There is a certain stereotype about performing plastering work, as if the work necessarily involves making a solution of cement, sand and water, which is applied to the wall with a trowel or other tools. Accordingly, when it comes to dry plaster, an association arises with a mixture of bulk building materials.

However, dry plaster for interior work is a well-known plasterboard wall decoration to many, which is the subject of this article.

Walls and ceiling finished with dry plaster

General idea of dry plaster

In the classic version, leveling mixtures are presented in the form of a ready-made solution. For their preparation, gypsum, cement, lime and solid filler were used. As a rule, it was purified river sand. Today, manufacturers supply ready-made powdered formulations to trading platforms, to which it is enough to add clean water in the amount recommended by the manufacturer. There is information about this on the packaging.

Sheet plaster - what is it? The second version of the finished product is presented in the form of durable solid sheets. Drywall is in greatest demand. These are sheets with a hard core based on gypsum, wrapped in a paper shell.

The latter acts as reinforcement so that the products do not deform during transportation and installation. Additionally, cardboard provides protection against mechanical damage and moisture penetration.

What will you need to prepare?

To start preparing plaster, you will need to prepare the following equipment and components:

- Container for preparing the working solution.

- A screw attachment for a drill, called a mixer.

- Drill powered by electricity.

- Materials for creating a plaster mixture.

- Warm water.

- Overalls to protect the skin - suit, gloves, boots.

- Eye and respiratory protection - goggles, respirator.

The mixing process creates a lot of dust, so it is necessary to use personal protective equipment.

Pros and cons of sheet material

Leveling sheets are used in construction without adding water or other solvents. This allows you to calculate the total weight of the structures being erected, as well as the load exerted on the base, before installation. This will allow you to think through the situation in advance with strengthening the support part, if necessary.

From the point of view of carrying out repair work, craftsmen note the following advantages of the material:

- simple cutting and processing (it is enough to have a construction knife with replaceable blades on hand);

- easy calculation of expenses (there are practically no leftovers, since surpluses can also be used);

- short period of time for covering walls and ceilings (no technological break is required to gain strength of the leveling layer).

The dimensions of dry plaster depend on the purpose of the paintings. The thickness is 0.65-1.25 mm, the height is 2.5-2.7 meters, and the width is usually 1.2 m.

Also, using plasterboard simplifies the process of laying hidden utilities: electricity, plumbing, ventilation. In the case of installing a support sheathing, it becomes possible to provide additional thermal and acoustic insulation.

The disadvantages mainly include the fragility and low load-bearing capacity of the material. This does not apply to the canvas as a whole, but to the local use of the coating for hanging household appliances on it. For heavy devices, it is necessary to strengthen the frame under gypsum board or form seats on a rough base. The sheet itself crumbles easily in the places where the fasteners are immersed.

General information

So, we figured out what dry plastering is. Naturally, it contains gypsum, which accounts for 93 percent of the total material. There is cardboard or paper on both sides of the gypsum layer, so the material does not crumble or crumble. In addition, dry gypsum plaster includes starch and organic substances, which improves its properties.

The main advantage of drywall is its versatility, as it is perfectly suited for subsequent finishing with a variety of coatings. Most often, decorative plaster, wallpaper, tiles, etc. are used for these purposes. .

Finishing moisture-resistant drywall with tiles

In addition, dry plaster has other advantages, among which are:

- The material is environmentally friendly, as it does not contain harmful substances, including the release of toxic elements during combustion.

- Flame resistant.

- Excellent sound insulation qualities, since the gypsum layer has an increased density, due to which it dampens sound waves.

- Wall finishing is much faster and easier than with traditional plastering.

- Low cost of finishing, especially considering that with traditional plastering with high-quality mixtures, the consumption of dry plaster per 1 m2 is 8-10 kg with a coating thickness of about 10 mm.

Drywall

Advice! An excellent finishing option is decorative bark beetle plaster, which can look harmonious in almost any interior.

Of course, this option for wall decoration also has some disadvantages:

- The material is not strong enough, as a result of which furniture and household appliances cannot be attached to dry plaster.

- Even moisture-resistant panels will not be able to withstand exposure to water. Therefore, in the event of flooding from above, the apartment will have to be renovated.

