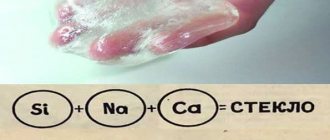

Processing concrete and wood products with liquid glass has been used for quite some time. This substance is added to cement, which speeds up the process of setting the mixture; it is used for waterproofing basements, for treating swimming pools and other hydraulic structures. Liquid glass in its original state resembles transparent or whitish crystals obtained by melting soda and silicon dioxide in certain proportions under pressure. This material was invented in the 19th century and is still actively used in construction and renovation work due to its unique properties.

For construction work, crystals are diluted with water, but most often the material is supplied in industrial packaging. When exposed to open air, LC dries instantly, forming a protective film, which allows it to be used for impregnation of products and structures in order to provide protection from moisture, fire and rotting.

What is liquid glass

Liquid glass is a silicate-based adhesive. Recently, you can often find that treating a body with polish is called liquid glass. The remedies actually vary.

When the material dries, a layer is created that does not allow liquids and air to pass through. In liquid form, it penetrates well into the surface to close all pores.

When the material dries, a layer is created that does not allow liquids and air to pass through.

Preparation of potassium glass

Sand boiling and potassium carbonate react with each other at temperatures over 1300 degrees Celsius. The finished product is dropped directly from the oven onto a special heavy-duty conveyor belt. Goes through the stages of cooling, hardening and silicate blocks. This product is notable for the fact that under certain conditions it flows into a liquid state and dissolves.

Therefore, potassium glass is used in liquid form with a certain water solution. The splitting reaction takes place in a specially equipped place and under pressure. After this, the product is subjected to filtration, adjustment of alkaline and silicic acids. Upon completion of all the necessary processes, it is processed to the customer’s required standards and transported in containers designed for this purpose.

Features, characteristics and composition of liquid glass

Sodium or potassium silicate is introduced into the base; microcrystals, which are responsible for closing the structure of the material, and quartz sand are also added. Coloring is not used, because coloring leads to deterioration of properties, and the seam will not be beautiful. A good waterproofing result is obtained due to the technical characteristics of the product:

- Moisture-repellent property;

- Antiseptic protection;

- Antistatic effect;

- High level of curing;

- Protective property against the harmful effects of alkaline acid substances;

- Fire resistance.

Coloring is not used, because coloring leads to deterioration of properties, and the seam will not be beautiful.

The main pros and cons of liquid glass

The choice of whether to treat a surface with liquid glass is easier when the positive and negative aspects of the process are known. The following advantages of the material can be noted:

- Creating a film that does not allow moisture to pass through;

- High level of adhesion, penetration into any surface cracks;

- Economical consumption, can be added to cement mortar;

- Reasonable cost;

- Long service life;

- Resistant to a variety of substances.

The presence of a large number of advantages does not exclude the disadvantages:

- Incompatible with all materials, can only be applied to concrete and wood;

- The layer is brittle, additional product should be applied on top;

- It is not possible to apply over another finishing material; paints and varnishes do not adhere to it;

- Carrying out the application requires special skills; it is almost impossible for a beginner to do the job with his own hands;

- The product cannot be tinted.

The product dries very quickly, so the work requires a fast pace from the master.

The surface is rarely covered with liquid glass separately; it is usually combined with another waterproofing material, but the product helps to obtain high-quality protection on concrete and wooden bases.

The surface is rarely covered with liquid glass separately; it is usually combined with another waterproofing material.

The use of “miracle glue” in modern construction

The main consumers of the described material are considered to be enterprises in the construction industry. The use of liquid glass in concrete is widespread. Silicate glue is characterized by a relatively low cost. And at the same time, it significantly improves the performance properties of the concrete solution, guaranteeing the latter excellent waterproofing. In addition, liquid glass has high antibacterial capabilities.

Due to this, mold never appears on the concrete into which it is added, and fungus does not appear. All pools these days, as well as structures operating at constantly high humidity, are concreted with compounds containing the “miracle glue” we are considering. It is worth taking into account that liquid glass hardens quite quickly. And in some cases it cannot be mixed with concrete before starting work. The builders found a way out of this situation.

