Advantages and disadvantages of Molly dowel

When fixed into a hole, the dowel is installed closed. Only when the screw is screwed in does the shape of the Molly dowel change, which is a conical or umbrella type support. It fits tightly in the hole. The screw itself is installed a little differently when compared to conventional dowels. It doesn't need to be screwed in. The screw is pulled out with a special tool. Use pliers to get the fastener in working order. This type of installation allows you to reuse the Molly dowel. If desired, you can easily remove it from the hole without losing the properties of the hardware.

Molly dowels are exclusively metal fasteners, which are mainly made of steel. Additional treatment in the form of galvanization provides anti-corrosion protection. If maximum protection is needed for serious projects, stainless steel dowels can be used. This is due to the high cost of the products.

According to experts, the main disadvantage of Molly dowels is the required free space. The fastener cannot be installed in a confined area. The pliers for installation and the hardware itself have certain parameters that require space.

Metal dowel for hollow structures

Fastening structures to sheet materials such as plasterboard, plywood, chipboard is carried out using special fasteners - dowels for hollow structures. Other names for such products: “butterfly dowel for drywall”, “Molly dowel”. Since such hollow and sheet building materials are becoming more and more popular every year, the need to buy a “butterfly dowel” arises among finishers more and more often. The description below concerns metal dowels.

Design

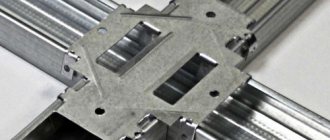

A metal dowel for hollow structures consists of two parts - a metal sleeve (collet) of a special design and a screw with a semicircular or countersunk head. A sleeve is required. It is always present in such fasteners. The screw can be selected separately. For example, HILTI calls such a sleeve “HHD drywall anchor” and is supplied without a screw. The specifics of the operation of a metal dowel are based on the special design of the sleeve. Initially, it has the shape of a cylinder with cutouts in the middle (spacer) part. On the side of the attached structure there is a support washer with pointed protrusions, on the opposite side the bushing has an internal thread.

For various fastening tasks, manufacturers produce “butterfly dowels” with a ring, a hook, a half-ring, an L-shape, a hex head or a slot. The drawing above shows a dowel screw with a semicircular head and a straight slot. With the growing popularity of drywall, the demand for such dowels is also growing. Today they are in the assortment of all major fastener manufacturers. For HILTI this is the HHD version, for FISCHER - HM, for MUNGO - MHD, for SORMAT - MOLA. Lower prices for metal dowels for drywall from Chinese manufacturers. The range of products is represented by thread diameters from M4 to M8, lengths from 23 to 66 mm.

Purpose

The Molly dowel is designed for attaching structures to hollow bases (hollow bricks and blocks), sheet materials (plasterboard, chipboard, thick plywood, etc.), and floor slabs. Due to the presence of voids in such materials, it is impossible to use friction anchoring, so the Molly dowels use the abutment principle. With their help it is convenient to attach a picture, lamp, shelf, mirror, cornice, bracket. With the help of such hardware, you can attach support frames and wooden frames to hollow structures.

Material of manufacture

The material used to make dowels for hollow structures is carbon steel.

Coating: galvanic zinc plating. For places with high humidity and exposed to increased corrosive effects, manufacturers produce stainless steel products. To solve simple fastening problems, you can buy a Molly dowel made of plastic, which is much lower in cost.

Installation features

Installation of metal dowels for hollow structures is carried out using the preliminary installation method. First, fasteners are installed on the seat, and then the required element is attached to it.

The installation sequence of the Molly dowel using a special tool is as follows:

- a hole of the required diameter is drilled in the base base

- The dowel screw is installed in the installation tool

- the dowel is inserted all the way into the prepared hole

- The dowel is secured using the tool. In this case, the screw is pulled out; in the place of the cutouts, the stops of the sleeve move apart and fit snugly to the base base

- the tool is disconnected, the screw is unscrewed

- the structure or part is attached and the screw is tightened

See the “butterfly dowel” installation technology below:

It is also possible to install the anchor using ordinary mounting pliers. The selection of fasteners is based on its compliance with the thickness of the base base and the required load. The maximum permissible base thickness is indicated in the marking. Below are the recommended permissible loads on a metal dowel for hollow bases

(according to FISCHER instructions).

