The topic of this article is mortar for plaster, but not a general description and tips for use, but specific information about the composition and proportions. This information will help you achieve the desired result of the repair: excellent appearance, strength and durability of the coating.

Plaster solutions are used for various purposes, for example, for leveling or decorating facades or interiors. But an important function of the plaster composition remains the protection of external and internal structures of buildings from various influences.

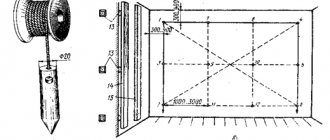

In order to prepare the required composition for plaster with your own hands, you need to have an idea of the correct proportions of the components (volume or weight). You also need to know in what form and in what order the components are mixed.

Why does one solution have different proportions?

Leveling plasters consist of several layers that have different functions:

- the spray is intended to create a strong connection between the base material and the overlying, main leveling layer;

- the covering is designed to give the main leveling coating the required evenness, and sometimes smoothness (the required surface quality for gluing wallpaper, applying paint);

- primer – the main leveling material, applied in one or more layers.

Since the functions are different, the solutions differ in their proportions and components. For example, for covering you need a finer filler, since the degree of roughness of the finish depends on the size of the grains. For spraying, the mixture is made thinner than for soil. Confusing the compositions for different layers is a violation of the finishing manufacturing technology.

applying a layer of spray

base layer

cover

The period from the moment of mixing the plaster mass to the beginning of its setting is called the life span. At this time, the plaster solution is mobile and can be applied, giving the mixture the desired shape. The lifespan depends on the types of components and composition. For example, gypsum has a short lifespan. To increase or shorten this period, additives are added to the mixture - hardening accelerators or retarders.

In addition to these additives, to give the plaster mixture the necessary qualities, antifreeze (for plastering walls in winter), antifungal and other additives are introduced. Any additives require a fairly precise dosage, since they have their own chemical formula. Their excess can significantly deteriorate the properties of the finished coating.

Compliance with the ratio of plaster components is important. Therefore, when mixing a mixture of individual components or diluting ready-made dry formulations, follow the recommended proportions. This is the only way you will create a plaster stone with the desired qualities.

Peculiarities

Plaster mortar is a wide range of mixtures. The spectrum includes various compositions, this is explained by the purpose of each material. The basis of any raw material is a binder. In addition to it, manufacturers include various additives in the composition. This is a pasty mass. It is spread on the walls or ceiling, stretching until a uniform layer is formed.

The composition of each mixture directly affects its purpose. For this reason, mixtures can be intended for interior or exterior use. Some compositions are relatively universal and are designed to work indoors as well as outdoors. A distinctive feature of these mixtures is their resistance to adverse environmental factors. One of the features of plaster compositions is granularity.

It is the size of the faction that indicates whether the composition is finishing or starting. Often it is the rough texture that is used to prepare the base for finishing. Depending on this, one or two plasters are used on one surface. In this case, one of them is preparing the base for applying the other. Due to the particle size and additional effect, the cost of the finishing coating is always higher than the starting counterpart.

Sometimes the plaster mixture is confused with the term “dry plaster,” which is usually understood as plasterboard sheets.

In fact, plaster is a composition based on a powder mixture or a ready-to-use solution.

In the first case, it is a binder and fillers in a balanced formula. They must be mixed before applying the plaster material to the prepared base. The second variety is notable for the fact that it does not require adjustment before use on the surface.

This material can have different shades. It depends on the components of the mixture.

- In one case it is a gray concrete color, in others it is dirty beige, sometimes milky.

- White is considered to be the basic color.

- The finished material on a creamy base can be colored. However, the range of shades of such mixtures is scarce. This forces you to paint the plaster mixtures yourself.

All solutions are divided into fatty, lean and normal. Mixtures of two or more components are called complex. In fatty varieties, the astringent component predominates. Therefore, they shrink and crack and require re-processing.

If the filler dominates, the solution does not shrink, but does not adhere well to the base. The normal composition is moderately plastic, easy to work, and durable.

Types of plaster mortars, their composition and proportions

In fact, plaster coatings are artificially produced stone. We can influence the characteristics of this stone already at the stage of preparing the relevant components, dosing, mixing, applying to the wall and creating appropriate conditions for hardening of the composition.

In the mixed composition, each of the components does its job:

- binds other components (astringents that react chemically with water, forming crystalline bonds);

- serves as a frame that already has strength, creates a structure (fillers are mainly chemically inert), creates a thermal or noise barrier (for example, perlite sand);

- becomes a medium in which particles of materials are placed and, at the same time, participates in the chemical transformation of the binder (water or solvents in polymer compositions);

- contribute to the quality of the solution itself and the properties of the artificial stone (various additives);

- give color to the solution and finished plaster (dyes and pigments).

