Polymer plaster is a dry construction mixture that is used to eliminate defects and decorate the surface. It is applied in a thin layer to the prepared area. The main difference between a polymer composition and a simple one is that the former is used for finishing walls. After its application, the surface does not need to be painted.

Types of polymer plaster by area of application

Dispersions of epoxy resin, acrylic or polyurethane are used as a binder component in polymer mixtures. A water-based solution is considered universal. It can be used for interior and exterior work. Compositions with any other solvent are used exclusively for exterior finishing.

Polymer facade plaster is divided into several types depending on the purpose:

- acrylic solution is used for finishing polystyrene foam insulation;

- base - styrene-butadiene, styrene-acrylic or polyurethane based;

- walls - styrene-acrylic or acrylic binder;

- mineral wool coatings - siloxane.

Recipes for making wood putty

If there is no store-bought mixture available, it is quite possible to make it yourself from available ingredients.

PVA and chalk

The simplest option for preparing putty is this. Combine crushed chalk and PVA glue to form a mass similar to thick sour cream. When large cracks need to be repaired, it is worth introducing some small sawdust into the mixture.

Varnish and chalk

In this recipe, water-soluble acrylic varnish is used instead of PVA, so the product can even be used to treat furniture and doors. Pound the chalk, pour it into the varnish in portions, mix thoroughly until a thick mass is obtained. If necessary, add a color of the desired shade.

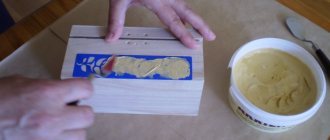

Preparation of putty mixture from varnish and chalk

Sawdust, chalk and nitro varnish

Mix equally the finest sawdust and crushed chalk, dilute the mass with nitro varnish. Due to its pungent odor, this putty is used only for exterior work.

Oil putty

The composition of this material is more complex. Take 280 g of linseed oil and 60 g of turpentine oil, 20 g of gelatin and casein each, 30 g of pumice powder, 18 g of ammonia 18%, 12 g of borax. First, the oils are combined with pumice, 300 ml of water is added and the mixture is heated in a water bath. Add the remaining ingredients. After the mixture reaches the consistency of a paste, remove it from the heat, allow to cool and use for its intended purpose. Apply this putty within an hour, otherwise it will harden.

Preparing putty from oil in a water bath

Modern wood putties are of high quality and durability. They eliminate various defects and solve a lot of other problems and tasks, therefore they are recommended for use to protect any wooden structures.

vote

Article rating

Reasons for the popularity of the material

The use of various chemical compounds helps improve the physical properties of the construction product and improve the quality of its adhesion to the surface.

Polymer plasters have many texture and color options, so they are well suited for finishing work. Used for processing concrete, plasterboard, cement-sand bases. They are often used for finishing basements and facades, as well as for interior decoration of walls of houses, administrative buildings, and public premises.

Experts highlight the following positive properties of the solution:

- frost resistance;

- elasticity;

- vapor permeability;

- water resistance;

- resistance to mechanical damage;

- durability (up to 20-25 years);

- rapid strength gain;

- solidity of the coating;

- environmental safety of the material.

The disadvantages include the following:

- high price (compared to simple mineral compositions);

- the surface requires preliminary preparation;

- the solution is sold only in finished form;

- Open packaging with the mixture is not stored.

Experts note that the advantages of the building material outweigh all its disadvantages.

Modified compositions for facades

Once upon a time, they used materials that were at hand for exterior decoration. If the decor was poorly applied or adhered to, a new component was added or replaced in whole or in part. Thus, the solution was improved.

Today, when there are substances available that can improve the technical characteristics of plaster, some experiments are also being carried out. This is the modernized composition for finishing the facade.

Cement-lime

This option is suitable for finishing surfaces made of:

- wood;

- bricks;

- concrete;

- buildings with complex geometric patterns in architecture.