Installation methods

There are only two ways to fix drywall: frameless or lathing. The method is selected depending on the general condition of the rough wall or ceiling. The list of tasks pursued by the master is also considered: carrying out insulation work, laying communications, camouflaging architectural elements.

Frameless

The supporting lathing is excluded when only surface leveling is pursued. In this case, the base has minimal deviations relative to the plane.

More often, this method is relevant in the case of an old foundation, where the walls need restoration and strengthening. The use of plasterboard allows you to reduce the time required for restoration work and reduce costs.

To fix plaster sheets, it is permissible to use various materials:

- Hardware. A hole is drilled in the base and a dowel is inserted into it under the self-tapping screw.

- Solution. There are specialized mixtures and various adhesives for attaching rigid sheets to walls. Plaster is less commonly used for finishing mineral substrates. When peeled off, the result is less durable, so this approach is acceptable for small areas that will be minimally exposed to mechanical loads. For example, these could be slopes.

- Polyurethane foam. It is better to use foam glue. The main thing here is that the action of the material is aimed at filling voids, and not at expanding. Then the risk of sheets bursting will be reduced to zero.

The first option is good in the case of fragile previously plastered walls with wooden sheathing. The other two are more relevant for stronger foundations, since additional load will be exerted due to the solutions. There is a risk of sheets of dry plaster peeling off, especially with heavy cladding (tiles, porcelain tiles, artificial stone).

Frame

To cover walls with plasterboard, a support frame is required. The canvas is considered a durable material, so it is planned to dismantle it after a long time. Based on this, the sheathing must match or exceed the service life of the leveling finish.

It is permissible to use wooden beams if they are dry and impregnated with special antiseptics. A more practical alternative is metal profiles made of galvanized steel. They are stronger, last longer, cope with loads better, are inert to biological and chemical reagents, and do not burn.

The frame method of fastening takes longer and is more expensive. But there are more advantages here than with the first method. It is possible to finish any structures without the use of temporary supports. It is permissible to change architectural forms, create partitions, hide communications and beams.

Attaching to a brick wall

Mark where the fastening will be. Drill with a Pobedit drill bit that matches the diameter of the dowel. Wrap a piece of tape around the drill bit to mark the desired hole depth.

The tape is not needed if the drill has an adjustable stop-limiter. Drill until the fence touches the wall.

Select an anchor that matches your screw and insert it into the hole flush with the wall. If necessary, hammer it in with a hammer.

fastening to a weak surface

Insert the screw through the hole drilled in the object to be attached, insert it into the mouth of the dowel and screw it in until it stops.

You can use extended dowels for frames. In this case, drill holes in the wall through the wood. Then insert the dowels and tighten the screws.

Types of factory mixtures

Powdered mixtures are the product that must be used for leveling mortar. Mix the composition of the dry plaster mass by adding water in the proportions specified by the manufacturer. It is recommended to bring the mixture to a homogeneous state using a construction mixer. It is often necessary to re-mix after a few minutes. This time is necessary for the binder to dissolve better in water.

Plaster

Gypsum is a product of natural origin. It is characterized by good water absorption and rapid hardening. The dry residue has high strength.

It is possible to provoke the formation of rust on metal objects.

Dry plaster mixture is used for interior work. It is recommended to level walls and ceilings in heated rooms with low levels of relative humidity. The solution is mixed in small portions, since the working time of the mass is about 15-20 minutes.

Limestone

Based on a lime binder, as a rule, two-component plaster is made with the addition of cement. The material is recommended for use inside a building, but it can be applied to facades with a mineral composition. Compared to its plaster counterpart, more time can be used to adjust the layer.

A notable property of the lime mixture is its good adhesion to the surface being treated. Compared to other dry compositions, this relatively inexpensive material retains heat in a room better and has high vapor permeability, which has a positive effect on the microclimate in a house or apartment.

Masters additionally note two points: elasticity and resistance to heat.

However, there are also noticeable disadvantages. These include relatively low strength and moisture resistance.

Cement

The basis of plaster with this binder is also sand. Additionally, to increase plasticity and adhesion, the composition contains functional additives.

According to its properties, the mixture belongs to the group of universal building materials. It is used equally often indoors and outdoors under a wide range of operating temperatures and relative humidity.

The main advantages of cement plaster are moisture resistance and high strength. You can work with the solution for more than an hour, so batches are made as needed immediately in a large container.

