Laminate as a floor covering has quickly gone from an exclusive finishing material to a mass-produced one. Affordable price, beautiful and aesthetic appearance, optimal service life, of course, provided that the class of material corresponds to the operating conditions, simplicity and ease of care - played a decisive role in the popularity of this floor covering.

Another plus is that laying laminate flooring does not present any difficulties even for a beginner. But, of course, a preliminary familiarization with the technology and compliance with all the rules and subtleties of installation will be required.

Buy laminate and underlay

omaric.ru Select laminate and underlay.

Buy the flooring in advance and leave it for 48 hours in the room where you plan to install it. The laminate will rest and its humidity will be equal to room temperature. It’s not worth purchasing two or three months in advance, since during repairs there will inevitably be wet processes and moisture, which laminate has no use for. Purchase the underlay based on the area of the room, but the laminate - with a margin of 5-10% for trimming. With direct installation there is always less waste, with diagonal and complex shapes of rooms - more.

How to choose a laminate?

Before starting work, the laminate must be selected correctly, taking into account the operational characteristics of the room. To help the consumer, there is detailed labeling on the packaging, which contains information about the product class, special characteristics and recommendations for use.

It should be borne in mind that the class of the product not only affects the price, but also informs what rooms the laminate is intended for.

Classes 21, 22 and 23 are recommended for apartments and residential buildings, and packages of material with the digital designation 31, 32, 33 and 34 are intended for commercial properties. That is, the higher the class, the higher the performance characteristics of the material.

| Symbol | Class | Intensity of use | Description | Application examples |

| Living spaces | ||||

| 21 | Low | Rooms with low intensity or short-term use. | Sleeping rooms. | |

| 22 | Normal | Premises with average intensity of use. | Living quarters, hallways. | |

| 23 | High | Premises with high intensity of use. | Living quarters, hallways. | |

| Service and office premises | ||||

| 31 | Low | Rooms with low intensity or short-term use. | Hotel rooms, private offices, conference rooms. | |

| 32 | Normal | Premises with average intensity of use. | Classrooms, private offices, boutiques. | |

| 33 | High | Premises with high intensity of use. | Corridors, shops, schools, large offices. | |

| 34 | Very high | Premises with very high intensity of use. | Airports, multi-purpose halls, ticket offices, shops. | |

| Industrial premises | ||||

| 41 | Low | Areas in which people work primarily while sitting and where light vehicles are occasionally used. | Repair and production of electronics, precision mechanics. | |

| 42 | Normal | Areas where people work primarily while standing and/or where vehicles are used. | Warehouses, repair and production of electronics. | |

| 43 | High | Other industrial premises. | Large warehouses, production workshops. | |

Considering the fact that the service life of laminate classes 21–23 ranges from 2-3 to 5 years, these materials are difficult to find on the domestic market. And the recommended class for residential premises is 31.

And this is completely justified, even though its cost is slightly higher, since the additional costs will be recouped primarily due to the fact that the more wear-resistant coating will last longer.

On average, if installation technology is followed , the correct choice of material according to characteristics and quality, laminate flooring can last, without requiring even minor repairs, for 10-15, and sometimes 20-25 years.

Also on the packaging there are symbolic images that provide information to the buyer about the special properties of this type of product:

- the possibility of using it with “warm floors”;

- increased resistance to mechanical stress;

- It is recommended to use furniture with rubber legs or wheels;

- flame retardancy;

- resistance to burning, for example, by cigarette ashes;

- resistance or instability to chemicals;

- UV resistance;

- hygiene;

- antistatic.

Laminate can be considered a universal floor covering - the only limitation for its use is excessive room humidity, although there are products on the market recommended for use in such conditions.

Prepare tools and materials

Not many tools are required to mark, trim and lay laminate flooring. Most devices are either readily available or inexpensive. In addition to tools, you will need some consumables. Here's the full list:

- five-meter tape measure;

- pencil;

- carpenter's square;

- compass;

- sharp knife;

- a hand saw with a fine tooth or a jigsaw, a circular saw;

- hammer or mallet;

- chisel;

- feather drills;

- drill or screwdriver;

- perforator;

- laminate staples;

- tamping block and wedges (can be replaced with pieces of laminate);

- laminate;

- substrate;

- vapor barriers (if necessary);

- plinth with fittings;

- transition thresholds;

- glue;

- scotch;

- masking tape.

Preparing the necessary tools

To lay laminate flooring you will need the following:

- roulette;

- jigsaw;

- spacer wedges;

- construction (or, alternatively, stationery) knife;

- pencil;

- hammer (rubber/wooden);

- breaker (you can use a pry bar instead);

- wooden block;

- square

Tools used when laying laminate flooring

Calculator for calculating the number of laminate boards per room

Go to calculations

Prepare the base

rmnt.net

The subfloor for laying laminate must be perfectly flat. Manufacturers allow differences of no more than 2 mm per 1–2 m. Otherwise, the locks will wear out due to loads and the slats will gradually separate.

Egger Group YouTube channel

Requirements for differences relate to the general plane of the surface, and not the horizontal. If the floor is without bumps or holes, but has a slope in any direction, then this will not affect the quality of installation.

Wooden floor

- Check all boards for bends and creaks. If necessary, strengthen the floor with self-tapping screws and replace bad areas.

- Make sure that the base differences are within acceptable limits. If not, level the floor using a scraper or lay down a layer of plywood.

Concrete floor

- Clean off pieces of plaster and sagging on the screed.

- Check height differences. If they are more than 2 mm, level the surface by grinding, self-leveling floor or additional screed.

- Wait until the concrete is completely dry. It takes 28 days.

- Vacuum or sweep the floor thoroughly to remove all dust.

Linoleum

- Check the base differences. If they are within acceptable standards, the laminate can be laid directly on top of the linoleum. If not, it is better to completely dismantle the coating.

- When laying on linoleum, additional waterproofing is not required.

Helpful tips on how to properly install laminate flooring

- Protect the coating from water, especially hot water. Even the highest quality slabs deteriorate when exposed to water.

- Storing boards in a vertical position is contraindicated. They become deformed, and the assembly process can turn into hard labor, and if stored improperly for a long time, the slabs can simply become unusable.

- For heated floors, it is recommended to choose a different coating option. But if you decide to use laminate, you should know that the floor temperature should not exceed 28 degrees.

