Renovating a bathroom is an expensive and time-consuming undertaking. Wall decoration requires a lot of money. But there are materials that allow you to quickly and inexpensively put everything in order. One option is moisture-resistant wall panels for the bathroom. They are of different types and in different forms of release. The general thing is speed and ease of installation and low cost (when compared with tiles).

The plastic under the tiles looks good

Kinds

Today, the domestic market offers a wide variety of all kinds of plastic products. Wall panels have several different variations for use in the bathroom. In fact, in terms of performance they are at the same level, however, in terms of functionality and appearance they differ quite sharply.

Leafy

Sheet models are very large elements. They differ from other brothers, first of all, in their size, but at the same time they are very easy to install. They are usually used with a pattern or image already applied. Sheet products are a high quality material that resists high levels of humidity and temperature changes.

Sheet panels

Typically, sheet panels are used for installation in the most difficult, from an operational point of view, areas. Often this is either a kitchen area or a bathroom, which allows the data in the room to be reliably protected. The main material used for the production of sheet products is fiberboard raw material. Eucalyptus additives containing natural resins, essential oils and other natural components are specially added to it.

This, together with protective impregnation, makes it possible to give sheet panels high strength and fire resistance. In addition, the production of sheet products from PVC material is allowed. In this case, it is a special sheet of medium-sized plastic. The resulting model is very convenient for transportation and installation. During installation, a very small number of joints and seams are obtained. This has a positive effect not only on the appearance of the shower, but also on its performance.

No. 5. Drywall

Drywall is rarely used today for finishing bathrooms, but it can be an excellent option for those who have very uneven walls in the bathroom, and the process of leveling them requires spending a lot of time and money. This option will also be useful for those who are planning to create an interesting interior in the bathroom with the presence of original architectural forms.

The main advantages of gypsocraton include:

- low price;

- light weight, which facilitates the installation process;

- excellent performance qualities, because plasterboard increases sound and heat insulation in the room.

You only need to choose moisture-resistant drywall, and it is easy to recognize by the characteristic green color of the sheets. Among the disadvantages of such a finish are:

- the need to additionally decorate the created surface, since the green sheets of gypsum plasterboard do not look very attractive, to put it mildly;

- the need to use additional components for installing gypsum plasterboard, which increases the cost of the structure.

What bathroom panels are there?

Wall planks appeared on our market not so long ago, which is why not everyone knows what types of this material can be found in stores. The first type is their MDF material, somewhat reminiscent of practical chipboards. MDF wall panels are made from pressed chips. The binder is lignin, which is released from wood when heated. Such materials are moisture-resistant, durable, hygienic, fire-resistant, and are not afraid of mold.

We recommend: How to make a chic ceiling on the balcony with your own hands and avoid unnecessary expenses?

MDF wall planks

The second type is PVC products. They are made from polyvinyl chloride, adding special softeners. At the final stage of production, the material is coated with varnish, which increases moisture resistance and resistance to damage. Finishing a bathroom with PVC panels is more in demand due to such advantages of the material as:

does not attract dust; is not afraid of temperature fluctuations; easy to clean.

By the way, PVC products are cheaper than MDF products, but they are better suited for the bathroom.

Painting

What paint can be used to decorate bathroom walls?

Any water-dispersion moisture resistant. I would prioritize like this:

- “Rubber” paint based on acrylic latex;

- Silicone;

- Latex;

- Acrylic.

Personally, I used Sevastopol rubber water emulsion “Rezel+” to paint walls free of tiles. The coating is easily washable, resistant to dry and wet wear and is not afraid of ultraviolet radiation.

The fact that I used the same paint to paint the plywood steps of the staircase to the second floor, which is used outdoors, speaks volumes about the quality of the paint. Rain, snow and the scorching Crimean sun over two years of operation did not affect the coating in any way.

The steps are plywood, coated with rubber paint.

What types of moisture-resistant wall panels for bathrooms are available?

There are quite a few options for finishing a bathroom; to determine the best material, it is important to analyze all the advantages and disadvantages of each of them. Finishing options can be divided into:

slatted typesetting; tile materials; sheet materials - it is advisable to choose them for large rooms.