All together, these components form a solution, which, when transformed, becomes an artificial stone.

The following are used as binders:

- cements (mainly Portland cement, also for plaster compositions...);

- plaster (alabaster and plaster are found on the counter);

- lime (quicklime and boiling water);

- clay;

- various polymer resins.

Classification according to other parameters

Let's consider an additional classification of plaster coating.

- According to the form of delivery;

- By application;

- According to operating conditions;

- According to the degree of gloss;

As a rule, the color range of such products is quite wide. But if the stencil does not contain the required color, you can use a color scheme and paint the decorative coating yourself.

Manufacturers who have the best decorative plaster with a wide range of colors:

- "Ruston"

- "Wall2Floor Top Coat"

- "Klondike"

- "Sambulador"

- "CeboGlam"

- "Tex-Color"

- "BauMit"

If a beginner is afraid of making a mistake, then it is best to pay attention to the manufacturer’s data.

Purpose of the components of the plaster mortar

As we already know, the plaster mixture consists of many different components. Each of which is important and performs its own functions. An excess or deficiency of one of the components of the solution will lead to a loss of quality. That is why it is important to know the purpose and functions of the components of the mixture.

Binder in plaster mortar

If the plaster solution contains only one binder, the composition is called simple. If there are two or more binders - complex. Not all binders get along with each other. For example, gypsum and cement are chemically unfriendly to each other. Therefore, they are used separately or with other binders.

cement

gypsum

clay

All binders, except polymers, are mineral substances, which is why plasters have the same name. Gypsum, cements and lime are pre-treated thermally, as a result they lose water and are able to react to its presence. When combined with water, these substances form saturated solutions and create crystals.

Liquid in plaster

The solution usually contains more water than is required for crystal formation. Liquid is also needed to give the mixture mobility (workability). In this case, excess moisture can be harmful (the strength of the solution decreases). It is for this reason that the ratio of water and other components must be observed.

Fillers

The production of binders, in addition to clay, requires a lot of costs, so they are much more expensive than fillers such as sand or sawdust. In addition, a solution containing only binders cracks when hardening. Therefore, to reduce the amount of binders (the cost of the solution), as well as to reduce cracking, fillers are introduced into the composition.

Fillers also give solutions a certain structure, for example, coarse sand is used for “bark beetle”; for other decorative mixtures, artificial or natural fibers and shell fragments are used as fillers.

It is better to purchase decorative mixtures ready-made. Their composition was developed and tested in practice by specialists.

Rough (leveling) plaster more often than other components has to be prepared on site. The consumption of leveling plaster mixture is higher, and the cost of a mixture prepared by yourself is lower.

Special additives for plaster mortars

To provide the plaster solution with the desired properties, modifying additives (universal and narrowly targeted) are used. Additives affect the binder (cement), enhancing or neutralizing its individual properties.

In solutions, additives perform the following functions:

- accelerate/slow down the process of crystal formation (setting), for example, for gypsum, the retarder is bone glue, milk, PVA;

- increase frost resistance (ferric chloride and other salts);

- improve plasticity (serve for some retention of water in the solution, prevent the process of delamination of the mixture), for example, liquid glass;

- increase the strength of the mixture (for example, reinforcing fibers (fiber) or additional binders).

Glazing

Glazing is the final operation of decorative plaster. Its purpose is to give the relief and/or painting surface resistance. The traditional way of glazing old mineral plasters is with beeswax: a piece of wax is used to mark the surface crosswise, then rubbed with a horn sponge, thin felt or rawhide polish.

glaze wax

Wax glazing is a labor-intensive and responsible operation. The wax is applied and rubbed many times, and at the same time it is necessary not to erase the relief or wipe the design. Suffice it to say that in the old days the quality of glazing was checked by placing the palm of the hand on the opposite side of the wall: it had to become warm through and through from heating by friction.

Nowadays, they are glazed either with transparent acrylic varnish - it easily penetrates the surface layer of any plaster - or with special one-time use glaze compounds; they are simply applied with a roller or brush. But there is a nuance: if a ready-made mixture is used, then it must be glazed with a composition from the same manufacturer, and intended specifically for this mixture. It is physically impossible to check the compatibility of all plastering products on the market.

It must be said that some manufacturers shamelessly use this circumstance for selfish purposes: the mixture seems to be inexpensive, and the glaze for it... there are no words, just a primordial Russian obscenity. Therefore, when choosing a ready-made mixture, be sure to read in the FIRM instructions what it is recommended to glaze it with, and ask how much it costs. As a last resort, acrylic varnish has not yet spoiled any plaster.