They use a “cunning” method, which involves treating an already erected concrete structure with a solution of water and liquid glass (the components of this mixture are taken in equal quantities). Silicate solutions are well suited for combating soil subsidence under erected buildings and structures. In this case, it is recommended to use liquid glass, the use of which does not require any large-scale work.

When combating subsidence, silicate glue is pumped into the ground under construction according to one of two schemes:

- One-step method - a mixture of a special hardener and liquid glass is formed, which is supplied under the building.

- Sequential technique - glass is pumped in first, then the hardening compound.

Impregnation of plaster and wood with liquid silicate solutions is common (we will discuss this below). Silicate glue is also added to zinc silicate paint, which protects metal products from corrosion for 25–30 years! Liquid glass is also included in modern particle boards. Their impregnation with “miracle glue” makes any wood products durable and very resistant to compression.

Areas of application of liquid glass

There are three main areas of use of liquid glass. The following areas can be identified for use:

- To treat the base to create a barrier from liquids and other environmental influences;

- Used together with a concrete mixture to improve waterproofing properties, the drying process will be shortened;

- For the production of various types of concrete.

It is used together with a concrete mixture to improve waterproofing properties and the drying process will be shortened.

Production

In Russia, the following types of liquid glass are produced in industrial quantities:

- sodium,

- potassium,

- mixed type.

Production is regulated by GOSTs:

- 13078-81,

- 18958-71,

- TU 21-23-109-78,

- 21-23-109-73.

Other types are produced in accordance with temporary standards of enterprises and specifications .

90% of the total production of soluble silicates comes from sodium liquid glass.

There are three main production technologies, all of which are characterized by high energy costs and the use of complex equipment.

But there is another, new one that is different:

- ease of production;

- using glass waste (cullet) as a silicon-containing raw material.

Let's take a brief look at each technology.

Sintering a mixture of natural sand and technical soda

Glass production includes the following steps:

- mixing anhydrous components;

- firing the resulting mixture in ovens at temperatures reaching 1300°C;

- cooling the fused components on a moving conveyor until glassy pieces (silicate blocks) form;

- placing the pieces in an autoclave to dissolve them with steam under pressure, or crushing the pieces into a powder, which is then dissolved in hot water.

Obtaining a product by processing silicon raw materials

The receiving process includes:

- grinding raw materials in a mill with a vibrator;

- adding sodium hydroxide (potassium, lithium);

- stirring silica raw materials at temperatures up to 1000°C with a saturated alkali solution; duration - from 30 minutes to 1.5 hours in an autoclave with a vibrator.

Hydrothermal method

The product is obtained by dissolving silicon raw materials with strong alkaline solutions .

This technology is more simplified.

It is not necessary to heat the components to temperatures close to 1000°C.

Heating will occur on its own due to the release of heat as a result of the alkaline reaction.

New technology - the use of cullet

Recyclable materials are pre-prepared:

- wash;

- cleared of impurities;

- crushed.

It is necessary to get rid of oxides of calcium, magnesium, iron and other metals so that the raw materials are suitable for further use.

After melting, the broken glass turns into a silicate block - in this form, the raw materials are used to manufacture the final product .

Liquid glass in finished form is obtained in a vibrating mixer as a result of 0.5 - 1.5 hours of interaction of the mixture with water heated to a temperature of 100 °C.

The use of recycled materials has a positive effect on the quality of the final product and at the same time solves the problem of recycling glass containers.

Recycling 10% of cullet reduces gas consumption by 3%. In other words, if you produce glass exclusively from cullet, gas consumption will decrease by 30%.

Natural gas is the main fuel used in the Russian glass industry.

Types of liquid glass

The constituent elements are potassium or sodium silicate. It is impossible to create a rating based on the type of this element that is selected for production and the funds are divided, because they differ in a number of properties:

- The first element has a protective property against alkalis, has a high degree of adhesion, and does not form a glass sheen on the surface;

- The second creates the same protection, but shines.

There is a granular type; water is added to the composition before use.

The constituent elements are potassium or sodium silicate.

Properties of potassium glass

Waterproofing properties of potassium glass

Sodium liquid glass is used in the production of concrete and other objects intended for use in buildings. Sodium silicate is used to create structures for water use: swimming pools, wells, basements.