Determine the direction of the light

The lamellas are laid parallel to the rays of light / education-web.ru

For laminate with chamfers, the direction of installation depends only on your preferences and the designer’s ideas. A coating without chamfers looks better when the slats are positioned parallel to the rays of light from the window. So the joints between the boards are almost invisible.

At the same time, laying along a wall with windows allows you to visually expand the room and is quite often used in narrow corridors and hallways.

What will you need for installation?

It takes 3-4 hours to lay laminate flooring in a room with an area of 15–25 m2 on a finished base. This type of coating refers to “floating floors”, which are not rigidly fixed to the base from below, but simply lie on it without fastening. Therefore, you just need to lay out individual laminate lamellas on a screed or flooring made of wood boards, connecting them firmly to each other.

To lay laminate flooring you will need the following tools:

Nothing particularly specialized is needed to install the coating in question. No special skills are required for this. Most home craftsmen can handle this tool without any problems and correctly. Installing interior doors with your own hands can still cause difficulties. With a laminated finish flooring, everything is much simpler.

Laminate in the interior

In addition to the lamellas of the laminate itself, in order to lay it on the floor, you will also need a plastic film for waterproofing. Plus, you will need a backing made of cork, foamed polyethylene or other similar material. The purpose of this lining is to increase sound insulation and distribute the load from individual laminate flooring strips to the base.

It is not recommended to neglect laying the substrate. It is provided with all step-by-step instructions from laminate manufacturers. If you don’t put it in, you can immediately forget about the coverage warranty.

Flooring options

Select installation method

There are two options: straight and diagonal. In the first case, the planks are placed along one of the walls, in the second, installation starts from the corner of the room and is done diagonally at an angle of 45 degrees.

On the left is straight laying, on the right is diagonal / dekoriko.ru, italstroy.ru

The direct method is the most common. It's simpler and faster. The amount of trimming and waste is minimal - 3–5%. If you are laying laminate flooring for the first time, choose this method.

Diagonal laying is used less frequently. This option is much more complicated, but also looks more advantageous. Especially on open areas of the floor. There is more pruning and waste - 10–15%. Of course, it requires skill and patience, so choose the diagonal method only if you are confident in your abilities.

Types of lock connections

Before laying the laminate, you should determine the type of interlocking connection of the selected type of material and select the installation method. If the laminate is equipped with:

1) with the “groove-tenon” system, then you should use the adhesive method, which practically repeats the principle of laying parquet boards. This option provides:

- increased connection strength;

- protection against moisture getting into the seams.

But this installation method requires certain skills and is quite labor-intensive. In addition, it does not ensure the durability of the coating, since the seams gradually dry out. An option to avoid this problem is to use laminate sealant , which has the necessary elasticity.

Minor repairs involving the replacement of one or two boards are quite problematic; the process of dismantling the covering for the purpose of its subsequent re-laying also becomes impossible.

2) the “LOСK” locking system, in which the laminate panels:

- first they are laid horizontally, maintaining the required gap between them;

- then the “tenon” of the board is mechanically aligned with the “groove” of the board of the adjacent row;

- and finally, the ends of their row are joined.

3) the “CLICK” locking system – the most convenient and reliable, which is also:

- the simplest and most affordable to implement, so it is worth paying attention, especially to those new to construction and repair who are deciding how to lay laminate flooring with their own hands and do it efficiently and quickly;

- the panels are also connected using the tongue-and-groove system;

- the main difference from the previous type is the joining at an angle of 30 degrees, after which the board is tilted and pressed to the base;

- Finally, using a mallet and a block, the panel is “hammered” into the adjacent board, until the characteristic sound of the end lock connection is activated.

See the video for types of locks:

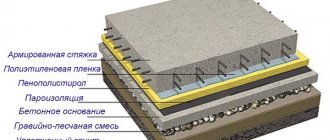

Install a vapor barrier

Since laminate is not 100% resistant to moisture, it is necessary to prevent it from getting into the slats. This is not relevant for a wooden base or linoleum, but when laying on concrete screeds, a vapor barrier must be installed.

Special membranes or ordinary polyethylene film with a thickness of 200 microns or more are used as an insulating layer. You can do without a vapor barrier if the substrate under the laminate has such a layer.

Film strips are laid overlapping / homemasters.ru

Lay the insulation with overlapping strips of 20 cm and connect the joints with tape. The canvases must be perpendicular to the direction of the substrate, and that, in turn, to the laminate. If the topcoat is laid from the front wall to the back, then the underlay is laid from left to right, and the vapor barrier is the same as the laminate.

How to determine what kind of substrate is needed?

Any step-by-step instructions for laying laminate necessarily begin with how to correctly select and then lay an element of such a floor as the underlay. But first you need to decide what functions it performs.

Most often, the substrate is credited with the functions of hydro-, heat- and sound insulation - and this is partly true, but it also performs more complex tasks:

- firstly, it plays the role of a so-called compensator, which is assigned the role of a damper of deformation processes. As a rule, they can appear as a result of fluctuations in humidity levels and temperature changes, during which the laminate behaves like wood - that is, it can reduce/increase its linear dimensions;

- secondly, it serves as protection for locking connections.

- thirdly, it corrects existing irregularities on the floor, even minor ones, but ignoring them can render the flooring unusable within a short period of time.

The substrate must be laid not only on a flat, but also on an absolutely clean base, which, according to technology, must first be thoroughly cleaned and vacuumed.

Underlay for laminate

Depending on the operating conditions and the type of laminate, the substrate used can have a thickness from a minimum of 2 mm to 12 mm. And in terms of its quality, it can be: 1) made of foamed polyethylene foam - the most widespread type, which provides:

- sufficient air exchange for the floor “pie”;

- noise absorption and sound insulation;

- reliable waterproofing;

- thermal protection.

It is chemically resistant, but has a short service life (on average 3–5 years), during which it cakes, reducing its thickness by half.

2) from foamed polystyrene:

- combines all the positive qualities of foamed polyethylene foam and fairly high performance characteristics;

- This material is often called “iso-noise” for its effective provision of soundproofing and noise-absorbing functions, guaranteed by a denser fabric structure.

3) cork backing for laminate:

- the most environmentally friendly type, as it is made from natural material;

- the only type of substrate that is produced both in rolls and in sheets (plates), which not only facilitates the installation process, but also reduces waste, which is important considering its cost.