Marking, designation

In the marking of dowels for hollow structures, as a rule, manufacturers indicate the version of the hardware and three main technical characteristics:

Examples of “butterfly dowel” markings from well-known fastener manufacturers:

FISCHER

HM 6 x 80 S, where

NM - designation of a fastener (metal dowel for hollow structures)

6 - metric thread diameter

80 - dowel length

S - screw type (S - semicircular head, straight slot, SS - hexagonal head, H - with hook)

MUNGO MHD-S 6x37/13, where MHD-S is the designation of the fastener 6 is the diameter of the metric thread 37 is the length of the Molly dowel 13 is the maximum thickness of the base material

Catalog products:

Please enable JavaScript to view the comments powered by Disqus. comments powered by

www.rusbolt.ru

Choosing Molly dowels: what to look for

When choosing fasteners, you need to take into account a number of characteristics and parameters of the Molly dowel. List of mandatory characteristics that are important to evaluate:

- hardware diameter: determined by the load that the Molly dowel must withstand. The increased diameter determines high load-bearing capacity;

- dowel length: for fixation and reliable connection with a dowel, you need to estimate the size of the spacer part, due to which the friction force will be created. If the length of the non-expanding part exceeds the thickness of the material layer, it will be impossible to guarantee reliable fastening;

- material: stainless steel is considered the most durable and resistant to external factors (water, dampness, chemical fumes).

When choosing a fastener, it is also important to obtain information from the labeling. Each standard defines its own values, indicated by markings. These can be the following parameters: thread diameter, length, screw type, base thickness and others.

What does it consist of?

The dowel screw can be divided into two components:

The working part, or spacer. When the screw is rotated inside the dowel, its working part expands and tightly grips the screw. In this case, the friction between the wall and the sleeve, sleeve and screw increases.

Non-spacer part. The so-called upper part that does not penetrate the wall. It retains its shape so that the screw does not come out of the fastening part. Its other purpose is to prevent the screw head from coming into contact with the wall.

Also, the dowel may contain various components and additions:

- Sleeve dissection. Slots run along the length of the working fluid to simplify deformation when twisting.

- Stoppers. Do not allow the dowel to twist or loosen.

- Spacers. Protrusions in the form of spikes, cuts. When in contact with a wall, the friction force increases several times and increases the strength of the fastening.

Types of Molly dowels for drywall

Molly dowels are special fasteners, so there are not many varieties of them. The dowels differ from each other in the material they are made from. Fasteners made of galvanized steel have a galvanic coating, while fasteners made of stainless steel have an anti-corrosion coating. The second option is considered more resistant to temperature changes, moisture, and water. Stainless steel hardware costs an order of magnitude more, but justifies the price with its performance properties.

In terms of design features, the dowels themselves are virtually no different. Only the types of screws used to secure them are distinguished. The following modifications are found:

- countersunk head - the head has a flattened shape, which is installed flush with the material or “recessed”. Due to the flat shape of the cap, it is difficult to dismantle it, so damage to the drywall itself is possible;

- semicircular head – remains on the surface, does not hide. Dismantling is easier;

- screw with hook - used for installing suspended objects and structures. Great for attaching to plasterboard ceilings;

- screw with a ring - for solving issues of installation of communications, non-standard objects of complex configuration.

Types of dowels for brick walls

Dowels are used to attach furniture, paintings or other objects to brick walls, as they can withstand heavy loads. In order for the fastener to be securely held in the base, it is necessary to select the correct type and size depending on the grade of brick or concrete. If the dowel is not used for its intended purpose, it may not withstand the load and fall out of the hole.

Types of dowels and their features

1. Externally, the dowel looks like a cork and has a cylindrical shape with a cavity. When the screw is screwed in, its body expands and rests against the walls of the hole. The most common are nylon and polyethylene expansion dowels. To prevent a screw or nail from falling inside, the fastener is equipped with a special collar equal to the diameter of the screw head.

2. For walls made of porous or hollow bricks, anchor fasteners are used. As soon as such a dowel begins to be screwed into the brickwork, its end expands or twists into a knot. The resulting “nut” inside the voids securely holds any object.