Characteristics of PVC wall panels for the bathroom

PVC is the most inexpensive material for finishing a bathroom. The production technology of polyvinyl chloride makes it possible to produce panels with imitation wood, natural stone or ceramic tiles in different colors. The main advantage of the material, in addition to moisture resistance, is that it is non-toxic even at high humidity. Interesting interior solutions using PVC panels for the bathroom are presented in the photo gallery.

PVC in the interior is not inferior to tiles

Related article:

PVC panels. In the publication we will look at sizes, applications, varieties, advantages and disadvantages, criteria for choosing the right panels, average prices, popular models, expert advice.

Characteristics of MDF panels for the bathroom

MDF panels for the bathroom are suitable only with a laminated coating, it prevents moisture from getting on the chipboard. If we compare the characteristics with PVC, MDF has undoubted advantages:

high strength; a large number of supports are not required, therefore the structure is more durable; the finished product is painted; it has heat and sound insulation.

The only drawback can completely negate all the advantages: hydrophilicity. Unfortunately, chipboard absorbs moisture; it will take a little time for the board to become unusable. To prevent this effect, it is necessary to apply additional coating and completely isolate unprotected areas.

The finished MDF sheet does not require additional decoration

Characteristics of fiberboard bathroom panels

Fibreboard fibers have a low density, and therefore are susceptible to moisture and can swell. To use fiberboard in conditions of high humidity, they must be treated with a composition with a moisture-resistant effect. For use in the bathroom, it is recommended to choose laminated hardboard - fiberboard sheets that are treated with bitumen impregnation, then covered with a film and a special composition with protective properties. Like MDF boards, it is necessary to control the integrity of the film coating; this is additional protection against high humidity; it must be without damage. During installation, all butt joints are treated with sealant.

It is not advisable to use laminated fiberboard in the bathroom

Related article:

Fiberboard: what it is, dimensions, sheet thickness and average prices, areas of application, varieties. The nuances of finishing walls, floors, and ceilings with slabs, useful tips and recommendations from experts - read all this and much more in our review.

Characteristics of moisture-resistant panels based on chipboard

Chipboards are made from shavings and small chips. Conventional slabs, like fiberboard, are afraid of moisture; they swell and lose their shape, which is not restored even after drying. Manufacturers produce moisture-resistant boards that contain binding components, and the surfaces are additionally laminated. For bathrooms, you should choose a material with a waterproof effect. In terms of cost, it is equivalent to moisture-resistant MDF for the bathroom, however, MDF has much better characteristics.

Laminated chipboard is also not entirely suitable for the bathroom

Related article:

Moisture-resistant tongue-and-groove chipboard is one of the most reliable and durable building materials, characterized by high strength and an affordable price. Read about the advantages and disadvantages, selection criteria and features of laying tongue-and-groove chipboard in our material.

Characteristics of acrylic panels for the bathroom

Acrylic lamellas are innovative developments of manufacturers. The color and structure of the material is affected by the concentration of additives. The surface gloss is much higher than that of PVC and MDF. The main advantages of acrylic can be highlighted:

high strength; resistance to mechanical damage; resistance to abrasion and light reflection; environmentally friendly product; absolutely waterproof.

The only drawback of acrylic does not overshadow the entire list of advantages - it is a high price. Only aquapanels can be considered as its competitor.

Assortment of acrylic slats for the bathroom

Glass wall panels

Tempered glass slats are quite popular for finishing bathroom walls. A smooth and shiny surface beautifully reflects glare from lighting, this effect will visually expand the space and the room will look radiant. The advantages of finishing include:

not afraid of temperature changes; resistant to high humidity; easy care; durability.

Bathroom interior with glass panels

Other types of wall panels

When choosing a material for finishing a bathroom, one cannot help but highlight aqua panels; today this is the most ideal solution. They are a fiberglass mesh filled with weightless expanded clay. Among the positive qualities it should be noted:

resistance to high humidity and temperature changes; easy maintenance; beautiful appearance; material can be bent.

During installation, the aqua panels are attached to the wall surface using special glue on a pre-assembled frame.

Aquapanel is the best solution for the bathroom

a brief description of

Although all materials have the same name, their properties are different. First of all, the degree of moisture resistance differs. PVC can withstand direct contact with water without harm, MDF and fiberboard - provided that the cuts are properly sealed and the integrity of the laminating film is intact. Chipboard-based panels are the most susceptible to moisture, so, if possible, they are best used for finishing the toilet, kitchen, corridor and other rooms with relatively normal operating conditions.

Looks like wood, but is actually wall panels

PVC sheet panels

Of all the ones listed, PVC panels are 100% waterproof. This is a sheet of plastic several millimeters thick (usually 3 mm) on which a design is embossed. An image is applied to the front of the panel using special abrasion-resistant paints. These moisture resistant bathroom wall panels can be used without any doubt. They are definitely not afraid of water.

PVC wall panels for tiles - ordinary decor

More interesting option

There are many variations of mosaics

In the form of a tile panel

This is what the bathtub looks like after gluing PVC boards under the mosaic

They are mounted directly on the walls - glued to a moisture-resistant compound. Moreover, the walls do not have to be perfectly smooth. The plastic hides irregularities well, especially notches, but it is better to remove sharp protrusions. Such panels are cut with scissors or a sharp knife and glued end to end. The joint can additionally be sealed with moisture-resistant sealant - transparent or matched to match.

To decorate the corners, there are also special plastic profiles that simultaneously join the material and give the joint a finished look. In general, a good option for budget renovation of bathroom walls.

MDF wall panels

In areas with high humidity and the possibility of direct water ingress, MDF-based wall panels can be used. This material uses high pressure technology, resulting in a very dense board. The wood particles are compressed so tightly that water practically does not penetrate between them. To improve the characteristics, additional binders and impregnations are added to the composition, which make the base almost waterproof. As a result, moisture-resistant MDF wall panels feel more like plastic.

There are different options

MDF sheet panels

This is what the wall looks like after finishing with tiled wall panels

A laminating film with a pattern is applied to this base and the whole thing is covered with a thin layer of transparent dense polymer. This film is an additional barrier to water and it is thanks to it that moisture-resistant wall panels for the bathroom can be used even in areas where water is directly exposed.

This type of finishing material has a peculiarity: to make the finish waterproof, the joints are coated with sealant. They also pass through the junctions with the floor and ceiling. To prevent moisture from getting inside the material through the cuts. This installation method guarantees a long service life of the finish, even in damp rooms.

When choosing a material, be careful: stores have large quantities of MDF wall panels for dry rooms. Installing them in the bathroom is a mistake, as very soon they will warp.

Fiberboard panels

Fiberboards are made using a similar technology, only the wood fibers have a larger fraction and lower density. Accordingly, they are more susceptible to moisture and can swell. To eliminate this drawback, the material is impregnated with moisture-resistant compounds. The best for bathrooms are fiberboard panels with bitumen impregnation, which are also called hardboard.

Based on impregnated fiberboard

Next, the fiberboard is laminated with a film, on top of which a protective coating is applied. This material is also called laminated hardboard or hardboard wall panels. As in the case of MDF, the film is an additional protection against moisture and it must be intact. During installation, it is also necessary to coat the joints and cuts with sealant.

Based on chipboard

Chipboard wall panels are made from even larger pieces of wood - shavings and small chips. Ordinary material is afraid of water. At high humidity it swells and after drying does not return to its normal state. For wall panels, a moisture-resistant version is used - with the addition of additional binders. As in other cases, the surface is laminated. But even after this, you should not use such finishing material in the bathroom. The exception is special waterproof panels. But their cost is almost the same as that of moisture-resistant MDF, and if you choose between the two, then MDF is clearly better.

Imitating wall tiles on sheet finishing materials is a way to quickly and inexpensively make bathroom renovations

Chipboard wall panels are well suited for finishing a toilet, corridor or hallway. They are rigid to withstand loads and significant mechanical stress. So they performed well in these premises. But when choosing, pay attention to the formaldehyde emission class. In the production of this material, synthetic binders are used that emit formaldehyde. This parameter is standardized and controlled. In documents it is designated by the Latin letter E and adjacent numbers. The lowest emission class is E0 - no higher than that of wood. Safe - E1. It is even allowed to make children's furniture from such materials. It is better not to take other materials - they cannot be used for residential premises.

Installation features

Moisture-resistant wall panels are classified into three groups according to the method of connection during installation:

Seamless. With this method, the panels are connected using the tongue-and-groove principle. When installation is carried out correctly, the result is a perfectly flat surface with barely noticeable joints.

It is important to take into account the quality of the material: the slightest deformation of the slab will make the joint noticeable.

With chamfer. This is a type of seamless connection. The difference is that the ends have chamfers - decorative recesses, which after installation create a relief on the surface.

Embossed. Connecting the slabs with a visible seam is part of the decor. Often the decor is stylized to look like lining, which is installed in this way. These are tough and resistant to mechanical damage products.

The panels are installed directly on the wall if it is level enough. Vertical or horizontal fastening is installed with glue.

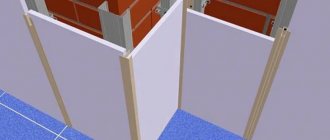

When the walls are uneven, with flaws and depressions, wall panels are installed on a sheathing - a wooden, plastic or metal frame connected to the wall with dowels. The result is a smooth wall.

Consumer electronics

Is it possible to hang a clock or install a TV in the bathroom?

No. Categorically.

As a former electronics repair service worker, I insist that it should not be used in high humidity. Dampness leads to gradual destruction of current-carrying paths, corrosion of the solder under BGA microcircuits and multiple short circuits on control boards.

At the same time, repairing damaged equipment is, as a rule, impossible: even if some of the boards with traces of track corrosion remain operational, no sane service technician will give you a guarantee that they will work for some more time.

This is why Italian mechanically controlled equipment is so highly rated on the washing machine market. It contains virtually no electronics that are so sensitive to moisture. I have many times encountered failures of Daewoo and LG electronic boards after just six months of operation, while the electromechanical Candy faithfully served me for 18 years and was handed over in fully working order to the buyer of my apartment.

Need I say that when moving, a washing machine from the same manufacturer was purchased to replace the indestructible Candy?

Preparation and components

It is recommended to perform PVC cladding in rooms with temperatures above +20 degrees. Before this, the vinyl panels and their guides are left in the room for several days to acclimatize the material. Then measurements are taken and markings are made for all fastening systems and holes that will protrude beyond the boundaries of the ceiling and walls. These can be built-in windows, cabinets, doorways and ventilation grilles. In addition, additional fasteners must be made for hanging equipment.

Once the planning and design choice has been resolved, preparation of the surface itself for finishing begins. The walls and ceiling are thoroughly cleaned of previous cladding, dust and dirt. It is also important to check that there is no fungus or mold on the base. If there are any, they are treated with antifungal and bactericidal agents. As for plastering the surface, it is optional.

We recommend: How to make your own office on the balcony

To install the panels, you should also ensure that you have all the necessary tools and components. This is, as a rule, a standard set consisting of a level, a hacksaw, self-tapping screws and an electric drill. Depending on the installation method, you will additionally need wooden beams, metal profiles, staples, fastening clips or glue.

What are there

The content of the article

1 What are they? 2 Brief characteristics 2.1 PVC sheet panels 2.2 MDF wall panels 2.3 Fiberboard panels 2.4 Based on chipboard

Moisture-resistant wall panels for the bathroom are not only the well-known PVC slatted panels. There are four more types of finishing materials of this type:

Based on high pressure MDF. Fibreboard laminated with moisture-resistant film. Chipboard coated with PVC film. PVC sheet panels.

Most often, wall panels for bathrooms are designed to look like tiles or mosaics. This is understandable - the most common design. The pattern also imitates the seams - they are slightly recessed and painted in a different color. Everything is like the original. If done well, you won’t immediately be able to tell whether it’s the tiles in front of you or the wall panels that look like tiles. The difference is in the degree of gloss. The panels are very light. But in recent years, the use of matte ceramics for finishing bathrooms has become increasingly popular - it is easier to care for (water marks are not visible). This is where it’s really difficult to discern the difference without touching the surface.

Most often, moisture-resistant panels for the bathroom are designed like tiles, but there are other designs

You can also find options that imitate stone (marble, wild stone), brickwork, wood, leather, and other natural materials. If we talk about appearance, the choice is wide, and there are very interesting designs.