The plaster has antifungal properties because it contains lime. Often used for rough leveling of both facades and interior walls. Passes steam well. The level of strength is not so good, but a nail driven into the wall will still hold up and cracks will not appear.

Polymer-cement

The cost of such a composition is quite small, therefore it is considered a budget option. To improve technical characteristics, a small amount of polymer material is introduced into the cement-sand composition.

Thanks to this, the plastered surface perfectly transmits vapors from the interior. Plus, you don't have to worry about the trim catching fire. Polymer cement plaster has excellent heat resistance.

Cement-ceresite

Professionals claim that this option is an improved lime plaster. In addition to the lime itself, ceresite also includes:

- ammonium salt in the form of an aqueous solution;

- ammonia;

- oleic acid.

These components can significantly improve absolutely all technical characteristics. In addition, moisture-repellent properties are improved. But such a solution does not adhere well to the base and the previous layer. Therefore, during work, be sure to use primers that increase adhesion and be sure to apply thin layers.

Classification

Depending on the purpose, the finishing solution is divided into special and decorative.

Depending on the type of solvent, the composition is:

- resin-soluble - epoxy or polyurethane (used only for outdoor use);

- water-soluble - PV-acetate, styrene-acrylic and butadiene-styrene (universal).

Depending on the base, plaster can be:

- siloxane;

- acrylic;

- polymer cement;

- silicone.

Polymer decorative plaster

The decorativeness of the finishing layer depends on a number of factors:

- composition and color scheme of the mixture;

- filler texture (shape and size of granules);

- method of applying the solution.

The following can be used as a filler for decorative polymer plaster:

- all types of sand (river, simple, mountain or quartz);

- fragments of stones or shells (for mosaic mixture);

- artificial granules (vermiculite or expanded clay);

- stone or metal dust;

- mica;

- flocks;

- synthetic fibers.

The properties of the final solution depend on the granule fraction. Depending on their size, the plaster can be fine-grained (for example, Venetian) or coarse-grained (filler diameter can reach 5 mm).

The polymer mixture is plastic, easily applied to the surface and quickly gains strength.

Acrylic

Acrylic-based building material is universal and is used for external and internal work.

It has a number of positive properties:

- The strength and ductility of the mortar helps protect walls from the effects of impacts.

- Resistance to moisture, UV rays, frost and temperature changes ensures the durability of the finish regardless of the weather conditions in the region.

- The vapor permeability of the plaster promotes good air circulation inside the room.

- Acrylic compounds provide additional sound insulation and retain heat.

- Carrying out the work does not require any special skills.

- Large selection of textures and colors of materials.

- Dirt on the finish is easily washed off with water.

- Good price-quality ratio.

Silicone

Silicone mixture is more often used for outdoor work. It is considered to be of higher quality and more durable. Walls covered with such a solution are completely protected from moisture, sunlight, frost and cracks. Thanks to this, the surface retains its original appearance for many years.

The composition of the building mixture includes:

- additives that provide resistance to weather conditions;

- silicone resins guaranteeing durability;

- synthetic fibers and organic fillers responsible for the decorative component;

- pigment that forms the color spectrum.

Dust and other contaminants are retained on the surface and do not penetrate into the finish. This makes it easy to get rid of them with plain water without the use of additional products. Additionally, the composition is enriched with components that protect coatings from mold and fungi. Thanks to this, silicone plaster can be used for finishing facades in regions with a humid climate.

The cost of this material will be slightly higher than that of other polymer compounds. However, it is fully justified by its physical properties and decorative characteristics.

Silicate

This type of plaster is based on liquid glass. It is used for exterior decoration of buildings. The finished solution hardens quickly, and application requires special skills. Therefore, it is recommended to entrust the work to experienced craftsmen.

The positive properties of the material include:

- heat and sound insulation;

- resistance to adverse climatic conditions and aggressive influence of the urban environment;

- average period of operation - 20-25 years;

- the finish does not allow moisture to pass through, but releases steam;

- goes well with shell rock and coarse concrete surfaces;

- can be applied to mineral wool and expanded polystyrene insulation;

- Dirt and dust are washed off with water without additional products.

