materials »

Drywall is often used in modern decoration because it has advantages. But this is a fairly brittle material, and it is only possible to secure something to it when arranging the interior using special fasteners. The Driva dowel is one of the options for modern fastening.

Application

They are used directly when finishing premises with plasterboard, as well as for interior finishing of renovated or new premises. That is, they are used in construction and arrangement.

Drywall sheets are secured using dowels during installation:

- false walls;

- niche;

- ceilings;

- skirting boards;

- built-in lamps.

Also, when you need to fasten 2 or several sheets together to strengthen the structure.

A dowel is required when arranging when you need to hang various interior items on a plasterboard wall:

- paintings, mirrors;

- shelves;

- hangers;

- Wall Clock;

- pots with flowers.

An ordinary screw or self-tapping screw will destroy the drywall and will not be able to support even a small weight. The Driva dowel is screwed into the material using a large-diameter thread with very rare turns, shaped like a drill. Therefore, it does not jump out and captures a large enough area to which the workload will be transferred. By distributing the weight over a larger area, the pressure on the material is reduced, and the fastening is many times more reliable.

Description of fasteners

The dowel is conventionally divided into working and non-working parts. The entrance hole at the top is decorated with a cuff, which can be secret, round, or cylindrical. The flap prevents the screw head from falling into the base.

Dowel parts:

- The non-working part is located at the top of the fastener and does not change shape when the screw is screwed in. Does not require adhesion to the walls of the hole.

- The spacer part opens and folds on the back of the partition wall. The shank is pulled in as the screw advances into the threads at the end.

In hollow materials, the length of the dowel does not coincide with the thickness of the base, so fastening is achieved by stacking and pulling the shank.

Dimensions and specifications

There are 2 types of Driva fasteners available - plastic and metal.

According to the calculated characteristics, plastic ones can withstand loads of up to 25 kg, and metal ones - up to 32 kg. Plastic dowels can be made from different materials:

- polypropylene;

- polyethylene;

- nylon.

All these materials equally meet the requirements for this type of fastener:

- durable enough for their purposes;

- do not collapse or deform over time;

- do not lose their properties at temperatures from -40 to +50С;

- hygienic, not subject to corrosion and oxidation;

- do not form condensation, so there are no leaks that could spoil the interior.

Metal products are treated with an anti-corrosion compound and also do not create problems throughout their service life.

The dowel has a sharp end, which facilitates its penetration into the material during the twisting process. The cap has slots for a Phillips screwdriver or a screwdriver bit.

Plastic and metal fasteners are available in two sizes:

- made of plastic - 12 by 32 mm and 15 by 23 mm;

- made of metal - 15 by 38 mm and 14 by 28 mm.

Gluing gypsum boards

For gluing plasterboard panels, cement or gypsum-based compounds are used. Sometimes polyurethane mastic and polyurethane foam are used.

Surface preparation

The walls on which the gypsum boards will be glued must be carefully prepared:

- remove from them the layer of old finishing (wallpaper, paint, etc.);

- remove sections of peeling plaster down to the base;

- clean the surface of loose plaster;

- remove dust, dirt, oil stains from the walls;

- clean the surface from fungus;

- knock down significant protrusions and cut off elements protruding from the wall (hooks, etc.);

- plaster cracks and deep depressions (as condensation can accumulate in them).

After repairs, the walls are alternately treated with an antiseptic and a deep penetration primer.

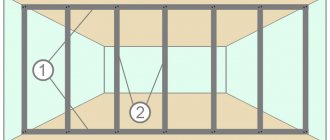

The next stage is marking the walls. It is carried out using a building level, a square and a tape measure. The ideal tool for marking is a laser level, but not everyone has one.

Why is this operation needed? In most cases, the walls are not perfectly level. Firstly, after marking, the first sheet of drywall will be accurately glued, which will avoid mistakes when installing the remaining panels. Secondly, marks of deformation gaps are applied to the walls, the width of which should be:

- at the ceiling - 3-5 mm;

- near the floor - 8-10 mm;

- between gypsum boards - 3-4 mm.