Is different:

- high heat, noise and sound insulation qualities;

- moisture resistance;

- increased wear resistance.

To some extent, a variant of a cork substrate can be considered a bitumen-cork two-layer material, which not only provides excellent ventilation of the base and floor covering, but also has the ability to correct uneven floors. But it has not gained a mass consumer and is therefore rarely used.

But, regardless of what type or type of underlay you plan to use, you should not use the “overlapping” technique when laying it, as this will lead to deformation of the floor covering and especially to breakage of the locking joints.

The joining method is recommended, but you should know that a small gap between the sheets will not affect the condition of the laminate in any way.

Video about joining tiles and laminate

Install the backing

The sheets of backing are connected end-to-end and do not overlap each other / srbu.ru

Place a layer of backing on the base. Connect all sheets or strips end to end and secure with tape. There is no need to overlap, as this will create unwanted differences.

Next, when installing the laminate, be careful not to move the backing. To do this, you can lay it not on the entire surface of the floor, but in parts.

Step-by-step instructions for beginners

The first thing you need to know about and, most importantly, observe is the creation of a technological gap between the wall and the array with a width of 10–15 mm, the task of which is to ensure solidity when linear dimensions change due to temperature fluctuations and humidity changes.

During installation, the control function of the gap size is performed by wedges, which are installed immediately before installation and removed after installation. And immediately after this, all gaps are closed with skirting boards, for fastening which special clamps are used.

Operation of the floor, the installation of which was carried out using an adhesive composition, is possible only after it has completely dried, and with the help of locking connections - immediately after completion of the work. But for greater strength and durability of such a coating, it is recommended to let the coating sit for at least a day.

DIY laminate installation

The general procedure for laying laminate flooring is as follows:

- first, before leveling the floor under the laminate, a complete inspection of the base should be carried out;

- after – a thorough cleaning is carried out using the dry method, but using a vacuum cleaner;

- to protect the surface of the base, it is recommended to prime it; it is especially important to treat wooden floors with antiseptics and fire retardants;

- the next step is laying a polyethylene film that performs the functions of a hydro- and vapor barrier layer;

- after this, the underlay is laid with the obligatory 2–5 cm over the walls, which can immediately cover the entire floor surface in the room or partially. The second option is more rational and is recommended for use, especially if the work is carried out independently, since damage and contamination can be avoided;

- You can use regular tape to secure the strips of the backing together.

Installation process on video:

After all the preparatory work has been completed, you can immediately begin installing the floor covering, using the selected diagram, which it is advisable to do in a graphical representation:

- laying laminate, as a rule, begins with installing the first lamella from the corner of the room closest to the window;

- Wedges are immediately placed, the task of which is to control the size of the gap between the wall and the coating;

- then the first row is covered with solid laminate panels until the outermost one, which should be cut to the required size, and the remainder of it used for the next row.

The second row is laid according to the same principle:

- immediately after the first, cut-off part of the lamella, whole elements are laid down to the outermost one, which should also be trimmed;

- use the remainder of it for the next row as the first element, etc. until the end of the room.

To make roundings, the last row of the laminate is completely additional, since it is necessary to adjust the dimensions of the lamellas not only in length, but also in width. For this:

- each lamella must be measured individually and cut taking into account the required gap to the wall of 10–15 cm;

- an individual approach in this case is a necessity, since discrepancies that are often invisible to the eye will immediately become visible if this fact is not taken into account in advance;

- after completing the laying of the laminate, you can begin trimming the substrate, which protrudes more than 2 cm onto the wall, which will serve as a shock-absorbing element for the floor;

- Then you can begin installing the skirting boards, the installation feature of which is that they are not attached to the floor itself, but only to the wall using clamps.

Calculate the layout of the slats

bricoartdeco.com

Laminate planks must be at least 20–30 cm in length and at least 5 cm in width. To achieve this, you must first estimate how entire slats fit along the length and width of the room. And then cut the planks of the first row so that the last one is no narrower than 5 cm.

Egger Group YouTube channel

Don’t forget about the expansion joint around the perimeter of the room and take it into account in your calculations. The slats are trimmed so that there is a gap of 7–10 mm between them and the wall.

If the room is more than 8–10 m in length or width, manufacturers recommend installing dividing thresholds. The latter will isolate sections of the laminate from each other to reduce deformation from fluctuations in humidity and temperature. Think about where to place these joints so that they are less noticeable.

The same joints will be at the junctions of the boards with the tiles or laminate of other rooms. In this case, it is better to install dividing thresholds strictly under the door leaf. So, with the doors closed, the joints will not be visible from either one or the other room.

Selecting a layout method

An experienced master will say: the correct finishing is laid at the design stage. It is not necessary to develop a professional drawing and draw up an estimate. A schematic image of the room is enough, which shows where the doors and windows are located. If you imagine the final picture, it is easier to choose a layout method.

In total there are over 50 styling options. We will not consider them all: it is unlikely that a finisher without experience will decide to use a complex method. It is enough to choose one of three basic methods.

- perpendicular to the window: if you arrange the slats so that the direction of the joining seams coincides with the direction of the sun's rays, the connections between them will become invisible;

- parallel to the window: the resulting shadow will emphasize the joints, but the room will seem more spacious;

- diagonally: the way the owners like it.

Usually the first option is chosen. It gives the impression of a monolithic floor. The second method is suitable for a long and narrow room: this way you can make it wider. In both cases, the laminate should be taken with a margin of 5-7%. The third method is optimal if the area of the room is small or you need to divide it into zones. In this case, the stock of material should be at least 15%.

Lay the first row

vdomishke.ru

Installation of the first row is the most difficult and responsible. All subsequent ones will copy the first one, so it is important to lay it evenly along the wall. Otherwise, the pattern will unfold and the floor will look ugly.

YouTube channel Kronostar

- Inspect the laminate locks and remove small debris and dust from them.

- Cut the lock on the short side of the first board and place it on the floor. Insert the second one into it at a slight angle.

- Align the width of the slats exactly to avoid any “teeth” and lower the second board, clicking the lock into place.

- Place wedges at each wall to accommodate the expansion gap. They can be cut from pieces of laminate.

- Completely assemble the first strip in this way.

- Don’t cut the last lamella, but for now just lay it overlapping on top.

- Mark the length of the last plank, trim it and install it in the right place. Don’t forget: it should be no shorter than 20–30 cm.