Despite the advantages, the mixture also has disadvantages:

- when finishing walls, primer and paint are additionally used;

- low elasticity of the coating;

- the pigment fades quickly in sunlight.

Siloxane

Despite the similarity of names, silicone and siloxane are not the same thing. The first is an independent polymer material, and the second is a separate functional group. These solutions contain more acrylic. The main task of siloxane is to form a waterproof film during the drying of the finishing layer. Silicone coating does not allow moisture to pass through the entire thickness of the coating, while silicone coating does not allow moisture to pass through only along the border.

When exposed to sunlight, the protective film loses its properties and is completely destroyed after 5-6 years. After this, the coating becomes vulnerable to weather and climatic conditions and quickly deteriorates. Therefore, the main disadvantage of such material is its fragility.

Polymer-cement composition

Polymer cement plaster belongs to a number of complex and multicomponent building mixtures. The addition of polymer fibers to the composition made it possible to increase the strength, elasticity of the coating, resistance to mechanical and vibration influences, and adhesion to other materials.

The elasticity of the solution is almost 10 times lower than that of cement. Polymers simplify the application of the mixture, but increase shrinkage when strength is gained. In this case, cracks do not appear. The layer turns out to be thin, so cement-polymer plaster is used to eliminate chips, cracks, design joints and carry out restoration work.

You won't be able to make the material yourself. The mixture is sold dry. The rules for preparing the solution and consumption are indicated on the packaging.

Failure to comply with the recommended proportions may negatively affect the performance characteristics of the coating. The plaster is diluted immediately before application, since it is not stored in finished form.

Weber-Vetonit

The Weber-Vetonit division, under the auspices of the international industrial group of companies Saint-Gobain, is represented in 62 countries. In the Russian Federation, production is organized in Yegoryevsk, Arzamas, Polevsky. This allowed us to offer our products on the same terms in many regions of the country.

Materials for plastering facades are presented in three mineral versions of the basic line; two modified cement compositions that are resistant to moisture and low temperature; a couple of decorative cement-polymer mixtures for a thin finishing layer. A line of ready-made polymer plasters PAS is imported from Austria.

The relatively high price should not be viewed in a negative light.

Because the declared 75 cycles of frost resistance determine the decent quality of the coating. Which is acceptable even in the northern latitudes of Russia. The brand's products are in demand by professionals and are suitable for amateur use. Overview table of dry and ready-mixes Weber-Vetonit

| Characteristics | TT | Stuk cement | Min koroed | Pas |

| Purpose | Basic leveling of concrete surfaces for cladding and decoration. | On concrete, brick, cellular concrete blocks, over previously applied cement and lime-cement plasters. During the cold season. | For a decorative and protective layer on the insulation system, over the base layer of plaster. | Decoration of smooth concrete and brick bases, plaster layers, plasterboard surfaces and gypsum fiber boards. |

| Astringent | Cement | Cement | Cement | Acrylates, silicones, silicates |

| Application temperature, 0C | 5…25 | -10…25 | 5…30 | 5…30 |

| Layer thickness, mm | 5-40 | 3-20 | 2.5 | 2 |

| Consumption, kg/m² (layer 10 mm) | 17 | 15 | 3 (2.5) | 2.9-3.1 (2) |

| Viability of solution, min | 120 | 120 | 60 | 15 |

| Price per bag 25 kg, rub (packing options and weights) | 360 | 470 | 532 (bag, 20) | 3,700 (bucket, 25) |

Weber-Vetonit philosophy:

Main characteristics

Polymer plaster for facades and interior walls has the following advantages:

- vapor permeability and moisture resistance provide protection from water, but do not interfere with the natural ventilation of the room;

- resistance to frost, sudden temperature changes and other weather conditions;

- long service life;

- high adhesion to other materials;

- Impact protection.