Before attaching drywall to a wall without profiles, sometimes a plane is built on it by screwing in dowel nails in increments of 200-300 mm. This work is performed on surfaces with significant differences. The depth of screwing in the dowel nails is adjusted according to the level or tension of the thread. The fastener caps will become the reference points for the gypsum boards. In these areas, you will need to apply an adhesive mixture to the wall. In addition, the adhesive is applied to plasterboard panels.

Drywall installation

Relatively smooth surfaces include concrete and plastered walls. Any adhesive composition, including polyurethane foam, is suitable for gluing gypsum boards to them. The glue is applied pointwise along the edges of the sheet and in its central part. The diameter of the glue “cakes” is about 150 mm.

Before gluing the gypsum board to the wall, pieces of plywood, tiles, etc. are placed on the floor. Plasterboard slabs will rest on them until the glue dries. After this, the pads can be removed: the necessary deformation gap will remain between the panel and the floor.

The drywall is pressed tightly to the surface, tapping lightly so that the adhesive mass spreads over it. The correct installation of the plasterboard is checked by applying a level to it. The next sheet is glued, departing from the first by a few millimeters.

Before installation, the edges of the latter are processed with a drywall plane or a construction knife. Subsequently, it will be easier to fill the gaps with putty.

Polyurethane foam is applied to panels and walls in a zigzag pattern or in lines. Polyurethane-based mastic is placed on the gypsum board along the perimeter of the slab. In addition, the adhesive composition is applied to the sheet in lines every 150-200 mm.

Features of plastic and metal elements

Driva plastic fasteners are used as a base, into which a regular self-tapping screw is then easily screwed. They are used for installing lightweight elements only on drywall. To secure 2 sheets of gypsum board together, you do not need to use a self-tapping screw.

In some cases, a metal dowel can also serve as a separate fastening element. Metal has stronger properties than plastic, which is why metal ones are used for fastening heavier interior items, for example, cabinets. In addition to plasterboard, more durable metal ones can be used when working with chipboard.

Spring anchor

This fastener element is also called a dowel, although this is not entirely true. It is often used for attaching suspended structures, such as lamps, to the ceiling. It is a screw equipped with two stops that are released by a spring.

They attach it like this:

- A hole of the required diameter is drilled in the ceiling.

- An anchor is inserted into it, having previously folded the blades and holding them from opening. Once behind the plasterboard surface, they will automatically open, ensuring reliable fastening.

Please note that it is impossible to dismantle the spring suspension.

A competent choice of fastening elements will not only ensure reliable fixation of suspended structures on the surface of the drywall, but will also protect the plasterboard from unnecessary damage.

DRIVA metal dowel with drill (for drywall)

Leave your phone number and receive an accurate calculation of the cost of your order + the possibility of an individual discount of up to 20%

Description:

The DRIVA dowel is structurally presented in the form of a cylindrical rod with a wide and high thread, specially designed for soft materials. Driva is available with or without a drill, also in two sizes for single and double drywall. The dowel head has wide sides and has a cross slot for mounting with a PH-2 bat.

Scope of application of the DRIVA dowel: used for fastening lightweight objects to thin-walled bases - plasterboard, plywood, chipboard and others. The peculiarity of the dowel is that it does not use the expansion principle for fastening, so it can be used with almost any screw, although it is preferable to use a universal screw. In addition, it does not require pre-drilling.

Installation method for drywall dowels:

Installs without pre-drilling. Using a screwdriver or a screwdriver with a PH-2 bit, the dowel is wrapped in the attached material, after which you can fasten the object using a self-tapping screw.

Price for a metal dowel for plasterboard with a drill (DRIVA) (RUB /1000 pcs.)

| Size(mm) | Pieces per package | Small wholesale (₽) | Wholesale (₽) | Large wholesale (₽) |

| 15x29 met. 1 layer | 100 | 7280 | 5075 | 4550 |

| 15x38 metres. 2 layer | 100 | 7280 | 5075 | 4550 |

Dowel-nails

Also used when hanging light objects on plasterboard surfaces. This fastener is popular because of its convenience and low price. It is usually made of plastic, but there are also aluminum varieties.

Installation is simple:

- A hole is drilled corresponding to the thickness of the hardware.

- The plastic part is carefully driven in with a hammer.

