Processing concrete and wood products with liquid glass has been used for quite some time. This substance is added to cement, which speeds up the process of setting the mixture; it is used for waterproofing basements, for treating swimming pools and other hydraulic structures. Liquid glass in its original state resembles transparent or whitish crystals obtained by melting soda and silicon dioxide in certain proportions under pressure. This material was invented in the 19th century and is still actively used in construction and renovation work due to its unique properties.

For construction work, crystals are diluted with water, but most often the material is supplied in industrial packaging. When exposed to open air, LC dries instantly, forming a protective film, which allows it to be used for impregnation of products and structures in order to provide protection from moisture, fire and rotting.

Kinds

There are several types of liquid glass. They are divided depending on the main substance used in the mixture.

Sodium

The formation based on sodium salts is characterized by a viscous structure, high strength and penetrating ability. It perfectly resists open fire and high temperatures, and the composition is also able to retain its shape even when the base on which it was applied is deformed.

Potassium

This material contains potassium salts. The structure of the mixture is loose, the composition has increased hygroscopicity, and forms a matte surface. Potassium compounds resist excessive heat and deformation well.

Lithium

It is used to provide the treated surface with protection from thermal effects. Produced in small batches. For some work, combined mixtures are used.

Let's sum it up

As a result, it can be noted that liquid glass is an excellent product that makes it possible to obtain a water-repellent layer on different surfaces. In addition, it is fireproof, antiseptic and thermal insulating. The component is in demand to improve the properties of various solutions. When preparing the solution, it is important to observe the proportions of the ingredients and use it promptly so that it does not lose its properties.

Liquid glass is an excellent product that makes it possible to obtain a water-repellent layer on different surfaces.

The most popular area of application is waterproofing various surfaces. The use of liquid glass is possible inside the house due to its harmlessness, but the layer can also withstand external influences, and therefore can be considered universal.

Characteristics

ZhS is a material of a viscous, viscous consistency, which dries quickly in air and forms a monolithic, durable, water-impervious base.

Liquid glass, sodium and potassium, have the following characteristics:

- Prevents water from penetrating through the surface treated with the solution.

- Protects wooden and concrete surfaces from the penetration of fungus and pathogens.

- Prevents the accumulation of static voltage.

- Protects the treated surface from fire.

- Protects the base impregnated with the solution from the effects of acidic compounds.

- Helps accelerate the drying process and strength gain of cement mortars.

Flaws

However, among all the advantages, a couple of disadvantages of the product stand out. You can note how quickly the product hardens, which requires the master to use it quickly. This also makes it difficult to understand which areas remain untreated and how much product should be applied to a certain area. Cannot be used for bricks or organic types of materials. It will not be possible to paint a layer of liquid glass.

For these reasons, it is often easier to hire a professional to apply the product. Otherwise, you can waste the component and not get a high-quality surface treatment. But, of course, this is accompanied by expenses for paying for the services of specialists.

You can note how quickly the product hardens, which requires the master to use it quickly.

Advantages and disadvantages

When working with RC in construction or during repairs, the following advantages are revealed:

- this material helps to quickly repair small cracks in concrete products and wood building structures;

- coating with liquid glass makes it possible to obtain a durable film that helps waterproof any surface;

- material consumption is low, while the cost of liquid glass is affordable for most categories of the population, so it can be used for work at home;

- if used correctly, the coating service life will be at least five years;

- Liquid glass for waterproofing can be used in places with unstable humidity levels.

There are also negative features of JS. The disadvantages include:

- this material is not used for processing brick buildings;

- ZhS cannot be the only material for obtaining reliable waterproofing; it is usually used together with other materials;

- for processing structures and products of reinforced concrete, it is advisable to have certain skills, since such solutions instantly dry and harden;

- To obtain a better coating and protect the base, it is necessary to apply a primer before the LC.

Advantages

There are a huge number of ways to use liquid glass; it is chosen for different solutions and surfaces, the reason for this is the advantages of this product:

- It has a high plastic property, therefore it covers surfaces well, filling pores;

- The dried layer has high strength properties and a high level of adhesion;

- Wear resistance, layer service life is 5 years;

- The film-like layer created by the product does not allow water to pass through;

- Reasonable cost and low consumption;

- Safe for human health, you can even use it in children's rooms.

The dried layer has high strength properties and a high level of adhesion.

Application areas of liquid glass

Housing systems are used in general construction work and for solving everyday problems. It is usually used to provide the following types of work:

- to ensure waterproofing of swimming pools, concrete screeds, foundations, basements, sewer pipes and wells;

- to enhance the refractory properties of mortars for masonry stoves;

- in order to protect concrete and wood products from rotting and mold formation;

- used as an additive in coloring compositions to obtain increased strength and fire-resistant characteristics;

- for gluing PVC plates and linoleum;

- for clogging open pores of damaged trees;

- for the purpose of restoring glass, wood and plastic products;

- for processing the car body;

- for organizing self-leveling floors.

Preparation of solutions with liquid glass

It is advisable to purchase ready-made impregnations and mixtures that are designed for specific tasks, but mixing the components yourself will cost less, so the necessary solutions are often prepared at the construction site.

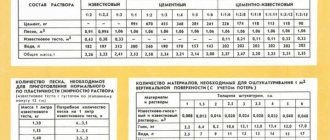

Proportions

To prepare a special solution using this substance for various purposes, certain proportions must be observed. How much of each substance to add to a particular solution depends on the application of the mixture.

Compositions for painting

The peculiarity of the effect of silicate compounds on pigments limits the number of color options. To prepare paints, potassium silicate is used, which, unlike sodium silicate, allows you to obtain a more uniform mixture.

Such compositions are sold ready-made (you only need to mix two components).

Primer compositions

To obtain a high-quality primer for concrete, you need to combine cement and glass in a ratio of 1 to 1, which can significantly strengthen the base. If the surface of the screed is planned to be covered with tiles, the solution is made lighter.

Surface impregnation

To increase the service life of structures and individual products, use an aqueous solution of liquid glass in a ratio of 1:5. Apply impregnation using a brush, roller or spray gun. Individual small elements can be completely immersed in the prepared solution.

Waterproofing composition

To protect concrete surfaces from moisture, prepare a solution from equal parts of sand, cement and glass. Add water until a plastic consistency is obtained. This mixture can be used to treat hydraulic structures.

Fire protection composition

Strengthening the JS of masonry mortar helps to increase the fire protection effect. Recommended composition of masonry mortar: cement and sand 1:3, water is added until a plastic formation is formed, glass - 20% of the total mass of the mixture. JS is added after preparing the CPR.

Antiseptic composition

To avoid damage to structures by mold, fungi and rot, it is recommended to treat surfaces with an impregnation consisting of equal parts of water and liquid iron. Both reinforced concrete and wooden structures are treated with this impregnation.

Repair composition

To eliminate cracks, seal joints between slabs and when pouring screed, it is necessary to combine the following ingredients: 1 part ZhS, 1 cement and 3 parts sand. The mixture must be prepared to a sufficiently thick consistency so that it does not flow out of the cracks during work.

Mixing instructions

In order to properly prepare a mixture with the addition of ZhS, you should follow the recommendations developed for compositions used to perform certain types of surface treatment and repair.

The dry components of the solution are mixed separately, and the liquid solution is also diluted separately with water. Add the dry components to the aqueous solution gradually, mixing the layers. If you want to make the mixture more plastic, increase the volume of water.

Subsequent application of liquid glass to the treated areas should be carried out taking into account finishing technologies.

Features of its storage

Storage should take place in a warehouse or other place inaccessible to children. Be sure to close the packaging tightly. If the composition freezes, the glass will not lose its properties after thawing. Also, after long-term storage, you can notice a white coating on the bottom of the container; it is not a sign of deterioration of the composition. According to the manufacturers' instructions, the product can be stored for 1 year after production. Do not use an expired product.

Storage should take place in a warehouse or other place inaccessible to children.

Methods of applying material

When working with liquid materials, it is necessary to use means of physical protection for the worker, for which they use protective suits and protective masks. Contact of the solution with the eyes can cause significant harm to health.

It is recommended to apply liquid glass with your own hands using a roller or brush. The final rise of the solution occurs within about half an hour, then the next layer is applied.

Repair mortars containing cement are applied with a spatula, but when performing work, one must not forget about the immediate setting of the mixture (usually within half an hour), so the volume of a single batch must be accurately calculated.

Waterproofing with liquid glass

Waterproofing mixtures using JS make it possible to treat any structures, including concrete and wood, in established areas with humidity exceeding the norm.

Foundation

To protect the foundation from destruction in a humid environment, it is necessary to apply liquid glass for concrete. The instructions for use indicate that for maximum protection this operation should be performed twice. After application, the layer must dry completely, then apply the next one. After the concrete base is impregnated with glass, the insulation is reinforced with other technical materials.

To eliminate cracks and mask the joining seams, prepare a repair composition in the following ratio: cement - 1 kg, water 750 ml, ZhS - 50 grams. To ensure better protection of the concrete base, it is recommended to use ZhS in the form of an additive in a volume of 5% of the total mass of the mixture.

swimming pool

To eliminate leaks in the bathtub of a structure, it is necessary to treat the surface of the concrete. The solution is evenly applied to the walls and floor of the structure. After one layer has dried, apply the next one. To reliably protect the structure, it is recommended to impregnate it three times.

From exposure to groundwater

Special concrete, which contains LC, can limit the flow of groundwater.

Basement

This important structure in the house and protecting it from leaks is the main condition for maintaining a favorable climate in the apartment and in the interior. Typically, owners are faced with the problem of cracks and poor waterproofing of joints. To get rid of the problem you will need:

- Clean cracks and seams from foreign objects and dust;

- Prepare a repair mixture in the following ratio: cement – 20 parts, liquid glass – 1 part. Maximum plasticity of the mixture should be achieved, for which its consistency is controlled by the volume of water;

- Cracks are sealed with a repair compound;

- Level the repair site by plastering it with the same mixture;

- The repair area is coated with water using a brush;

- After 24 hours, a layer of GS is applied.

When performing waterproofing work, it is necessary to remember the chemical reactions that occur with mixtures in which liquid iron is present. Due to the rapid hardening of the solution, in order to save material, it is recommended to prepare small volumes for work.