The solution has a number of positive properties:

- Provides protection from groundwater;

- From aggressive atmospheric influences;

- With increased moisture resistance of premises.

Protective properties of potassium glass against corrosion

Silicate particles not only strengthen the surface treatment, but are also an excellent anti-corrosion agent. Silicate particles enhance the anti-corrosion properties of any metal. This solution is considered one of the best in rust prevention.

Potassium glass active antiseptic

Mold, mildew and dampness will never bother construction sites that have been treated with soda glass. Thanks to its adhesive abilities, silicate penetrates deeply into different layers of the surface and allows you to quickly and efficiently connect building materials and mortars of any density composition. They will not only strengthen this fastener, but also enhance the effect of the mortar.

Fireproof properties of potassium glass

Materials such as concrete, brick, and metal are used in construction. They themselves are fire resistant. Additionally, plastic and wood materials are used, which are known to have quite fire-hazardous disadvantages. It is in the places where they are used that liquid glass is used, which has a fire resistance of more than a thousand degrees Celsius.

Service life of potassium glass

When using sodium silicate, a protective layer is formed on the surface of the object, which increases the strength of the structure. The crystalline properties of glass allow it to penetrate solid layers of material at the molecular level. This not only strengthens, but also protects structures from rapid destruction under the influence of internal and external factors. If you use sodium silicate in cement mortar, it will increase its quality and strength by one and a half times.

Ecology and potassium glass

No harmful impurities were found in sodium silicate crystals that could adversely affect human health. This type of glass is considered environmentally friendly, which increases its advantages over other construction innovations.

How to choose liquid glass for waterproofing

There are several types of liquid glass on sale. They are selected for different needs. The presence of sodium silicate in the composition is better suited for creating a barrier against water. Potassium silicate is better suited to create fire protection against fire on wooden material, it also has antiseptic and vapor permeable properties.

Potassium silicate is better suited to create fire protection on wood material.

Comparison of potassium and sodium based glass

The material is produced on potassium and sodium bases.

Potassium-based, it is resistant to atmospheric and chemical influences and is used in the manufacture of protective paints.

Sodium-based compounds are most often used to construct a waterproofing layer for floors and foundations, in the production of antiseptics, adhesives and fire-resistant mixtures.

Characteristics depending on the type:

When liquid glass is added to lime, calcium silicate is formed, which has high strength.

How to work with liquid glass for waterproofing: general application recommendations

To treat the surface with this product, you need to prepare the surface first. It must be clean and grease-free. The product is used after the walls are painted. The tool used is a roller or a brush.

For the cement mixture, use a wide spatula.

All layers must dry well. How long liquid glass dries will depend on the environment. It takes a little time, but to get the best result, it is advised to wait a day for active use, especially when it comes to the field.

All layers must dry well.

Liquid glass for concrete: instructions for use and preparation of the mixture

You can prepare a mixture of cement and liquid glass even at home, while observing a number of requirements. Violation of the mortar manufacturing technology can lead to the formation of cracks in concrete.

Liquid glass should be added to the dry mixture. To do this, first combine all the dry ingredients in the required proportions and mix them thoroughly without using water. Then liquid glass, previously diluted with water, is gradually poured into the composition.

It is necessary to strictly observe the ratio of all ingredients when preparing the solution in accordance with the recipe used for a specific type of work. For example, if we are talking about the amount of glass in concrete, then it should not exceed 25% of the total weight of the mixture. To prepare a primer using a cement composition and silicate glue, the ratio can be 1:1.

It should be taken into account that it is liquid glass for concrete that accelerates the speed and density of hardening of the solution. The instructions for use recommend preparing the mixture in small quantities and using it quickly.

To waterproof the concrete surface, liquid glass is applied in several layers

The setting time depends on the amount of liquid glass added to the concrete. If the mixture contains 2% of this substance, then it begins to set within an hour, if 5%, then after 40 minutes. The hardening process also depends on the proportion. If more than 4% silicate glue is added to the solution, the strength of the concrete after complete hardening will decrease by about 25%. However, if the concrete contains only 3% liquid glass, the strength of the structure will increase.