Against the background of significant advantages, it is worth noting the noticeable disadvantages of the mixtures. The applied mass dries longer than analogues (1 cm can take over 48 hours, a layer of 8 cm can take about two weeks). It is difficult to level a smooth surface with the composition, since the sand mixture does not have time to contact the base and crumbles.

How to prepare the solution

The solution is prepared in accordance with the instructions, which are detailed on the package with the dry mixture. Most often, two recipe options are offered: per bag and per 1 kg of dry powder.

To do this, you will need a spacious container (basin or bucket) and a drill with a mixer attachment. It is not recommended to mix components with water manually; undissolved particles may remain, which will create unevenness when applying the mass.

Proportions of components for plaster

| Cement-sand | Mortar | ||

| Component name | Qty | Component name | Qty |

| Cement M-400/M-500 | 6 kg | Lime | 6 kg |

| Sand | 18 kg | Water | 12 l |

| Lime dough | 3 kg | PVA glue | 0.9 l |

To impart plasticity to the cement composition, it is recommended to add a plasticizer to the solution. Liquid soap or dishwashing detergent works well for this function. No more than 3% of the total volume is added to the plaster.

Lime mortar is highly plastic due to the physical properties of lime, so there is no need to enrich it with a plasticizer. Sometimes PVA glue is added to the composition to increase adhesion (no more than 5%).

Consumption is calculated taking into account the curvature of the surface. When the vertical deviation is up to 20 mm, the layer thickness is formed from 6 to 20 mm. According to average calculations, it turns out to be 13 mm. For 1 m2 you will need 15 kg of plaster (or one bag per 2 m2).

Application technology

The dry mixture is poured into a working container, the recommended amount of water is added, and everything is mixed with a mixer until smooth. Minor differences in the surface are filled using a trowel and a façade spatula. To form a large layer, the plastering process includes several steps:

- the foundation is prepared;

- beacons are installed;

- using a ladle or trowel, the surface is sprayed/primed with a solution;

- fill the voids and remove excess mixture using the rule;

- cover the rough finish with a finishing layer using spatulas or trowels.

Often, novice craftsmen make mistakes in relation to cracks, weak areas and the thickness of the leveling layer. It is important to pre-embroider the first ones, hammer them with mortar and secure them with a mesh. The latter must be eliminated so as not to cause a destructive process, the detachment of a new composition. If it is necessary to exceed the plaster layer allowed by the manufacturer, then it is necessary to carry out intermediate reinforcement with fiberglass or metal mesh with cells larger than 5x5 mm.

Formulation options

Plaster varies in composition and characteristics. Next, we will analyze in more detail individual construction plaster mixtures and the conditions for their use.

Putty based

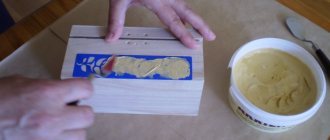

Almost any putty is suitable for preparing plaster at home. The exception is oil, as it does not meet the plaster requirements.

Putty based

Compound:

- Putty – 6 kilograms.

- Water – 2 liters.

- PVA glue – 200 grams.

Preparation:

- Prepare a suitable container to mix the solution.

- Pour in the mixture.

- Dilute the contents with water in a fine stream, stirring constantly to avoid the formation of lumps.

- Lastly add PVA glue. If there is no glue, replace it with drywall grout.

- Stir until a homogeneous mass is formed.

With primer

As the main material, as in the previous version, putty is used in a ratio of 3:1.

Compound:

- Putty – 9 kilograms.

- Primer – 3 liters.

- Grout – 200 grams.

- Color – added depending on the required saturation.

Preparation is carried out in the same way. The only difference is that instead of water, the mixture must be diluted with a primer. This type of plaster is used for decorative surface decoration. Therefore, the primer is used in an exceptional white color to prevent loss of quality of the selected shade.

Cement

Used as a basis for further finishing of the wall surface. There are three types of cement plaster:

- Cement-sand. Consists of cement, sand, water. Perfect for protecting walls in rooms with high humidity. It can also be used for cladding facades or interior decoration.

- Cement-lime. The difference lies in replacing water with milk of lime.

- Cement-clay. Used for finishing interior walls of rooms with moderate humidity.

