stone fireplace, when it is necessary to strengthen the foundation and prepare a fire-resistant base, but still there are some nuances in this matter. The best place to install an electric fireplace is a wall in the back of the house or even a corner. In this case, the appearance of the fireplace will not be blocked by daylight, and the entire interior will become more cozy and comfortable.

This solution will create optimal prerequisites for the construction of the system, and will also make it possible to carry out construction work more quickly and accurately.

Drawings and their creation are an integral part of preparation. It is the creation of a plan that makes it clear what the finished object will be like, its geometric proportions and aspect ratios, as well as determine its shape and preferences for finishing.

Preparing the base

Considering that fireplaces are fire hazardous equipment, preparation of the floor and adjacent walls should be provided before covering the fireplace with fireproof plasterboard.

Floor preparation

The fireplace insert has a significant mass. Plus is equipment with an increased fire hazard. Therefore, at the first stage, a concrete base is prepared:

- The portal is marked on the floor.

- The formwork is being installed.

- The base is primed and filled with concrete.

- After hardening, a podium is laid out (4 rows of brickwork). Then install metal corners under the firebox.

- Lay the final level of masonry.

The whole process is carried out strictly according to the level. A misalignment of the foundation and podium will cause problems with the quality installation of the firebox.

Preparing the wall

The simplest option is when the adjacent wall is made of aerated concrete, foam concrete blocks or bricks. In this case, it is plastered and whitewashed. If the adjacent wall is made of flammable materials (logs, beams, etc.), then the following work is performed:

- Treating the wall with fire retardant compounds.

- Fastening a foil-coated basalt slab to a metal profile. A ventilation gap is required between the wall and the facing slab. The dimensions of the protective screen should be 500 - 600 mm larger than the dimensions of the future furnace.

- Fixing drywall, which is puttied, and clinker or porcelain tiles are laid on top.

Other options: asbestos board, magnesite. If the equipment will be installed in a corner, the joint between the walls is treated with a special fire-resistant sealant.

The same thermal insulation is also applied under the chimney. You should know that the gap from the fire-resistant wall to the rear surface of the firebox must be at least 100 mm, from the combustible surface - at least 700 mm.

Design selection

Let's start with the fact that the first step is to establish in which place in the room the fireplace should be installed.

If you turn to a professional designer who is drawing up a design project for you, then this specialist will figure out where and what to install and how to place it.

But if you have taken on its role, then when creating the interior you will need to take into account some rules for installing a fireplace.

Everything will depend on the size of the room where it will be placed. If the room is small, then you can use two options: corner and in the form of a niche, slightly protruding from the wall.

The first option has several advantages:

- Small sizes.

- Does not take up useful space in the room.

- Fits well into the design.

- Can be used as a decorative shelf or cabinet.

The only negative is that the corner option cannot always be used. Usually the corners of the room near the window are covered with curtains, on the opposite side there is an entrance door in one corner, and on the other side the fireplace is not so clearly visible.

Therefore, it is best to give preference to the usual front element. Moreover, it is possible to build a small structure that will fit well into the interior of the room and will not take up much space.

This is interesting: Baroque style in the interior - undisguised luxury and wealth

Design

This is the very first stage, during which several important points should be taken into account, especially for functional fireboxes:

- It is necessary to determine the location for the equipment in the room relative to the walls and furniture arrangement. At the same time, do not forget about fire safety: the distance from flammable surfaces to the firebox is at least 700 mm.

- The base for the equipment is recommended to be made of concrete with a height of 300 mm. The perimeter of the foundation should extend beyond the dimensions of the firebox by 250 - 300 mm on each side.

- The recommended gap between the firebox and the plasterboard structure is 50 mm.

- An air vent box should be provided.

- Podium. The design must provide air flow for heating and support the weight of the firebox.

- The thickness of the fireproof wall finishing and a technical gap of 100 mm between it and the firebox.

