Where is latex putty used?

All walls and ceilings in new homes and renovations require further processing to create a protective and decorative coating or to level the surface.

- In each specific case, depending on the purpose and condition of the walls and the room as a whole, it is possible to apply a starting and finishing putty mixture.

- One of the new finishing materials is latex putty.

- In comparison with other known types (including similar acrylic ones), this putty can be applied in a very thin layer, even less than 1 mm.

- At the same time, the strength of the latex coating is higher, and the consumption is lower than that of acrylic.

Another interesting fact is that even an inexperienced person who decides to do their own repairs for the first time can feel like a master, since latex-based putty is easy to work with and easily lays on the surface being treated, perfectly leveling it.

Recommendations for selection

A real owner always tries to make good repairs. At the same time, the quality of puttying walls, ceilings and other surfaces plays an important role. Therefore, you should know the important rules:

- When starting to putty the surface, it is necessary to take into account the type of base on which the putty will be applied, the humidity of the room and the subsequent finishing material.

- For wooden and metal surfaces, only acrylic putty is suitable.

- It is not recommended to use latex in wet rooms. Acrylic is best suited.

- Acrylic putty is suitable for exterior finishing of facades, as it is moisture-proof, resistant to sunlight, and quite durable.

- If you plan to paint the walls, buy ready-made putty. It can be latex or acrylic. But it should have a uniform consistency without lumps.

- Pay attention to the expiration date . If the putty is more than 1 year old, inquire about the conditions of its storage and transportation. It cannot withstand sub-zero temperatures, losing its properties.

- Check with the seller for the conditions for returning low-quality putty.

- Buy products from reputable manufacturers.

Repair and constructionComment

Characteristics of latex-based putty

The description of latex putty can begin with the disclosure of its component composition. As is already clear from the name, the main component of this putty mixture is synthetic latex.

It has excellent binding properties; resistance to water, alkalis and oil; It is resistant to atmospheric influences, ultraviolet radiation, and mechanical influences.

To regulate the properties of latex, other components are added:

- Plasticizers,

- Thickeners,

- Purified water,

- Stabilizing substances

- Fillers,

- Antiseptics,

- Modifiers, etc.

Thanks to plasticizers, the plastic and strength properties of the finished putty mixture are increased and the possibility of cracking is reduced. Antiseptic substances help prevent the appearance of mold on surfaces covered with latex-based putty.

All components in the total mass determine the properties of the finished putty mixture and the coating made from it, and also determine the scope of application of the latex putty.

Material properties

If we talk about the composition, it includes various plasticizers, antiseptics, binders and hardeners. The connecting link is the polymer component, thanks to which the use of latex putty allows you to protect walls from high humidity due to the formation of an elastic layer, which is durable and easy to process (see also the article “Materials for finishing ceilings - a huge selection for every taste”).

The main advantages can be considered the following factors:

- With this composition you can apply the thinnest layers, even if they are thinner than a millimeter, the coating will be reliable and durable. Therefore, if you are faced with the choice of latex or acrylic putty, and want to cover the walls with the thinnest layer, then the choice is obvious. Acrylic cannot be applied in a thin layer without losing its strength properties.

- Wide choice of colors. You will avoid unnecessary costs, time and money on purchasing paint and coloring, since you can purchase a latex composition of the desired color. In fact, this is a very big advantage that no other type of mixture can provide.

In the photo: this group of materials gives the surface the desired color

- The material is very convenient to work with - the mixture is sold ready-made, so it is impossible to make a mistake when diluting and creating the wrong consistency. Simply open the bucket and get to work. The elasticity of the composition simplifies its application, which is very important when doing DIY work.

Different packaging of the material will help you purchase the right amount, which will save significant money.

- Another very important property is the highest adhesion to almost any substrate. The composition works on the principle of liquid rubber - it fills all cavities and irregularities and adheres tightly to the surface.

- When hardened, the putty forms a film that does not crack or crumble, which distinguishes it favorably from acrylic and cement compositions. You do not need to be afraid that in places where the layer is thin, cracks will form and the coating will crumble.

This type of product also has some disadvantages, but they are few, which once again indicates high quality:

- The biggest drawback is the price. But if you take into account such factors as complete readiness for use immediately after purchase, ease of use even for inexperienced specialists and ready-made color, then it becomes clear that the cost is completely justified.