How to cut laminate

- Place a wedge against the wall and place the board to be cut on top of the row in which it will lie.

- Mark with a pencil the distance to the front surface of the adjacent lamella.

- Draw a straight line using a square.

- Cut the board to the mark with a jigsaw, hacksaw or circular saw.

When using a jigsaw, consider the direction of the teeth. If they are oriented away from you, the laminate should be face up. If the teeth are facing you, turn the board face down. This way you will avoid chipping.

If you don't have a power tool, cut with a hacksaw or other fine-toothed saw. Do not apply much force so that the cut is neat and without chipping. To be on the safe side, you can stick masking tape along the line.

What to do if the wall is uneven

- Completely assemble one strip and move it close to the wall.

- Using a compass, find the place where the laminate is as far away from the wall as possible.

- Using a compass, mark this distance on the laminate along the entire length of the strip.

- Draw a line along the marks. It will completely copy all the irregularities of the wall.

- Cut out pieces on each laminate board, reassemble the row and install.

Installation of skirting boards

The plinth is installed at the final stage of finishing. Before installation, it must be cut at an angle of 90°: this will ensure the strength of the connections. There is no need to adjust all the planks at once: it is better to do this during fastening. When one element is fixed, the next one is joined to it, and only then is it fastened.

You cannot attach the baseboard to the laminate itself. It is fixed to the wall. How exactly to attach the profile depends on what material it is made of. If you chose the laminated MDF option, look at the back side - there should be a groove there. A special clip is attached to the wall, and the profile itself sits on it. The joints are coated with glue. Proceed with caution: if you try to fix the baseboard several times without success, the grooves will become loose.

A miter box is used to work in corners. The profile is inserted with the side closest to the user, and the edge is located at the bottom of the tool. Then the baguette is cut at an angle of 45°. Hold the baseboard firmly while cutting, otherwise the seam will be uneven and a gap will appear during joining that cannot be sealed.

Before attaching the corner, check whether the elements fit tightly. If everything was done correctly, there will be no gaps.

Consider the drawing

bricoartdeco.com

Most types of laminate are produced with an arbitrary pattern, and it is unlikely that the lamellas will match one another. In fact, this is not necessary: this way the coating will look too artificial and will look like linoleum.

Some manufacturers have laminate with pattern selection. This is usually indicated on the packaging and in the instructions. To ensure the design matches, the boards must be used in order from one pack.

If you plan to lay the laminate flooring staggered, open three or four packages and take one lamella from each. This will make the drawing as arbitrary as possible.

About the advantages and features

The advantages of this flooring include ease of installation (often you can do it yourself) and relatively low cost. Therefore, if you give preference to laminate, you can save a considerable amount, since you will not have to involve specialists in the work. In principle, even a person far removed from repair and finishing work can handle the installation. Of course, if you follow the step-by-step instructions. Which, in fact, is what this material is dedicated to.

What do the images on laminate packaging mean?

On a note! The installation procedure itself is associated with other stages of floor finishing, such as choosing a suitable material and preparing a rough base. Some points will be omitted in the article, because they are already covered in other publications (links are provided below), where everything is described in detail. Well, let's get started!

Place the remaining rows

YouTube channel Kronostar

Continue laying subsequent rows in a similar manner. Collect the slats along the short side into one strip, and then install it in the previous row and snap it into place. With the remaining piece from trimming, in order to save money, you can start a new row.

stroy-podskazka.ru

Cut the lamellas of the last row to the desired width, assemble them into one strip and finish laying. You may need a Z-clip to snap them in place.

How to make a pipe joint

Egger Group YouTube channel

- Place a board and mark the center of the pipe.

- Using a square or tape measure, measure the distance from the wall to the center of the pipe.

- Mark the center of the hole for the pipe on the slats.

- Using a jigsaw or a feather drill, make a hole 8–10 mm larger than the diameter of the pipe.

- Cut out the piece of laminate that is interfering with installation, and after installation, glue the piece into place.

- The holes themselves can then be covered with plastic rosettes.

How to make a joint with a door frame

YouTube channel Kronostar

- Take a piece of laminate 15–20 cm wide, insert it into the lock and move it close to the door frame.

- Place masking tape over it.

- Place the hacksaw on a piece of wood and cut through the door frame. The protruding part goes all the way through, and the deep part is 5–7 mm.

- Use a chisel to chop off the cut pieces and check how the laminate fits.

TOP 3 laminate manufacturers

| Photo | Name | Rating | Price | |

| #1 | Tarkett | ⭐ 97 / 100 | More details | |

| #2 | Kronospan | ⭐ 95 / 100 | More details | |

| #3 | Quick-Step | ⭐ 92 / 100 | More details |

Quick-Step

pros

- warranty service life – 25 years;

- large selection of decors;

- There are models for wet rooms;

- no burnout observed;

- secure locks.

Minuses

- chemical odors are felt;

- marriage is common.

Quick-Step laminate

Kronospan

Kronospan laminate is produced in Russia and has a German level of quality, and also meets the highest European standards. The Russian buyer really liked the product.

Kronospan

pros

- simple installation;

- decent technical characteristics;

- excellent price/quality ratio;

- environmentally friendly and harmless to health;

- abrasion resistant;

- a wide range of.

Minuses

- there are unreliable locks;

- There are defective lamellas.

laminate Kronospan

Tarkett

The Tarkett company produces various floor coverings: laminate, parquet boards and linoleum. During the existence of the company, it has taken a leading position and entered the top five world leaders in the production of floor coverings.

Tarkett

pros

- a wide range of;

- high strength and reliability of layer connections;

- long service life;

- reliable lock;

- easy to install and operate;

- affordable price.

Minuses

- It is not advisable to use in places with high humidity;

- low sound and heat insulation.

Tarkett laminate

Install the thresholds

pol-exp.com

There are several types of thresholds. In addition to appearance, they differ only in the mounting option. Some are held on through dowels, others on hidden ones, and others have a special mortgage that is attached to the floor with screws and to the front part with a latch.

The nuances of installing one type of threshold or another are always indicated on the packaging. In general, the procedure is as follows:

- Measure the required length of the threshold and cut off the excess part.

- Distribute the fasteners evenly across the entire width of the opening.

- Drill holes using a hammer drill along the marks.

- Secure the threshold: all the way through, inserting screws into the groove or through the mortgage.