- The screw rod is also driven in with a hammer. It has Phillips slots in case you need to remove the screw. But it is almost impossible to get the plastic part out of the gypsum board.

USEFUL INFORMATION: How to decorate a studio apartment: interior design

For all their convenience, these hardware are used for fastening only light objects to a plasterboard surface.

Benefits of use

This type of fastener is convenient and easy to use. No special training or qualifications are required during installation. The only difficulty, as with any other fastening method, is to accurately mark the landing spots so as not to leave them when screwing in the dowels.

Since they are used for working with soft materials, they are very easy to tighten. No hammer drill or carbide-tipped drills are required, so there is no dust or noise.

How to make the right choice

When choosing fasteners to mount in drywall, many factors are taken into account. This is the load that is planned, and the possibility of dismantling, if necessary, the cost is also not the last item on this list. This is a rather individual process and, in each specific case, the choice is different. But still, the most reliable method is fastening into load-bearing profiles, because, unlike a small dowel, the area over which the load is distributed in this case is tens, or even hundreds of times higher. Therefore, it is better to provide a profile in advance in the place where the fasteners are planned.

vote

Article rating

Driva and molly fasteners

Depending on the shape of the head and thread of the drywall dowel, it is customary to distinguish the following types:

- Driva is available in two varieties: metal and plastic, with the latter considered more popular. Drywall withstands plastic drives very well, and their installation is simple. It is enough to drill a hole with a diameter of 6 mm and insert the product into it. After using the cross bit, you need to cut it into the sheet and screw the screw into the internal slot. Also, the Driva dowel for drywall provides for the dismantling of the fastening.

- Molly - high-quality and therefore expensive fasteners. They are characterized by high load thresholds and the possibility of dismantling. The molly dowel for drywall has a simple operating principle. First you need to make an eight-millimeter hole using a drill. Then insert the product into the sheet and press the two-pronged edge onto it. Finally, you need to press the structure against the sheet using a screwdriver along the internal thread.

There are two types of drives: metal and plastic; this type of fasteners is very easy to install.

As you can see, there is a wide variety of fasteners. Therefore, when choosing them, remember that a certain drywall screw may be suitable for some purposes, but in other cases its use is unacceptable.

Butterfly dowel

This fastening element received its name because, when tightened, its shape resembles a butterfly. When a screw is screwed into it, the wings of the dowel open and rest against the surface of the drywall on the reverse side. To prevent the element from scrolling, special cuffs are provided.

By design, the “butterfly” can be considered as a lightweight and cheaper version of the Molly dowel.

This type of fastener is intended for small lamps, cornices or baseboards, fixing electrical wiring, switches. According to the manufacturers, it can withstand loads of up to 28 kg.

The instructions for installing the butterfly dowel are simple:

- In the right place, using a drill of the appropriate diameter, a hole is made for the dowel.

- The side “wings” are compressed by hand, after which the fastening element is inserted into the hole. It should fit tightly, so it is recommended to use a hammer for upsetting. In this case, the notches on the dowel body should penetrate the drywall from the front side. This will prevent the element from scrolling.

- When screwing in the self-tapping screw, you need to ensure that the wings are tightly pressed to the surface of the sheet on the back side of the drywall.

The nuances of butterfly installation are shown in the video.

USEFUL INFORMATION: Direct suspension for drywall and with traction: factory and homemade

Advantages of this type of fastening:

- ease of installation;

- Possibility of removal if necessary.

There are also disadvantages:

- To use, you need free space behind the surface of the gypsum board.

- The use of these dowels is limited by the thickness of the plasterboard coating - up to 12 mm. That is, when installing gypsum boards in two or more layers, such fasteners will not work.

Flaws

Disadvantages include load restrictions. But this is due to the properties of the drywall for which they are created. The dowel itself will withstand much more than drywall can withstand. In this regard, Driva has a multiple margin of safety.

Sometimes the disadvantage is the excessive length of the product. If behind the soft drywall there is a structure made of hard material (concrete, brick, metal), the dowel cannot be screwed in completely. Then there are 2 options:

- use fasteners for hard materials;

- screw the dowel in as far as possible, unscrew it, cut it to length with a metal file exactly to size and return it to its place.