Video: an example of glazing in a video from a varnish manufacturer

Specifics of plaster compositions

Since buildings need to be plastered outside and inside, where the finishing is exposed to different conditions for a long time, the compositions of plastering solutions are also specific. Facade surfaces are subjected to more severe mechanical stress, are watered by rain, hit by hail, endure frost and heat, and are scorched by direct sunlight. Therefore, solutions for external conditions should be more resistant to all these “troubles”.

There are mixtures for facades, interior work and universal ones. The latter can be equally used for outdoor and indoor decoration.

All basic data on the proportions of plaster solutions for exterior and interior decoration are contained in the table from the standard.

spray and soil during external and internal plastering

The following figure shows the proportions of the covering.

cover - proportions

Composition of mortar for plastering external walls

Mortars for external walls differ in their base. Gypsum and lime compounds are not used for exterior finishing. An exception is plastering of closed loggias and balconies, where there is protection from water ingress. Therefore, the main binder for facade compositions is cement. Cement-lime (popular) and cement-polymer (more expensive) compositions are also used.

Clay is not afraid of frost and sunlight. But clay plaster must be protected from erosion. For facades in regions with a dry climate, if water does not directly fall on the plaster, plastering with lime-clay and lime-gypsum mixtures is used.

Possible mistakes

The quality of the final plaster depends on the correct preparation of the composition and compliance with the proportions of materials. Errors can result in cracks on the surface, peeling, and swelling.

Poor mixing of the solution leads to cracks due to the high concentration of binder or filler in one area. Cracks also appear from exposure to too low or high temperatures or drafts. Therefore, after applying the plaster, it is best to close all windows and doors.

A new layer can be applied only after the previous one has completely dried.

There is a misconception that if you add more cement, the strength of the mortar will increase. But this is not true. Of course, the solution will become denser, but when it dries, cracks will quickly form on the surface.

Before applying the plaster, you must ensure that the surface is completely dry. Otherwise, the coating will not adhere well and will quickly peel off. But an overdried surface will not retain the coating. It is also not recommended to make layers that are too thin or thick.

For better fixation of the plaster mixture, you should make sure that the surface is sufficiently rough. If you apply layers of different thicknesses, then after drying this will be noticeable by the uneven color of the surface due to different drying times.

The strength is affected by the amount of binder and the absence of contamination in the materials. Gypsum plaster cannot be used on concrete surfaces; this can lead to destruction of the surface. It is also not recommended to apply lime mixture to plaster.

Necessary tools and materials for work

To prepare mortar for plaster, you need the appropriate tools and equipment. You can mix the plaster manually (with a shovel in a trough) or in a mortar mixer (mechanically). It all depends on the amount of work and capabilities. To mix a small portion, you can use a mixer.

To get started, you should purchase the appropriate materials in advance with a reserve (about 20%):

- individual components or dry mixtures ready for mixing;

- color or pigments;

- prepare clean water (tap or rain);

- additives (available in hardware stores);

- containers;

- a shovel is useful for pouring filler into the mortar mixer;

- To open the packages you will need a knife;

- trowel (and other tools for applying compounds).

Production technology

Each dry mixture is prepared according to certain recipes, which may differ from one manufacturer to another. The products are manufactured in several stages using special equipment:

- The drying drum is filled with sand. Inside it is mixed and sorted according to the size of the fractions - small, medium or large.

- When the auger is filled with sand of the required caliber, the machine stops working. In automatic mode, the material is shipped and transported to the cement bunker.

- At the next stage, substances are added to the mixture that impart certain properties. The ingredients are thoroughly mixed and sent to the packaging bin.

- Finished products are packaged in paper bags.

How to mix plaster

To prepare solutions for plastering walls, follow a certain mixing sequence. If the binder and filler are free-flowing, and the composition is mixed manually, the dry components are pre-mixed.

After this, liquid components are added to the container. In this case, liquid additives (for example, milk of lime) are added to the water in advance and stirred. In this sequence, it is possible to prepare a plaster batch with an even distribution of all components in the mixture.

Perlite sand is very light and produces a lot of dust. To facilitate the kneading process, it is moistened by pouring water into the bag.

If the batch is prepared in a mortar mixer, then water is poured in first and the engine is turned on. Then other liquid components are added there. Then cement and sand are poured. It is not recommended to pour the entire volume of water into the mortar mixer at once, since the sand is usually wet. And there is no need for excess water in the solution. Do not forget also about maintaining the proportions for the plaster.

Gypsum (gypsum dry mixtures) is poured into a container with water. The container is selected taking into account the expansion of the mortar mass.

Preparing the walls

Preparing walls for decorative plaster is carried out in the following order:

- Seal up the cracks.

- Putty with durable cement putty.

- They plaster with a falcon in the air WITHOUT LIGHTHOUSES, even surface ones; There is no need to achieve perfect evenness, as for painting or wallpaper - the decor will hide minor imperfections.

- Thoroughly remove dust with dry dust mat, then suck it out with a vacuum cleaner with a dust collector.