The finishing material is sold in the form of a dry mixture and a ready-made solution. Methods for preparing and using plaster are indicated by the manufacturer on the packaging. It is not recommended to deviate from the instructions. Violations of technology reduce the durability of the coating.

Kiilto

Finnish company with a century-old history. Since 1995, the Kiilto plant has been operating in the Leningrad region, since 2000 in the Moscow region, and since 2010 in the Kaluga region.

The range of plasters consists of thin-layer, reinforced and universal dry compositions. Prices are in an affordable range. In relation to these products, domestic consumers did not express any complaints. This is a good indicator for cement mixtures with a declared 50-year frost-resistant cycle, which in real conditions require repairs after 20 years.

Kiilto mixtures can be used to insulate, rough and finely level walls.

2-3 hours of the mortar being in motion allows beginners to plaster without rushing, and professionals to work with large volumes. Overview table of Kiilto mixtures

| Characteristics | TF | TR | TT |

| Purpose | Leveling walls made of concrete, brick, aerated concrete. | Insulation, leveling and repair of foundations made of concrete, brick, aerated concrete, cement plaster. | Correction of errors and repair of plaster layers, finishing. |

| Astringent | Cement | ||

| Application temperature, 0C | 5…30 | ||

| Layer thickness, mm | 5-25 | 2-30 | 2-10 |

| Consumption, kg/m² (layer 10 mm) | 18 | 14 | 14 |

| Viability of solution, min | 120 | 180 | 180 |

| Price per bag 25 kg, rub (packing options and weights) | 160 | 210 | Negotiable (bag, 30) |

Report from Kiilto's festive event:

Technology of applying polymer plaster

Plastering work is carried out at a temperature of +5…+30°C. The walls must be protected from wind, precipitation and direct ultraviolet rays. Optimal air humidity is no higher than 75%. The application technology depends on the decorative features of the selected material. Before starting work, the surface is primed and leveled. After this, a uniform base coat is applied using a trowel. Its thickness depends on the size of the filler. The larger the fraction, the thicker the coating will be.

When the base dries a little, apply a second layer with a spatula and create the desired decorative effect. Finishing, such as varnishing, is carried out only if required by the technology. In most cases it is not needed.

How to prepare the solution

Before application, the finished composition only needs to be mixed. In most cases, you cannot add water to it, because... it will destroy the polymer bonds, and the material will last less than the manufacturer claims. But if the mixture is too thick and difficult to apply, you can dilute it with liquid (no more than 10% of the total volume of the solution).

If you purchased the plaster in dry form, then it must be diluted in accordance with the instructions. Violation of proportions can negatively affect the quality of the coating. The dry powder is mixed with liquid until a homogeneous mass is obtained and left for 15-20 minutes to form a crystalline network. Then the composition should be mixed again.

How to prepare the surface

Polymer plaster for interior work is applied exclusively to the prepared wall. Before finishing begins, the previous coating (wallpaper, varnish, paint, etc.) is removed from the surface, the brick seams are unstitched, and a mesh of reinforcement is attached to the wooden panels. Chips and cracks are covered with cement mortar.

Grease stains, fungus, mold and rust are treated with special products, and dust is removed. After this, the wall is primed and left to dry completely for 24 hours.

Applying plaster yourself

Decorative plaster is applied with a spatula. Its width is selected depending on the area being processed. Experts recommend choosing tools that are comfortable to hold in your hand and do the job with them. The solution is applied in a thin layer. Most often, the fraction of components does not exceed 4-5 mm. The thinner the layer, the less risk that the coating will begin to peel off over time.

Caring for fresh coating

In order for the material to last for the number of years stated by the manufacturer, it is necessary to strictly adhere to the technology for applying façade polymer plaster. Fresh finishes must be protected from direct sunlight and drafts. These factors will contribute to drying too quickly and, as a result, severe shrinkage. This can cause cracks and chips. If the layer dries unevenly, the color of the coating will be uneven, with streaks and spots.