- If the fastener is not through, tap the threshold through a soft guide until it is completely seated.

Instructions for installing coverings with “Click” locking systems

Step 1. It is recommended to start laying from the far corner. The protruding wide element of the locking connection should “look outwards”. Place the lamella in the corner, use wedges to set the required deformation gap. Alternatively, wedges can be installed after laying the entire first row.

The board is laid in the corner

Step 2. Place the groove of the second into the lock of the first lamella. Install it at the desired angle (this should be indicated by the manufacturer in the instructions).

The groove of the second board is inserted into the end lock of the first board.

Step 3. It is important not to allow any distortions - both in the direction and in the width of the lamella.

Warp in width

Directional skew

Step 4. Also, after snapping, the edges of the slats should match exactly. In our example, an angle of 15 degrees is required for engagement.

In this example, an angle between them of 15° is required to engage the locking parts of the boards

Step 5. Next, simply lower the lamella to the floor so that the mechanism works.

After this, the attached board is simply lowered onto the floor plane

Step 6. If you need to cut the board (as in the example), then it is better to mark for cutting right on the spot.

It turned out that the next board in the row should be shortened

Step 7. Rotate the lamella 180 degrees in both planes. Place the edge that will not be cut against the spacer wedge next to the wall to allow for the required gap.

The board rotates 180 degrees in both the longitudinal and transverse planes

Step 8: Next, draw a straight line along the cutting line using a square.

The cutting line is drawn

Step 9 : Trim. It is better to use a jigsaw, although in a pinch a hacksaw will do (as in the photo).

Cut in progress

Step 10. Turn the cut board over and insert it into the lock of the previous one.

The cropped fragment is inserted

Step 11. Lower it down in the same way as described above. If everything was done correctly, the fragment will fit perfectly into place.

With proper marking, this fragment will fit perfectly into place with the required gap from end to wall

On a note! If the trim is longer than needed, you can use it to start the second row.

If the remaining trim has a length greater than the minimum allowable, then it can well be used as the first board of the second row

Having previously installed the wedge, lay the board close to the finished row so that it touches it along its entire length.

It is laid out from the beginning of the row (with a wedge installed)

To make it clearer, here is a cross-section of the profile of the boards prepared for mutual engagement in the lock

Step 12. Assemble the entire second row according to the principle described above.

The entire strip of the second row is being assembled

Step 13. Raise the entire strip to the required angle so that the tenon fits into the groove (assistants may be required). Then lower the strip while pressing it forward. As a result, the lock should work.

If everything is level, then the lock should work along its entire length.

Step 14. Collect all remaining rows in the same way.

Laminate installation process

Step 15. If you come across heating pipes, proceed as follows. Start with markings. Place the lamella against the wall (with a wedge) and draw a transverse line that corresponds to the axes of the pipes.

There may be heating pipes near one of the walls.

Step 16. Connect this board to the laid strip, move it towards the pipes and mark lines that correspond to their centers.

2 more lines are planned

Step 17. Where the lines intersect, make holes (their diameter should be 2 cm larger than the diameter of the pipes). Use a core drill for the job.

Drilling locations

Step 18. Make a continuous cut along the drawn transverse line. Separate from the lamella a piece with a pair of cut semicircles.

A fragment with two semicircular cutouts is separated from the board

Step 19. Assemble the entire row of covering, starting from the heating pipes.

Next, the entire row of laminate is installed, starting from the pipes

Step 20. Coat the ends of the cut piece with glue.

The ends of the cut fragment are coated with glue

Step 21: Place the piece in place and support it with spacer wedges.

The fragment is installed in place and propped against the board with a wedge from the wall

Step 22. After this, install decorative frames for the passage of pipes (they are sold dismountable).

Installation of collapsible decorative round frames for pipe penetration

Step 23 You should end up with something like this.

This is what this node should look like in the end

Step 24. We should also talk about the installation near the door frame. It is better not to cut the laminate along its contour (it will look unsightly, because the baseboard is not installed here), but to make a groove in the lower part of the box for installing the lamella.

The best way is to cut a groove on the bottom of the box for inserting a laminated board

Step 25: Once you have cut the groove, you may notice that it will not allow the slat to be raised for winding. But this problem can also be solved.

The groove is cut, but it does not allow the board to be lifted in order to move it along with the row being laid

Step 26. First, insert the lamella that will fit into the groove into the lock, then slide it flush against the wall. Then assemble the entire row (without this lamella). As a result, a slight gap is formed.

First, the board, which should fit into the groove of the door frame, is inserted into the lock, and then moved close to the wall

Step 27. On the last lamella of the laid strip from the lock at the end, cut off the protrusion that “looks” vertically with a chisel.

Using a chisel, on the last board of the laid row, the vertically facing protrusion is carefully cut off from the end lock

Step 28 Apply a bead of glue to the edge of the lock.

After this, a strip of glue is applied along the edge of the lock.

Step 29. Slide the outer lamella back so that it meets the coated end. When the glue dries, the connection will be very strong.

And all that remains is to move the outer board back until it joins the glue-coated end of the laid one

Step 30. When laying the last row, you will most likely have to cut the boards to width. Carry out the markings on site.

Sooner or later, the turn of the last row comes

Step 31. Turn the lamella 180 degrees along the longitudinal axis, rest it against the spacer wedges. Draw a cutting line along the edge of the previous row.

A cutting line is drawn exactly along the edge of the working surface of the previous laid row.

Step 32. Install the first board of the last row.

The first board of the row is ready

Step 33. Trim the other boards in the same way and assemble the entire strip.

All other boards in the row are trimmed in the same way.

Step 34: Finally, remove the spacer wedges along the “dead end” wall. Also add wedges around the perimeter (they are no longer required). All that remains is to install the skirting boards without connecting them rigidly to the slats.

At this point, the installation of the laminate flooring can be considered complete.