Wall panels based on MDF, fiberboard and chipboard are available in three types:

In the form of slats (slats), which are joined using a lock. In the form of square or rectangular tiles. The sizes can be different - 50*50 cm and 100*100 cm. They can be joined using locks, special profiles or end-to-end. Sheet panels. These are larger slabs that can be used to cover the entire height (or almost the entire height) of a wall at once. Width is usually 120 cm, height 250 cm or 270 cm.

Moisture-resistant panels for the bathroom can be in the form of slats or slats

Interesting release form - slabs of different sizes

Sheet moisture-resistant wall panels are a quick way to finish a bath or toilet

The release form is chosen depending on the design that they want to obtain. Please note that the installation method depends on the release form. Slatted wall panels are attached to the sheathing; the other two types can also be mounted on a frame, or directly on the wall. In this case, the choice depends on how curved the walls are.

Varieties

Panels for interior wall decoration have different shapes and dimensions.

Produced in three types:

- leafy;

- tiled;

- rack and pinion

Sheet panels

The dimensions of the sheet panels are large: height 2.20 m - 3 m, standard width - 1.25 m. This is a clear advantage over other types: quick assembly. With variations in height, it’s easy to find the optimal parameters so that the panel occupies the space from floor to ceiling in one sheet, without joints. Width joints can easily be turned into a unique design solution.

The panels are made from PVC and laminated particle boards. They imitate natural wood, brickwork or natural stone. They come in plain colors: monochrome or with a pattern.

If the wall surface is moderately uneven or has flaws, when installing moisture-resistant wall panels, you can do without preliminary preparation: leveling or lathing.

Slab panels

Tile panels - square or rectangular. Popular sizes: 1 m x 1 m and 1.20 m x 0.80 m.

During installation, a sheathing with cells of identical sizes is required.

Sometimes individual fragments are connected using connecting profiles. They are visible between the slabs and often have a contrasting shade. Due to this, the volume of the decor is created.

Slatted panels

These are long and narrow products. Their dimensions:

- length 260 – 300 cm;

- width 8 – 50 cm.

The technique of laying slatted panels requires perpendicularity: if the laying is horizontal, the sheathing is attached vertically; with vertical fastening, a frame with horizontal slats is required.

Materials for production: glass, polyvinyl chloride (PVC), laminated MDF and chipboard. Plastic is more common.

Strengths

Wall panels have their own advantages, thanks to which they enjoy well-deserved popularity. It is no coincidence that they are considered as the main replacement for ceramic tiles. Although it is considered the main and permanent finishing material for the bathroom. Therefore, the strengths of wall panels already speak volumes; all that remains is to list them.

Advantages of the material:

The affordable price allows even people with low incomes to purchase panels. The absence of excess during installation makes the products very attractive from a cleanliness point of view. Antibacterial properties make it possible to use the bathtub for its intended purpose, and not to fight mold. Hiding defects and communications is also an advantage. The possibility of installing lighting in wall-mounted models is also present. The variety of choices on the market makes the products very popular among designers. Moisture resistance is the main feature of wall panels.

Advantages and disadvantages of installing wall panels

Finishing the room with wall panels for the bathroom can be called an almost ideal option. And all thanks to the advantages of this finishing material. Let's look at them in a little more detail:

Availability. The cost of PVC wall panels for the bathroom is low. Further installation of materials will also be inexpensive. Compared to laying tiles, repairs using panels will cost about half as much. Fast installation speed. Plastic panels for the bathroom are reminiscent of a children's construction set - you just need to connect the parts together. There is no need to carry out additional preparation of the walls. This will save your time when carrying out repairs - the material is attached to profiles made of wood or metal. Practicality. Walls finished with PVC wall strips do not require special maintenance. In addition, a properly created structure will have practically no joints in which dirt “likes” to get clogged. All cleaning comes down to simply wiping the walls with a damp cloth.Easy to repair. In case of accidental damage, the product can be easily replaced without removing the entire structure. Durability. Plastic wall panels for the bathroom are moisture-resistant and reliable. They are not afraid of humidity and temperature fluctuations. In addition, using this finishing material, it is easy to create a unique design in the bathroom.