Helpful advice! Sodium silicate, in addition to its waterproofing function, has antibactericidal and antifungal properties. The chemical composition of the material is an unsuitable environment for the development of any life.

Technological features of the mixture and types of impregnation of concrete with liquid glass

Liquid glass in a solution mixed in M400 cement at a temperature of 20 ° C begins to set after 2-3 hours, and completely hardens within a day. Over time, the monolithic base will only become stronger. The maximum hardness effect is achieved after a maximum of 4 weeks. Liquid glass is also used as an impregnation of various surfaces, ensuring their smoothness, evenness and waterproofing. Treatment of concrete with liquid glass is carried out for the following structures:

- concrete floor;

- flat roof;

- wells;

- swimming pools;

- basements;

- plinths;

- concrete walls and ceilings.

After the liquid glass dries, all pores in the concrete become clogged.

The impregnation process includes several stages. First of all, preparation of the base is required. To do this, the surface is thoroughly cleaned of old coating, paint, debris, dust and dirt. Next, the surface is cleaned with a metal brush and the base is covered with a 2 mm layer of bitumen emulsion. The base is given time to dry.

Then the surface is impregnated with a solution of liquid glass. The proportions of liquid glass in concrete depend on the type of surface (in accordance with the instructions for use). If the surface is horizontal, then a layer of 2-3 mm is applied to it and the mixture is smoothed with a spatula. The floor and ceilings are poured in several layers, taking a break for a certain number of hours. The surface can be used after a couple of days.

During work, you need to adhere to a number of recommendations. In particular, the solution must be distributed evenly. The coating should be done as quickly as possible, without allowing the composition to harden. Reliable impregnation is ensured by applying the mixture in two or even three layers. To insulate walls and ceilings, use a special spray bottle, which promotes uniform distribution of the solution. Cover the surface in two or three layers.

How to prepare a solution with liquid glass

The ratio of solvent to glass can be varied. Here you should study the instructions on the packaging. Because an individual brand may have different requirements. It is better to dissolve the material using a construction mixer, then it will be easier to obtain a homogeneous solution.

It is better to dissolve the material using a construction mixer, then it will be easier to obtain a homogeneous solution.

Methods of using liquid glass

ZhS can be used in different ways. They are suitable for different tasks, knowing them will help you choose the right option:

- Coating method, pure liquid iron is used, most often sodium. It is used for surfaces that attract dirt and are porous. Drying takes half an hour or an hour;

- The penetrating method involves the same process as the previous one, but water is added to the composition. It is used to cover hard-to-reach areas and requires prompt work;

- Application in concrete mortar.

It is used for surfaces that attract dirt and are porous.

Liquid glass for concrete waterproofing

In construction, they often resort to diluting liquid glass in a concrete mixture to improve its quality. To obtain the desired high-quality effect, the features of the process should be taken into account:

- It is unacceptable to add liquid glass to the finished mixture; they start by preparing the mixture, and add glass to the water, mix them, then pour them into the dry mixture;

- The ratio of materials can be varied in order to obtain various properties, so the recipe is selected according to the situation, and then strictly adhered to;

- Adding liquid glass helps improve the solution, but the curing process will be shortened, so it is recommended to prepare a small amount at a time.

The ratio of materials can be varied to obtain different properties.

Other properties of silicate glue

The active use of liquid glass in construction and other industries is determined, as mentioned, by the special characteristics of this material. Its high astringent properties depend on the cooking point (in other words, the liquefaction temperature), which varies between 760–870 °C. Silicate glue is characterized by a pH value of 11–13 units. At the same time, it is often called neutral, which is incorrect.

It is impossible to change the pH of the solution by a significant amount. If you add 10 to 100 parts of water to it, the pH will change by a maximum of one unit and become equal to 10–12. The described glue hardens at different temperatures – from -2 to +10°. When diluted, it returns to its original state without losing its properties. True, it is undesirable to store glue at subzero temperatures due to the risk of crystals appearing on its surface. After heating, they cannot be eliminated.

Drying of glass is carried out at elevated and natural temperatures. To speed up the process, manufacturers usually dry the finished product at a temperature of about 375 °C. Silicate glue dissolves in water without residue. If salt compounds, ketones, alcohol-containing substances, ammonia or aldehydes are added to its solution, a so-called “salting out effect” is observed. The described glass is incompatible with organic compounds, with the exception of urea, alcohol and sugar.