After facade finishing work, you need to ensure that no moisture gets on the surface during the first 24 hours after application. Rain can wash away the plaster layer, which will shorten its service life. To protect the coating from adverse climatic influences, it is recommended to take preventive measures, for example, covering the walls enclosing scaffolding with film or other special material.

It is important to remember that with high humidity, it will take longer for the composition to harden. This must be taken into account when planning further finishing work.

Putty process

Before carrying out construction work of any complexity, it is necessary to ensure compliance with safety precautions and protect your hands and face. It is advisable to clear the room of unnecessary objects and furniture; if this is not possible, experts recommend covering all things with polyethylene. To prevent dry hands, you need to wear gloves and protect your face with a high-quality respirator. In order for this process to go quickly and without problems, it is necessary to prepare in advance the necessary tools for work and subsequent cleaning:

- broom, bucket, washcloth;

- primer and wood putty;

- brush, trowel, roll of sandpaper, scraper, spatula, steel wire brush.

Manufacturers

On the building materials market you can find polymer decorative plaster for external and internal work from domestic and foreign manufacturers. Russian-made solutions will be cheaper than their European counterparts. But in order not to make a mistake with quality, it is recommended to give preference to branded products.

Among the Russian companies, the following companies are distinguished, whose products are not inferior in quality to their foreign analogues:

- "Osnovit";

- "Terracotta";

- Perel.

Among European manufacturers, experts prefer the following brands:

- Knauf;

- Decorazza;

- Bergauf;

- Seresit.

Often, after opening branches, foreign companies organize subsidiaries that produce similar products under a different brand. The cost of such plaster will be cheaper without losing quality.

Glims

The result of more than 20 years of presence of GLIMS-Production JSC on the Russian market should be considered a developed scientific and production base and a range of building mixtures, without which the construction and finishing of the facility is impossible.

External plaster mortars are represented by dry mixtures: a troika of cement and a decorative cement-polymer composition. A limited range of modifiers, responsible for the working time of the solution and the resistance of the finished layer to external influences, brings GLIMS plasters into the middle price category. In the climatic conditions of central Russia, local cracks, without peeling off the coating, appear after 10 years and are repaired without problems.

The finished coating’s adhesive properties are not inferior to expensive analogues, which is why “Glims” is in demand by professionals for fulfilling budget orders.

And because the mixtures are mixed quickly and without lumps, they are easy for beginners to work with. GLIMS Product Overview Table

| Characteristics | Tweed | VeluR | CS 50 | PRO DMF |

| Purpose | Leveling brick and concrete walls; repair of the plaster layer. | Leveling and thermal insulation of block and brick masonry, walls made of slag and expanded clay concrete. | For facades made of any mineral materials, acceptable for manual and mechanical application. | Finishing of prepared facades with a thin layer with a “bark beetle” or “fur coat” texture. |

| Astringent | Cement | |||

| Application temperature, 0C | 5…30 | |||

| Layer thickness, mm | 5-20 | 5-35 | 3-40 | 2 |

| Consumption, kg/m² (layer 10 mm) | 12 | 8-9 | 14-15 | 3 (2) |

| Viability of solution, min | 120 | 240 | 180 | 240 |

| Price per bag 25 kg, rub (packing options and weights) | 318 (bag,20) | 424 (bag,30) | 303 | 696 |

Presentation of products from the Glims trading house:

Polymer cement mortar: areas of application and products made from it

A relatively new material has appeared in modern construction technology - polymer concrete.

Thanks to its versatility and improved quality characteristics, it has confidently supplanted traditional cement mixtures.

The whole secret lies in the polymer binder in the composition, which determines the increased strength properties of polymer concrete products.

An interesting feature is the possibility of using recycled plastics in the production of polymer concrete, and the quality of the finished material does not suffer from this.

