Paint consumption per square meter, per 1m2

This article provides information on paint consumption per square meter, as well as the conditions on which paint consumption depends.

We will touch on types of paint, such as: oil-based, water-dispersion and water-based, facade. We’ll also talk about the consumption of enamels, in particular about PF-115. Let's analyze the consumption of drying oil. Try calculating your consumption in the extended version of the paint consumption calculator, you can also read the article about the consumption of plaster materials and calculate the consumption of plaster for walls in the calculator.

Oil paint consumption

Oil paints use drying oil as a binder, which polymerizes after application to the surface. Consumption can vary from 140 grams per meter to 250. Let's look at it in more detail: For a flat surface, we will need about 150 grams per meter, that is, with a kilogram can we can paint about 6.5 meters. For a rough surface, more will be required, approximately 160 g/m. Colored paint per 1m2 will require 130-140 grams.

Consumption of enamel pf-115

Consumption of acrylic-based water-dispersion paint

Acrylic-based water-dispersion paints are used both indoors and when working on facades. They have a matte appearance and are tinted with color pastes. They provide a large palette of colors that do not fade in the sun. The manufacturer indicates consumption up to 8 m2 per 1 liter, but in practice the covering capacity is usually 115 g/m2 (i.e. 1 liter per 6-7 m2). The fact is that the manufacturer indicates the given consumption rates in a thin layer, on a smooth surface, under ideal conditions. In practice, much depends on the absorbency and surface roughness. The method of application also matters. For example, when using a spray gun, less paint will be used than when working with a roller. Again, a roller is more economical than a brush. Be aware that you will need 5-15% more paint than indicated on the package. Apply acrylic paints in 2-3 layers on a clean, dry base. Moreover, a high-quality composition will cover the color of the base in 2 layers, while a cheaper version will require 3 layers. Thus, cheap paint can actually cost more.

The color can last on concrete without visible changes for up to 5 years, then it darkens and after 2-3 years it can begin to peel off. If such paint is applied to plaster, cement, etc. , then priming can be done with it, diluted with water up to 10%. Then a layer of undiluted paint is applied.

Consumption of water-based paint

Water-based paints are used for finishing ceilings and any other surfaces, except those that were previously painted with glossy paint. When calculating paint consumption, you need to focus on the consumption per square meter specified by the manufacturer. On average it is 1 liter per 7-11 m2. For some water-based paints, one liter is enough for 14-18 m2 in one layer. But the indicated consumption may not coincide with the actual one; the absorbency of the surface should be taken into account. To reduce paint consumption and increase service life, it is recommended to treat the surface with a hardening primer. Do not apply water-based paint in a thick layer. Most often, 2-3 layers are made, each subsequent one is applied after the previous one has dried, after 1.5-2 hours. Paints based on butadiene styrene are highly resistant to moisture, but may turn yellow when exposed to light.

Facade paint consumption per 1m2

Almost all types of paints can be used as façade paint, so it is concluded that a specific type has its own consumption. Approximate consumption values are from 160 to 250 grams per square meter, while the consumption of white paint is always greater than other colors. Painting the facade will protect it well and preserve it, so the work should be done carefully and not try to save money.

Drying oil consumption per 1m2

Drying oil consumption ranges from 100 to 130 grams per square meter. By pre-coating a wooden surface with drying oil, you can save paint by 10-15%

The concept of “paint hiding power”

The greater the hiding power, the better the new paint covers the color of the old one, thus, the better the hiding power, the more economical the use. The best indicator is 20-40 g/1m2 of surface.

Preparing for coloring

Before carrying out paint and varnish work, it is worth thoroughly preparing the surface for painting. This is necessary so that the enamel lays down in an even and thin layer, giving the canvas a beautiful appearance.

What to do before painting:

- Free the canvas from dirt and dust. This can be done with a damp cloth;

- Make the surface smooth using putty;

- Treat the canvas with primer.

Advice! In order to reduce enamel consumption, you need to repair all the irregularities in the canvas, making the surface as smooth as possible.

GENERAL PROVISIONS

1.1. These standards apply to paints and auxiliary materials used for anti-corrosion protection of steel building structures of buildings and structures at the installation site.

1.2. The standards are intended to calculate the need and control the consumption of paint and varnish and auxiliary materials during painting work at the installation site.

1.3. The standard for the consumption of paints and varnishes is taken as the basis for calculating the consumption rates of paints and varnishes.

Consumption standard is the maximum permissible amount of paint and varnish material required to obtain a coating of one layer 1 micron thick on a surface area of 1 m2 (Table 1).

1.4. Consumption rate - the amount of paint and varnish material established per unit of production, taking into account all factors influencing its value. In these “Standards”, 1 ton of metal structures is taken as a unit of production (Table 2).

1.5. Auxiliary materials include solvents and substances that are part of paints and varnishes and are an integral part of them when applied to the surface to be painted (Table 3).

1.6. Consumption rates reflect the design, technological and organizational features of production and contribute to the maximum use of paints and varnishes, as well as the identification and use of internal reserves.

How to store PF-115 paint

The PF-115 material contains flammable substances as well as toxic additives. Therefore, paint should be stored in certain places, preferably not in a residential area.

- And away from sunlight and heat sources.

- The ideal temperature for storage is from -50 to +60 C.

- Also, the enamel is stored only under a well-closed lid.

This is necessary so that the paint does not lose its beneficial properties (to avoid drying out) and does not release toxic substances into the space.

STANDARDS AND CONSUMPTION STANDARDS FOR PAINT AND AUXILIARY MATERIALS

2.1. Standards and standards are designed for paints and auxiliary materials used for painting steel building structures during the installation of buildings and structures.

Submitted by VNIPI Promstalkonstruktsiya Minmontazhspetsstroy USSR

Ministry of Montazhspetsstroy of the USSR June 25, 1984

Effective date: January 1, 1985

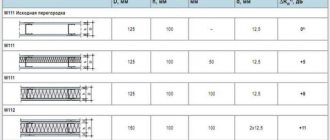

2.2. The consumption standards for paints and varnishes in g/(m 2 × µm) per 1 layer are presented in table. 1. Dashes in the table indicate that these paints and varnishes are not applied using the specified method.

2.3. The standards are calculated taking into account the physical and chemical indicators of paints and varnishes and the efficiency factor (Appendices 1 and 2).

2.4. Codes of paints and varnishes are given in accordance with the “All-Union Classifier of Industrial and Agricultural Products”, M.: Book, 1977.

2.5. The consumption rates of paints and varnishes of initial viscosity in kg per 1 ton of metal structures (per one layer of coating) are given in table. 2. In columns 4-9, the consumption rates of paints and varnishes and solvents are given for methods of pneumatic and airless spraying and brush painting; in columns 10-11, average consumption rates are given, calculated on the basis of columns 4-9 and taking into account the specific gravity of methods for applying paints and varnishes in the industry (see clause 3.4.). Average consumption rates are used to determine the planned need for paints and varnishes.

2.6. The standards are set for one layer of coating. The required number of layers is taken according to the project.

2.7. Consumption rates for paints and varnishes in kg/t are calculated according to the methodology given in Appendix 1, based on the following initial data:

standards for consumption of paint and varnish material, taking into account technological losses during application by various methods, g/(m 2 × µm) (see Table 1);

optimal coating thickness, microns (see Table 2);

specific gravity of the complexity group of the painted surface of metal structures (Appendix 3);

coefficients of complexity groups of the surface to be painted (Appendix 4);

the average value of the coefficients characterizing the condition of the painted surface for hot-rolled steel when applying the 1st or 2nd layer of coating (Appendix 5);

The average area of the painted surface in 1 ton of metal structures is 29 m2.

2.8. In case of a significant deviation of the area of the surface to be coated in 1 ton of metal structures from the average area, the consumption rate must be recalculated taking into account the correction factor

,

where: F

f

- actual painted area, m 2;

F

с -

average painted area, m 2.

2.9. In table Table 3 shows data on the compatibility of solvents and auxiliary substances with paints and varnishes and their quantitative ratio as a percentage to the base paint and varnish material in the initial viscosity.

2.10. Consumption rates are calculated for applying paints and varnishes at air temperatures not lower than +15 °C. In case of significant deviations in air temperature (for example, applying perchlorovinyl enamels at subzero temperatures), it is necessary to ensure the temperature of the working compositions in accordance with the requirements of regulatory and technical documentation, i.e. 18-22 °C.

Principles for determining dye consumption

How to paint the walls in a room from choosing paint and color to using a roller

Painting a Saturated Surface

The consumption of the dye, which must be determined in order to calculate the required amount for a certain area to be painted, is divided into two main types:

- Theoretical consumption, including the total consumption of a substance per square meter;

- Natural loss of coloring matter that occurs during the process of painting walls or any other surface.

Paint loss can also be divided into two main types: apparent type loss and actual type loss. Obvious type of paint loss implies an increased thickness of the paint layer on the painted surface, which leads to greater paint consumption per square meter. Actual paint loss implies the transfer of the coloring composition due to inaccurate use of paint.

Impact of abrasive type profile

In the case where the surface to be painted was amenable to sandblasting, the thickness of the layer of paint on the convexities of the abrasive type profile will be significantly less than in the recesses of this surface.

This is a rather important point, since the thickness of the layer of paint on the protuberances has the maximum value for the quality of the entire surface being painted. Therefore, we can safely say that that part of the paint that was not included in the layer on the convexities is considered missing on the profile itself, which has no special significance as a surface to be finished.

Due to the fact that the surface profile was obtained due to sandblasting type processing, the total loss of the coloring composition is equal to the surface composition of the abrasive itself that was used on this surface.

When the abrasive consists of metal chips, the roughness of the surface being painted will not lead to excessive consumption of the coloring composition. In the case where the abrasive consists of coarse natural materials, such as coarse unwashed sand or medium-fraction gravel, the loss of the coloring composition on such a surface can be considered quite significant.

This type of abrasive is characterized by increased absorption of liquids, which leads to the absorption of liquid paint particles. Therefore, the layer of paint composition is of rather poor quality, which leads to repeated painting of the surface and greater consumption of the paint composition.

In order to avoid excessive paint losses, it is necessary to treat such a surface with special compounds that will saturate the abrasive and allow the surface to be painted in one high-quality layer.

Distribution of the coloring composition

Paint distribution is a process in which the master tries to paint the required surface in such a way that the thickness of the layer of the paint composition is the minimum acceptable, which will lead to the consumption of the paint composition, which is indicated in the consumption characteristics of this type of paint.

The additional consumption of the paint composition depends on the method used to paint the desired surface (using a spray gun, roller or brush). In addition, the type of surface being repaired itself, and in particular its porosity and ability to absorb moisture, also affects the additional consumption of color.

Color to create the desired shade

In the case where the required surface has a rather porous composition, the consumption of the dye will significantly exceed the indicated standards, even when painting is carried out using a spray gun.

Accordingly, any other method of painting such a surface will only increase the minimum consumption of the coloring composition. The distribution of the coloring composition for such surfaces is considered the most difficult, given that the surface must first be treated with special compounds and antiseptics.

Paint write-off standards

Today, most people choose painting to decorate the ceiling and walls. To purchase the required quantity of any paint and varnish material, its consumption per 1 m2 is calculated. In this case, you should take into account the structure of the material and the specifics of the surfaces that need to be painted. What are the consumption rates for PF-115 paint per 1 m2 and how can I find out the exact indicator?

The abbreviation PF in the name of the enamel means PENTAPHTAL. It’s easy to decipher – the paint material contains alkyd resins and semi-dried oils, which allow the paint to dry quickly.

Cost of paint PF-115

PF-115 is considered an inexpensive material for finishing all types of premises. However, the final cost will depend on the manufacturer, place of sale and popularity of the store.

As a rule, small hardware stores stand out for their low prices on paint and varnish materials. In large stores of a certain brand, the price of enamel can be several times higher than in a regular hardware store.

The average price for PF-115 enamel varies from 50 to 100 rubles per 1,000 grams.

Advice! You should not purchase paint if the cost per kilogram is below 40 rubles. Such a low price indicates a low-quality product. The tested material always contains the GOST marking.