3. Nail dowels are used for fastening slats under cladding with finishing material; they are small in size. They come with a nail. Install them together through a hole in the rail and wall. Then they hammer it in with a hammer.

4. Special umbrella dowels are used to attach thermal insulation. An umbrella is inserted into the hole in the wall and through the insulation, and then a nail (plastic or metal) is driven in. For large loads, for example, up to several tons, metal dowels for concrete and brick are used.

5. Metal fasteners are best suited for suspended ceilings. In the event of a fire, the plastic ones will melt and the ceiling will collapse.

- reliable fastening that can withstand heavy loads;

- easy to use;

- Can be used both indoors and outdoors.

Due to the presence of spikes and whiskers on them, they do not turn while screwing in the screw.

How to properly attach Molly dowels?

To work with Molly dowels you need to follow certain rules. To install the fastener in plasterboard material, you will need to tighten the screw twice. If you are fastening suspended structures, then the screw is installed in one go.

Molly dowels are most often used for fastening structures and interior items, rather than other materials. To correctly calculate hardware parameters and consumption, it is important to calculate the load that the fastener will withstand. If you are attaching a dowel to a plasterboard wall, its working load will be from 12 kg. In order not to make a mistake with the length of the dowel, it is important to take into account the following factors when making calculations: surface thickness and thickness of the structure. After summing up these indicators, fasteners are selected. The resulting figure must match the size of the non-expanding part of the hardware.

To quickly create a connection, you will need special pliers. This is a tool with a slot that perfectly grips the surface between the washer and the head. The dowel is pulled out during installation. If you don’t have such pliers in your arsenal, you can try to solve the problem using pliers. The process will take longer and requires some effort.

Basic algorithm for installing a Molly dowel:

- A hole of the required diameter is made in the drywall using a drill. The resulting hole should match the diameter of the Molly dowel.

- The collet is fixed to the maximum depth so that it rests against the base of the drywall. If difficulties arise, use a hammer with a rubber working surface.

- Then you can proceed to screwing in the fasteners. The easiest way to screw in a screw is with a screwdriver or screwdriver. Even after this, Molly's dowel remains in the same position.

- We take pliers and pull out the screw. The collet is folded.

- We continue to pull out the screw, after which we fasten it a second time, grabbing the structure that needs to be fastened. If you need to install hanging items, the screw is simply screwed in again.

Varieties

There are many types of fasteners used when installing drywall products.

But it is important to choose the most appropriate products for a particular case. In addition, you should know the rules for installing the described fastening elements, which will ensure the reliability and durability of the structure being formed.

The dowel used for fastening gypsum plasterboard products must meet a number of requirements:

- have an anti-corrosion coating;

- be made of high-quality and high-strength metal;

- The spacer elements of the part must ensure high-quality fixation of the plasterboard base to the base surface of the building.

All drywall dowels are distinguished by the fact that they are made according to the harpoon expansion principle, which ensures strong and reliable fastening.

There are two main groups of drywall dowels:

- checkpoints;

- unclenching.

Walk-throughs are very convenient for mounting on the ceiling. They are most often used for installing massive chandeliers, interior spotlights and sports equipment. The spring pass-through dowel consists of a threaded metal rod, folding locking wings and a spring mechanism. In the void on the inside of the plasterboard structure, a spring mechanism opens the locking hook-wings, thereby creating a reliable fastening.

The end of a spring drywall anchor can be made in the form of a ring, half ring, screw or rod. The required type of tip is selected based on the type of object that needs to be attached (for example, a tip in the shape of a ring is usually used when attaching electrical wires, and a tip in the shape of a half ring of a hook is used for hanging various lighting equipment). The spring dowel is ideal for installing elements to plasterboard walls lined with tiles. To decide which type of fasteners of the described type is suitable for your design, it is worth taking a closer look at the advantages and features of the use of each type of dowel.

Drywall dowels are made from polypropylene and have many advantages compared to other fastening materials

Dowel molly

The molly dowel definitely cannot be classified as a cheap fastener; the price for it is really high, but there is no doubt about the quality.