- Under all plasters, except Venetian, they are primed with a deep penetration primer on stone or plaster.

- Under Venetian plaster - make a base with sand, see below.

Beacons cannot be used in base plaster for the following reason: the base layer may not be very even, but it must be perfectly uniform. Sealed grooves from removed beacons, dried induced beacons disrupt this uniformity, which in a couple of years will lead to peeling of the decor.

It is better to use warm base plaster on expanded vermiculite. Foam plastic, etc. is not durable, but in decorative plaster, as nowhere else, one must observe the immutable finishing principle: the strong and heavy should not fall on the light and weak.

Why do you need warm plaster? The decor is inherently heterogeneous, which is why it is sensitive to the temperature gradient (temperature difference) across the thickness of the layer. Load-bearing walls are now built more from sand-lime brick and concrete, which have a fairly high thermal conductivity, which is why during sudden changes in weather the gradient can go beyond the permissible limits. If the box is made of ceramic bricks, then they are now heated not with stoves, but with radiators, and they don’t make meter-thick walls, which can give the same result.

Venetian lining

Applying natural Venetian plaster requires significant physical effort, and replacing sand with marble dust reduces the adhesion of the mixture. In addition, for the Venetian to show itself in all its glory, the substrate under it must reflect the light with shine.

The ancient method of priming for Venetian is painting with lead or zinc white (tucia) on linseed oil with an admixture of fine quartz sand and ground pearls that have aged and lost their value. Now the base surface under the Venetian is painted with pearl acrylic paint, also with the addition of sand, to improve adhesion due to roughness.

How much sand do you need? Approximately 5-15% by weight. A nail test is accurately determined by the dried paint: the nail should go on easily and smoothly, and a uniformly rough white spot should remain on it. If individual scratches are visible, there is not enough sand or it is too coarse. If it slows down like sandpaper, there is a lot of sand.

Is it possible to prime the old fashioned way? Not recommended. Firstly, there is no point in replacing pearls with a cheaper, but still expensive pearl pat: pat is made from the scales of small herring fish - sprat, sprat, herring, kibinago - and in terms of its physical and chemical properties it is not a pearl at all. Secondly, a city apartment is not a family nest. Someday there will be a renovation again, and the oil that has soaked into the wall will appear as stains on the wallpaper or paint, and it is very difficult to get rid of them.

Ready-made plaster mixtures

It is easier for beginners to use ready-made plaster mixtures produced by various companies. The finished mixture already contains various additives, so you can’t expect “surprises” from the behavior of the solution when laying it on the wall and hardening the mass. The packaging contains information on how to properly make the batch, the specifics of the composition and its characteristics.

Dry mixtures are prepared according to the instructions that can be found on the packaging. During transportation, partial settling of heavier filler particles in the packaging is possible. Therefore, in order to avoid some deviations in the composition of different batches, it is recommended to dilute the dry mixture entirely (the entire package).

Ready-made formulations have an expiration date. It is better to purchase mixtures that are still far from expiration date. To ensure that the finish on large walls is uniform, it is better to take mixtures for preparing plaster from one batch.

Preparing a solution for plaster is a seemingly simple job. But the quality and properties of the finish depend on how well and correctly the plaster batch is prepared.

What can be used to create a decorative effect

You can make different drawings on the surface using completely different means. For this purpose, methods with special application of the composition are in the first row. Work with a notched trowel or trowel can be used; they move randomly, or equally in one chosen direction.

Ready-made textured rollers, stencils, which can even be simply cut out of cardboard of different density. From available items you can use paper that is crumpled, plastic bags, a sponge, and unusual objects.

You can make different drawings on the surface using completely different means.

Coloring compounds

If plaster, pre-painted in the desired shade, is applied, it is advisable to protect the surface with a varnish. When finishing facades, it is necessary to carry out painting on a dried base of the plaster layer.

The coloring process consists of the following technology:

- Preliminary priming of the material is carried out.

- For painting, use a roller with long pile, apply one layer of paint, wait until the layer dries completely.

- The application of the 2nd layer should be carried out with a roller with short bristles; it is also necessary that the layer dries well.

- The final layer is applied with a varnish, then the coating will be glossy. If desired, you can also add shiny elements to the varnish base, but then you need to stir frequently so that all the sparkles do not remain at the bottom of the bucket.

If plaster, pre-painted in the desired shade, is applied, it is advisable to protect the surface with a varnish.

Decorative plaster is an option for creating a unique coating on the wall; you can get a variety of patterns on the surface. The master can show his imagination. At the same time, it is possible to significantly reduce repair costs if you prepare the solution yourself; this does not require purchasing a huge amount of ingredients. Also, obtaining the product is not difficult, and the result will look much as beautiful as the finished composition from the manufacturers.