- And one more important factor: if the composition freezes during storage, its properties deteriorate significantly. You are unlikely to be able to work with such a mixture, so it is better to check the production date when purchasing and pay attention to the conditions in which the products are stored; in a cold pavilion, as a rule, such goods deteriorate.

Purpose of latex putty mixture

Leveling and finishing of wall and ceiling surfaces for further cladding;

- Sealing seams in butt joints of plasterboard boards and screw heads;

- Elimination of various small defects (cracks, chips, dents);

- Restoration work on wooden doors, windows, floors, panel walls and furniture;

- Finishing work in rooms with high humidity;

- Creation of the thinnest leveling layer without weighing down the structure;

- Wall decoration.

Thanks to its excellent plasticity, latex putty is convenient to apply to any surface, even to curved elements of unusual shape.

Which putty should I buy?

In order to choose a putty and not overpay, it is important to build on the existing technical conditions. For example, gypsum putty is not suitable for use in a damp environment; if you use a finishing solution, you can significantly exceed the cost of painting work. The rules for using putties are regulated by GOST, but it is easier to consult with the builders who will use the solution before purchasing the material.

Recommendations for choosing putty:

- Give preference to well-known brands;

- Monitor the expiration date and storage conditions of the material;

- Carefully study the composition and purpose of the materials. For residential areas, the use of putties with toxic or harmful components is not allowed;

- Putties with sand are perfect for initial finishing and working with large layers; they are poorly suited for finishing, since the thickness of the applied layer may be less than the size of the grains of sand included in the solution;

- If the rooms have high humidity or poor ventilation, give preference to putties with a water repellent;

- For ceilings and walls, different putties are usually used, which is associated with different thicknesses of the applied layer;

- Low price of material means low cost of components. This may mean heterogeneity of the solution, a large filler fraction or poor quality of binders.

If you still have questions, the specialists of the Alphacem group of companies will suggest the most suitable brands and types of putties for your cases.

Acrylic putties are popular because of the components they consist of. Acrylic has all the necessary strengthening properties and the ability to interact with different surfaces. It can be used for both interior and exterior work.

Types of surfaces suitable for treatment with latex putty

- Brick;

- Ceramic block;

- Wooden;

- Wood fiber;

- Gas and foam concrete;

- Plasterboard;

- Plastered, etc.

Latex-based putty can be used on almost all surfaces. The only material forbidden for her is metal due to its weak adhesion to it.

Before choosing and purchasing a putty mixture, it is important to know all the pros and cons of latex putty.

Technology

Preparing walls for applying Tex Profi putty

First you need to measure the amount of putty treatment. Considering the expected thickness of the putty, calculate the need. The sellers of the store where you bought it will tell you how to calculate the required consumption of putty per 1 m2 of substance.

Removing old wallpaper

Before applying putty, those surfaces that have been painted should be cleaned of previous whitewash or old paint. Sand surfaces with a glossy texture to a matte finish. Remove abrasive and dust by wiping with a damp cloth. Treat areas affected by fungus and mold with antiseptics.

Antiseptic treatment

Coat the cleaned surfaces with a water-dispersion primer.

When the primer has dried, you can begin to putty.

Primer

Plasterboard surfaces with joints and cracks are sealed with sickle tape. In this place about puttying drywall under wallpaper. It is glued on top to joints and cracks. The entire space around it is sealed so that the joint is not noticeable.

Necessary materials

Before you begin, you must purchase the following materials:

deep penetration primer. It is applied to the processing surface to strengthen and reduce moisture absorption. This will greatly facilitate all subsequent operations.

Deep penetration primer

serpyanka ribbon. This attribute is a must-purchase. When puttingtying walls under wallpaper from sheets for various purposes, it will not allow cracks to appear in the joints.

Serpyanka ribbon

Required Tools

To work you will need the following tools:

brush;

Brush

roller;

Roller

- the dishes are smaller than the bucket with purchased putty.

A latex substance in an open container releases moisture to the surrounding air, loses elasticity and its best consumer properties; - grater. This tool will need to grind the surfaces after processing;

Grater

one spatula 35 cm wide. It is needed for applying the putty mixture to the walls. The second spatula is 10 cm wide. It is needed for subsequent processing of hard-to-reach places;

Spatula

In order to align internal and external corners, an angle spatula is required.

Angle spatula

Application

When all the treated seams are dry, they are sanded and a primer is applied on top. Here's how long it takes for putty to dry. The puttying process is simple, since the substance is fully prepared by the manufacturer for use, is elastic, and easy to apply. Even a beginner can handle it.

It is not carried out using traditional sanding paper of various grain sizes. The operation is performed with a damp foam sponge. It washes away excess putty mixture

It is important not to allow the putty to dry completely, but to sand the slightly damp surface

Advantages of latex-based putty

- Increased strength and hardness of the coating;

- Possibility of applying a light and super-thin layer (less than 1 mm);

- Convenience and ease of use;

- High elasticity and penetrating ability;

- Excellent adhesive properties;

- Good wear resistance and durability of the finished coating;

- Resistant to UV radiation and weathering;

- Withstands temperature changes;

- Not subject to shrinkage (does not bubble or crack after hardening);

- Low consumption;

- Available in various colors;

- Vapor-tight, does not absorb moisture;

- Eco-friendly;

- Possibility of creating decorative reliefs on the surface.

Thanks to these capabilities, latex putty mixtures are widely used for interior and exterior work.

Unlike others, after hardening, latex putty does not stain clothes and hands if you accidentally touch it, and when grouting with a damp sponge, it does not crumble and does not form fine dust.

Main differences

| Characteristic | Latex | Acrylic |

| Defining Component | latex | acrylic |

| Application area | Interior work | External and internal works |

| Varieties | Finish | Start, finish, universal. There are special ones for wood, metal, and drywall. |

| Release form | Ready liquid mixture | Ready-made liquid mixture or powder requiring additional preparation |

| Price | Higher | Below |

| Color palette | It has a wide variety of colors and shades, and white putty can be tinted | Usually white |

| Surface | Concrete, drywall, brick, plaster, wood | The same + metal |

| Application tool | Putty knife | Spatula, spray gun |

| Application layer | 1-2 mm | Up to 3 mm |

| Waterproof | Average | Excellent |

| Drying speed | Dries slowly, a day or more | Dries quickly within 24 hours |

| UV resistance | Weakly stable | Stable, therefore used for outdoor work |

| Coating strength | More durable | Less durable |

Disadvantages of latex-based putty

- High price;

- Limited temperature storage ranges: cannot be stored in frosty conditions.

The purchase costs are recouped due to the low consumption, high strength and durability of the coating. Also, due to the fact that the putty does not absorb moisture, and therefore does not draw it out of the facing materials, paint and adhesive mixtures are used more economically.

Kinds

Most common building materials manufacturers have seen widespread adoption and increased demand for their products. Which one is better? Each company decided to take advantage of this popularity and create their own latex putty production company.

Today there are a significant number of companies manufacturing building materials, and this complicates the choice of material.

Tex

Specialists in the field of repair activities are satisfied with this type, in cases where they are not buying fakes.

Tex

It does not burst, lays down very delicately, and sanding the surface of products is not particularly difficult. The surface is just as smooth and uniform.

Vetonit

According to the characteristics, it has an average indicator. But it’s easy to use, easy to dilute, and quick drying will only be a plus.

Vetonit

But when you start pasting the trellises, difficulties may then arise, since you will be able to remove the old wallpaper together with the putty. Often, in addition, it is capable of getting wet and pieces, along with the wallpaper, falling off the wall.

Knauf

More suitable for repair experts. Due to the fact that sanding is more difficult, it should be applied very carefully in order to make fewer mistakes.

Knauf

The highest quality putty is a composition from the German manufacturer “Knauf”. It is used by leading specialists in the field of renovation and design. It must be applied very carefully, for this reason it is not recommended for beginners.

Shitrock

It is soft to use, does not curl, and sands well. You just need to buy from a manufacturer of a foreign manufacturer (for example, the USA) - others were not suitable in quality.

Shitrock

In addition, it is possible to highlight the Sheetrock brand. If you have decided to buy putty from this manufacturer, then you need to highlight the fact that there are currently many fake putty consistencies from this manufacturer.