This article will discuss the areas of application of polymer cement mortar and products made from it.

Bolix

The history of the development of the Polish brand Bolix began with the production of building mixtures for its own needs in 1991. Today, this well-known European manufacturer of insulation systems and construction chemicals works under the supervision of the Asian corporation Berger Paints India.

The product range consists of more than 10 types of products. Plaster masses are represented by mineral, polymer and mixed compositions - 6 lines in total.

In terms of coating quality, Bolix products are not inferior to mixtures of Ceresit and Knauf, but are more expensive - on average by 25%. Because they are not produced in Russia yet, only in Poland. In addition, the price changes not only by region, but also due to the economic and political situation in the world.

Bolix dry facade plasters allow professionals to work quickly and efficiently.

The working qualities of ready-made finishing solutions will also appeal to amateur beginners. Because with an extended working period it is not difficult to obtain a “professional” uniform coating. Overview table of Bolix plaster compositions

| Characteristics | MP 15 | S | SIT | DECO |

| Purpose | Protective and decorative thin-layer coatings on smooth mineral substrates. | Decorative and protective coating for mineral wool and polystyrene foam. | Design of prepared concrete walls and cement-lime plasters. | For the design of smooth and prepared mineral bases and sheet gypsum materials. |

| Astringent | Cement | Silicates | Silicones | Acrylates |

| Application temperature, 0C | 5…25 | |||

| Grain, mm | 1.5 | 1 | 2 | 2 |

| Consumption, kg/m² (layer thickness, mm) | 3.8 (2) | 2-2.5 (1) | 3.5 (2) | 4.8 (2) |

| Viability of solution, min | 60 | 30 | 45 | 15 |

Video about Bolix:

Caparol

Caparol is a brand of the German family company DAW, which has been producing building materials for over 120 years. 15 years in Russia. Here, the interests of the 5th generation of owners are represented by 10 regional representative offices, led by DAV-Russland LLC. Due to this, the group's annual turnover exceeds 1.5 billion euros.

In the category of facade plasters, there are 7 types of ready-made solutions on a water-dispersion basis, 6 options of dry composition on a mineral binder. The materials are expensive, the consumption in the description is honest, the result is impeccable.

All known problems with facade finishing layers arise from attempts to circumvent the recommended technology. For example, by eliminating intermediate priming or greatly diluting the aqueous dispersion of the solution.

Having easily understood the purpose of the composition, an amateur plasterer can ignore the shelf life and make a mistake with the consistency.

The result will be overspray and an uneven surface. It is cheaper to entrust the work with dry and ready-made mixtures that have lain for more than six months to professionals. Caparol product overview table part 1

| Characteristics | Edelkratzputz K 40 | Sylitol K 30 | Buntstein |

| Purpose | Finishing layer for Capatect A and B thermal insulation systems. | The final layer of Capatect thermal insulation. Acceptable on durable mineral coatings. | Decorative plaster for WDV or VHF systems, can be applied to prepared concrete, leveling plasters, drywall. |

| Astringent | Lime-cement | Silicate | Acrylic |

| Application temperature, 0C | 5…30 | ||

| Layer thickness, mm | 4-14 | 3 | 2 |

| Consumption, kg/m2 (layer 10 mm) | 19 | 3.7 (3) | 5 (2) |

| Price per bag 25 kg, rub (packing options and weights) | 2 500 | 4,590 (bucket) | 6,600 (bucket) |

Caparol product overview table part 2

| Characteristics | AmphiSilan | ThermoSan |

| Purpose | Decor with pebble texture on Capatect-WDV thermal insulation, concrete, cement plaster, durable dispersion paint. | For the protection and decoration of walls coated with matte dispersion, silicate plasters, thermal insulation systems made of mineral materials. |

| Astringent | Silicone | Polymer complex |

| Application temperature, 0C | 5…30 | |

| Layer thickness, mm | 1 | 2 |

| Consumption, kg/m2 (layer 10 mm) | 1.4 (1) | 2.4 (2) |

| Price per bag 25 kg, rub (packing options and weights) | 3,870 (bucket) | 8,500 (bucket, 20 kg) |