Video - How to properly lay laminate flooring

Table. Instructions for laying coverings with “Click” locks without an assistant.

| Steps, photo | Description of actions |

| Step 1 | Start laying the first row. There shouldn't be any difficulties here. |

| Step 2 | Move the entire row towards the wall, installing the wedges described above to maintain the deformation gap. |

| Step 3 | Prepare the boards for laying the second strip. |

| Step 4 | Since you don’t have assistants, you will have to assemble the entire row one lamella at a time. Start with the starting board - slide it into the lock at the required angle. |

| Step 5 | After that, lower it to the floor. |

| Step 6 | Lay the next board. Connect it in the end lock, for which you move it as close as possible to the first board. |

| Step 7 | Due to the fact that the lock has not yet been inserted along the length, such a protrusion is visible (see photo). |

| Step 8 | A gap along the longitudinal seam is also visible. |

| Step 9 | Now lift the lamella to the desired angle. |

| Step 10 | Move its right end forward as much as possible so that the gap there disappears. |

| Step 11 | Keeping the right edge pressed, lightly hit the ridge on the end with your left hand. As a result, the lamella should engage. |

| Step 12 | When the gap disappears, lower the board to release the lock. |

| Step 13 | Take the next board. Start with the end connection. |

| Step 14 | Wind the lock by lifting the lamella and press the right edge tightly. |

| Step 15 | Short punch with your left hand. |

| Step 16 | As a result, the lock should work. |

| Step 17 | Here is another photo of the process, but from a different angle. Same end connection. |

| Step 18 | The lamella needs to be raised, pressing the right edge as much as possible. |

| Step 19 | Left hand strike again. |

| Step 20 | At the end, the lamella must be lowered for the lock to finally work. Proceed in the same way until you have laid all the covering. |

On a note! This is an effective, but disparaging method for laminate flooring, which should only be used in a desperate situation.

Calculation of the amount of laminate

In order to calculate the amount of material required, you do not need to download a construction calculator.

- First, we find out the area of the room by multiplying its length by its width.

- We find out the area of the laminate using the same formula, and since almost all laminate boards have a length of 1 meter, it is enough to measure the width of the board.

- Divide the area of the room by the area of the laminate - we get the number of boards!

Example:

Room – 16 m²

Laminate - length 1 m, width 0.2 m. Area = 0.2 m²

The required number of boards is 16: 0.2 = 80 boards.

How to eliminate joints between multi-level coverings of adjacent rooms

We looked at how to properly lay laminate flooring. But there is one more important point.

Often during installation, multi-level joints are formed between the laminate and the threshold or flooring of adjacent rooms. How to deal with them?

They are easily neutralized using thresholds. If you need a straight joint, a metal threshold will do. It is the most durable. For joints that are curved, there are flexible thresholds.

Types of thresholds:

- single-level - the most common, designed for joining laminate flooring in adjacent rooms;

- multi-level - used for joining a laminate floor to another surface, the level of which differs in height;

- one-sided - used for joining with doors;

- corner - for connecting coverings at an angle of 90 degrees.

Stage 4. Warm floor under laminate (if necessary)

It is not always possible to lay heated floors in a wooden house under laminate. If the apartment initially has wooden floors installed, then installation is possible, but has its own characteristics.

In the case of concrete floors covered with a finished wooden floor, it is recommended to completely dismantle the boards, pour a screed on top of the concrete base, and then lay a warm floor on top of it.

There are also a number of requirements for the quality and composition of the laminate that will be laid on top of the heated floor:

- the thickness of the die must be at least 7 mm;

- the formaldehyde emission class must be E0 or E1. Indicators E2 and E3 are prohibited from being laid in tandem with heated floors! When heated, they will evaporate dangerous amounts of harmful substances into the air.

Even if all the requirements are met, the heated floor cannot be heated too much. The maximum permissible temperature is 30–32 °C. When used at higher temperatures, the laminate will quickly become unusable, releasing toxic substances.

If you comply with all installation and safety requirements, the flooring will last a long time and will not harm the health of residents and their pets.

Types of heated floors

Warm floors come in three types:

- water. The screed contains pipes connected to the heating system. This option is the least expensive, but with this option it is difficult to regulate the heating temperature. It is worth noting that water floors are allowed only in private houses or apartments with autonomous heating. Residents of apartments with central heating are prohibited by law from installing this type of heated floor - this will result in a fine and forced rework of the entire system;

- electric. This option is much more expensive both in terms of installation and during operation, but it can be installed in any room. Also, the advantages of an electric floor include convenient temperature control (you can control not only the number of degrees, but also use several thermostats to turn on only individual zones of the heated floor) and a relatively small level of raising the floor;

- thermomats. This type is also called film infrared heated floor. Installation under laminate on a wooden floor is also acceptable for all rooms. During installation and operation, this is the most convenient option, but at the same time the most expensive. Therefore, you need to accurately calculate the required heating area (there is no heated floor under massive furniture) so as not to overpay.

Each option has its own installation and operation features, so when choosing, you need to focus on a specific situation.

Laying heated floor elements

According to the installation technology, water and electric heated floors require the presence of a screed laid on a layer of thermal insulation materials.

With this approach, the floor can no longer be considered wooden. But if during the renovation process it is already planned to use screed or mixtures to level the wooden floor under the laminate, then they can be combined with the installation of a heated floor.

But with this technology, before installation you will have to:

- Remove the boards completely.

- Cover the joists with moisture-repellent compounds and cover with a vapor barrier film.

- Fill the space between the joists with thermal insulation materials.

Only after this can you begin installing the screed and heated floor.

To avoid “wet” work with cement-sand mixtures, the “dry installation” option was invented. In this case, the logs and the space under the boards are processed according to the same scheme:

- The prepared boards are laid on top of the logs and grooves are made into them with a milling cutter for cables or pipes.

- Special metal plates are laid on top of the gutters to distribute heat evenly, and the cable is laid along them.

Another option for “dry installation” is using polystyrene boards. In this case, the subfloor is covered with an overlapping film. The edges are connected with construction tape. Polystyrene mats with bosses are laid on top, and a cable or pipe is laid along the gutters.

You can implement any of the options, but when carrying out repairs yourself, it is advisable to take into account your own skills and not attempt too complex work. The simplest option in this case would be to install a film thermomat under the laminate on a wooden floor.

In this case, it is enough to spread a reflective substrate (foil side up) on the prepared floor and place thermomats on top of it in the right places.

The film is connected to the thermostat. After which the entire floor is covered with thick polyethylene film (waterproofing barrier).

An important point: when installing a heated floor on a wooden floor, it is imperative to provide a ventilation system for the joists, otherwise they will rot very quickly.

Regardless of the type of heated floor chosen and the method of its installation, before laying the laminate, the heating system must be checked. Don’t just inspect the pipes or “ring” the wires, but connect them.

The water heating system is tested at the highest possible pressure. When testing electric heating, the test takes place in several stages, including turning the floor on and off.

Each time you turn it on, you need to increase the temperature by 5°C, gradually bringing it to the maximum permissible (this may take 2-3 days).

Recommendations

Laminate flooring should be laid in compliance with the following simple rules:

- Before installation, the lamellas must lie in the room in a horizontal position for at least a day to cool down or warm up to room temperature.

- Laying laminate flooring is only permitted on dry substrates. If a concrete screed was originally made, then laying the coating is permissible only after it has completely dried.

- Before starting work, the rough foundation must be thoroughly swept so that there are no pebbles or other debris left on it. If you leave them under the laminate, sooner or later the substrate will tear first, and then the coating itself will be damaged.

- To identify differences in the subfloor, you should use a long rule or level - the slightest deflections will be visible in the gaps that appear.

- It is best to lay the planks away from the window so that the seams along the locks are less visible in daylight.

- Compensation gaps 8–10 mm wide should remain between the walls and the laminate. Without them, the laminated coating, during thermal expansion, will rest against the wall surface and rise like a mound in the middle of the room.

- To prevent the slats from moving during installation and closing the gaps along the walls, spacer wedges should be placed. Then they clean up.

- Compensation gaps must also be made in the middle of the room if the coating is more than 10 meters long. Afterwards, these seams must be closed with decorative thresholds made of plastic or metal.

- The substrate and waterproofing should be glued with tape at the junction of their individual strips. At the same time, you cannot nail this sublayer to the rough base with nails or screw it with self-tapping screws. Gaps are not allowed here.

- The first row is laid against the wall with a tenon, for which it is pre-cut so as not to interfere.

If the walls are uneven, then special attention should be paid to placing spacer wedges and laying the first row. The smoother the first slats are laid out, the more reliable the connection of all the remaining slats will be.

If you strictly follow the given step-by-step instructions and recommendations, the laid laminated coating will last for many years. There is nothing particularly difficult about its installation. In order to figure out how to choose the entrance door to an apartment and then install it, you will have to use your head completely. With the floor finish in question, things are not so scary.

Step-by-step instruction

Features of locks

The vast majority of laminate flooring is available with two types of locks on the transverse edges: conventional and easily assembled (the so-called “Quick-step”).

Conventional locks are latched by connecting the ends at an angle and then lowering one of the panels. This type of flooring is assembled in rows: first, all transverse seams in the row are connected, and then the assembled row is snapped at an angle to the already laid canvas.

Easy-to-assemble panels are mounted one at a time: the longitudinal seam is connected at an angle, then the die is lowered and snapped into place with the previous one. This coating can be assembled either in rows or with a ladder.

There is information on the Internet that there are transverse locks of the “LOCK” type - they supposedly snap into place in the stacked position by tapping the row from the end. From my own experience and the experience of my colleagues, I can say that I have never seen such locks. It is quite possible that such castles exist (existed), but I am inclined to believe that someone wrote something stupid, and others simply stole it. Unfortunately, this phenomenon does occur.

Often, for panels with conventional locks, you can find similar nonsense in the attached instructions: a row is assembled without connecting the transverse locks, and then these locks are connected using a clamp and a hammer. However, in reality the design of the lock does not allow this. As a result, when trying to connect the transverse seams, either the locks or the place where the clamp stops break. This suggests that you cannot always trust the manual from the manufacturer, especially an inexpensive one.

In the above-described options, the longitudinal locks are connected in the same way: at an angle, followed by lowering. Laminate flooring with more complex locks is very rare. Mostly they are found in square dies, which are assembled without spacing subsequent rows. Such locks are assembled in the same way, at an angle with lowering, however, to snap the lock into place, you must lower the attached panel lower than the previous one. This can be done by placing a small gasket, a few centimeters thick, such as a square, under the already laid one.

The canvas with “complex locks” is assembled in separate panels: first the transverse lock is attached, and then the longitudinal one. Such locks do not fall apart when the row is slightly lifted to attach new dies.

Stage 3. Alignment

The rules for laying laminate flooring on a wooden floor require that the base be level. In most cases, the old floor does not meet the necessary conditions and must be further leveled. There are several ways to do this.

With a scraper or planer

This method is suitable for removing small differences and layers of old paintwork. Most often, it is used in cases where the boards are in excellent condition and do not require significant repairs.

This process does not cause any difficulties. There are only two points worth paying attention :

- before starting work, it is good to “recess” the heads of the fasteners (nails or screws) into the boards so as not to damage the tool during scraping;

- During the work process, regularly check the degree of leveling with a level so as not to get carried away and remove excess.

To eliminate serious irregularities, it is better to choose other methods.

Using plywood

This is one of the most popular methods for leveling wood floors. Depending on the level of curvature of the base, laying plywood on a wooden floor under a laminate is done in two ways:

- If you need to correct small unevenness (difference of 1–2 cm), then the plywood is attached directly to the boards.

- To eliminate significant defects, additional logs are laid on the boards, and sheets of plywood are laid on them.

The second method, although it allows you to level out significant unevenness, is only suitable for rooms with high ceilings, as it leads to a significant rise in the floor level (10–20 cm).

Plywood selection

When choosing what kind of plywood is needed for a laminate floor, you need to take into account the characteristics of the room, the level of curvature of the floor, the fastening method and the expected load.

All existing types of plywood are distinguished according to several criteria:

- grinding level. Sheets can be sanded, unsanded, or with one-sided sanding;

- type of wood. Most often in stores you can find various variations of coniferous species, but there are birch leaves;

- thickness. Manufacturers offer many different options ranging from 3 to 40 mm;

- level of moisture resistance. It depends on the composition of the glue used to glue the individual layers;

- degree of fire resistance (achieved with special impregnations).

There is no point in laying expensive birch plywood under laminate. You can also save on sanding. Minor roughness under the substrate will not damage the laminate.

As for moisture resistance, this is a controversial issue. If the room is dry and warm, it will be enough to coat ordinary plywood with special water-repellent and anti-mold compounds, it will be cheaper. When installing in damp rooms, private houses, or on the first floors, it is better not to skimp and use only moisture-resistant materials.

What you definitely shouldn’t skimp on is thickness. Thin sheets will not withstand the load and will not be able to level the floor to the required extent.