Application of liquid glass by coating method

The coating method is considered the simplest. It can be done using a roller, brushes or spray gun. Proceed as follows:

- Clean the surface and degrease. Concrete must be brushed to obtain an even coating.

- For a concrete surface, usually 1 layer of the product is sufficient; if a deeper finish is necessary, more layers are made, each one must stand and dry until the next half hour to forty minutes.

For a concrete surface, 1 layer of the product is usually sufficient.

The feasibility of waterproofing with liquid glass at various sites

It is popular to create waterproofing from this material, and the result is effective. It can also be selected in the following cases:

- Treatment of a concrete product located outdoors helps to obtain moisture protection, after which the item can be used under water;

- Waterproofing pools is easier with this substance;

- Treatment of basement structures helps to obtain antiseptic and moisture protection;

- Treatment of the foundation forms a film-like coating against water to protect the rest of the structure.

Waterproofing pools is easier with this substance.

Foundation waterproofing with liquid glass

The foundation is usually treated with the coating method described above. Seams can be processed using a penetrating technique. Work stages include:

- The seam and joining parts are embroidered, U-shaped grooves are made in the area of the cracks, and all debris is removed from them.

- A 5% concentrated solution of glass and water is prepared and poured into the cement.

- The prepared solution is used to close the recesses.

The foundation is usually treated with the coating method.

Waterproofing a well with liquid glass

The well must be protected from the inside. The main thing is that its rings are well secured. To improve fixation, you can cover the seam areas with ropes made of flax or jute, coated with liquid glass. They proceed to applying LC, the first layer consists only of glass, the second of cement mixed with sand and glass.

The well must be protected from the inside.

Do-it-yourself waterproofing with liquid glass: general recommendations

Carrying out waterproofing work yourself begins with cleansing and removing fat. The mixture is prepared and the product is applied to the material using a roller, brush or spray. There can be several layers, then each should dry for about 30-40 minutes before moving on to the next one.

There can be several layers, then each should dry for about 30-40 minutes before moving on to the next one.

Liquid glass for waterproofing: useful tips and safety rules

Recommendations from specialists will be useful to obtain good properties from the coating. And the application will be carried out at the proper level. They advise:

- The material cannot be used for bricks, it will lead to destruction of its structure, and the answer to the question whether liquid glass can be applied to glass will be no;

- Prepare the solution in small portions, the hardener acts quickly;

- The proportions must be strictly observed.

The technician must wear protective gloves and clothing to avoid contact with the skin.

Prepare the solution in small portions; the hardener acts quickly.

Liquid glass is the best option for waterproofing various surfaces. Suitable only for concrete and wood, but on them the coating will serve as a reliable layer against water that lasts for a long time. The process must be carried out in compliance with all the rules, otherwise the result will not be of high quality.

Using ZhS

The use of liquid glass in construction is due to its qualitative properties. It increases water resistance, which is especially important when constructing foundations for hydrological structures (fountain, pool, etc.). It also increases the heat-resistant qualities of bases for stoves, fireplaces and other heating devices.

Coating insulation of the pool bowl with glue Source dm-art-design.ru

The more liquid glass you add to concrete, the faster it will set, for example:

- if the material is 2%, then you can walk on the solution after a day;

- at 10% – after 6 hours.

Excellent waterproofing and heat-resistant mixtures are prepared from this glue. The primer is made from cement, water and liquid glass. Excellent insulation is obtained from glue and sand. The use of liquid glass has shown excellent results on the walls of wells, wet tunnels and basements.

The refractory mixture is made from sand and cement with the addition of office glue. The walls of the fireplace and stove are treated with it using a wide brush. In addition, you can use liquid glass for wood in the form of an antiseptic. To do this, the glue should be diluted with water.

Wood treated with glue Source www.cedar-stuff.com

Liquid glass is applied to a vertical surface in an even layer using a regular paint brush; on a horizontal surface it is easier to pour it and spread it with a squeegee or spatula. If the coating with liquid glass is supposed to be double-coated, then the first layer must dry completely.