Philosophy of DAW - material manufacturer Caparol:

Types of additives for cement: features, dosage, use

In order to choose the right product for the implementation of your tasks, it is important to know the characteristics of each substance. According to GOST 24640-91, additives for cement are divided into the following types: plasticizing, air entrainers, mixture set accelerators, set retarders, sealing agents, corrosion inhibitors, antifreeze, polymer, coloring.

Let's take a closer look at each type:

Advantages

A plasticizer is a special product in the form of a powder, liquid or ready-to-use solution, which, when added to a cement mixture:

- increases the degree of elasticity and fluidity;

- increases the hardness and strength of a monolithic structure up to 125-140%;

- reduces the concentration of water in the solution by 5-15%;

- increases resistance to temperature fluctuations;

- reduces the percentage of material shrinkage after hardening;

- increases adhesion between the components of the cement mortar and with metal products;

- prevents the occurrence of corrosion formations on fittings and other elements;

- reduces the amount of cement used in mortar by up to 15%;

- reduces the likelihood of air voids;

- increases the total coverage area by reducing the thickness of the solution poured;

- improves workability and saves labor resources.

In addition, plasticizing additives make cement more homogeneous, holistic and durable. Thanks to this, the material does not delaminate, does not become covered with a “network” of cracks, and is stored longer before use.

Important! When carrying out construction work at low temperatures (-10°C and below), it is not recommended to greatly reduce the amount of cement in the solution

Types and areas of use

Depending on the effect they have, plasticizing additives for cement are divided into 4 groups:

- Super strong - capable of increasing mobility by 3-4 times and the plasticity of the solution by several levels (for example, from P1 to P6) without reducing the strength and density of the material. The product is made on the basis of sulfuric acid, 30% formaldehyde, naphthalene and sodium sulfate. Super-strong plasticizing additive for cement is suitable for any construction work: pouring, screeding, plastering.

- Strong - a substance made on the basis of acrylic polymers, inorganic salts, lignosulfonate. Strong plasticizers increase the workability of the cement mixture, increase thixotropy and plasticity by 3-4 levels (from P1 to P3). Recommended for use in molding various structures, screeds and plaster.

- Medium – an additive that increases the waterproofing properties of cement; improves resistance to sulfates and chlorides; increases the mobility of the material from P1 to P3. Medium plasticizers are traditionally used for building foundations and laying plinths.

- Weak - a product created from sodium, fluorine and potassium methyl siliconate increases the plasticity of cement by only 1 level, but at the same time significantly improves its waterproofing characteristics. It is advised to choose weak additives if you need to build small cement structures.

All classes of plasticizing additives increase the density of cement, due to which it conducts heat better (especially important when used for screed under heated floors).

Garden decor, gutters and other products

Many decorative elements on a personal plot are cast from a cement mixture. However, their service life is not quite acceptable. Temperature changes, wind, rain and aggressive environments (fertilizers, etc.) negatively affect the properties of concrete. Here polymer concrete can also come to the aid of gardeners.

Decorative elements and stones, glitters and pigments can be additionally added to the composition to give a certain effect. By skilfully selecting gravel and dye, you can obtain a structure close to natural stones.

Polymer concrete has the advantage of being easy to work with. Processing natural stone is more labor-intensive and, accordingly, more expensive.

These elements made from other materials wear out quickly and need to be replaced regularly.

The introduction of resin and reinforcing plastic fillers significantly strengthens these structures.

In addition, monuments are often made from polymer concrete. Due to the properties of the material, they have a long service life without deteriorating from exposure to the sun, rain, frost and other climatic conditions.