Caparol

Fits perfectly on walls, so they appear perfectly straight and smooth. Relatively inexpensive in terms of cost and consumption with other options. For people who have decided to start repairs for the first time, it is better to buy Caparol latex putty.

Caparol

You only need to directly purchase building materials in branded shopping centers, or you can choose putty directly from the manufacturer’s factory.

On wood

- common color palette;

- easy to apply and easy to sand;

On wood

- slight thermal shrinkage after drying;

- excellent adhesion.

Latex wood putty “Colorika Aqua” is an environmentally friendly product, odorless:

- ready-to-use products;

- will not require one or another high-quality training;

- has optimal adhesion;

- dries quickly;

Colorika Aqua

- easy to apply, including vertical materials;

- has slight shrinkage after drying;

- produced in different colors.

Wood putty “Colorika Aqua” is specialized in processing holes, sealing cracks, as well as correcting defects in wood products, intended to prepare the surface for further painting.

The composition includes acrylic copolymers, fillers, additional additives and chemically prepared liquid.

Latex putty Tex

All the above characteristics fully apply to such a composition as Tex latex putty from a leading manufacturer of high-quality paint and varnish products in Russia.

All products of this brand, including putties, are certified and time-tested. Under the Tex brand, ready-to-use putty mixtures are produced for both interior and exterior work; for leveling and finishing various surfaces; for dry and wet rooms.

- Among all the putty compositions of this company, the Universal latex putty stands out, developed according to the recommendations of professionals, and which has earned the title “People's Brand”.

- This mixture in finished form and in different weights (from 1.5 to 30 kg) is packaged in appropriate containers, which is very convenient. When it is necessary to carry out small restoration work, it is enough to take a small container; To process large surfaces, large batches of putty mixture will be required.

A universal putty of white color with a cream tint is ready for leveling work in dry rooms on wall and ceiling surfaces made of concrete, brick, plasterboard, fiberboard, MDF and other materials for subsequent painting or wallpapering.

The putty mixture is easy to apply, economical in use and cools quickly. The drying time for latex putty is 4 hours. For subsequent priming or facing work, it is necessary to wait at least 12 hours.

Acrylic putty

Depending on the properties of a given finishing material, the places of its application are determined.

Basic properties:

- Has good adhesion to the surface being treated.

- Environmental friendliness and durability.

- Resistance to low temperatures, as well as temperature changes.

- Does not form a film on the surface, so the walls can breathe.

- Elasticity of the material.

- Protection of walls from ultraviolet radiation.

- Able to protect against moisture and keep the room warm.

The above properties make it possible to use this finishing material indoors and outdoors.

Using an acrylic mixture.

Tips for use

- The drying time for this material is approximately one day. Work should be carried out at positive temperatures, because low temperatures make the elastic properties of the material lower.

- One layer of putty should not exceed two millimeters, and the total thickness of the layers should not exceed ten.

- The most suitable surface for working with such material is wood. Although it adheres perfectly to any surface.

- To putty metal products, choose putty that matches the color.

- When working with this putty, you must use a spatula, but depending on the consistency, you can use a spray gun.

- The finishing material does not require special mixing with water, since it is sold ready-made. Just mix thoroughly before use.

- You can use both starting material and finishing material.

- When sealing a large volume, this putty should be applied in several stages, waiting for the previous one to dry. If you immediately seal it in one layer, it may crack.

Acrylic putty: use of material for work on the outside of a building

This material is used mainly for outdoor use.

Some tips for use:

- Before starting work, the surface must be cleaned of old finishes, dirt and completely leveled.

- A mandatory item is priming before starting work.

- The finishing material should be mixed as necessary.

- When working, use a spatula.

- After the material is applied to the surface, it must be rubbed, or the surface must be treated with a roller to create the desired pattern. This must be done before the material has dried.

So we got acquainted with these two finishing materials. It is almost impossible to choose which one is better, because latex putty is more suitable for interior work, and acrylic putty for finishing the outside of a building. Although the choice is still yours.