We recommend: Installing an outlet in the bathroom - basic requirements, installation instructions

Plastic Wall Panels for Bathroom

But, like any other material, bathroom wall panels also have disadvantages. Let's compare the panels with ordinary tiles. When creating panels, special processing is used to increase the moisture resistance of the material. Ceramic tiles are much more durable in this regard. The material is also quite easy to damage if accidentally hit with something heavy. What you use for finishing the bathroom is up to you, but if you choose wall panels, you need to find out what types of manufactured materials exist.

Tile

This material is the undisputed leader in all parameters that are important to us. Judge for yourself:

- It does not wear out under dry or wet abrasion. At all. This is one of the few materials for which you can safely use abrasive cleaners;

- The service life is practically unlimited. If you're happy with the aesthetics of your tiled bathroom, you don't have to renovate it at all;

- The seams can be easily made completely sealed using, for example, epoxy grout. This means that there is no need to worry about fungus even in a damp room.

Tile allows you to forget about repeated repairs for an unlimited time.

I used clear silicone caulk to seal the seams between the tiles above the tub. It is transparent - because, unlike white, it does not turn black over time.

Where exactly in the bathroom can you use tiles? In two combined bathrooms of my house it is used:

- As a covering for floors and walls. The ceiling of the bathroom on the first floor is suspended and made of plasterboard. It is coated with ordinary water-based paint;

- On the floor and on the wall directly above the bathtub. The tile protects those surfaces that most often come into contact with water.

In the attic floor bathroom, tiles are used directly above the bathtub and protect the walls from splashes.

Features of choosing products by size and appearance

Finishing materials for the bathroom can be classified into the following types of slabs:

type-setting racks are an analogue of lining, sheet width can be 13-28 cm, length - 2.5-3.8 m, thickness - from 0.8 to 1.4 cm; sheet - they are characterized by simpler and faster installation. Standard sheet dimensions: 1.25×2.5 m, thickness - 0.3−0.7 cm; stacked tiles - made in the form of a square with a side of 30−95 cm. They can be combined in different colors, creating an interesting interior in bathroom.

You should know this! Using sheet plates you can mask wiring and wall errors. Tiled and slatted ones are often chosen only for decorative finishing, since they are small in thickness.

Panels for tiles and mosaics for the bathroom - photos in the interior

PVC panels for bathroom wall tiles are very similar to ceramics, only much cheaper. Their installation is quite simple and convenient, compared to slatted material. Most often, owners opt for slabs measuring 30x30 cm; it is considered the most profitable. Another great option is PVC panels for the bathroom with mosaics, which are presented in the form of square sheets coated with a mosaic coating. The front side is embossed and can be glossy or matte.

Slatted plastic panels for the bathroom - photos of interesting designs

Slatted panels have a narrow shape and are installed in a vertical or horizontal direction. Depending on the installation method, you can visually raise ceilings or expand the space, which is useful for small areas. Manufacturers produce a wide range of slats in a variety of colors. Examples of beautiful bathroom interiors with PVC panels can be found in the photo catalogue.

Sheet plastic panels for bathroom

The main advantage of sheet panels is that you can transform your bathroom in a short time. In addition, installation is carried out with a minimum number of butt joints. The only thing you should pay attention to is that you cannot create an interesting design or pattern; the interior can turn out to be quite monotonous. They are easy to care for; they do not allow moisture to pass through, even in butt joints, which means that the possibility of fungus forming underneath them is minimized. In addition, plastic has excellent noise and sound insulation.

What are moisture-resistant wall panels

Moisture-resistant panels are a finishing material that is resistant to humid environments. Available in flat sheets of different sizes and shapes.

A number of materials with varying levels of hygroscopicity are used in production:

polyvinyl chloride (PVC); cork; pressed wood fibers, shavings and dust (chipboard and MDF); mirror; glass or acrylic.

Moisture-resistant wall panels are decoratively attractive: they are available in a wide range of colors, various reliefs and structures. The laser technique of applying a pattern to the surface imitates expensive finishing textures:

ceramic tiles; marble covering; natural wood; wild stone.

Photo printing techniques are used on polymer materials. The products are used to decorate the kitchen wall apron and are used as a bright accent in the design of bathrooms.