The finishing material used for exterior and interior work, capital construction and cosmetic repairs is plaster. Its features depend on the type, and there are quite a lot of them, since various elements are added to the mixture that can enhance its basic qualities or add aesthetics to the coating. Let's look at some types, and also determine what the thermal conductivity of plaster is and what the indicator is for different types of material.

Decorative plaster

Definition

Thermal conductivity of a material is the transfer of internal energy from more heated parts to less heated parts. The mechanism of heat transfer differs depending on the state of aggregation of the substance, as well as the temperature distribution over the surface of the material. In other words, the ability of a body to conduct heat is thermal conductivity. It is determined by the amount of heat that is capable of passing through a certain thickness of material in a certain area for a specified time (naturally, for the convenience of calculations, all indicators are equal to one). But plasters differ in the layer of application, which means the indicator will be different

Thermal conductivity of building materials

The design of energy-efficient house technologies should be carried out by specialists, but in real life everything may be different. It happens that home owners, for a number of reasons, are forced to independently select materials for construction. They will also need to calculate thermal parameters on the basis of which thermal insulation and insulation will be carried out. Therefore, you need to have at least a minimal understanding of building heating engineering and its basic concepts, such as thermal conductivity coefficient, in what units it is measured and how it is calculated. Knowing these “basics” will help you properly insulate your home and heat it economically.

What is thermal conductivity

Thermal conductivity of a brick wall: without insulation;

with insulation on the outside; with insulation inside the house; In simple terms, thermal conductivity is the transfer of heat from a hotter body to a less hot one. Without going into details, all physical materials and substances can transmit thermal energy.

Every day, even at the most primitive everyday level, we are faced with thermal conductivity, which manifests itself in each material differently and to a very different extent. For example, if you stir boiling water with a metal spoon, you can get burned very quickly, since the spoon heats up almost instantly. If you use a wooden spatula, it will heat up very slowly. This example clearly shows the difference in thermal conductivity between metal and wood - for metal it is several times higher.

INTERESTING: Slate: types of sizes, pros and cons

Coefficient of thermal conductivity

To evaluate the thermal conductivity of any material, the thermal conductivity coefficient (λ) is used, which is measured in W/(m×℃) or W/(m×K). This coefficient indicates the amount of heat that can be conducted by any material, regardless of its size, per unit time over a certain distance. If we see that some material has a high coefficient value, then it conducts heat very well and can be used as heaters, radiators, and convectors. For example, metal heating radiators in rooms work very efficiently, perfectly transferring heat from the coolant to the internal air masses in the room.

If we talk about the materials used in the construction of walls, partitions, roofs, then high thermal conductivity is an undesirable phenomenon. With a high coefficient, the building loses too much heat, to retain which it will be necessary to build rather thick structures indoors. And this entails additional financial costs.

The thermal conductivity coefficient depends on temperature. For this reason, reference literature indicates several coefficient values that change with increasing temperatures. Operating conditions also affect heat conductivity. First of all, we are talking about humidity, since as the percentage of moisture increases, the coefficient of thermal conductivity also increases. Therefore, when carrying out this kind of calculations, you need to know the real climatic conditions in which the building will be built.

Heat transfer resistance

Thermal conductivity coefficient is an important characteristic of any material. But this value does not accurately describe the thermal conductivity of the structure, since it does not take into account the features of its structure. Therefore, it is more appropriate to calculate the heat transfer resistance, which is essentially the reciprocal of the thermal conductivity coefficient. But unlike the latter, the calculation takes into account the thickness of the material and other important design features.

During construction, as a rule, multilayer structures are used, such as frame or SIP houses. One of these layers is an insulating material that maximizes the value of thermal resistance. Each layer of such a structure has its own resistance and must be calculated based on the thermal conductivity coefficient and the thickness of the material. By summing the resistance of all layers, we get the total resistance of the entire structure.

It is important to note that the air gaps that are located in the partition structure and do not communicate with the outside air significantly increase the overall heat transfer resistance.

Modern construction trends include the use of synthetic materials such as EPS PIR boards and Izolon as insulation, which have excellent characteristics, are convenient and easy to install.

INTERESTING: Gas silicate. Types and characteristics

Thermal conductivity, density and heat capacity coefficients have been calculated for almost all building materials. Below is a table with information about the coefficients for all materials that can be used in the construction of buildings. Even just looking at these data, it becomes clear how different the thermal conductivity of building materials is and how much the coefficient values can differ. To simplify the choice of material for the buyer, manufacturers indicate the value of the thermal conductivity coefficient in the passport for their product.

| Material | Density, kg/m3 | Thermal conductivity, W/(m deg) | Heat capacity, J/(kg deg) |

| ABS (ABS plastic) | 1030…1060 | 0.13…0.22 | 1300…2300 |

| Aggloporite concrete and concrete based on fuel (boiler) slags | 1000…1800 | 0.29…0.7 | 840 |

| Acrylic (acrylic glass, polymethyl methacrylate, plexiglass) GOST 17622-72 | 1100…1200 | 0.21 | — |

| Alfol | 20…40 | 0.118…0.135 | — |

| Aluminum (GOST 22233-83) | 2600 | 221 | 840 |

| Fibrous asbestos | 470 | 0.16 | 1050 |

| Asbestos cement | 1500…1900 | 1.76 | 1500 |

| Asbestos cement sheet | 1600 | 0.4 | 1500 |

| Asbozurite | 400…650 | 0.14…0.19 | — |

| Asbomica | 450…620 | 0.13…0.15 | — |

| Asbotekstolit G (GOST 5-78) | 1500…1700 | — | 1670 |

| Asbothermite | 500 | 0.116…0.14 | — |

| Asbestos slate with high asbestos content | 1800 | 0.17…0.35 | — |

| Asboshifer with 10-50% asbestos | 1800 | 0.64…0.52 | — |

| Felt asbestos cement | 144 | 0.078 | — |

| Asphalt | 1100…2110 | 0.7 | 1700…2100 |

| Asphalt concrete (GOST 9128-84) | 2100 | 1.05 | 1680 |

| Asphalt in floors | — | 0.8 | — |

| Acetal (polyacetal, polyformaldehyde) POM | 1400 | 0.22 | — |

| Airgel (Aspen aerogels) | 110…200 | 0.014…0.021 | 700 |

| Basalt | 2600…3000 | 3.5 | 850 |

| Bakelite | 1250 | 0.23 | — |

| Balsa | 110…140 | 0.043…0.052 | — |

| Birch | 510…770 | 0.15 | 1250 |

| Lightweight concrete with natural pumice | 500…1200 | 0.15…0.44 | — |

| Concrete on gravel or crushed stone from natural stone | 2400 | 1.51 | 840 |

| Concrete on volcanic slag | 800…1600 | 0.2…0.52 | 840 |

| Concrete based on granulated blast furnace slag | 1200…1800 | 0.35…0.58 | 840 |

| Concrete on ash gravel | 1000…1400 | 0.24…0.47 | 840 |

| Concrete on crushed stone | 2200…2500 | 0.9…1.5 | — |

| Concrete on boiler slag | 1400 | 0.56 | 880 |

| Concrete on sand | 1800…2500 | 0.7 | 710 |

| Concrete based on fuel slag | 1000…1800 | 0.3…0.7 | 840 |

| Dense silicate concrete | 1800 | 0.81 | 880 |

| Solid concrete | — | 1.75 | — |

| Thermal insulating concrete | 500 | 0.18 | — |

| Bitumen perlite | 300…400 | 0.09…0.12 | 1130 |

| Petroleum bitumens for construction and roofing (GOST 6617-76, GOST 9548-74) | 1000…1400 | 0.17…0.27 | 1680 |

| Aerated concrete block | 400…800 | 0.15…0.3 | — |

| Porous ceramic block | — | 0.2 | — |

| Bronze | 7500…9300 | 22…105 | 400 |

| Paper | 700…1150 | 0.14 | 1090…1500 |

| Booth | 1800…2000 | 0.73…0.98 | — |

| Light mineral wool | 50 | 0.045 | 920 |

| Heavy mineral wool | 100…150 | 0.055 | 920 |

| Glass wool | 155…200 | 0.03 | 800 |

| Cotton wool | 30…100 | 0.042…0.049 | — |

| Cotton wool | 50…80 | 0.042 | 1700 |

| Slag wool | 200 | 0.05 | 750 |

| Vermiculite (in the form of bulk granules) GOST 12865-67 | 100…200 | 0.064…0.076 | 840 |

| Expanded vermiculite (GOST 12865-67) - backfill | 100…200 | 0.064…0.074 | 840 |

| Vermiculite concrete | 300…800 | 0.08…0.21 | 840 |

| Woolen felt | 150…330 | 0.045…0.052 | 1700 |

| Gas and foam concrete, gas and foam silicate (foam block) | 300…1000 | 0.08…0.21 | 840 |

| Gas and foam ash concrete | 800…1200 | 0.17…0.29 | 840 |

| Getinax | 1350 | 0.23 | 1400 |

| Dry molded gypsum | 1100…1800 | 0.43 | 1050 |

| Drywall | 500…900 | 0.12…0.2 | 950 |

| Gypsum perlite solution | — | 0.14 | — |

| Gypsum slag | 1000…1300 | 0.26…0.36 | — |

| Clay | 1600…2900 | 0.7…0.9 | 750 |

| Fireproof clay | 1800 | 1.04 | 800 |

| Clay gypsum | 800…1800 | 0.25…0.65 | — |

| Alumina | 3100…3900 | 2.33 | 700…840 |

| Gneiss (facing) | 2800 | 3.5 | 880 |

| Gravel (filler) | 1850 | 0.4…0.93 | 850 |

| Expanded clay gravel (GOST 9759-83) - backfill | 200…800 | 0.1…0.18 | 840 |

| Shungizite gravel (GOST 19345-83) - backfill | 400…800 | 0.11…0.16 | 840 |

| Granite (cladding) | 2600…3000 | 3.5 | 880 |

| Soil 10% water | — | 1.75 | — |

| Soil 20% water | 1700 | 2.1 | — |

| Sandy soil | — | 1.16 | 900 |

| The soil is dry | 1500 | 0.4 | 850 |

| Compacted soil | — | 1.05 | — |

| Tar | 950…1030 | 0.3 | — |

| Dense dry dolomite | 2800 | 1.7 | — |

| Oak along the grain (wood) | 700 | 0.23 | 2300 |

| Oak across the grain (GOST 9462-71, GOST 2695-83) | 700 | 0.1 | 2300 |

| Duralumin | 2700…2800 | 120…170 | 920 |

| Iron | 7870 | 70…80 | 450 |

| Reinforced concrete | 2500 | 1.7 | 840 |

| Reinforced concrete | 2400 | 1.55 | 840 |

| Wood ash | 780 | 0.15 | 750 |

| Gold | 19320 | 318 | 129 |

| Limestone (cladding) | 1400…2000 | 0.5…0.93 | 850…920 |

| Products made of expanded perlite with a bitumen binder (GOST 16136-80) | 300…400 | 0.067…0.11 | 1680 |

| Vulcanite products | 350…400 | 0.12 | — |

| Diatomite products | 500…600 | 0.17…0.2 | — |

| Newelite products | 160…370 | 0.11 | — |

| Foam concrete products | 400…500 | 0.19…0.22 | — |

| Perlite phosphogel products | 200…300 | 0.064…0.076 | — |

| Sovelite products | 230…450 | 0.12…0.14 | — |

| Frost | — | 0.47 | — |

| Iporka (foamed resin) | 15 | 0.038 | — |

| Coal dust | 730 | 0.12 | — |

| Hollow-core stones made of lightweight concrete | 500…1200 | 0.29…0.6 | — |

| Solid stones made of lightweight concrete DIN 18152 | 500…2000 | 0.32…0.99 | — |

| Solid stones made from natural tuff or expanded clay | 500…2000 | 0.29…0.99 | — |

| Building stone | 2200 | 1.4 | 920 |

| Carbolite black | 1100 | 0.23 | 1900 |

| Asbestos insulating cardboard | 720…900 | 0.11…0.21 | — |

| Corrugated cardboard | 700 | 0.06…0.07 | 1150 |

| Cardboard facing | 1000 | 0.18 | 2300 |

| Waxed cardboard | — | 0.075 | — |

| Thick cardboard | 600…900 | 0.1…0.23 | 1200 |

| Cork cardboard | 145 | 0.042 | — |

| Multilayer construction cardboard (GOST 4408-75) | 650 | 0.13 | 2390 |

| Thermal insulating cardboard (GOST 20376-74) | 500 | 0.04…0.06 | — |

| Foamed rubber | 82 | 0.033 | — |

| Vulcanized rubber, hard gray | — | 0.23 | — |

| Vulcanized rubber soft gray | 920 | 0.184 | — |

| Natural rubber | 910 | 0.18 | 1400 |

| Solid rubber | — | 0.16 | — |

| Fluorinated rubber | 180 | 0.055…0.06 | — |

| Red cedar | 500…570 | 0.095 | — |

| Lacquered cambric | — | 0.16 | — |

| Expanded clay | 800…1000 | 0.16…0.2 | 750 |

| Expanded clay peas | 900…1500 | 0.17…0.32 | 750 |

| Expanded clay concrete on quartz sand with porosity | 800…1200 | 0.23…0.41 | 840 |

| Lightweight expanded clay concrete | 500…1200 | 0.18…0.46 | — |

| Expanded clay concrete on expanded clay sand and expanded clay foam concrete | 500…1800 | 0.14…0.66 | 840 |

| Expanded clay concrete on perlite sand | 800…1000 | 0.22…0.28 | 840 |

| Ceramics | 1700…2300 | 1.5 | — |

| Warm ceramics | — | 0.12 | — |

| Blast-furnace brick (fire-resistant) | 1000…2000 | 0.5…0.8 | — |

| Diatomaceous brick | 500 | 0.8 | — |

| Insulating brick | — | 0.14 | — |

| Carborundum brick | 1000…1300 | 11…18 | 700 |

| Red dense brick | 1700…2100 | 0.67 | 840…880 |

| Red porous brick | 1500 | 0.44 | — |

| Clinker brick | 1800…2000 | 0.8…1.6 | — |

| Silica brick | — | 0.15 | — |

| Facing brick | 1800 | 0.93 | 880 |

| Hollow brick | — | 0.44 | — |

| Silicate brick | 1000…2200 | 0.5…1.3 | 750…840 |

| Silicate brick from those. voids | — | 0.7 | — |

| Slotted silicate brick | — | 0.4 | — |

| Solid brick | — | 0.67 | — |

| Construction brick | 800…1500 | 0.23…0.3 | 800 |

| Treble brick | 700…1300 | 0.27 | 710 |

| Slag brick | 1100…1400 | 0.58 | — |

| Rubble masonry made of medium-density stones | 2000 | 1.35 | 880 |

| Gas silicate masonry | 630…820 | 0.26…0.34 | 880 |

| Masonry made of gas silicate thermal insulation boards | 540 | 0.24 | 880 |

| Masonry of ordinary clay bricks on cement-perlite mortar | 1600 | 0.47 | 880 |

| Masonry of ordinary clay bricks (GOST 530-80) on cement-sand mortar | 1800 | 0.56 | 880 |

| Masonry of ordinary clay bricks on cement-slag mortar | 1700 | 0.52 | 880 |

| Masonry of ceramic hollow bricks with cement-sand mortar | 1000…1400 | 0.35…0.47 | 880 |

| Small brick masonry | 1730 | 0.8 | 880 |

| Masonry made of hollow wall blocks | 1220…1460 | 0.5…0.65 | 880 |

| Masonry made of 11-hollow silicate bricks with cement-sand mortar | 1500 | 0.64 | 880 |

| Masonry made of 14-hollow silicate bricks with cement-sand mortar | 1400 | 0.52 | 880 |

| Sand-lime brick masonry (GOST 379-79) with cement-sand mortar | 1800 | 0.7 | 880 |

| Triple brick masonry (GOST 648-73) with cement-sand mortar | 1000…1200 | 0.29…0.35 | 880 |

| Cellular brick masonry | 1300 | 0.5 | 880 |

| Slag brick masonry with cement-sand mortar | 1500 | 0.52 | 880 |

| Masonry "Poroton" | 800 | 0.31 | 900 |

| Maple (tree) | 620…750 | 0.19 | — |

| Leather | 800…1000 | 0.14…0.16 | — |

| Technical composites | — | 0.3…2 | — |

| Oil paint (enamel) | 1030…2045 | 0.18…0.4 | 650…2000 |

| Silicon | 2000…2330 | 148 | 714 |

| Organosilicon polymer KM-9 | 1160 | 0.2 | 1150 |

| Brass | 8100…8850 | 70…120 | 400 |

| Ice -60°C | 924 | 2.91 | 1700 |

| Ice -20°С | 920 | 2.44 | 1950 |

| Ice 0°C | 917 | 2.21 | 2150 |

| Polyvinyl chloride multilayer linoleum (GOST 14632-79) | 1600…1800 | 0.33…0.38 | 1470 |

| Polyvinyl chloride linoleum on a fabric base (GOST 7251-77) | 1400…1800 | 0.23…0.35 | 1470 |

| Linden, (15% humidity) | 320…650 | 0.15 | — |

| Larch (tree) | 670 | 0.13 | — |

| Flat asbestos-cement sheets (GOST 18124-75) | 1600…1800 | 0.23…0.35 | 840 |

| Vermiculite sheets | — | 0.1 | — |

| Gypsum cladding sheets (dry plaster) GOST 6266 | 800 | 0.15 | 840 |

| Lightweight cork sheets | 220 | 0.035 | — |

| Heavy cork sheets | 260 | 0.05 | — |

| Magnesia in the form of segments for pipe insulation | 220…300 | 0.073…0.084 | — |

| Asphalt mastic | 2000 | 0.7 | — |

| Basalt mats, canvases | 25…80 | 0.03…0.04 | — |

| Stitched glass fiber mats and strips (TU 21-23-72-75) | 150 | 0.061 | 840 |

| Mineral wool mats stitched (GOST 21880-76) and with a synthetic binder | 50…125 | 0.048…0.056 | 840 |