Unis

The Unis group of companies, the largest domestic manufacturer of building materials, has been present on the market for almost a quarter of a century. The product list includes 90 items of goods, and the research and production potential allows us to ship 2,500 tons of products daily to different regions of Russia.

Facade plaster is offered in three dry versions: basic line; a range of glass fiber reinforced mixtures; decorative compositions for creating textured thin-layer surfaces.

Pros: average price and good performance characteristics of the solutions. Disadvantages - inclusions of metal particles that stood out as rusty spots as the plaster set; an abundance of counterfeit goods in the form of a cement-sand mixture with an unpredictable proportion of both components.

Issues with spot rust on the layer were resolved by the manufacturer after the first complaints.

Counterfeits still have to be detected by packaging with a non-original design. Best of all, professionals will handle the choice and possible shortcomings. An amateur without experience working with decorative compositions based on white cement can make many mistakes. Overview table of Unis mixtures

| Characteristics | Silin façade | Silin reinforced | Unis decor |

| Purpose | Leveling walls made of mineral materials. | Repairing cracks up to 60 mm deep, filling joints, leveling masonry. | Finishing textured finishing of prepared surfaces. |

| Astringent | Cement | Cement | White cement |

| Application temperature, 0C | 5…30 | ||

| Layer thickness, mm | 5-30 | 2 | |

| Consumption, kg/m² (layer 10 mm) | 14-16 | 4.5 (2) | |

| Viability of solution, min | 180 | 60 | |

| Price per bag 25 kg, rub. | 190 | 200 | 585 |

Video about Unis:

Polymer cement waterproofing: disadvantages and limitations

Cement and sand, which provide high strength to this waterproofing material, are also the cause of its main disadvantages, including:

- high susceptibility to cracking when processing load-bearing elements in buildings where the shrinkage process is active;

- fragility and tendency to cause crumbling cracks to appear in rooms with dry, hot air;

- the need for strict adherence to proportions in the process of preparing the working solution when using dry mixtures.

Working in accordance with the instructions and choosing a composition that is suitable for its characteristics will allow you to avoid troubles and the shortcomings of the material will not manifest themselves during the entire service life.

Bolars

Domestic manufacturer Bolars with 16 years of experience, laboratory, factory, warehouses and 5 representative offices throughout Russia. It was noted for its production volume of 600,000 tons of dry construction mixtures over the past year.

Plaster for facades is presented:

- “dry” line of 4 options for the base layer, 4 decorative and heat-insulating compounds;

- a dozen ready-made water-dispersed acrylic and silicone solutions.

All are not cheap, but this does not save them from problems. The disadvantages of demanding cement compositions arise from improper mixing and poor surface preparation. With polymer ones, there are changes in consistency, differences in undertones, and differences in grain fraction. 90% of issues can be resolved at the acquisition stage - taking into account the timing and choosing mixtures from the same batch.

It is convenient for a beginner to work with fresh Bolars mixtures.

Professionals can handle any options, even those that are slightly expired - work experience allows you to recognize substandard material by the type and consistency of the solution. Overview table of Bolars products

| Characteristics | Facade | Bark beetle | Easy Wall | Crystal, Mineral |

| Purpose | For manual and mechanical application to plaster, concrete, brick, stone and block masonry. | Finishing of prepared surfaces made of mineral materials. | For the inner layer of a façade insulation plaster system. | For plastered and putty surfaces, wood and gypsum sheet materials. |

| Astringent | Cement | White cement | Cement | polymers |

| Application temperature, 0C | 5…30 | |||

| Layer thickness, mm | 2-20 | 2-4 | 5-60 | 1-3 |

| Consumption, kg/m² (layer 10 mm) | 13-14 | 4 (3) | 2.4 | 1.5-3.5 |

| Viability of solution, min | 180 | 60 | 15 | |

| Price per bag 25 kg, rub (packing options and weights) | 220 | 480 | 600 (11.5) | 2 000 |

Video about the company Bolars: