The direction of the lining of the internal surfaces - horizontally or vertically - matters only for wooden lining, since it largely determines its subsequent durability. This is much less important for plastic lining. Other methods (“herringbone”, diagonal) are not considered further, if only because they sharply increase the labor intensity of the work and increase the consumption of material. In return, you can only get the originality of the final appearance of the surface. In this regard, it is appropriate to recall that of all types of finishing materials, lining (and especially from valuable wood) is considered the most expensive.

The lining looks advantageous with any installation method

Povagonke.ru

The direction of the lining of the internal surfaces - horizontally or vertically - matters only for wooden lining, since it largely determines its subsequent durability. This is much less important for plastic lining. Other methods (“herringbone”, diagonal) are not considered further, if only because they sharply increase the labor intensity of the work and increase the consumption of material. In return, you can only get the originality of the final appearance of the surface. In this regard, it is appropriate to recall that of all types of finishing materials, lining (and especially from valuable wood) is considered the most expensive.

The lining looks advantageous with any installation method

Tricks, nuances

Once the material is purchased and delivered to your home, it needs to be adapted to the future location. Before finishing the walls with clapboard (example in the photo), the panels are dried for 1-2 weeks indoors or outdoors.

If the material was located outside, it will have to be left for another day or two in the room where repairs will be made to decorate the walls. This manipulation will avoid possible deformation of the boards on the wall.

Then, no longer worrying about possible unpleasant consequences, they proceed directly to work.

Craftsmen prefer to fasten the boards to the sheathing with special clips (mounting):

- Drilling;

- Starters;

- Kleimers.

Claimers are the most productive. Installing one mounting point takes a couple of seconds. They do not spoil the wooden lining.

Required protection:

- Grinding;

- Primer;

- Coating with acrylic varnish (colorless, tinted).

The varnish will not only protect against damage and radiation, but will also add fire resistance to the material.

The influence of laying direction on the ratio of the geometric dimensions of the room

Sometimes you want to change the proportions of a room, for example, make it higher/lower or shorter/longer. For large rooms it is possible to install an additional interior partition. In other cases, the required visual effect can be achieved by nailing the boards in a certain sequence.

What are the ultimate possibilities for changing the direction of laying panels? You can “raise” the ceiling if you take the vertical direction of installation of the panels, and make the room lower if you lay the lining horizontally. It is important to adhere to the chosen laying direction along the entire perimeter of the room, since its arbitrary change (for example, one of the walls is sheathed vertically and the other horizontally) does not produce an aesthetically consistent impression, although it can sometimes be justified by purely pragmatic considerations. For example, an abundance of openings, when vertical installation involves less material consumption than horizontal installation.

The external impression of a longer wall is usually created by one whose design contains a significant number of horizontal lines. Thus, it is quite possible to “lengthen” the wall if you nail the material to it horizontally. Of course, the final decision can only be made after careful analysis:

- ratio of free surfaces of the walls of the room;

- relative position of door and window openings;

- the predominant direction of natural light in the room.

The last factor deserves special attention. If the room faces the south or southeast, then the sun's rays come in during the first half of the day. If in such a room you nail the panels horizontally, then as a result you can successfully get rid of the unpleasant effect of shadows in the gaps between adjacent lining boards. Accordingly, for rooms facing opposite sides of the world, a similar result can be achieved by sheathing the walls vertically.

Finally, the vertical direction of laying allows you to mask the connecting elements of the board, which are located in its end part. If you nail the material horizontally, then all the connecting parts will be visible.

Headlining

The ceiling lathing is mounted on hangers or brackets. The horizontal level is set with a laser level, focusing on the lowest point of overlap. A fishing line is stretched along the walls, and frame bars are placed along it in increments of 25-35 cm for eurolining, 40-60 for other types. When finishing an entire room with clapboards, first the walls are sheathed, then the ceiling.

Before fixing the lining, all communications are laid and embedded parts for massive lamps are installed. If the ceiling is insulated, use a stapler to attach a vapor barrier film to the sheathing or wooden wall from the side of the ceiling. Thermal insulation is inserted between the frame bars and covered with a membrane. The rough surface should be directed towards the insulation.

They begin to install the lining on the side opposite to the entrance so that the last cut board does not catch the eye. If the length of the lamellas is insufficient, use a layout with joints along one line or with staggered seams. The border is covered with a decorative strip or the ends are carefully sanded. Then the docking point is neat and unnoticeable.

The influence of laying direction on the durability of sheathing

Under normal temperature and humidity conditions in the room, the direction of laying - horizontally or vertically - does not affect the durability of wooden lining, not to mention plastic. But this factor will be of great importance if you nail wooden boards in the bathroom or in any of the bathhouses and saunas. The same is true for exterior cladding or laying lining in an unheated room, for example, in a garage.

For a garage, lining is also suitable as finishing

Let's consider the positive and negative factors of various methods of laying lining for rooms with sharply different microclimates.