Working principle of the molly dowel:

- Under this dowel, a hole with an eight-millimeter diameter is made with a drill;

- After this, the molly is inserted into the gypsum board, the two-pronged side is pressed tightly against the sheet, which helps prevent the anchor from twisting during the fixation stage;

- Then, using a screwdriver that comes with the molly dowel, the structure is pressed against the sheet along the internal thread.

It should be noted that the central part of the sleeve is twisted, which ensures reliable fixation of the molly in the drywall. The rivet will be in place.

Advantages of molly:

- Ability to withstand fairly high loads;

- There is an option for dismantling if necessary;

Molly screws come in one set with dowels.

Driva

Driva is one of the most popular types of fasteners. Driva is available in two types - plastic and metal.

Driva plastic dowels are purchased more often, and there are more of them on sale.

How to attach the driva dowel:

- Drill a 6mm hole;

- Insert the dowel;

- Using a cross bit, cut it into the gypsum board like a standard self-tapping screw;

- After this, screw a screw or self-tapping screw with a diameter of 3.5 or 4.5 mm into the internal cross-shaped slot of the driva dowel.

That's all. The only difficulty that can arise is in selecting the right self-tapping screw. When choosing a self-tapping screw, keep in mind that driva has a length of 23 mm (plastic) and 33-44 mm (metal).

The Driva dowel for drywall has a fairly wide range of applications and is available in two subtypes

It remains to mention one more well-known brand of fasteners - fischer.

Drywall fasteners: is it possible to replace the Molly dowel?

There are other types of fasteners that can be used to secure structures to drywall. The Molly dowel is considered the most convenient and widespread hardware. But does he have an alternative?

Plastic dowels are made from durable materials that have proven themselves in the market. At the end of the plastic dowel there is a drill, due to which it is screwed into the drywall independently. You don't have to make a pilot hole to attach the dowel. The final step will be screwing in the screw. It will fix the fastener in the hole and provide good load-bearing capacity.

Metal Molly dowels work on the same principle as their plastic counterparts. The main advantage will be the material of manufacture. High-strength steel can withstand more loads and demonstrates excellent performance properties.

When working with drywall, the Molly dowel remains the most durable and effective fastener. Even taking into account its increased cost, fasteners remain most in demand when attached to drywall.

Fasteners: types and purpose

Contents: Fasteners: types of self-tapping screws Anchor: types and application Dowels: purpose and types How to attach objects to drywall: molly

The question of how and with what to fix something on a wall or ceiling interests many people. Previously, everything was simpler - nothing was used in the household except nails, dowels and screws. Now times are different - different repair and construction technologies are being used, which has led to an increase in the variety of fasteners. In this article, together with the website stroisovety.org, we will study all the main fasteners of our time, understand their purpose and decide in which cases it is advisable to use one or another fastener.

Existing types of fasteners

Fasteners: types of self-tapping screws

There are not so many varieties of self-tapping screws. They can be classified only according to three main characteristics: by the material into which they are screwed, by size and purpose.

Based on materials, self-tapping screws are divided into two subtypes:

- metal screws;

- wood screws.

There shouldn't be any questions here. Both self-tapping screws can be produced in different lengths, diameters, and they can also have different thread pitches. As a rule, types of screws for metal are distinguished by a fine thread pitch, while the same product, intended for fastening wooden products, has a large thread pitch.

Types of self-tapping screws photo

It should also be noted that metal screws can be of two types - self-drilling and those that require preliminary drilling of the metal to tighten. The first ones have a small drill at the tip - its size characterizes the thickness of the metal into which these products can be screwed. A prominent representative of such self-tapping screws are the well-known “tex”, which are used to connect drywall profiles. As for the second subgroup of screws for metal, these include the black self-tapping screw used for attaching drywall to the profile.

In addition to the above, all self-tapping screws can be classified according to purpose. Roofing fasteners of this type and general-purpose screws can be divided into a separate group. Roofing screws have a wide head with a press washer that seals the hole to prevent water from flowing through it. By the way, self-tapping screws for profiles, which are used when installing plasterboard structures, are general-purpose products.

Wood screws photo

Anchor: types and application

Quite a lot of people try to use this fastener for other purposes. For example, quite often they are used to try to attach objects to brick walls. The result of this, as a rule, is frayed nerves and huge holes left after removing them from the wall. It should be remembered that the stud anchor and anchor bolt are designed for use in concrete surfaces, and in soft materials they simply scroll.