Ratio of components in cement plaster

To prepare various types, compositions differing from each other in the ratio of components are used. So, to spray the surface of the walls, a ratio of 1:4 is required, the surface is primed with a solution in a ratio of 1:3, and the finishing coating is done with a steep solution - 1:2. First, mix the dry ingredients, then add water or milk of lime. The result should be a mixture with the consistency of sour cream.

Clay

Clay plaster is divided into several types:

- Clay-sand. Mainly used for finishing wooden buildings.

- Clay with the addition of sawdust, wool, felt and other materials.

- Clay-sand with the addition of fibers. It is distinguished by its ability to retain heat indoors.

The main components of clay plaster are sand, clay and water. Based on the type of work, compositions with different ratios of components are made. So, to prepare a mixture for outdoor use, you need to mix the components in a ratio of 0.2:3:1.

Clay mortar

With lime

There are three types of plaster using lime:

- Lime-gypsum mortar. Used for finishing decorative coating. Gypsum affects the setting speed of the solution. The ratio of components is 1:4, where the smaller number is dry gypsum powder.

- Lime-clay. To create plaster you will need: clay - 1 kilogram; lime dough – 0.5 kilograms; sand – 3-6 kilograms.

- Lime-cement mortar. Created in a ratio of 1:1:5. The composition is represented by a lime mixture, cement and construction sand.

Plaster

Preparation of gypsum plaster requires the presence of dry gypsum.

Compound:

- Gypsum powder – 6 kg.

- Water – 2 liters.

- PVA glue – 200 grams.

Advice! If you plan to carry out rough plastering of the walls, then add sawdust to the composition. The suggested ratio requires 1 kilogram. Larch sawdust is not suitable for use.

Venetian

Preparing Venetian plaster will require considerable effort. This material consists of marble, malachite and quartz chips. Slaked lime is also added in a proportion of 50-60% of the total volume and the color shade required to create a decorative layer. The resulting mixture should resemble batter in consistency.

Example of "The Venetian"

Versailles

Not everyone can afford ready-made Versailles plasters, but they can be prepared using more affordable components. For this you need:

- Finishing putty. This type is recommended, differing in the content of fine elements.

- Plasticizer. Necessary to extend the setting period of the composition.

- Dyes. They can be added to the working mixture or applied directly to the finished surface.

- Fillers. This category includes sand, stone chips, shells, fibers, and glass beads.

Versailles

Which option should you prefer?

The choice of leveling plaster is determined by a number of factors.

If you need to hide a lot of communications, carry out a quick finish, and do not plan to hang heavy objects or household appliances, then it is better to choose drywall. Ceilings with large differences and bases that are weak in terms of strength are also better sheathed.

Mixtures for preparing solutions do not require additional materials. They fill all voids, create a monolithic coating, and have high strength and load-bearing capacity. When the differences are small, it is more profitable and expedient to use powdered formulations.

Useful tips and tricks

Only a correctly completed process of preparing the mixture will allow you to obtain high-quality wall coverings. To do this, follow these tips:

- Knead only in clean containers. The presence of an old solution will reduce the quality of the mixture produced.

- The consistency should be creamy. Otherwise, there is a risk of reducing the adhesive properties of the material.

- If the water balance is disturbed, the solution will tear or violate the designated shape.

- When purchasing components, look at their expiration dates.

Decorative plaster in the interior - photos and ideas

It is difficult to think of a situation, room or style for which it would not be possible to find a suitable collection of decorative plaster.

Furniture handles (70 photos): types, materials

What plaster should I use where?

Recommendations for what solution to use for plastering walls with your own hands in different rooms and different surfaces:

| Room | Material |

| bathroom | cement plaster |

| facade plaster | cement |

| kitchen work area | cement |

| bedroom, corridor, living room | gypsum, cement |

| interior ceiling decoration | only plaster |

| ceilings balcony, loggia, bathrooms | cement |

| in damp, poorly heated rooms | I recommend cement or lime plaster |

| basement with very crooked walls | mortar |

| alignment of the façade plinth | mortar |

| slopes inside | plaster |

| slopes outside | cement |

It is better to sheathe the ceilings of the balcony, loggia, and bathrooms with something. Insulate the ceiling of the balcony and cover it with cement plaster. In bathrooms, you can safely use moisture-resistant gypsum plasterboard on the ceilings. Moreover, it is easier to prepare drywall for painting. It is often called dry plaster. Bedroom, corridor, living room - if the budget is not high, then everything else is cement (except for the ceilings). If the budget is a little higher, then the residential part of the premises is gypsum plaster

These are purely my recommendations, and I use these principles to select a solution. It is impossible to say unequivocally which plaster is better, each for its own purposes. Hope this helps you.