| (GOST 9573-82) | |||

| MBOR-5, MBOR-5F, MBOR-S-5, MBOR-S2-5, MBOR-B-5 (TU 5769-003-48588528-00) | 100…150 | 0.038 | — |

| Chalk | 1800…2800 | 0.8…2.2 | 800…880 |

| Copper (GOST 859-78) | 8500 | 407 | 420 |

| Mikanite | 2000…2200 | 0.21…0.41 | 250 |

| Mipora | 16…20 | 0.041 | 1420 |

| Morozin | 100…400 | 0.048…0.084 | — |

| Marble (cladding) | 2800 | 2.9 | 880 |

| Boiler scale (rich in lime, at 100°C) | 1000…2500 | 0.15…2.3 | — |

| Boiler scale (rich in silicate, at 100°C) | 300…1200 | 0.08…0.23 | — |

| Deck flooring | 630 | 0.21 | 1100 |

| Nylon | — | 0.53 | — |

| Nylon | 1300 | 0.17…0.24 | 1600 |

| Neoprene | — | 0.21 | 1700 |

| Wood sawdust | 200…400 | 0.07…0.093 | — |

| Tow | 150 | 0.05 | 2300 |

| Gypsum wall panels DIN 1863 | 600…900 | 0.29…0.41 | — |

| Paraffin | 870…920 | 0.27 | — |

| Oak parquet | 1800 | 0.42 | 1100 |

| Piece parquet | 1150 | 0.23 | 880 |

| Panel parquet | 700 | 0.17 | 880 |

| Pumice | 400…700 | 0.11…0.16 | — |

| Pumice concrete | 800…1600 | 0.19…0.52 | 840 |

| Foam concrete | 300…1250 | 0.12…0.35 | 840 |

| Foam gypsum | 300…600 | 0.1…0.15 | — |

| Foam ash concrete | 800…1200 | 0.17…0.29 | — |

| Polystyrene foam PS-1 | 100 | 0.037 | — |

| Polyfoam PS-4 | 70 | 0.04 | — |

| Foam plastic PVC-1 (TU 6-05-1179-75) and PV-1 (TU 6-05-1158-78) | 65…125 | 0.031…0.052 | 1260 |

| Foam resopen FRP-1 | 65…110 | 0.041…0.043 | — |

| Expanded polystyrene (GOST 15588-70) | 40 | 0.038 | 1340 |

| Expanded polystyrene (TU 6-05-11-78-78) | 100…150 | 0.041…0.05 | 1340 |

| Expanded polystyrene "Penoplex" | 35…43 | 0.028…0.03 | 1600 |

| Polyurethane foam (TU V-56-70, TU 67-98-75, TU 67-87-75) | 40…80 | 0.029…0.041 | 1470 |

| Polyurethane foam sheets | 150 | 0.035…0.04 | — |

| Polyethylene foam | — | 0.035…0.05 | — |

| Polyurethane foam panels (PIR) PIR | — | 0.025 | — |

| Penosilalcite | 400…1200 | 0.122…0.32 | — |

| Lightweight foam glass | 100..200 | 0.045…0.07 | — |

| Foam glass or gas glass (TU 21-BSSR-86-73) | 200…400 | 0.07…0.11 | 840 |

| Penofol | 44…74 | 0.037…0.039 | — |

| Parchment | — | 0.071 | — |

| Glassine (GOST 2697-83) | 600 | 0.17 | 1680 |

| Reinforced ceramic ceiling with concrete filling without plaster | 1100…1300 | 0.7 | 850 |

| Flooring made of reinforced concrete elements with plaster | 1550 | 1.2 | 860 |

| Monolithic flat reinforced concrete floor | 2400 | 1.55 | 840 |

| Perlite | 200 | 0.05 | — |

| Expanded perlite | 100 | 0.06 | — |

| Perlite concrete | 600…1200 | 0.12…0.29 | 840 |

| Perlitoplast-concrete (TU 480-1-145-74) | 100…200 | 0.035…0.041 | 1050 |

| Perlite phosphogel products (GOST 21500-76) | 200…300 | 0.064…0.076 | 1050 |

| Sand 0% moisture | 1500 | 0.33 | 800 |

| Sand 10% moisture | — | 0.97 | — |

| Sand 20% humidity | — | 1.33 | — |

| Sand for construction work (GOST 8736-77) | 1600 | 0.35 | 840 |

| Fine river sand | 1500 | 0.3…0.35 | 700…840 |

| Fine river sand (wet) | 1650 | 1.13 | 2090 |

| Burnt sandstone | 1900…2700 | 1.5 | — |

| Fir | 450…550 | 0.1…0.26 | 2700 |

| Pressed paper plate | 600 | 0.07 | — |

| Cork plate | 80…500 | 0.043…0.055 | 1850 |

| Facing tiles, tiles | 2000 | 1.05 | — |

| Thermal insulation tile PMTB-2 | — | 0.04 | — |

| Alabaster slabs | — | 0.47 | 750 |

| Gypsum slabs GOST 6428 | 1000…1200 | 0.23…0.35 | 840 |

| Wood-fiber and particle boards (GOST 4598-74, GOST 10632-77) | 200…1000 | 0.06…0.15 | 2300 |

| Slabs made of expanded clay concrete | 400…600 | 0.23 | — |

| Polystyrene concrete slabs GOST R 51263-99 | 200…300 | 0.082 | — |

| Resol-formaldehyde foam boards (GOST 20916-75) | 40…100 | 0.038…0.047 | 1680 |

| Plates made of glass staple fiber with a synthetic binder (GOST 10499-78) | 50 | 0.056 | 840 |

| Slabs made of cellular concrete GOST 5742-76 | 350…400 | 0.093…0.104 | — |

| Reed slabs | 200…300 | 0.06…0.07 | 2300 |

| Silica slabs | 0.07 | — | |

| Flax insulating slabs | 250 | 0.054 | 2300 |

| Mineral wool slabs with bitumen binder grade 200 GOST 10140-80 | 150…200 | 0.058 | — |

| Mineral wool slabs with synthetic binder grade 200 GOST 9573-96 | 225 | 0.054 | — |

| Mineral wool slabs with synthetic bond (Finland) | 170…230 | 0.042…0.044 | — |

| Mineral wool slabs of increased rigidity GOST 22950-95 | 200 | 0.052 | 840 |

| Mineral wool slabs of increased rigidity with an organophosphate binder | 200 | 0.064 | 840 |

| (TU 21-RSFSR-3-72-76) | |||

| Semi-rigid mineral wool slabs with starch binder | 125…200 | 0.056…0.07 | 840 |

| Mineral wool slabs with synthetic and bitumen binders | — | 0.048…0.091 | — |

| Soft, semi-rigid and hard mineral wool slabs on synthetic | 50…350 | 0.048…0.091 | 840 |

| and bitumen binders (GOST 9573-82, GOST 10140-80, GOST 12394-66) | |||

| Foam plastic boards based on resol phenol-formaldehyde resins GOST 20916-87 | 80…100 | 0.045 | — |

| Expanded polystyrene boards GOST 15588-86 without pressing | 30…35 | 0.038 | — |

| Polystyrene foam plates (extrusion) TU 2244-001-47547616-00 | 32 | 0.029 | — |

| Perlite-bitumen slabs GOST 16136-80 | 300 | 0.087 | — |

| Perlite-fiber slabs | 150 | 0.05 | — |

| Perlite-phosphogel slabs GOST 21500-76 | 250 | 0.076 | — |

| Perlito-1 slabs Plastic concrete TU 480-1-145-74 | 150 | 0.044 | — |

| Perlite cement slabs | — | 0.08 | — |

| Construction slabs made of porous concrete | 500…800 | 0.22…0.29 | — |

| Thermobitumen thermal insulation slabs | 200…300 | 0.065…0.075 | — |

| Peat thermal insulation slabs (GOST 4861-74) | 200…300 | 0.052…0.064 | 2300 |

| Fiberboard slabs (GOST 8928-81) and wood concrete (GOST 19222-84) on Portland cement | 300…800 | 0.07…0.16 | 2300 |

| Carpet covering | 630 | 0.2 | 1100 |

| Synthetic coating (PVC) | 1500 | 0.23 | — |

| Seamless gypsum floor | 750 | 0.22 | 800 |

| Polyvinyl chloride (PVC) | 1400…1600 | 0.15…0.2 | — |

| Polycarbonate (Diflon) | 1200 | 0.16 | 1100 |

| Polypropylene (GOST 26996 – 86) | 900…910 | 0.16…0.22 | 1930 |

| Polystyrene UPP1, PPS | 1025 | 0.09…0.14 | 900 |

| Polystyrene concrete (GOST 51263) | 200…600 | 0.065…0.145 | 1060 |

| Polystyrene concrete modified to | 200…500 | 0.057…0.113 | 1060 |

| activated plasticized Portland slag cement | |||

| Polystyrene concrete modified to | 200…500 | 0.052…0.105 | 1060 |

| composite low-clinker binder in wall blocks and slabs | |||

| Modified monolithic polystyrene concrete based on Portland cement | 250…300 | 0.075…0.085 | 1060 |

| Polystyrene concrete modified to | 200…500 | 0.062…0.121 | 1060 |

| Portland slag cement in wall blocks and slabs | |||

| Polyurethane | 1200 | 0.32 | — |

| Polyvinyl chloride | 1290…1650 | 0.15 | 1130…1200 |

| High Density Polyethylene | 955 | 0.35…0.48 | 1900…2300 |

| Low density polyethylene | 920 | 0.25…0.34 | 1700 |

| Foam rubber | 34 | 0.04 | — |

| Portland cement (mortar) | — | 0.47 | — |

| Pressspan | — | 0.26…0.22 | — |

| Cork granulated | 45 | 0.038 | 1800 |

| Mineral cork based on bitumen | 270…350 | 0.28 | — |

| Technical plug | 50 | 0.037 | 1800 |

| Shell rock | 1000…1800 | 0.27…0.63 | — |

| Gypsum grout mortar | 1200 | 0.5 | 900 |

| Gypsum perlite solution | 600 | 0.14 | 840 |

| Porous gypsum perlite solution | 400…500 | 0.09…0.12 | 840 |

| Lime mortar | 1650 | 0.85 | 920 |

| Lime-sand mortar | 1400…1600 | 0.78 | 840 |

| Light solution LM21, LM36 | 700…1000 | 0.21…0.36 | — |

| Complex mortar (sand, lime, cement) | 1700 | 0.52 | 840 |

| Cement mortar, cement screed | 2000 | 1.4 | — |

| Cement-sand mortar | 1800…2000 | 0.6…1.2 | 840 |

| Cement-perlite mortar | 800…1000 | 0.16…0.21 | 840 |

| Cement-slag mortar | 1200…1400 | 0.35…0.41 | 840 |

| Soft rubber | — | 0.13…0.16 | 1380 |

| Ordinary hard rubber | 900…1200 | 0.16…0.23 | 1350…1400 |

| Porous rubber | 160…580 | 0.05…0.17 | 2050 |

| Ruberoid (GOST 10923-82) | 600 | 0.17 | 1680 |

| Iron ore | — | 2.9 | — |

| Lamp soot | 170 | 0.07…0.12 | — |

| Sulfur rhombic | 2085 | 0.28 | 762 |

| Silver | 10500 | 429 | 235 |

| Expanded clay shale | 400 | 0.16 | — |

| Slate | 2600…3300 | 0.7…4.8 | — |

| Expanded mica | 100 | 0.07 | — |

| Mica across layers | 2600…3200 | 0.46…0.58 | 880 |

| Mica along the layers | 2700…3200 | 3.4 | 880 |

| Epoxy resin | 1260…1390 | 0.13…0.2 | 1100 |

| Freshly fallen snow | 120…200 | 0.1…0.15 | 2090 |

| Stale snow at 0°C | 400…560 | 0.5 | 2100 |

| Pine and spruce along the grain (wood) | 500 | 0.18 | 2300 |

| Pine and spruce across the grain (GOST 8486-66, GOST 9463-72) | 500 | 0.09 | 2300 |

| Resinous pine 15% humidity (wood) | 600…750 | 0.15…0.23 | 2700 |

| Reinforcing rod steel (GOST 10884-81) | 7850 | 58 | 482 |

| Window glass (GOST 111-78) | 2500 | 0.76 | 840 |

| Glass wool | 155…200 | 0.03 | 800 |

| Fiberglass | 1700…2000 | 0.04 | 840 |

| Fiberglass | 1800 | 0.23 | 800 |

| Fiberglass | 1600…1900 | 0.3…0.37 | — |

| Pressed wood shavings | 800 | 0.12…0.15 | 1080 |

| Anhydrite screed | 2100 | 1.2 | — |

| Cast asphalt screed | 2300 | 0.9 | — |

| Textolite | 1300…1400 | 0.23…0.34 | 1470…1510 |

| Termozit | 300…500 | 0.085…0.13 | — |

| Teflon | 2120 | 0.26 | — |

| Linen fabric | — | 0.088 | — |

| Roofing felt (GOST 10999-76) | 600 | 0.17 | 1680 |

| Poplar (tree) | 350…500 | 0.17 | — |

| Peat slabs | 275…350 | 0.1…0.12 | 2100 |

| Tuff (facing) | 1000…2000 | 0.21…0.76 | 750…880 |

| Tufobeton | 1200…1800 | 0.29…0.64 | 840 |

| Lump charcoal (at 80°C) | 190 | 0.074 | — |

| Gas coal | 1420 | 3.6 | — |

| Ordinary hard coal | 1200…1350 | 0.24…0.27 | — |

| Porcelain | 2300…2500 | 0.25…1.6 | 750…950 |

| Glued plywood (GOST 3916-69) | 600 | 0.12…0.18 | 2300…2500 |

| Fiber red | 1290 | 0.46 | — |

| Fibrolite (gray) | 1100 | 0.22 | 1670 |

| Cellophane | — | 0.1 | — |

| Celluloid | 1400 | 0.21 | — |

| Cement boards | — | 1.92 | — |

| Concrete tiles | 2100 | 1.1 | — |

| Clay tiles | 1900 | 0.85 | — |

| PVC asbestos tiles | 2000 | 0.85 | — |

| Cast iron |

| Shevelin | 140…190 | 0.056…0.07 | — |

| Silk | 100 | 0.038…0.05 | — |

| Granulated slag | 500 | 0.15 | 750 |

| Granulated blast furnace slag | 600…800 | 0.13…0.17 | — |

| Boiler slag | 1000 | 0.29 | 700…750 |

| Cinder concrete | 1120…1500 | 0.6…0.7 | 800 |

| Slag pumice concrete (thermosite concrete) | 1000…1800 | 0.23…0.52 | 840 |

| Slag pumice foam and slag pumice gas concrete | 800…1600 | 0.17…0.47 | 840 |

| Gypsum plaster | 800 | 0.3 | 840 |

| Lime plaster | 1600 | 0.7 | 950 |

| Synthetic resin plaster | 1100 | 0.7 | — |

| Lime plaster with stone dust | 1700 | 0.87 | 920 |

| Polystyrene mortar plaster | 300 | 0.1 | 1200 |

| Perlite plaster | 350…800 | 0.13…0.9 | 1130 |

| Dry plaster | — | 0.21 | — |

| Insulating plaster | 500 | 0.2 | — |

| Facade plaster with polymer additives | 1800 | 1 | 880 |

| Cement plaster | — | 0.9 | — |

| Cement-sand plaster | 1800 | 1.2 | — |

| Shungizite concrete | 1000…1400 | 0.27…0.49 | 840 |

| Crushed stone and sand from expanded perlite (GOST 10832-83) - backfill | 200…600 | 0.064…0.11 | 840 |

| Crushed stone from blast furnace slag (GOST 5578-76), slag pumice (GOST 9760-75) | 400…800 | 0.12…0.18 | 840 |

| and agloporite (GOST 11991-83) - backfill | |||

| Ebonite | 1200 | 0.16…0.17 | 1430 |

| Expanded ebonite | 640 | 0.032 | — |

| Ecowool | 35…60 | 0.032…0.041 | 2300 |

| Ensonite (pressed cardboard) | 400…500 | 0.1…0.11 | — |

| Enamel (organosilicon) | — | 0.16…0.27 | — |

Table of thermal conductivity, heat capacity and density of materials

Cement-sand

Depending on the strength of the coating, the proportions of sand to cement are selected - 1:4 or 1:3. It also depends on the brand of cement and sand fraction. This solution is practically not elastic, so it is used for mineral surfaces as a base coating, and not for sealing cracks and cracks. With a layer density of 1800 kg/m3, the thermal conductivity coefficient of the plaster will be 1.2.

Thermal insulating polymer plaster.

Synthetic binders are irreversible. That is, losing water when drying, they transform into a different chemical state in which their interaction with water is limited. Therefore, although they are diluted with water, they become waterproof once dry.

Another significant factor is vapor permeability. Acrylic plasters “breathe”, that is, they are not a vapor barrier; they allow vapors to pass through without trapping them underneath. This prevents moisture from accumulating in the previous layer.

Common fillers are used as heat insulators.

Polymer solutions are the most moisture-resistant and water-resistant. Therefore, they are used for facade heat-insulating plaster, creating coatings in bathrooms, dressing rooms, vestibules, loggias, corridors, kitchens and bathrooms.

Decorative

This is exclusively a finishing material for finishing work. Its composition may include polymer and synthetic resins, various impurities that give it the necessary aesthetic properties. Decorative plaster can be used to decorate facades and interior parts of a building. The facade composition with polymer additives with a density of 1800 kg/m3 has a thermal conductivity coefficient of 1.

Thermal insulating plaster for external use.

External wall insulation is more effective than internal insulation. According to the first scheme, heat is retained and accumulated inside the wall array. In the second, the wall is not protected, the thermal energy is evaporated.

Thermal insulating external façade plaster must have not only low thermal conductivity, but also sufficient moisture resistance. It’s not just about the safety and durability of the layer. Wet insulation conducts heat better. When the water in the thickness of the layer turns into ice, the insulation itself becomes a source of cold.

Wet insulation, including exterior plaster finishes, is much less protective of a home. When freezing, it cools the walls, impedes the movement of steam and quickly collapses.

Non-waterproof plaster coatings used for external thermal insulation plaster must be protected by curtain walls. Ventilated canopy structures are the most rational.

Warming

This is a composition that includes various additives that provide such features as:

- frost resistance;

- strength regardless of the amount of precipitation and surrounding climatic influences;

- sound absorption;

- high degree of adhesion;

- good elasticity.

Depending on the additives, the elasticity coefficient of insulating plaster at a density of 500 kg/m3 is 0.2.

Comparison using a table

| N | Name | Density | Thermal conductivity | Price, euro per cubic meter | Energy costs for | ||

| kg/cub.m | min | Max | European Union | Russia | kW*h/cubic m. | ||

| 1 | cellulose wadding | 30-70 | 0,038 | 0,045 | 48-96 | 15-30 | 6 |

| 2 | fibreboard | 150-230 | 0,039 | 0,052 | 150 | 800-1400 | |

| 3 | wood fiber | 30-50 | 0,037 | 0,05 | 200-250 | 13-50 | |

| 4 | flax fiber whales | 30 | 0,037 | 0,04 | 150-200 | 210 | 30 |

| 5 | foam glass | 100-150 | 0.05 | 0,07 | 135-168 | 1600 | |

| 6 | perlite | 100-150 | 0,05 | 0.062 | 200-400 | 25-30 | 230 |

| 7 | cork | 100-250 | 0,039 | 0,05 | 300 | 80 | |

| 8 | hemp, hemp | 35-40 | 0,04 | 0.041 | 150 | 55 | |

| 9 | cotton wool | 25-30 | 0,04 | 0,041 | 200 | 50 | |

| 10 | sheep's wool | 15-35 | 0,035 | 0,045 | 150 | 55 | |

| 11 | duck down | 25-35 | 0,035 | 0,045 | 150-200 | ||

| 12 | straw | 300-400 | 0,08 | 0,12 | 165 | ||

| 13 | mineral (stone) wool | 20-80 | 0.038 | 0,047 | 50-100 | 30-50 | 150-180 |

| 14 | glass fiber wool | 15-65 | 0,035 | 0,05 | 50-100 | 28-45 | 180-250 |

| 15 | expanded polystyrene (pressless) | 15-30 | 0.035 | 0.047 | 50 | 28-75 | 450 |

| 16 | extruded polystyrene foam | 25-40 | 0,035 | 0,042 | 188 | 75-90 | 850 |

| 17 | polyurethane foam | 27-35 | 0,03 | 0,035 | 250 | 220-350 | 1100 |

The indicator of thermal conductivity properties is the main criterion when choosing an insulation material. All that remains is to compare the pricing policies of different suppliers and determine the required quantity.

Insulation is one of the main ways to obtain a structure with the required energy efficiency. Before making your final choice, carefully determine the conditions of use and, armed with the table provided, make the right choice.

Perlite

This is one of the varieties of decorative plasters, which consists of volcanic rocks. The plaster contains special acidic glass, which gives the coating an aesthetic appearance and adds various practical qualities. The unique ability that the material has is foaming and increasing in size when heated. It must be said that perlite plaster can increase in volume 10 times. This results in an outwardly dense, but light enough layer for the main surface. The density of the layer can fluctuate between 350...800 kg/m3, due to which the thermal conductivity of the plaster also fluctuates - 0.13...0.9.

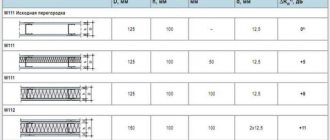

Main characteristics of plasterboard sheets of all types

Every builder knows that plasterboard is one of the most convenient and versatile materials for finishing walls and constructing floors. The modern market offers a wide range of types of gypsum boards with different technical characteristics depending on the intended purpose and operating characteristics. The following article will tell you how to choose the right material and not get confused among the variety of manufacturing companies.

1 - GKL, 2 - GKLO, 3 - GKLV, 4 - GKLVO

GCR classes and features of their application

Drywall is a multilayer board of gypsum and paper. This design allows the material to be used not only as a finishing material, but also to create full-fledged interior partitions. If you follow certain rules, you can hang shelves on them, as well as glue wallpaper, lay tiles, and simply paint them. But you should definitely take into account the characteristics of the room and choose the right type of gypsum board.

So, there are several types of sheets:

- standard (hl),

- moisture resistant (GKLV),

- fire-resistant (gklo),

- fire and moisture resistant (gklvo).

In addition, some manufacturers (for example, Knauf) offer the consumer a so-called super sheet. It differs from the standard one in its fibrous structure, which improves the properties of drywall, increases its strength and facilitates the cutting process. It is convenient to use supersheet for the construction of interior partitions.

There are other options: arched, acoustic and vinyl plasterboards. Arched plasterboard has less weight and thickness, which allows you to create complex, curved structures. Vinyl is convenient because its surface is ready for decorative finishing and does not require putty.

Structure, characteristics and composition of drywall

The name “plasterboard” speaks for itself: between the layers of cardboard there is a “filling” of gypsum. At first glance, the simple composition causes numerous positive characteristics of this material:

- safety,

- environmental friendliness,

- surface smoothness,

- mechanical strength,

- ease of processing,

- low price,

- fire resistance,

- high noise insulation characteristics,

- relatively light weight of a sheet of drywall.

Table 1 shows the characteristics of a gypsum board sheet of standard composition.

Table 1. Technical characteristics of a plasterboard sheet with a thickness of 12.5 and a width of 1200 mm

In addition, there are certain differences in the composition of different types of gypsum. The insulated sheet on one side has a layer of polystyrene foam, which directly affects the thermal conductivity of the plasterboard structure. This material does not have a cardboard covering at all, which makes it resistant to moisture and open fire. The gypsum board perfectly “resists” flames and is fire-resistant thanks to the reinforcing inclusions made of fiberglass. Moisture-resistant drywall contains special additives against mold, as well as silicone. Sheets are usually made in a different color scheme from others - pink or green.

Review of manufacturers

Any experienced builder will advise purchasing materials for repairs only from well-known and trusted companies. Among the plasterboard manufacturers represented on the domestic market, Knauf and Gyprok enjoy the greatest consumer trust. Overall dimensions and weight of gypsum board sheets are given in Table 2.

Table 2. Drywall characteristics

The table shows how much a gypsum board sheet of the most common types weighs. For other manufacturers, indicators may differ from those given, so you should definitely check them.

Safety and environmental friendliness of the material

Since standard gypsum board contains only two components (gypsum and cardboard), high-quality material cannot pose any health hazard. But an unscrupulous manufacturer may well use mineral material from environmentally unfavorable areas in the production process. Therefore, when purchasing, you should definitely check quality certificates and compliance with GOSTs.

In what cases is drywall really harmful? Such situations arise when:

- The manufacturer uses additives containing phenol or formaldehyde. This occurs with materials made in China.

- Precautions are not taken when cutting and edging. Such work is always accompanied by increased dust emission, so it is best to carry it out with a respirator.

- Rooms with high humidity, window openings and slopes are finished with standard gypsum board in order to save money. The material not only breaks down, but also contributes to the formation and development of mold, which is dangerous to human health.

- Using inappropriate putty to seal joints.

It can be seen that if you follow simple rules, gypsum board is a completely safe finishing option, both for humans and for the environment. The main thing is not to skimp on quality and to follow the technology for processing and installing slabs.

Installation technologies

The technology for installing plasterboard sheets on walls and ceilings is somewhat different. An example is the method of covering walls using a metal frame. This method is very reliable and allows you to decorate the surface with ceramic tiles. Since the tiles have considerable weight, in order to support it, drywall must be installed on the frame.

Main finishing stages:

- Calculation of material consumption, taking into account the weight and dimensions of one sheet of drywall.

- Drawing up estimates and purchasing consumables.

- Surface marking using a laser level.

- Installation of a metal frame.

- Sheathing it with plasterboard sheets.

- Sealing of seams and finishing.

Dry

There is such a thing as “dry plaster”. For those who don’t know, in construction terminology this means ordinary drywall. Essentially, the sheets are made up of the same elements as regular gypsum plaster (liquid), except that they are dried, pressed, molded and mounted onto cardboard sheets. The thermal conductivity of dry plaster will also depend on the density of the material. The average thermal conductivity coefficient is 0.21.

Limestone

The most common type of plaster for interior work. One of its main qualities can be called pure whiteness, which is perfect for further finishing work, especially painting or applying decorative liquid wallpaper. It consists of a mixture of slaked lime and river sand. Proportions may vary. Thermal conductivity at a density of 1500 kg/m3 will be equal to 0.7.

Each mixture has its own indicators, which are indicated on the packaging. It must be said that a paper bag of dry mixture is an instruction not only for use, but also for its composition. There you can find the basic properties of each composition.

How to calculate wall thickness

In order for the house to be warm in winter and cool in summer, it is necessary that the enclosing structures (walls, floor, ceiling/roof) must have a certain thermal resistance. This value is different for each region. It depends on the average temperatures and humidity in a particular area.

Thermal resistance of enclosing structures for regions of Russia

In order for heating bills not to be too high, it is necessary to select building materials and their thickness so that their total thermal resistance is not less than that indicated in the table.

Calculation of wall thickness, insulation thickness, finishing layers

Modern construction is characterized by a situation where the wall has several layers. In addition to the supporting structure, there is insulation and finishing materials. Each layer has its own thickness. How to determine the thickness of insulation? The calculation is simple. Based on the formula:

Formula for calculating thermal resistance

R—thermal resistance;

p—layer thickness in meters;

k is the thermal conductivity coefficient.

First you need to decide on the materials that you will use during construction. Moreover, you need to know exactly what type of wall material, insulation, finishing, etc. will be. After all, each of them makes its contribution to thermal insulation, and the thermal conductivity of building materials is taken into account in the calculation.

First, the thermal resistance of the structural material (from which the wall, ceiling, etc. will be built) is calculated, then the thickness of the selected insulation is selected based on the “residual” principle. You can also take into account the thermal insulation characteristics of finishing materials, but usually they are a plus to the main ones. This is how a certain reserve is laid down “just in case.” This reserve allows you to save on heating, which subsequently has a positive effect on the budget.

An example of calculating the thickness of insulation

Let's look at it with an example. We are going to build a brick wall - one and a half bricks long, and we will insulate it with mineral wool. According to the table, the thermal resistance of walls for the region should be at least 3.5. The calculation for this situation is given below.

- First, let's calculate the thermal resistance of a brick wall. One and a half bricks is 38 cm or 0.38 meters, the thermal conductivity coefficient of brickwork is 0.56. We calculate using the above formula: 0.38/0.56 = 0.68. A wall of 1.5 bricks has this thermal resistance.

- We subtract this value from the total thermal resistance for the region: 3.5-0.68 = 2.82. This value must be “added” with thermal insulation and finishing materials.

All enclosing structures will have to be calculated

- We calculate the thickness of mineral wool. Its thermal conductivity coefficient is 0.045. The thickness of the layer will be: 2.82 * 0.045 = 0.1269 m or 12.7 cm. That is, to ensure the required level of insulation, the thickness of the mineral wool layer must be at least 13 cm.

If the budget is limited, you can take 10 cm of mineral wool, and the missing amount will be covered with finishing materials. They will be inside and outside. But, if you want your heating bills to be minimal, it is better to use the finishing as a “plus” to the calculated value. This is your reserve during the lowest temperatures, since thermal resistance standards for enclosing structures are calculated based on the average temperature over several years, and winters can be abnormally cold. Therefore, the thermal conductivity of building materials used for finishing is simply not taken into account.

Necessity of calculations

Why is it necessary to carry out these calculations, is there any benefit from them in practice? Let's take a closer look.

Assessing the effectiveness of thermal insulation

Different climatic regions of Russia have different temperature conditions, so each of them has its own standard indicators of heat transfer resistance. These calculations are carried out for all elements of the structure in contact with the external environment. If the structural resistance is within normal limits, then you don’t have to worry about insulation.

If thermal insulation of the structure is not provided, then you need to make the right choice of insulating material with suitable thermal characteristics.

Heat loss

Heat loss at home

An equally important task is predicting heat losses, without which it is impossible to correctly plan a heating system and create ideal thermal insulation. Such calculations may be necessary when choosing the optimal boiler model, the number of radiators required and their correct placement.

Such calculations in a building are carried out for all building envelopes interacting with cold air flows, and then summed up to determine the total heat loss. Based on the obtained value, a heating system is designed that should fully compensate for these losses. If the heat losses are too large, they entail additional financial costs, and not everyone can afford this. In this situation, you need to think about improving the thermal insulation system.

Separately, we need to talk about windows, for which the heat transfer resistance is determined by regulatory documents. There is no need to do the calculations yourself. There are ready-made tables in which resistance values are entered for all types of window and balcony door structures. The heat loss of windows is calculated based on the area, as well as the temperature difference on different sides of the structure.

The calculations above are suitable for beginners who are taking their first steps in designing energy-efficient homes. If a professional gets down to business, then his calculations are more complex, since many correction factors are additionally taken into account - for insolation, light absorption, reflection of sunlight, heterogeneity of structures and others.

Description and comparison of insulation

Today, the consumer can choose a material whose properties satisfy his needs to one degree or another. The installation of insulation depends on the choice you make - whether you can handle it yourself, or whether you will have to call in specialists. The structure and texture of materials matters.

Based on this criterion, we can distinguish:

- Plates are building materials of different densities and thicknesses, which are made by gluing and pressing;

- Foam blocks - made of concrete, with the inclusion of special additives, the porous structure is obtained due to a chemical reaction;

- Cotton wool – sold in rolls, has a fibrous structure;

- Crumbs or granules - loose compactor includes foam substances of various fractions.

Properties, cost and functionality of the material - this is what attention is paid to. Usually the material indicates which surface it is intended for.

The raw materials for insulation can be different, but in general it can be organic and inorganic.

Organic insulation is made from peat, wood and reeds. Inorganic insulation materials are minerals, foamed concrete, substances containing asbestos, etc. It is worth learning to evaluate and understand the properties of various substances.

The nuances of using insulation

There are some useful recommendations that can be taken into account when choosing insulation and subsequent installation. For example, for the floor and ceiling, that is, horizontal surfaces, you can use literally any material. But an additional layer with high mechanical strength should be used - this is a prerequisite.

Well, for walls (vertical surfaces) you need to use materials in the form of slabs or sheets. If you choose rolled or bulk material, then over time the materials will definitely begin to sag. This means that the fastening method must be impeccable. And this is a separate topic.