When attaching sheets directly to boards, the thickness of the plywood under the laminate should be 10–12 mm. When laying on a lathing made of logs - 16–20 mm.

In some cases, to add rigidity to the structure, plywood is laid in two layers. So that the seams of the top layer do not fall on the joints of the lower sheets. In this case, the thickness of each layer should be 8–10 mm.

Laying and processing

The first method of laying plywood is much easier. The main thing is to follow the main points:

- before installation, it is advisable to remove the most protruding “bumps” on old boards using a scraping machine or a plane;

- treat the boards with antifungal and moisture-repellent compounds;

- It’s good to “drown” the nail heads. Don't be afraid of damaging the floor boards. Plywood will hide all dents. If the nail cannot be hammered in properly, it should be pulled out;

- Attach the plywood sheets to the old base using self-tapping screws in increments of 15–20 cm. In this case, you need to ensure that the screw does not get into the edges and corners of the plywood sheet;

- A technological gap of 5–10 mm should be left around the perimeter of the room (for possible expansion of the wood). If the area of the room is very large, it is advisable to make additional technological gaps between the sheets every few meters.

Installing plywood on joists under laminate is more difficult, but it gives more possibilities. In the technological space you can hide communications, insulation, or sound insulation. With this method of flooring there are many more stages:

- logs must be set according to level. The maximum difference between the lags should not exceed 3 mm. If after installation the difference in level is large, the protruding beams should be cut off with a plane, or the logs should be built up too low;

- treat logs with anti-mold and moisture-repellent compounds;

- place insulation under the laminate on the wooden floor, communications and hydro- and sound insulation (if necessary) in the gap between the subfloor and plywood;

- cut the plywood. This point needs to be treated with special attention. Since plywood is attached only to logs, and the width of one beam usually does not exceed 10 cm. Therefore, for fastening, one sheet of plywood requires no more than 5 cm. Taking into account the technological distance from the edge, an error in cutting even a centimeter will make the sheet unsuitable for installation on lags. Therefore, you should first draw up a diagram on a sheet of paper, on which you will not only indicate all the dimensions, but also mark the sheets. The same marks must be applied to individual pieces of plywood when cutting. This will make the installation process easier;

- lay and secure the sheets according to the drawn up diagram. In this case, you need to ensure compliance with the technological gap around the perimeter of the room.

Regardless of the flooring method, the preparation of plywood for laying laminate is the same. Using a scraper, unevenness and significant differences between individual sheets are removed.

If there are significant defects on the plywood (knots, cracks), they should be covered with putty. After this, the surface is cleaned and treated with moisture-repellent and anti-mold compounds (even if moisture-resistant plywood was used during installation).

Do you need plywood for laminate flooring?

Due to the fairly high cost of plywood, many are looking for other methods of leveling. To save money, instead of plywood, you can lay OSB or chipboard under the laminate on a wooden floor.

But such a replacement is only suitable for dry rooms, because the moisture resistance of these products is much worse than that of plywood. You can, of course, buy moisture-resistant OSB boards, but then you won’t be able to save much. OSB and chipboard spread similarly.

However, you should not lay fiberboard under the laminate for leveling. This material is too thin and fragile and is not suitable for these purposes. At the same time, its moisture resistance indicators are much worse than even chipboard, not to mention plywood.

Leveling the floor without plywood

If you don’t have the desire, tools or necessary skills to level a wooden floor with chipboard or plywood, then you can do without them. Depending on the number of defects and the level of curvature, the base can be corrected in three ways:

Putty

This method is suitable for eliminating cracks and minor defects. In some cases it is used as a complement to other alignment methods.

Self-leveling mixture

Another interesting way to level a wooden floor under a laminate. Suitable for those who make repairs slowly (the process will take about a month).

In this case, preparing the wooden floor for laminate is the same as before laying plywood. But, in addition to cleaning and removing rotten boards and protruding nails, before leveling the wooden floor with a self-leveling mixture, you need to seal all seams and cracks (putty or silicone sealant).

After this, you need to waterproof the wooden floor. This is done using special moisture-resistant mastics or primers applied in a thick layer, or by covering the floor with polyethylene.

You need to use dense polyethylene and cover it not only with the entire floor plane, but also extend onto the walls by 6–8 cm. A damper tape should be installed around the entire perimeter of the room. After this, the surface is filled with the prepared mixture and left for three weeks until completely dry.

When choosing a mixture, the label should indicate that the composition is suitable for wooden bases.

You should also pay attention to the service life of the mixture. That is, the time during which the prepared composition must be completely consumed (filled and leveled). Depending on the duration, it can range from 20 minutes to an hour.

It is worth considering that these mixtures come in two types: starting and finishing. To level the floor under laminate, the starting mixture is enough and there is no point in overpaying for the finishing mixture.

Sand-cement screed

This option is the most affordable, so the question is often asked whether it is possible to make a regular screed on a wooden floor. It is possible, but it must be floating. That is, the cement-sand mixture should not stick to either the floor or the walls.

When implementing this method, all preliminary work remains unchanged. The boards are checked, cleaned, defects and cracks are covered with putty, and nails are removed.

Next comes waterproofing. In this case, it can only be made from dense polyethylene. If the width of the strip is not enough for the entire room, then the two strips are overlapped (at least 30 cm) and secured with construction tape. The polyethylene should extend 5–7 cm onto the walls, and a damper tape should be installed around the perimeter of the room.

With this design, the cement screed will be in a polyethylene “bowl” and will not come into contact with the wood. In addition, it is advisable to strengthen the screed with a reinforcing mesh; it is placed at a height of 2 cm from the base. Unlike a self-leveling mixture, here the screed will have to be leveled manually using the beacon rule.

If it was not possible to place insulating materials in the space under the boards, you can improve the thermal and sound insulation of the floor with the help of a properly selected underlay for the laminate.

Is it possible to lay laminate flooring on an uneven floor without leveling it?

Can. In the only case, if after renovation the apartment is put up for sale. New residents, of course, will more than once remember this renovation with a kind word and spoil the karma of the “repairmen”, but laying the laminate will be quick and relatively inexpensive.

If you are making an apartment for yourself, it is still worth finding the energy and time to level the wooden floor under the laminate with a mixture or plywood. Otherwise, the locks of even the most expensive and high-quality laminate will wear out very quickly, and the floor will have to be completely re-laid, and this will be much longer and more expensive.