By vertically positioning the panels you can achieve:

- facilitating conditions for natural removal of condensation from walls;

- reducing material consumption (there is no need to cut each panel to size);

- speeding up the coating installation process.

Horizontal placement of the lining ensures:

- identical operating conditions for each row of boards;

- ensuring good ventilation of the room due to the presence of longitudinal gaps between adjacent panels of material;

- facilitating repairs when it is necessary to replace one or more boards that have become unusable.

At the same time, horizontal laying creates conditions for ensuring greater durability not only of the lining itself, but also of its frame, since when the boards are placed vertically, condensate will constantly accumulate on the sheathing beams. This means that in order to prevent the substrate from rotting when placed vertically on the sheathing frame, you will have to attach additional support bars on which the sheathing will be mounted. It is clear that the size of the room will decrease as a result.

The question of whether to lay the lining horizontally or vertically is also important for room ventilation. For example, when laying horizontally, natural ventilation noticeably deteriorates, therefore, it is necessary to equip the room with a forced supply and exhaust ventilation system, which is expensive and labor-intensive to install.

Summarizing all of the above, we can conclude that for rooms with special operating conditions it is more profitable to place cladding panels not vertically, but horizontally, even at the expense of the labor intensity of finishing work. In a bathhouse, attaching the lining horizontally is much more profitable, since the boards below will wear out faster from moisture, and it will be easier to replace them than the whole thing in the case of vertical installation.

Common mistakes

To avoid mistakes, it is important to know how to properly attach the lining:

- Choose well-dried material;

- Prime and paint before installation so that there are no areas difficult to reach for finishing;

- Leave a gap between the board and the adjacent wall to compensate for shrinkage or expansion;

- Secure the first, last and outer elements firmly - with nails or self-tapping screws;

- When finishing interior decoration, insert the tenon into the groove tightly so that cracks do not form when the wood dries out;

- When sheathing the outside, gaps are left in the tongue and groove joint to compensate for moisture expansion of the wood;

- Select nails, screws and clamps according to the size of the lining;

- Clamps are not intended for fastening boards in unheated rooms and outdoors;

- Do not carry out work in the cold or in the rain;

Do not neglect treatment with antiseptics, fire retardants, and protective paint compounds.

What are the conditions of the steam room casing?

As you know, in a steam room the highest air temperature is in the upper part.

The closer to the ceiling, the higher the temperature of the steam. With proper ventilation arrangement, fresh air enters the steam room from the outside from below, which, rising upward, is heated to the desired steam temperature. The heated steam, circulating through the steam room, falls down. Along the way it gives off its heat and, having reached the lowest level, has the lowest temperature. At the same time, its relative humidity undergoes the opposite changes, that is, the higher it is, the lower the humidity. Thus, unfavorable conditions for wooden structures and elements are created in the lower part of the steam room.

These are important conditions that should not be neglected when finishing a bath. After all, the wooden parts located at the bottom of the steam room will experience increased exposure to wet steam both during and after steaming. And this cannot but affect their service life due to wood rotting.

Types of lining for facade work

Panels for facade finishing are made from plastic, metal, fiber cement, and wood.

It is difficult to clearly determine the best lining. The choice always depends on the operating conditions and purpose of the building. Before choosing cladding, specialists must take into account the climatic features of the area, the type of structure and its operational properties.

In order to make a competent comparative description of the lining, you should consider its features in such parameters as cost, durability, service life and safety.

Sometimes the fundamental factor when choosing lining is the cost of the building material. However, cheap does not mean good.

Popular wooden lining

Of course, wood has a higher price and the cost of such panels depends on the type of wood and class. Today on the market there is a wide selection of Eurolining class “A” or “Extra”. More durable wood, strict quality control and the difference in defects determine a fairly high price.

The most common is class “B” pine lining, which is excellent for cladding country houses, terraces, and bathhouses.

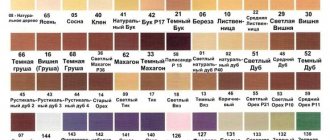

Cladding classes

Plastic (vinyl) lining will cost an order of magnitude cheaper, but at the same time, it does not provide that natural appearance that many people like so much.

The service life depends on the characteristics of use. Atmospheric precipitation, temperature, air humidity and other criteria have a direct impact. Therefore, when choosing the type of forcing, all these factors should be taken into account.

Plastic lining is not at all afraid of moisture, but at the same time it does not have sufficient resistance to temperature changes. Vinyl tolerates exposure to UV radiation, but does not withstand mechanical influence from the outside. Any small impact is enough and the integrity of the panels can be damaged.

Vinyl siding

The popularity of vinyl panels is also due to the variety of color schemes, which allows you to select the appropriate range for the style and exterior of the building. The scope of vinyl products is very wide; they are widely used for cladding balconies, loggias, and gazebos. But low frost resistance makes this material undesirable for cladding houses in climate zones with strong temperature changes.

Example of façade finishing with vinyl siding

Wood is characterized by increased resistance to mechanical damage, is not afraid of sudden temperature changes, but does not like moisture. Specialists treat wooden lining with special protective compounds to improve its performance characteristics. Wood creates an atmosphere of warmth and comfort that no other material can convey.

If we talk about safety, then vinyl lining is not subjected to fire-resistant impregnation. When burned, vinyl melts, evaporating harmful substances.

Wooden finishing is an excellent solution for a bathhouse, terrace or private home. To increase fire resistance, the boards are pre-treated with a special impregnation. The unique structure of wood, its healing properties and environmental friendliness determine the wide demand for this material.

If not properly cared for, wood quickly loses its properties. It may crack and become deformed. It is for this purpose that before installing this material, specialists carry out thorough treatment with special antiseptic and hydrophobic mixtures. This prevents the appearance of mold, mildew and protects the wood from moisture penetration. As for care, wood is difficult to wash and clean. Over time, it can change its shade and lose its original freshness.

Comparison of plastic and wood siding

Plastic, on the contrary, is easy to maintain. It is enough to wipe with a damp cloth or use cleaning agents and the vinyl looks like it was originally covered. Despite its high resistance to UV rays, plastic may lose its color brightness over time, which does not in any way affect its performance properties.

Vinyl lining is often called laminated panels that perfectly imitate the structure of wood, artificial stone or metal, which allows you to implement any design idea.

Vinyl siding for shiplap

Brick siding

Thus, the following advantages can be identified from plastic lining:

- low weight;

- UV resistance;

- variety of colors;

- long service life;

- ease of care;

- ease of installation.

Which is better, vertical or horizontal finishing of the steam room

To give a logical explanation for this issue, we will first consider the option of finishing a steam room with a vertical lining arrangement, and then assume that the wall cladding is horizontal. After that, we will draw conclusions about which is better.

Vertical arrangement of the lining

When the lining is positioned vertically, it heats up unevenly. So, in the lower part adjacent to the floor, its heating temperature will have the lowest value, and near the ceiling - the highest. In this case, the air humidity at the bottom will be the highest.

It is not difficult to imagine what will happen if you repeatedly heat and cool a sufficiently long wooden element. This is its unpredictable deformation: bending along a plane, propeller-like, warping and other changes in the original shape.

And if its opposite parts are exposed to air with varying degrees of humidity, then, on top of everything else, wood rotting processes may also occur. Unfortunately, this will apply to all elements of vertical cladding in the floor area along the entire perimeter of the steam room.

Some tips

- When using self-tapping screws, it is advisable to pre-drill holes in the boards with a drill of a smaller diameter, this way you will protect yourself from unwanted cracks and splits in the wood.

- Use only high quality material. You don’t need lining with cracks, areas untreated from bark and deformation. Read about the choice of materials in the article.

- When installing the lining, use the most dry acclimatized wood. You will find an analysis of how to properly dry boards here. It is better to carry out work in warm weather. Also make sure that the humidity percentage in the room is no more than 65%, only then bring in the wood and start working.

Conclusions and recommendations

At one time, when choosing a method for covering a steam room, I settled on the horizontal option. It has been serving well for several years without any serious damage or changes to its original shape. Every year I am once again convinced of the correctness of the choice I made.

Based not on empty space, I recommend that you also choose a horizontal arrangement of the lining. True, you have the right to do as you see fit. In any case, I hope that this article will help you take into account the above nuances so that finishing the steam room is not done in vain.

And finally, watch this video about horizontal installation of lining. Find mistakes that should not be made when decorating a bathhouse with your own hands. And I’ll tell you about them immediately after watching the video.

- For a steam room, the lining must be made of wood such that when heated it does not release resin.

- The installation direction is incorrect. Even if water doesn’t get on the casing, you can’t escape the dust. And when washing the wall, moisture will inevitably get into the gaps between adjacent elements. And this will create conditions for wood rotting.

- Regardless of the nature of the room, horizontal cladding should start from the top, securing the first element with the groove down. Then neither moisture nor dust will be scary. For example, water will flow down the wall, going around the longitudinal joint along the outer surface of the groove, and will in no way be able to get inside the joint.

- There is no air space between the inner surface of the lining and the second layer of vapor barrier. To ensure air circulation and thereby prevent the processes of wood rotting, 20-30 mm thick strips should be placed on top of the vapor barrier on the vertical posts, and the lining should be fixed to them. The space under the lining will provide natural air circulation, drying and removing excess moisture.

- Remember, what you can get away with in an ordinary room is unacceptable in the steam room of a Russian bath

with its rather extreme conditions.

Dear friends! If it’s not difficult, share it on these social networks with your friends. Thank you!

How does installation work?

Everything happens in order.

The sheathing is being done. Without it, channels appear where moisture collects, dampness appears in the room, fungus may develop, and the wall will even begin to rot. Therefore, they carry out repair work according to all the rules. Even if the walls of the house are perfectly smooth and are themselves wooden, it is still necessary to install sheathing before covering the wall with clapboard.

The clapboard wall decoration is installed with mandatory channels for ventilation (they are specially cut out in the boards). No way without lathing. It should be made of wood, like the panels. This is important, because the material acts as a damper. Particularly important when using min. materials on the walls. The same function is supported by gaps (deformation) between the wall itself and the boards. Connectors range from 5 mm and larger.

For example, there are often cases where wooden boards are laid on steel sheathing (as when installing drywall). After a short time, the material begins to expand and cracks appear. But, having removed the plinths several years after installation, it is discovered that the seemingly smooth surface of the wooden sheathing has only slightly moved around the edges. It doesn’t matter what type of sheathing will be, the basis for its installation is the same for everyone: the sheathing bars must be positioned strictly perpendicular to the boards.

Don’t forget about the bars that are located at the edges:

- The ends of the boards should not hang;

- When installing the lining diagonally, its sheathing must have a frame (solid);

- The thickness of the bars starts from 20 mm, width - from 30 mm;

- The size of the installation step of the bars is at least 4 boards wide;

- From the ends, the fastening points are placed at a distance starting from 50 mm.

Rules for fastening lining - video instructions

One of the building materials that is in constant demand in the construction market is lining. A large assortment, a wide palette of colors and textures make these cladding panels universal. It is important to install them correctly; the functionality of the surface and its aesthetic appearance depend on it.

Methods of fastening lining, types of materials

Main varieties: wood, MDF, plastic, coated aluminum. The shape is a plank with a tongue-and-groove system. Thanks to this lock, the facing panels fit tightly to each other and are easy to fix vertically or horizontally.

Materials

- The most affordable, budget option is made of polyvinyl chloride (PVC). The texture can imitate wood and stone, and a wide palette of colors is available.

- Aluminum lining with polymer coating. It is made from thin sheet steel. Such panels must be fixed to a metal profile.

- MDF is a narrow board made of finely dispersed chips, pressed using a vacuum-thermal method. During the manufacturing process, resins are released that glue the board together. On top it is covered with a film of various textures, including one that visually replicates the cut of the tree. Beautiful, practical and inexpensive material.

- Wood is the most popular type of cladding. Natural wood has a beautiful texture, low thermal conductivity, and emits a pleasant aroma. It is more often used for interior decoration, including the walls of baths and saunas.

Based on quality indicators, the following are distinguished:

- 4 classes: extra, A, B, C.

- Eurostandard (eurolining): deep groove, wider tenon and offset profile. On the reverse side there are vertical gutters for accumulating condensate. Suitable for rooms with high humidity.

- An American imitation timber, which is slightly thicker than a regular plank (standard - from 8 to 10 mm, American - 14 mm).

- The exterior decoration is most often made from a block house; from the outside it resembles a processed log. A house with such horizontally attached panels looks like a log house.

Planks made of PVC, wood, MDF are installed in the same way - on a wooden sheathing using self-tapping screws, nails, and clamps.

Varnish and paint selection

Means to maintain the excellent appearance of the panels for a long time are used in the initial stages, before covering. And walls covered with natural clapboard, an example in the photo below, must be treated upon completion with additional colorful materials.

In addition to them, to give a spectacular finish to the lining laying, at the end of the repair, the wood is coated with tint compounds.

It is based on a couple of components that greatly influence the appearance of the finish. Varnish happens:

- Alkyd;

- Acrylic;

- With a water base;

- Polyurethane;

- Mixed (acrylic with polyurethane).

Alkyd takes a long time to dry. For faster drying, use special. solutions. This varnish will give the room a sharp, not very pleasant smell, which is difficult to dissipate. But these little things can be tolerated, because the alkyd will give the boards reliable protection from moisture.

Acrylic – quick-drying. Used inside and outside buildings. Moisture-resistant, tolerates high temperatures well. The presence of many shades and colors is attractive. All surfaces treated with this varnish can be washed without problems, dirt and dust can be easily removed from them.

Water-based varnish is the safest and most environmentally friendly among all products. Dries quickly, odorless. Characterized by the absence of chemicals. solvents. There are water- and dirt-repellent varnishes. Caring for materials coated with this varnish is very simple. The cost is quite high.

Polyurethane. The most versatile one today. It will prevent the wood from turning yellow. Shades are offered in brightly saturated, semi-transparent shades. The product is presented for every taste. Do not forget about the primer of the required tone, especially if the choice fell on a light varnish color.

An interesting, practical, often used when covering walls with boards yourself is impregnation of wood with oil. Thus, the panels acquire an unobtrusively shiny, beautiful tone.

For our climate, in order for the board to look perfect for more than 10 years, it must be treated with acrylic varnish in two layers.

Types of fastening material

The lining is nailed down with finishing nails with small heads. The heads are slightly visible, there is a high probability of chipping the wood of the panel tenon. Fixing with nails is a less effective method compared to self-tapping screws and clamps.

Correctly fasten the strips with small self-tapping screws (2.5-3 mm). Some craftsmen first recommend making a hole using a thin drill, then fixing the screw to prevent chips or cracks from forming. This method is mainly used for hard wood (oak, elm).

Claymers are the best option. You can nail any type in such a way that the connecting element will not be visible from the outside. It is a small complex bent metal holder. One side of it is inserted into the tenon, covering it, and the platform leg is nailed to the sheathing.

How to install the lining correctly?

When using a block house for external walls, the first thing to do is to impregnate them with compounds that prevent the penetration of moisture, antiseptics. The timber and panels are also coated with products that increase resistance to the external environment, the formation of mold and mildew. For this purpose, moisture-resistant impregnations, antiseptics, special varnish, and stain are used. After treatment, the wood must dry.

Horizontal installation is carried out in such a way that the spike is on top. This rule will prevent water from penetrating into the gaps between the planks. Metal profiles are used less often. First, metal brackets are attached to the wall, then the profile is fixed to them according to the level.

Installation of sheathing under the lining

They start with markings. It is necessary to measure and beat off two perfectly even vertical lines, top and bottom, with a distance of 5 cm from the floor and ceiling using a coated cord.

- Next, the frame is fixed to the wall. Begin by installing the top and bottom horizontal panels. They are installed along the marked lines. Then you need to nail the beam vertically (with a distance of 5 cm from the corner of the wall), connecting it with horizontally installed planks to form the basis of the perimeter.

- The size of the timber is selected based on the unevenness of the walls. If they are relatively even, then you can take a thinner one (10x20 mm). Vertical fastening is most often done on a frame made of 20x40 mm elements. The perimeter of the sheathing must be perfectly level; each stage is checked using a level.

- The beams are installed vertically in increments of 50 cm. A reinforcing frame is placed horizontally between them as spacers, including the space around windows and doors.

Nowadays they make bars for sheathing with a drilled longitudinal gap for fastening, or special metal plates with a slot for connecting elements. Thanks to this, the so-called “floating frame” is fixed, which prevents its deformation during shrinkage of the building and expansion during temperature changes.

The easiest way to install a vertically installed plastic lining. It differs in that it almost does not form seams. It can be attached using staples and a stapler, since it is quite light, or thin self-tapping screws can be used. Do not tighten them too much so as not to deform the plastic.

It is better to connect MDF to the sheathing with self-tapping screws or clamps. Due to the dense structure, it will be difficult for nails to enter the surface of the tenon, and chips may form. With clamps, the wall will look more aesthetically pleasing, since they are not visible at all, and can also be easily dismantled if necessary.

When installing wooden panels and eurolining, all types of fasteners are used. The nails are driven into the tenon at a slight angle. The occurrence of cracks and chips is minimized. Self-tapping screws must be screwed in strictly perpendicularly. The best way for regular lining is with clamps. The lining, characterized by the presence of an offset side profile, is fixed to the wall sheathing using any method. The connection point is covered by the next plank. The adjustment is carried out using a mallet, a rubber hammer, or take a piece of lining and insert it into the groove, lightly tapping it.

It is important to pay attention to the following points:

- An expansion joint (3.4 mm) is left between the panels. For the same purposes, a 5 cm indentation is made from the ceiling and floor. The seams are covered with corner molding for the ceiling (fillet), and below - with a floor plinth. The first element is always inserted vertically from the corner of the doorway with the tenon (ridge) forward. The latter is trimmed to the size of the remaining gap. Using a stop, for example, a nail puller, it is inserted into the wall slot.

- The peculiarity of ceiling installation is that it is difficult for one person to carry out. Fundamentally, the scheme is no different. Thin self-tapping screws with a sharp end are more convenient; working with clamps is more labor-intensive. Expansion joints are also left on the ceiling along the edges.

- Not all types of wood are used in the bathhouse. Pine and spruce are not suitable, as they release resins at high humidity and temperature. Most often, cladding is selected from linden, aspen, hardwood, Canadian cedar, and larch. The sheathing must be made floating. The ideal option for cladding is eurolining. It has an elongated spike and longitudinal grooves on the reverse side where wet condensation accumulates and drains. Nail only on galvanized, copper nails and self-tapping screws. The planks should not be driven tightly together with a mallet, leaving a gap for thermal expansion of the wood.

Sequence of finishing work

The first step is choosing a wall decoration option. Fastening the lining can be done in two ways:

- Along the walls;

- Along the sheathing.

The first option is preferable in a wooden house, since wood tends to expand or shrink in size and “breathe”. If the base material is the same as the coating, their joint oscillatory motion will not cause multidirectional stresses leading to deformations and the appearance of defects on the surface.

In brick and concrete houses, before attaching the lining, a sheathing is installed, which can also serve as a frame for laying thermal insulation. It is convenient to place corrugated hoses for electrical wiring and heating pipes in the space between the covering and the wall.

The second is the correct measurement of the room and calculation of materials. This will help you avoid unnecessary expenses or waste time on additional trips to purchase missing components. The amount of lining is determined based on the area of the walls, excluding openings. The length of the ceiling and floor plinth is equal to the perimeter of the room. To decorate the corners you will need shaped strips. Materials are purchased with a margin of 10-15% for defects or other defects.

Wood is a living structure, sensitive to fluctuations in humidity and temperature.

Before starting work, it is unpacked, allowed to “get used” to the new conditions, and treated with antiseptics and fire retardants, if there is no factory preparation.

Before installing the sheathing or directly attaching the lining to the wall, prepare the surface - clean, level, seal the cracks, and coat with antiseptic compounds. This will protect the structure from the appearance of mold and fungi.

The third step is installing the sheathing. Most often it is made from wooden blocks with a cross-section of 20x30, 40x50 or larger. The thickness of the element depends on whether insulation will be laid under the lining. A ventilation gap is left between the thermal insulation layer and the coating, which prevents condensation from accumulating.

The frame pitch is 40-60 cm, the direction is perpendicular to the finishing boards. The space between the bars should be filled tightly with insulating roll or slab material. For residential premises this is usually mineral wool; outside, expanded polystyrene foam or other polymers are more often used. They are not afraid of moisture. Before attaching the lining, perform a vapor barrier and waterproofing. A film or membrane is used that allows the liquid to evaporate, but does not allow it to pass in the opposite direction.

The geometry is controlled using a bubble or laser level. Dowels or construction nails are used as fasteners for the sheathing.

Wood paneling. Part 1. Horizontal or vertical?

Before you understand the method of fastening the lining, you need to understand the method of fastening the lining. And this is not tuftology at all; before deciding how (in the sense of nails, clamps, etc.) to mount each plank to the frame, we need to decide in what style we will mount them: vertically or horizontally, from top to bottom or from bottom to top, groove up or down, etc. Oddly enough, there are many options.

Usually, in order to decide on a design, it is recommended to look at photos of objects. This is a good idea, but not in our case. Most often, photos of lining are posted by developers or craftsmen whose goal is not always high quality, but often a banal quick profit. And they post photos of their economical work, and not of practical objects; the Internet is filled with them, creating the impression and misleading us that this is public opinion, and therefore a proven, practical option. Let us figure out what is practical and what is economical.

Selection of lining and calculation of area

For quality work, it is necessary to select the right material and calculate its quantity.

It is necessary to sheathe the inner surface of a room such as a bathhouse only with materials that can withstand:

- large temperature changes;

- high humidity;

- constant contact with water and various substances.

Board type and material grade

Today, the building materials market is filled with a variety of linings from many manufacturers. Lamellas are produced both Russian and foreign. Eurolining is available with various profile cross-section options. Also, wooden lining can vary in the surface quality of the back and front sides of the board, the shape of the lock and its dimensions, the type of material and other equally significant parameters.

Most often, lining of several popular profiles is used.

- Eurolining, which has clear sharp edges and forms seams visible to the naked eye when covering.

- Softline with more rounded corners.

- Calm. The seam with this finish is almost invisible, because it does not have recessed shelves. It can imitate timber and have both quite sharp and smoother rounded edges.

- A lawnhouse, the front side of which is not smooth, but with various patterns. The design on the lamella of the lawnhouse is applied using figured milling on more expensive materials and using hot stamping on cheaper ones.

- Blockhouse (siding).

- Double-sided lining. Both the groove and the tenon of such a board are located exactly in the middle, so both sides turn out equally smooth - you can choose between them. However, this material has almost no ventilation (the ability to “breathe”), so it is not very suitable for interior decoration of wet rooms such as a bathhouse, swimming pool or sauna.

To determine the type of purchased lining, you can use the European DIN standard. The difficulty is that many manufacturers use various GOSTs and even their own specifications, so first of all it is necessary to look at the surface quality of the material itself, and not at the markings. All lining is produced using the same equipment and using the same technology, so the grade of material is determined during inspection after the completion of the manufacturing process.

- Premium (or extra). Almost perfect quality of the lining. Neither branches nor cracks are allowed on the slats. A light blue tint, small chips, roughness and imperfections are possible only on the inside.

- Class A. The knots on such a board should not be more than 1 cm in diameter and occur no more than once in a one-meter-long area. Cracks, if any, should be very small and, of course, not through. It is advisable that the manufacturer putty them himself. All other defects are allowed only on the inside.

- Class B. Knots in diameter can be no more than a third of the lamella, but in any quantity. The presence of through cracks and open pockets is also allowed.

- Class C is all the remaining lining, on which blue spots and a large number of large knots are visible. There may even be gaps on the surface of the side that is visible after installation. However, it is believed that lining of this class cannot be used for finishing walls.

Wood

A bathhouse is not only a steam room, but also a wash room, a dressing room or even a swimming pool. For each room it would be more appropriate to choose wood of a certain species.

Wood is divided into two categories:

- coniferous: pine, spruce, cedar;

- deciduous: linden, aspen and others.

One of the most popular material options for eurolining is linden board. Linden is quite durable, does not change the fiber structure for a long time and is resistant to various negative factors. The atmosphere of the linden bathhouse is full of freshness and cleanliness.

Aspen lining is easy to work with; time only makes this material stronger. If the surface of such a lining darkens, it is easy to return it to its original appearance by sanding the surface. Both linden and aspen are used to decorate the hottest and most humid room in saunas - the steam room.

It is also possible to use cedar for its finishing, however, due to the fact that cedar heats up very quickly, discomfort may occur when touching the sun loungers and walls made of this material. Coniferous trees are used mainly to cover the washing room or dressing room. Pine and spruce release resin abundantly and, like cedar, have a high heating rate, but using this material will save money and choose from an extensive decorative range of linings. It should be noted that coniferous wood must first be deresined in order to avoid a large number of stains on the walls.

Design solutions

First, a few words about the design aspect of cladding with wooden lining.

With a horizontal arrangement of the lining, the length of the wall visually increases, and a vertical arrangement will increase the height of the ceilings. Monotonous cladding can cause negative feelings. A combined finish looks good, for example: up to waist level - horizontally, above - vertically. An interesting option is mounting diagonally. When mounting the lining vertically on the wall, as well as when mounting it on the ceiling, the boards are mounted with a tenon towards the entrance. This disguises the gap in the groove of the lining.

In rooms with normal humidity, the cladding method is just a matter of taste. It’s another matter if it’s a bathhouse, unheated premises or external cladding.

Lining surface treatment

Indoors, the lining can be left in its original form, since it is not subject to extreme changes in weather conditions and has a beautiful wood grain. But if there are frequent changes in temperature and humidity in the room, for example in kitchens, bathrooms, especially on balconies, saunas and baths, then in such cases it is necessary to carry out protective treatment of the surface of the lining. Otherwise, the surface of the wood will turn blue and dark gray.

You can process and paint the lining before installation or after installation. However, it is advisable to paint the new lining before installation. Because, like any lumber, lining has a small percentage of shrinkage. As a result of shrinkage, unpainted areas will appear at the joints of the interlocking joints in the form of lighter stripes that were not visible before shrinkage. In this case, it will be necessary to additionally paint the surface of the lining.

The surface of the lining can be coated with different types of paints and varnishes. To do this, you need to decide why you need to treat the surface. If the lining is installed outdoors and is exposed to direct exposure to ultraviolet rays, precipitation, and sudden temperature changes, then it is necessary to choose the most protective materials that cover the lining with a thick film. Such protective compounds include all kinds of antiseptics against fungus and insects, and compounds that increase the fire resistance of wood. After treatment with antiseptics, the lining on the street is covered with one of the types of paints based on acrylic, oil or latex. It is recommended to treat the lining that will be installed outdoors with antiseptics on both sides; the cut ends also need to be treated well.

To paint lining indoors, choose compositions that do not create a dense film on the surface of the material, which preserve as much as possible the beautiful wood texture, giving it a specific shade. Compositions for interior painting preserve the breathability of wood and at the same time create a protective layer against moisture, prevent the accumulation of dust, protect against insects, and preserve texture and color. Such materials include: wax-based compositions, oil-based compositions for wood, different types of stains and varnishes for wood. Indoors, the lining can be processed only on one front side.

Thus, in order to choose a material for treating the surface of the lining, you must proceed from the technical characteristics of the room and your own taste preferences. There is no universal recommendation for painting lining.

Having completely assembled the lining and processed its surface, the final stage is to cover its end parts on the ceiling and near the floor with baseboards, as well as look at the decorative corner in the corner of the walls, if aesthetics require it.

Having considered all the stages of self-installation of lining, we can conclude that almost anyone can cope with this process. It does not require years of experience or great physical strength. The process of laying lining is quite exciting and interesting. And working with natural wood always brings only pleasure.

Bath solution

Let's consider the pros and cons of each method of attaching lining in a bathhouse:

| Criteria | Vertical | Horizontally |

| Moisture | + Easier for moisture to drain | + The frame is vertical and there are no obstacles to the drainage of condensate that forms on the foil behind the lining. + The lining is laid with the tenon facing up and water will not get into the groove. |

| Ventilation | — The fastening beam goes horizontally, closing the possibility of ventilation under the lining | |

| Rotting | + Easy to replace bottom boards | |

| Floor repair | + It is enough to remove a couple of lining strips | |

| Shrinkage and cracks | — The temperature below and above has a significant difference. Expansion and shrinkage are more noticeable. | |

| Installation | + Easier, faster | |

| Price | + Cheaper |

The most important thing: we attach the starting board of the lining

Regardless of the installation method chosen, it is very important to install the first board exactly. All others will be measured by it. Therefore, the first plank must have ideal geometry. And one more thing: even if you glue clapboard to the wall, place the first board on nails/screws.

For vertical installation, use a plumb line; for horizontal installation, you will need an accurate building level.

When installing cars horizontally, control the position using a building level

You can put marks on the wall using a laser level.

It is important to position the first plank on the wall correctly

Do not secure the first plank completely until you have it exactly aligned. You can drive a nail at the top (for vertical installation), place it at the bottom and fix it there. Then - in the middle, making sure that the edge of the board goes exactly along the mark/beam/cord. We divide each half in half and put fasteners there. We repeat until the nails/screws stand every 40-50 cm or in each crossbar of the sheathing. Always check that the bar is positioned correctly. With horizontal installation everything is the same, only the direction changes.

How to nail the lining? Vertical or horizontal?

Often words contain a reflection of the action that follows them. So, if someone tells you that he will nail such a finishing material as lining, then my advice: run away from such a master, he poses a danger to wood material.

Yes, let it be at least a plastic lining. Nailing panels is a thing of the past, when protruding nail heads did not seem such an ugliness, how scary they have become since the advent of hidden fasteners today!

The correct term is: laying the lining, installing the board or installing it. The quality and durability of your repair depends on the correctness of the installation process, regardless of whether the lining is mounted vertically or horizontally.

So, in this article I will answer the questions:

Photo 1. Installing eurolining vertically

What is the best way to lay the lining vertically or horizontally?

This question is often asked by our customers. The answer will depend on what goal you want to achieve:

If the ceilings are low and you want to visually “raise” the room, increase the height of the room, then you can’t think of a better way;

Photo 2. Vertical laying of lining

If you want to increase the length of the room, you need to lay the panels in a horizontal position. They seem to “stretch” the room and it will seem longer.

Photo 3. Angarsk pine lining installed horizontally

How to choose the size of hidden fasteners?

For the best visual effect, there are two types of fastening, both of them are hidden, a clamp and a wood screw

with a special design, because ordinary self-tapping screws often split wood:

Lining vertically or lining horizontally, it doesn’t matter, hidden fastening will make the surface monolithic. Such fasteners are common for light wall panels, but they are reinforced for heavy ones (for example, larch).

Photo 4. Regular and reinforced gluer.

Number of clamper is 3.5; 4; 5; 6; 7; 8; indicates the thickness of the rear groove in mm. To find out which number you need, simply attach a ruler to the rear groove of the panel.

The clamp is put on the back groove of the board and screwed to the block.

Photo 5. Fastening to a reinforced clamp.

Placing the lining both vertically and horizontally using screws. Not every self-tapping screw is suitable for this purpose. If there is no cutter or drill at the tip, and the head is not designed to be “sunk” into the wood, then you can expect a lot of broken tenons and defects.

The best ones for the job are: “Fischer” self-tapping screw, “ESSVE skirting”, “SWG”, “ESSVE floor” screws with a drill at the tip. Self-tapping screw thickness 3.0-3.5 mm, length 30-50 mm.

Photo 6. Wood screws SWG 3.2x50 (34)

Lathing.

Everything here is basically simple.

For interior decoration use dry, planed timber 30/40; 20/40; 20/30 and other small sections.

Photo 7. Lathing on the attic ceiling

The lathing is usually placed in increments of 0.5 meters. To ensure that the logs are level, use a building level.

For installation, you can use ordinary self-tapping screws. I don't recommend black ones, they break easily, better take yellow ones.

IMPORTANT.

If you are going to mount the lining vertically, then the sheathing is installed horizontally, and if the lining is mounted horizontally, then the logs should be in the opposite direction.

Photo 8. Horizontal ceiling lathing

Which wood behaves best in a bathhouse or sauna?

The use of wood in bathhouses and saunas requires the panels to not only have a beautiful appearance, but also such qualities as low density and the absence of resin.

It doesn’t matter whether the lining in the sauna is installed vertically or horizontally - it’s a matter of taste. It is important that it be made of linden or cedar.

Photo 9. Sauna made of linden eurolining, Extra grade

Photo 10. Sauna made of cedar lining, grade AB.

Plastic material in the bathhouse?

– No, absolutely not, unless you are an enemy to your health. The decoration of such premises should only be high-quality, environmentally friendly wooden panels.

The LesoBirzha online store will help you with the choice of material, experienced consultants will tell you how to install correctly, select fasteners, and our teams of carpenters will save you from the problems associated with installing the lining, whether vertically or horizontally, I repeat, it’s a matter of your taste, as well as design problems that you solve with the help of repairs.

Preparing the lining for installation

- Before installation, it is necessary to remove dirt; it is advisable to do this with a dry or slightly damp cloth.

- Next, you need to treat the outer part with an antiseptic, which will prevent the formation of mold and insects. We have already discussed the antiseptic treatment of lumber in another article. After processing is complete, allow the material to dry.

- Also, at the beginning of work, it is advisable to apply a thin layer of varnish or other coating-protecting agent to the boards. It is much more convenient to paint boards in a horizontal position and before they are mounted on the wall. In this case, the paint layer will be more even and without smudges. Over time, the coating will need updating.

Important! Do not use lining varnishes when installing in a bathhouse, since paints and varnishes emit harmful substances when heated.