Which plaster is better for leveling walls, gypsum or cement? The conclusion from all of the above is that it is impossible to say which plaster is better. Because each mixture is for different purposes and has its own advantages and certain properties.

Decorative materials

plastering of walls along beacons using decorative materials helps to hide minor construction defects.

Flowers on the wall - tips for using flowers in interior design. Beautiful combinations and interesting design options (85 photos + video)Wallpaper combination: modern options and rules for use in the interior. 105 photos and videos gluing master class

Purple walls - beautiful ideas for using purple and recommendations for choosing combinations (95 photos + video)

These mixtures are actively used to decorate surfaces, giving them different textures and structures, emphasizing the aesthetics of wall decoration in different rooms and functional spaces.

Venetian

To carry out surface treatment processes, a special mesh is used for plastering walls, which ensures reliable fastening of the material.

These mixtures from different manufacturers are applied in several layers and help to reproduce on the surface a perfectly even coating or texture of various materials.

Technical characteristics of plaster

Here we will talk about the main properties and characteristics of different types of plaster. Consumption, layer size under different conditions, drying time and much more.

Plaster consumption

Consumption:

- The average consumption of gypsum mortar is 9 kg per 1 m2 with a layer thickness of 1 cm. The cost of 30 kg is approximately $6

- The average consumption per square meter of cement composition is on average 15 kg with a layer thickness of 1 cm. The cost is approximately 25 kg - $2.5

- Consumption of lime material per 1 m2 is on average 12 kg with a thickness of 1 cm. Cost 35 kg - 1.5$ Cost of cement for a bag of lime - 0.5$

I think it will be useful for you to know how much plaster costs, at least approximately. In terms of price, it’s up to you to decide what is more profitable for you and what is more convenient to work with for this price. But as for the choice, I will help you come to this conclusion now. And so, you must decide what work is being performed and where, what your budget is (low, average or above average).

Minimum and maximum layer

| material | minimum layer |

| gypsum rotband knauf | 5mm, in practice 2mm |

| cement plaster | 5 mm, in practice 3 mm |

| Lime plaster | 10mm |

| material | maximum layer |

| gypsum rotband knauf | 50mm |

| cement plaster | 20 mm < reinforcement required |

| Lime plaster | 7 cm with reinforcement |

Shelf life of plaster

If stored correctly, the shelf life of the dry gypsum mixture is 6 months. As for cement, practice shows that if stored correctly, it does not lose its properties for a very long time. But if it has absorbed moisture from the air and become hard in the bag, then you can safely throw it away.

How long does it take for plaster to dry?

Gypsum begins to set in 45-60 minutes if you mix it correctly in clean water. Complete drying occurs after 2 weeks. The cement mixture on a brick wall with a 2 cm layer begins to set after 4 hours. Lime plaster can set differently depending on the amount of cement in the mix. It may set in 30 minutes, or maybe in a couple of hours. How long does it take for plaster to dry before applying putty? You can continue work after complete drying and visual evaporation of moisture from the leveled surface. But complete drying and hardening of cement and lime mortar occurs after 1 month.

The drying of plaster mortars directly depends on the humidity and temperature in the room; as a result, the drying time may vary.

Storing material on the balcony

It is not recommended to store dry mixture on the balcony for two reasons:

- At night, the temperature drops, and in winter, storage conditions in general are greatly violated.

- high humidity or excessive dry air.

The material should be stored in bags strictly according to the instructions indicated on the packaging. By the way, I also don’t recommend storing it in the basement for a long time. In general, I do not recommend storing leftover material and storing it. There is a very high probability that the remains will have to be thrown away over time.

Textured

Beautiful and easy-to-use textured plaster for walls allows you to imitate different textures when treating surfaces in the house with it.

The level of relief and texture of the coating depends on the fillers included in the textured plaster, which makes it possible to imitate the pattern of stone and wood on the walls.