Now let's talk about the types of anchors. It is difficult to classify them, since they have a general purpose. In this regard, only three types of anchors can be distinguished: these are the fastening anchor, the hook anchor and the loop anchor. The first can be called universal, the second are designed to hang objects on them, and the third to cling to something.

Fasteners: anchors

All anchor screws can also be divided into two parts according to their design (the principle of their expansion). In one case, the anchor may have a bolt with a wedge at the end (they are clamped with a nut), and in another case, the wedge itself is a nut (tightened by rotating the bolt). All anchors are produced in a fixed range of standard sizes - the smallest has a length of 50mm, and the diameter can be 6 or 8mm. The largest anchor measures 400mm in length and 22mm in diameter.

The question of how to install an anchor bolt is very simple to solve - the main thing is to choose the right drill size. If the anchor has a diameter of 10mm, then you need to drill the hole with a drill of the same diameter - you should not expect that the anchor will clamp into a 12mm hole. It won't happen no matter how hard you try. It also doesn’t cost anything to wrap around anchors – there’s no point in it. Then it’s simple - the anchor is inserted into the hole and clamped with all force with a screwdriver or open-end wrench.

Anchor sizes

Dowels: purpose and types

There are only three varieties of these fasteners - a metal dowel (familiar to almost everyone since childhood), a mounting one with a plastic plug, and a spacer one, which is scientifically called a “Bierbach dowel.” Let's start in order.

- The metal dowel is the oldest of all types of fasteners. Designed for driving into almost all surfaces. However, it cannot be installed with a hammer into any material - as a rule, it is loaded into a pneumatic, electric or cartridge gun. They differ from each other only in length and diameter.

- Mounting dowel is the most common of all types. It is produced in two variations, differing from each other in the shape of the plastic stopper. In one case, the dowel is intended to be installed in a concealed position, but in the other case it is not (the plug of the last dowel has a mushroom-shaped cap). Mounting dowels are installed using a hammer drill and a hammer - first a hole is drilled, then a plastic plug is inserted into it, into which a steel nail with some kind of thread is driven. Such a nail can easily be unscrewed from the plastic cork with a screwdriver if the need arises. The diameter of such dowels can be 6, 8, 10, 12 and 14 mm, and the length from 35 mm to 250 mm.

Mounting dowels photo

- Expansion dowel (Bierbach).

Made from steel, it has proven to be excellent when used in concrete. It consists of two wedges, movably connected to each other by a washer of one of them. It is installed in a pre-drilled hole, into which it is wedged with one blow of a hammer. You can't think of anything better for fixing suspended ceilings. Bierbach dowel photo

How to attach objects to drywall: molly

There is a single fastener that allows you to attach anything to drywall. People call it “Molly” from the name of the manufacturer that developed this fastener. This mount consists of two parts - a hollow folding tube with slots and a nut at the end and a screw. As the screw is screwed in, the tube is folded and crimped on one side and the other of the drywall.

There are two types of such fastenings - metal and plastic molly screws. Metal is certainly more reliable - it is mounted using special pliers. To install plastic fasteners, just drill a hole with a diameter of 8mm, insert the fastener into it and tighten the self-tapping screw.

Fasteners Molly photo

It should be understood that only light products can be hung on “clean” drywall in this way. If we are talking about objects of medium weight, then at the place of their attachment you need to install a mortgage profile. It is better to install things that are too heavy (for example, a TV) using pins with collets or long anchor screws.

To conclude the topic, I would like to devote a few words to studs with collets, which are used to fasten something at a large distance from the plane. With their help, it is quite easy to hang large and bulky objects from the ceiling. Such fasteners consist of two separate parts - a pin and a collet. As the pin is screwed into the collet, the latter expands and wedges itself into the pre-drilled hole. The studs can have different diameters and a standard length of 1 m.

Types of molly fasteners

These are the types of fasteners used in modern repairs and construction. In addition to the fasteners described above, there are other less common, but at the same time unique products of their kind - they are called specialized, and they are used to solve narrow-profile problems. Of course, we should also mention screws and bolts, but everyone knows about them, and these fasteners differ only in length, diameter and thread pitch.