Have you ever experienced unbearable joint pain? And you know firsthand what it is:

- inability to move easily and comfortably;

- discomfort when going up and down stairs;

- unpleasant crunching, clicking not of your own accord;

- pain during or after exercise;

- inflammation in the joints and swelling;

- causeless and sometimes unbearable aching pain in the joints...

Now answer the question: are you satisfied with this? Can such pain be tolerated? How much money have you already wasted on ineffective treatment? That's right - it's time to end this! Do you agree? That is why we decided to publish an exclusive interview with ARMEN DZHIGARKHANYAN, in which he revealed the secrets of getting rid of joint pain, arthritis and arthrosis.

Attention, TODAY only!

What is important to pay attention to

It is mandatory to carry out any construction work (including putty) in special clothing and gloves;

- It is important to work in a constantly ventilated area;

- Do not store the container with the putty mixture at subzero temperatures;

- Before using, keep the putty jar for some time in the room in which further work is planned, in order to adapt to the temperature conditions (especially in the cold season);

- Before applying the putty mixture, prepare the surface (clean, treat with primer and antiseptic, let dry);

- Use putty only at temperatures not lower than +5°C;

- Gently adjust the finished but not yet completely dried latex layer with a slightly moistened foam sponge.

About the rules for carrying out puttying work

Professional recommendations:

- It is worth purchasing 30% more mixture than necessary. It is almost impossible to distribute the putty evenly. In some areas the layer will be thicker, which will increase material consumption.

- Glossy surfaces are sanded. After processing they should become matte.

- When applying, use 2 spatulas. A wide mixture is applied to the wall. A narrow spatula is designed for spreading building material.

- If the putty is made from powder, it must be used within an hour. Even with constant stirring, the solution quickly hardens.

- The putty should be distributed using vertical or circular movements.

- When the work surface is affected by mold or fungi, it must be cleaned and treated with a special compound.

- At the stage of sanding latex putty, you can use a foam sponge soaked in warm water. However, the surface should be treated before the mixture hardens. Grinding of hardened material can be done using a special device or sandpaper.

Regardless of whether latex or acrylic putty is used, experts do not recommend applying a layer thicker than 5 mm. If you do this, it may crack later. Do not try to straighten all the waves and stripes that appear after applying the composition. You can get rid of them during sanding.

When working with mixtures, it is necessary to protect the respiratory tract with masks and respirators. Despite the comparative safety of the material, gloves should be worn.

Contact of mixtures with mucous membranes is unacceptable. Internal work is carried out in a well-ventilated area, away from open fire.

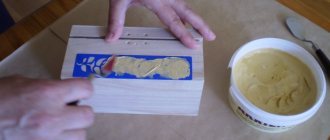

Photo of using latex putty

Advantages and disadvantages

With the support of such a composition, you will get a fairly flexible putty layer on the desired surface that dries uniformly. Thus, the material has the smallest volume and linear dimensions of the casting during their formation, as well as cooling from the casting temperature to the ambient temperature.

Due to these features, cracks and bubbles will not appear, and the putty will not crumble.

Key benefits:

- comfortable to use, flexible due to latex;

- very easy to apply, in the thinnest layers;

- adheres well;

- no shrinkage, which prevents cracks from appearing;

- after complete drying they do not crack.

It has two minor drawbacks that can be easily overcome:

price. Compared to other types, the price of latex putty is quite high. But you will reimburse these expenses with the result of the repair work performed and the speed of activity;

low temperatures – rather weak reaction to temperature changes

If during operation you notice that the product does not meet the listed requirements, the mixture may have frozen; Buy it preferably in stores with a guarantee of product return or exchange for a fresh product.

Please note that the product is completely covered with a lid and there are no traces of dried particles on it. Because after the completed manipulations, scratches appear during work, which again need to be puttied

conclusions

Latex putty carries the following positive criteria. Professionals use latex putty only with a thin ball, because it does not always withstand a few millimeters of additional thickness. Plus, you can always save a lot.

A layer of, for example, 3 mm will be just right. Observe only one nuance: when sealing joints or holes, its thickness should not be higher than 1 mm.

A huge advantage of latex putty is the compatibility of its use with a variety of decorative and paint materials . The putty is elastic, so no additional sanding is required. We recommend that you familiarize yourself with the material that will tell you how to “putty” or “putty” correctly.