- To accurately determine the dimensions of the portal, you should take into account the parameters of the facing material: profiles: guide – 27×28 mm and rack – 27×60 mm). For cladding, it is recommended to use fireproof or moisture-resistant plasterboard with a thickness of 12.5 mm.

- The design of the portal and its decoration should fit organically into the interior.

The listed parameters will help you avoid installation errors.

Imitation of fire in a fireplace: design options

Decorative home hearths made of gypsum plasterboard require compliance with fire safety standards, since such a design is designed exclusively for artificial fire.

There are several ways to create an artificial imitation of fire

Most often, craftsmen use the following types of fire imitation:

- Use of steam.

- Creation of "theater fire".

- Use of salt lamps.

- Installation in the TV hearth.

The most difficult way to create a decorative flame is with steam. Not everyone can create such an imitation, because it will require a specific set of components and special equipment, as well as skills in working with electronics.

To make a fire of this kind, you need to prepare:

- DMX controller.

- Fan with a diameter of 9 cm.

- LED RGB lamp.

- DMX decoder.

- 3 ultrasonic fog generators.

These devices must be selected according to the parameters of the built fireplace, the layout, as well as the manufacturer and characteristics. It all depends on what initial result the master wants to get. All these devices are included in steam electric fireplaces, as well as concert electrical devices that create the effect of steam.

If the master wants to use exactly this method of simulating a flame, it is important to provide the necessary parameters for the components and mount the fireplace of the required size. The operating principle of such an electric fireplace looks like this:

The operating principle of such an electric fireplace looks like this:

- A fog generator should be placed at the bottom of the container into which water is previously poured.

- The generator has a membrane that creates vibrations at a specific ultrasonic frequency, providing reduced pressure. Therefore, it turns out, one might say, a vacuum and the water evaporates at room temperature.

- Thanks to this, the steam rises.

- The top is illuminated by an LED lamp.

- A diaphragm is installed above the structure.

Assembly using technology will make it possible to create a more natural imitation of flame yourself in a false fireplace. The second way is the theatrical option. As is already clear, this method is used in theatrical circles for various kinds of productions. However, it is also suitable for making a dummy, imitation of fire.

To make such an imitation yourself, you need to prepare the following items:

- A piece of light white silk fabric.

- 3 halogen lamps with reflectors.

- Silent, powerful fan.

- 3 filters: red, orange and blue.

- A box or a special bowl for assembling a false structure.

When everything is prepared, you can begin assembly according to the following scheme. A fan should be installed at the bottom of the box or bowl. The cord must be routed out. Next, you need to attach halogen lamps to one axis so that the light is directed upward. Then, at a distance of 20 mm above the lamps, you need to install light filters.

The next step is to attach the flaps to the box, bowl along the edges of the fan. When you turn on the fan in the power supply, not a real fire will appear in the fireplace, but very similar to a natural one. This method is quite simple and makes it possible to create an almost real, mesmerizing flame in the fireplace.

Dream come true!

Layout

Work should begin with the manufacture of the box. We can safely say that this stage of work is the most important, because already at this stage the foundation, strength and stability of the future fireplace are laid. As a rule, the frame is made of UD and CD profiles. First, from a design drawn on a piece of paper, transfer the outline of the fireplace to the wall and partially to the floor. In this case, use a level, thereby achieving accuracy

Profile frame

When the entire frame is ready, you can begin covering it with plasterboard. After this, each formed joint is covered with a special putty.

If you want to make a footstool, you will need to additionally build a frame for it from a profile. Subsequently, logs can be placed on this foot as decoration.

Before installing an electric fireplace, you will need to thoroughly putty the entire structure. After grouting, the fireplace will be ready for finishing work.

Video description

Try making a fireplace according to the instructions in this video or use it as an example to assemble your own design:

The instructions provided are suitable for simple wall-mounted models. Angular, asymmetrical and other complex shapes require an individual approach to frame assembly. Some craftsmen first make it completely, and only then fasten it in place.

It is important! When an electric fireplace is built into a plasterboard structure, the combustion chamber frame is assembled taking into account the fact that after plating its internal parameters will decrease.