Author of the article Alexander Kulikov

stroisovety.org

What types of fasteners are used for drywall?

For plasterboard bases, other dowels are also used, which are designed for fastening to porous materials. Let's look at the main types of fasteners:

- “butterfly”: can withstand up to 30 kg of load. This type of fastener is suitable for installing various interior items, lamps, electrical wiring and other light objects. Due to the presence of protruding elements that form a kind of “skirt,” wings are formed when the fasteners are tightened. To install into the hole in the dowel, you need to clamp the tabs. The notches are held in the plasterboard base to prevent any unwinding. The “wings” are adjacent to the material. The main advantages of the butterfly dowel are the possibility of reusable use and easy installation;

- “umbrella”: the design of this type of dowel provides for the presence of two folding elements on springs, which are at an angle of about 180 degrees. This dowel is designed for fixing objects in hollow bases. This is the best mounting option if you need to hang the lamp from the ceiling. To install the dowel, clamp the folding “legs” and place it in the hole. After this, the dowel opens in the shape of an umbrella. The fastener may have a hook or ring, from which structures can be conveniently suspended;

- dowel-nail: consists of two parts - a plastic element and a metal screw. After installing the dowel-nail, it will be almost impossible to dismantle the plastic part, but the screw itself can be unscrewed with a screwdriver. The dowel-nail is fixed with a hammer. With the help of such fastening a small weight is fixed;

- Driva: has a conical shape with a flat head. The tip is made in an acute-angled shape. The screw that is screwed into the dowel can be through or blind. This fastener can be used independently without pre-drilling holes. Even with a simple screwdriver you can easily screw the dowel into the drywall. During the process of fastening the screw, one part of the dowel is deformed. Due to its expansion, the hardware will not be able to unwind arbitrarily. This type of dowel is good because it can be fixed in drywall even with a minimum distance between the gypsum board and the support. Driva clamps are reused after dismantling;

- The Fischer dowel has a self-tapping thread, so it easily passes through drywall. The dowel expands when the screw is installed, and the thread itself is fixed in the material. Due to the design features of the modern dowel, the connection does not weaken over time;

- ceiling dowels for plasterboard and hollow materials. The design of the dowels has spring parts with which they are fixed to the sheets, holding them on the back side of the material. There is an abundance of caps and hooks that distinguish fasteners from each other;

- Sormat is available in two materials – nylon and metal. Only light objects can be attached to drywall with such a dowel. The tip of the dowel has a threaded part with protruding teeth. This allows it to easily pass through the drywall base without a pilot hole. Simple installation is facilitated by a 5 mm pitch between threads. When working with Sormat, there is minimal risk of sheet deformation or weakening of the connection;

- NAT is a nylon dowel whose clamps resemble “wings.” They are held by the base from the wrong side. With permissible loads on the fastener, it cannot be pulled out or loosened. The hole itself does not loosen.

Installation rules

The technology for installing the dowel is simple, but requires precise adherence to the instructions.

- Before choosing a product, calculate the possible load - maximum and working. Based on these data, a dowel is selected. For calculations, use the tables in the reference book.

- A hole is drilled for the collet. The diameter of the sleeve and the hole are the same.

- Insert the collet into the hole so that the teeth touch the surface.

- Screw in the screw using a screwdriver or screwdriver.

- Use pliers or pliers to pull out the screw. The sleeve with slots folds and creates a stop on the inside of the surface.

- The screw is completely pulled out and re-fastened through the fixed part. If a model with a hook or ring is used, the screw is simply screwed in again.

When can you not do without a Molly dowel?

All-metal fasteners are suitable not only for fastening into drywall, but also into hollow walls or sheet materials. The opening mechanism on the back side of the hardware provides better fastening strength. The load-bearing load is determined not only by the parameters of the dowel itself, but also by the characteristics of the base material. The Molly dowel is perfect for sheets up to 26mm thick. If the wall is insulated and you used insulating material when installing it, difficulties may arise when installing the dowel.

Molly dowels, the elements of which are made exclusively of durable steel, are indispensable for installation in fire hazardous areas. Once installed, you can dismantle and even reuse the hardware. Galvanized dowels are intended for rooms without exposure to moisture, precipitation, or temporary connections. Stainless steel products are considered the most resistant to external factors.

Application

When using electric devices for screwing in dowels, you need to be very careful, since excessive force during installation can damage the drywall sheet. Drilling a hole in hammer drill mode for working with plasterboard is prohibited.

In tiled surfaces, a hole is made for the dowel in accordance with its size. In this case, it is better to stop at the molly dowel. To quickly perform fastening, you can use a dowel. The advantage of this product is the fact that no additional holes need to be made in the material, which allows the integrity of the structure to be preserved as much as possible.

There are several simple recommendations for screwing dowels into drywall:

- First of all, it is worth identifying what characteristics the drywall you are going to work with has, and also determining the weight of the product to be attached.

- It is important to select the correct screw if it is not included in the standard package for the dowel, since the screw can damage the fastener from the inside.

- The hole must be drilled slightly larger in diameter than the part itself. This feature of the work allows you to avoid cracking of the material during installation of the part.

- The holes must be thoroughly cleaned of crumbs and dust. To do this, you can use an ordinary home vacuum cleaner.

- A screwdriver that is screwed in without a screwdriver should not turn at the end point of installation. To do this, you should not fix it in the base all the way, leaving this work to a screwdriver with the appropriate setting.

- When the umbrella dowel or mushroom is already installed in its place, and the desired product is firmly located on the fastener, the hole formed in the sheet of drywall must be carefully masked using acrylic if it is small in size. In another situation, additional use of putty will be required. A positive feature of acrylic is its rubberized base, due to which you can significantly reduce the level of pressure of the fastener on such a fragile material as drywall.

- The butterfly dowel has a certain installation technology - you need to press the folding blades of the product and push it inside. Even a regular screwdriver can screw this dowel to the required position.

Fasteners for drywall today are presented in a wide variety

Therefore, the choice in favor of one or another product should be made based on the level of complexity of the structure that needs to be attached, its functional tasks and installation technique, taking into account the cost of the products

You can learn how to install drywall with your own hands by watching the video below.

Dimensions and specifications

There are 2 types of Driva fasteners available - plastic and metal.

According to the calculated characteristics, plastic ones can withstand loads of up to 25 kg, and metal ones - up to 32 kg. Plastic dowels can be made from different materials:

- polypropylene;

- polyethylene;

- nylon.

All these materials equally meet the requirements for this type of fastener:

- durable enough for their purposes;

- do not collapse or deform over time;

- do not lose their properties at temperatures from -40 to +50С;

- hygienic, not subject to corrosion and oxidation;

- do not form condensation, so there are no leaks that could spoil the interior.

Metal products are treated with an anti-corrosion compound and also do not create problems throughout their service life.

The dowel has a sharp end, which facilitates its penetration into the material during the twisting process. The cap has slots for a Phillips screwdriver or a screwdriver bit.

Plastic and metal fasteners are available in two sizes:

- made of plastic - 12 by 32 mm and 15 by 23 mm;

- made of metal - 15 by 38 mm and 14 by 28 mm.

Description

Molly dowel is one of the types of fasteners for drywall and similar materials. By default, such a product is formed entirely from metal. There are almost no structural differences from the butterfly type fastener. However, eliminating plastic elements increases the load-bearing capacity. True, this is achieved only at a higher cost of the structure itself.

The main components are screw and sleeve blocks. The screw is either included by default or selected at your discretion. The metal collet is the sleeve that is empty inside.

Since the collet may contain rifling inside, this makes it difficult to select a suitable screw. An alternative option involves equipping the screw from the original kit with a support washer. This washer will have a pair of jagged, pointed protrusions. It is mounted on a surface, which will prevent the collet from spinning uncontrollably during installation. Finally, there are modifications of screws with countersunk heads or with regular tips in the shape of a semicircle.

The principle of operation is quite simple: the molly dowel is inserted into the required hole when it is folded. Next, tighten the required screw inside. When this happens, the spacer is compressed. In this case, a support is formed in the form of many petals, reminiscent of a “tent” or an umbrella. It will be pressed firmly against the underside of the material being processed.

Such an anchor needs to be attached a little differently than in the case of a simple “butterfly”. The screw may not be screwed in, but, on the contrary, pulled out. To work with it you need dowel pliers or assembly pliers. But a typical plumbing tool from a home workshop will not help. Molly dowels can be dismantled and reused (this is not possible with a simple butterfly); manufacturers even specifically emphasize that dismantling will not affect operating parameters.

It is worth noting that the described type of dowels will require quite a significant amount of free space for installation. Manipulating with pincers and pliers in a confined space is extremely difficult, because this tool itself has a certain length.

Please note: only special designs can be used for double plasterboard. This fastener includes a tip in the form of a drill. Only such an end part can be safely and reliably screwed into a thick sheet. As an alternative, you can use “self-aligning” dowels, strips and other types of fasteners. But this is a separate topic that requires special analysis; but for hollow structures, a standard Molly dowel is also perfect.

Selection nuances

Molly dowels are produced by a variety of companies specializing in the production of fasteners. Therefore, it is unlikely that you will be able to select a suitable product based only on the “name” of the company, because the assortment now includes products from companies that are little known to Russian buyers. Molly dowels under the Fischer brand have won the undisputed leadership in the world. The German company produces all types of fasteners possible at the current technical level; The price difference between them is quite noticeable.

Fans of Finnish products should pay attention to products under the Sormat brand. This company supplies molly dowels for sheet materials

For 50 pieces in original packaging you will have to pay at least 650 rubles.

Russian analogues are noticeably more accessible. Depending on the specific brand and the characteristics of the product, you can buy 100 dowels for 190-500 rubles. The price of installation work practically does not depend on the use of fasteners. Even a special installation tool is quite accessible. No special skills are required either; however, the fee for Molly turns out to be quite significant for a large volume of work.

The products of the Liechtenstein company Hilti demonstrate quite good results in practice. She has passed the most severe tests and has repeatedly proven herself to be the best. As for the already mentioned products from Sormat, as well as from German suppliers Tox and Kew, they are generally of high quality, but have not been certified for particularly difficult conditions.

And one more consideration - this time in relation to the material from which the fasteners are made:

- in the absence of special requirements, you need to take modifications with zinc protection;

- for bathrooms, kitchens, and unheated rooms, alloyed stainless alloys are better suited;

- Only the lightest objects can be hung on plastic supports - regardless of the microclimate.

Benefits of use

This type of fastener is convenient and easy to use. No special training or qualifications are required during installation. The only difficulty, as with any other fastening method, is to accurately mark the landing spots so as not to leave them when screwing in the dowels.

Since they are used for working with soft materials, they are very easy to tighten. No hammer drill or carbide-tipped drills are required, so there is no dust or noise.

Folding spring dowel

This is a screw with two toothed plates that are moved apart by a spring. They are produced in galvanized steel. Reusable.

The set includes a hook for hanging lamps and chandeliers. Installation is very simple:

- A dowel is installed in the finished hole, holding the blades so that they do not open;

- Having opened on the opposite side of the plasterboard, they will grab with two sharp teeth so that the rod does not rotate;

- Now you can tighten the self-tapping screw with a screwdriver.

You can buy any dowels in a store or market. Taking into account all the features of your case, you can choose the most successful option.

Knauf-Hartmut

Withstands the heaviest loads on drywall dowels. Allows you to attach massive structures up to 55 kg on two-layer walls, about 35 kg from one layer and up to 6 kg/linear meter when placed on the ceiling.

Installation:

- Prepare a hole with a diameter of 1.3 cm in the gypsum board;

- One of the guide elements must be shifted so that the anchor strip made of galvanized steel profile fits into the hole;

- Align the guide elements so that their ends are at the same level. The anchor bar is in working position;

- Insert the plastic locking sleeve all the way;

- Place the plastic strips to the sides and break off the excess. The anchor strip securely fixes the fastener in the hole;

- Screw the screw into the dowel.

A dowel nail is used when there is no void between the dry plaster and the main wall. Nails are used for through fastening of skirting boards, cornices, and door frames.

Most often it is made of plastic.

- The sizes of these dowels for drywall are from 4 to 14 cm. Diameter is 4-7 mm.

- When it is hammered into a hole, it wedges and does not scroll.

- The hat is made in the form of a mushroom or hidden. Removing the nail is impossible without destroying the dry plaster.