Self-tapping screws: price

The cost of self-tapping screws depends on their type and size. The average price of one piece will be a couple of rubles. In a pack, which includes from 100 to 500 pieces of self-tapping screws, one copy will cost a little less - about one ruble.

Toxicosis: causes, consequences, treatment It is incorrect to assume that nausea only bothers a woman in the morning. It can last all day, but is most pronounced in the morning. This comes from.

13 signs that you have the best husband Husbands are truly great people. What a pity that good spouses don't grow on trees. If your significant other does these 13 things, then you can s.

7 Body Parts You Shouldn't Touch with Your Hands Think of your body as a temple: you can use it, but there are some sacred places that you shouldn't touch with your hands. Research showing.

Charlie Gard Died A Week Before His First Birthday Charlie Gard, the terminally ill baby the world is talking about, died on July 28, a week before his first birthday.

11 Weird Signs That You're Good in Bed Do you also want to believe that you please your romantic partner in bed? At least you don't want to blush and apologize.

These 10 little things a man always notices in a woman Do you think your man doesn’t understand anything about female psychology? This is wrong. Not a single little thing can be hidden from the gaze of a partner who loves you. And here are 10 things.

We delve into the programmable deformation of the Drive Click TP10 self-tapping dowel

Judging by the design, the Drive Click TP10 dowel is an advanced version of the KLA M dowel. In online stores, the dowel is sold in packaging from the Belarusian company EKT. However, there is information on the network that such dowels are also produced by the Spit company. However, this is not the most important thing. What is more important is whether a dowel of such a complex design copes with the task of attaching objects to plasterboard walls.

Contents of delivery

A set was purchased in one of the Leroy Merlin stores - 6 dowels and six 4.5x45 screws.

Main characteristics

| Type: | self-tapping dowel |

| Application: | anchor for walls made of standard plasterboard, conditionally for walls made of porous concrete |

| Material: | polyamide/nylon |

| Weight: | 1 gram |

| Nominal pullout force: | 0.09 kN |

| Nominal shear force: | n.d. |

| vendor code | 565806. |

Dimensions and design

The Drive Click TP10 dowel has an original design.

The thickness of the dowel (excluding thread) is 8 mm. The diameter of the cap is 11 mm.

The tail part of the dowel is a drill of an original shape - in the form of a three-pronged crown. The dowel itself has original slots. Their purpose is to force the dowel to break in the programmed places during the installation process, increase the expansion of the dowel body and strengthen the fastening.

The thread has a large pitch - more than 5 mm between adjacent threads. Such a wide thread pitch allows you to effortlessly screw the dowel into the drywall without unnecessarily breaking the mounting hole.

Inner diameter - 5.5 mm.

The internal profile shape is similar to a Phillips cross slot.

How to tighten the Drive Click TP10 dowel

Unfortunately, there were no recommendations from the manufacturer regarding the best tool to use to mount the dowel. Therefore, we will try all options: PH, PZ and straight slot.

Phillips. Tight contact and reliable twisting are ensured only by PH2. By the way, it was this slot that was used in the subsequent test drive.

Pozidriv. PZ2 is also best suited here. There was no significant difference in ease of installation compared to PH2.

Straight slot. Of all the sizes of a straight slot, only 6 mm allows you to tighten the dowel. But even then, the tip of the bit goes in very shallowly - literally 2-3 mm. Therefore, this option is not compatible with Drive Click TP10.

Check in action. Installation in a standard sheet of plasterboard.

The manufacturer recommends using the Drive Click TP10 dowel to attach objects to a single sheet of drywall. Therefore, we test on a standard sheet with a thickness of 12.5 mm.

For installation we use a PH2 bit and a screwdriver. The dowel screws in easily (you can even get by with a regular screwdriver). After a little tightening (the main thing is not to overdo it), it sits tightly in the sheet, without play.

Photo from the back of the sheet. The dowel came out almost 25 mm from the back. This point must be taken into account during installation - there must be a void of at least 25 mm behind the drywall. On the left, by the way, you can see the shank of the KLA M dowel from the previous test drive. You can clearly see how much larger the Drive Click TP10 is than the KLA M.

We will screw the complete 4.5x45 screw into the dowel.

At first, the screw is tightened strictly according to the manufacturer's plans - it enters the tail section and breaks it. And then... To understand what happened, watch the video that we specially shot for clarity.

The broken shank did not go deeper into the dowel and did not increase the expansion of the dowel. It rotated freely without providing any decent fastening.

Driva

The dowel called Driva consists of a hollow conical rod with a flat head based on a screw thread for a profile with an acute angle. Externally, the head is similar to the shape of a cap, like self-tapping screws or self-tapping screws, which is expressed by the presence of Phillips slots for working with a screwdriver.

The rod part has a diameter of about 15 mm. In the internal cavity, a blind version of a through-type hole is formed, intended for an easier process of screwing in a screw.

The design is proposed on the basis of a drill, similar to a trident or the shape of a perk and with its absence. Available in a metal version made from zinc alloy or a plastic version made from propylene.

Usually used if it is not possible to use other types of fastening due to lack of internal space.

What are its advantages:

- It has its own drill, which eliminates the need to first create a nest for it;

- Can be used if the distance from the drywall to the main wall is too small;

- There is a possibility of dismantling.

Features of choosing dowels for drywall

Today, when installing to plasterboard structures, various types of hardware are used. The most widely used dowel for plasterboard is “Driva”. With its help, you can fasten objects of different thicknesses by cutting hardware directly into the hole prepared in the sheet.

For the molly variety, a slightly different type of installation is used. Elements with screw parts included are installed in 8 mm holes. The two-pronged side prevents the anchor from scrolling, pressing tightly against the material. The screw then presses the fastener against the sheet from the inside. Molly models are more expensive than Driva, but they have advantages:

- the part is very firmly fixed in the drywall thanks to the screwed-in central part of the sleeve;

- fasteners can withstand loads of up to 35 kg;

- parts can be dismantled without destroying plasterboard structures.

A simplified version of "molly" is called "butterfly". This is a fastener with intermediate “wings” that straighten in the hole when the screw is turned. For stationary fastenings, a dowel-nail is suitable, the main advantage of which is quick installation.

If you have any difficulties choosing fasteners, contact the Magkrep manager responsible for the product group. He will help you and place an order and delivery to anywhere in the Russian Federation.

Kinds

There are several types of dowels that allow you to attach suspended structures to gypsum boards:

- Butterfly.

- Driva plastic or metal screwdriver.

- Molly.

- Fischer dowel.

- KNAUF Hartmut.

- An ordinary dowel-nail.

- Spring-loaded.

Each of these types of fasteners has advantages and disadvantages. To figure out which one is more profitable to use in a specific situation, let’s take a closer look at them.

Self-tapping screws for attaching drywall to a metal profile

It’s easy to find out and select such hardware:

- A fine thread pitch will ensure a reliable connection to the metal frame.

- Length varies from 16 to 152 mm. For high-quality fastening, the length of the self-tapping screw must exceed the thickness of the material being screwed twice. Therefore, when installing drywall in one layer, 3.5 × 25 mm screws are used, in two layers - 3.5 × 35 mm.

- The cone head is recessed into the drywall. It is most convenient to use a screwdriver with a special limiter attachment during installation: it will not allow you to drive the screw too deeply and damage the material.

Craftsmen who professionally work with drywall use a tool with automatic feeding of screws. It costs a lot, so there is no point in purchasing it to renovate one apartment.

Methods for attaching heavy elements to gypsum boards

Quite often, to hang items such as boilers, televisions or heating radiators, experts recommend cutting an opening/niche in the cladding and installing it directly on a load-bearing wall. An example of attaching a boiler to plasterboard in a bathroom However, in this case, the whole point of preliminary plasterboard finishing is lost , and it is not always possible to use such a technique. How to optimally use such methods for securing heavy objects to gypsum board finishing.

- Installation of mortgages under the cladding.

- Installation of anchors in the wall under the finishing material.

- Use of special fasteners.

What nuances should be taken into account when choosing one method or another? Example of mounting a boiler

Mortgages

Using mortgages is one of the most reliable methods. It consists of attaching wooden blocks to the wall at the stage of assembling the frame. But, there are some nuances that should be taken into account when choosing such a technique.

- A fixed heavy part cannot be moved to another area.

- The cross-section of the mortgage must be selected so that it practically touches the back side of the drywall sheet.

- Installation of bookmarks is possible only at the stage of assembling the frame; if there is a ready-made finish, it is unrealistic to use this technique.

Taking into account such factors, it is not always possible to use mortgages. But, nevertheless, the inclusion of such parts in the design is mandatory when assembling plasterboard walls and installing partitions.

Anchors

You can hang a lot of very heavy objects on the anchor, for example, a boiler or a heating radiator, the weight of which is 80-100 kg or more. This is what drywall anchors look like

However, this technology also has its own characteristics:

- If the distance of the cladding from the load-bearing wall is large, it is impossible to fasten massive elements.

- Anchors can only be used with appropriate wall materials (brick, concrete); fragile gas and foam blocks or raw brick will not withstand the load.

In the first case, the problem can be solved by combining a mortgage with an anchor, and in the second option, special fasteners are required, for example, a crocodile dowel.

Drywall dowels

These methods of hanging heavy objects are quite reliable and easy to use. Depending on the situation, the following hardware is used: dowel - umbrellas, butterflies or moths. Characteristics of a butterfly dowel with dimensions But, there are factors in this fastening technology.

- Various types of fasteners have restrictions on maximum load.

- Some fixation options require specialized devices to allow installation.

- Once items are moved, repair work will be required to remove the holes, and some types of dowels are very difficult to remove.

Review of dowels for plasterboard structures

- plastic. Can be either polyethylene or nylon;

- metal. To produce such a dowel, a zinc alloy is used.

To fasten an object of a certain mass to a plasterboard wall, it is necessary to use various fasteners: molly dowel (or molly), driva dowel (or driva), butterfly dowel, anchor, self-tapping screws, etc. Our article will tell you about what technical Each type of fastening elements for plasterboard walls and profiles has characteristics. In terms of their advantages, butterflies are similar to molly. But they can only support up to 38 kg. Dowel nail. Fastening using this product is carried out permanently, eliminating the possibility of further dismantling. Used in through-hole installations for cornices, cable ducts, door frames, slats, baseboards, etc. Sometimes, instead of molly, some use a drywall anchor

Frameless drywall fastening

Installing plasterboard to a wall or ceiling does not always involve the use of metal profiles as a frame; a simpler method involves the use of ordinary gypsum glue, on which plasterboard sheets are laid. But in order to install sheets correctly using this technology, you will have to level the walls or ceiling or carry out a set of preparatory work. Among the advantages of the absence of profiles, it is necessary to note:

- the strength of the base, which does not crumble, does not have fungus on the surface. Often such requirements apply to rooms with high humidity, for example, to the bathroom;

- the wall is reliably protected from dampness and does not freeze. This finishing method is perfectly applicable to the bathroom and kitchen.

Let's take a closer look at the frameless method of attaching drywall, which is often applied to corridors, loggias, kitchens, bathrooms and toilets.

Tool for working with drywall.

When asking how to attach drywall, preparation is important. Therefore, all tools and materials should be prepared immediately:

- sheets of plasterboard (for the bathroom and kitchen you need to take moisture resistant);

- gypsum dry mixture;

- container for diluting glue, tools for applying it;

- painting knife;

- rule;

- spatulas, putty;

- building level, fishing line;

- tape measure, simple pencil.

Stages of working with drywall

First, measurements are taken of the walls, and markings are made on their surface for placing sheets. In order to secure them correctly, you must follow a simple rule: cross-shaped joints are not allowed.

Table with step-by-step instructions for installing gypsum boards.

The surface is cleaned of dust and treated with a primer. Drywall sheets are cut in accordance with the characteristics of the room. To properly fix the GVL, it is necessary to prepare a gypsum adhesive mass. Slow-hardening starter putties are excellent for this; often, PVA glue or regular wallpaper glue are added to the mixture to increase the hardening time.

How to attach drywall with glue? Using a notched trowel, the mixture is applied to the surface of the sheet, after which the drywall is attached to the wall, maintaining gaps of 5-7 mm between the plates, up to 10 mm from the floor and up to 5 mm from the ceiling. After drying, the joints will have to be treated with putty.