Comparison of materials from Dulux, Tikkuril and other popular manufacturers

Painting the walls

Each manufacturer improves the technical characteristics of the material with its specific additives. As a result, the hiding power of similar compositions varies from company to company. The table shows white matte paint for the ceiling.

| Firm | The basis | Coverage rates 1 liter, per m2 |

| Dulux | latex | 9 — 13 |

| Dulux | water-soluble | 7 |

| Marshal VD | water-dispersed | 7 — 9 |

| Tikkurila Fincolor | water-dispersed | 7 — 9 |

| Tex | water-soluble | 4 — 6 |

| Tex | based on latex and acrylic | 9 — 12 |

| Beckers | latex | 8 — 12 |

| Beckers | water-based | 7 — 10 |

When buying paint, add to the estimated quantity the cost of losses of 5 - 7%, depending on experience and the location of the surface. The smallest for the floor, since there is nowhere for liquid to drip and drain. For walls, consider the tool:

- spray gun – 3%;

- roller with medium pile 4 - 5%;

- brush up to 7%.

The largest amount of the composition is absorbed when applying the first layer. High-quality soil and materials from one manufacturer save their costs and drying time.

Adblock detector

Rules for calculating the amount of paint

The calculation scheme is simple: determine the area of the surface to be painted, assess its condition, estimate how many layers need to be applied, and how to whitewash it. Each of the listed parameters will need to be taken into account after obtaining the basic requirement for the amount of paint by increasing it.

It is allowed to leave it in the same size if it is possible to bring the surface into a condition that meets the regulatory requirements for painting. It must be taken into account that the weight of the contents of a 1 liter jar for PF-115 is 1.5 kg.

Surface type

The surface of various structures is inspected for readiness for coating before painting begins. If it is metal, pay attention to rust, dirt in the form of dust, and traces of grease. The surface profile also matters. The old paint layer is removed from any base, the roughness of the walls and ceiling is leveled by preliminary application of putty or primer.

Depending on the surface material, paint consumption in 1 layer is as follows:

- metal – 100-150 g/m²;

- reinforced concrete, plaster – 150-250;

- wood – 75-150.

Covering capacity according to the condition of the surface: smooth metal is covered with 1 liter of paint on an area of 14-16 m², rough metal - 6-10 m². The same amount of coloring composition when applied to concrete is enough for 4-6 m², for plaster - 16, for wood along the grain - 8-10, for textured wallpaper - 10 m².

When to paint multiple layers

In practice, they paint twice. The solution consumption for the first layer is 10% higher.

If wood is painted for the first time, then you should take into account the paint consumption for 3 layers.

It is necessary to coat the surface twice or thrice under the following circumstances:

- wood is painted for the first time;

- color saturation required;

- high fluidity of whitewash;

- the need for bright colors;

- multidirectional overlay of layers: vertically, horizontally.

Consider: Why Painting Your Living Room Is So Appealing

The initial color also affects the number of coatings - you can refresh a light wall with a single layer of whitewash. If the color is applied dark, you will have to paint it twice. The second layer is applied to the dried surface.

The waiting time for nitro paint is 0.5-3 hours, water-based paint is 2-8 hours. Alkyd compounds dry within 24 hours.

Pre-priming reduces the number of coats. This rule does not apply when painting wallpaper - they are not primed. In this case, surface preparation is carried out with a solution of acrylic paint and water diluted in a ratio of 80:20. The number of layers is not limited, but the desire for growth increases the cost of repairs.

Method of application and consumption

Surface painting is carried out in 2 ways: manually and using mechanized means. In the latter case, whitewash or color is sprayed onto the base using compressed air.

Each painting tool has a different effect on paint consumption:

- Brush made of natural or synthetic bristles. Used for small volumes of work. Losses during coloring are 10-15% depending on the qualifications of the artist.

- A device in the form of a roller with short or long pile. It is used in conjunction with a special bath - paint is poured into it, the excess color is dipped and squeezed out of the shaft. The tool is designed for processing large areas. Consumption exceeds the standard indicator by 5-10%.

- A sprayer or spray gun is an economical device for painting. Reduced paint consumption is achieved by applying a thin layer of coating, unattainable with the first two tools. The number of losses is 3-5%.

Pay attention to: Painting ceramic tiles in the bathroom, kitchen, floor: choosing the necessary paint, step-by-step work technology

It is economical to paint surfaces with a spray gun or sprayer.

Consumption is also reduced by diluting the nitro paint by half with a thinning solvent. The thickness of water-based paint is reduced by adding 10% water to it.