Wooden houses are becoming increasingly popular structures; the naturalness of the material and the ability to obtain a durable and attractive coating using specialized means are contributing to the increase in the number of such structures. One of these substances is wood oil, which is recommended for all wood products. Particular attention must be paid to the choice of product; the features of oil for coating wood will be discussed below.

Features of oils for internal work, characteristics and properties

Treating wood with oil helps create additional protection; a film-like coating is obtained from moisture. However, oil for exterior woodwork differs in properties from the type for interior work. Due to various external factors influencing the material.

When working indoors, the treatment must have the following properties:

- Environmental friendliness;

- Presence of antiseptic components;

- Good coating properties to improve appearance;

- Quick drying;

- High-quality barrier against ultraviolet radiation.

Treating wood with oil helps create additional protection; a film-like coating is obtained from moisture.

Ecological cleanliness

Wood oil for interior use may not be harmful to people. This does not allow the use of surface painting compositions that have components that emit a pungent odor and are toxic. In particular, to saturate the surface, do not use substances containing white spirit as a thinner.

Wood oil for interior use may not be harmful to people.

Degree of antiseptic protection

Application of products to walls inside a building containing highly concentrated elements is also not applicable. As a standard, manufacturers write on their products what finish they are intended for.

However, not all packages may indicate this property; an example is tar oil, where the point of use only for outdoor work is not always indicated.

Application of products to walls inside a building containing highly concentrated elements is also not applicable.

Decorative effect

Wood impregnation oil not only protects, but changes the appearance of the material. Therefore, you need to choose taking this moment into account. It is better not to use pattern enhancers for the walls of the house if we are talking about the inside.

For this reason, wax is a sought after substance to cover such a surface. It is used as an additional element in impregnations. Wax is less suitable for outdoor paint; the coating will not last long.

Wood impregnation oil not only protects, but changes the appearance of the material.

Polymerization speed

How long it takes for wood to be impregnated with oil depends on the addition of special substances that shorten this process. Drying elements or other oils with a shorter drying time are used. This is important for drying at home, where exposure to ultraviolet radiation is limited, and it affects the drying speed.

How long it takes for wood to be impregnated with oil depends on the addition of special substances that shorten this process.

Selection according to wood type

Wood oil is always selected for a specific species. It is recommended to have with you a test piece of wood of the same type and quality of processing that is typical for wood trim. Test application even on small areas will help to quickly evaluate the behavior of the composition in contact with wood, as well as the decorative effect.

To begin with, all coniferous woods practically do not need to be impregnated with oil. If absolutely necessary, thick formulations applied in one layer should be used. This is due to the presence of a large amount of resins in the pores, due to which the wood loses its ability to absorb even fluid oils. Therefore, it is necessary to achieve rapid drying of the oil on the surface and in the surface layer.

Thick, saturated oils are also used when processing low-density wood (linden, alder), especially fruit species that have the most developed vascular system. There are no obstacles to impregnation with thick oil, while excessively fluid compositions will penetrate too deeply and will forever remain in a liquid state, deprived of oxygen.

A completely opposite approach is used when processing beech, birch or sycamore. Due to the high density of such wood, they are impregnated either with unmelted oil or with solvent-containing compounds. Often, when working with dense hardwoods, they are treated in a combination way: first with oils that penetrate well into the wood, and then with thick compounds with a high proportion of solids and wax.

Classification and types of oils for interior work

Why impregnate a wooden base with oil? To obtain high-quality protection and extend the durability of the material. For this, various types of oils can be used to impregnate wood; the properties obtained from them may vary slightly.

To decide which oil to treat wood with, take into account the following types of its division:

- Pure formulations, without additional additives;

- Optimized solutions;

- Using thinners in production;

- Wax or non-wax;

- With or without elements that speed up the drying process;

- Combined compositions that can immediately act as an antiseptic, primer mixture and water protection.

To obtain high-quality protection and extend the durability of the material, the wooden base is impregnated with oil.

How to avoid spontaneous combustion?

The process of oil oxidation upon contact with air is accompanied by an increase in temperature, which can lead to spontaneous combustion of oil-vapor rags, tampons, sponges, etc. Before disposal, all consumables that were used for wiping off linseed oil should be thoroughly dried in a straightened state outside the room, or better yet, soaked in water or immediately burned. To store the dispenser and other tools in contact with oil, use airtight containers.

vote

Article rating

Pros and cons of wood oil

To assess the advantages and disadvantages of specific types of oil formulations, it is necessary to study the specifics of each. There are a large number of types of funds. Below, they will be briefly described individually.

There are a large number of types of funds.

Tung oil for wood

A safe oil that can even be used for dishes and food storage. A reliable layer of biological formations is created.

A safe oil that can even be used for dishes and food storage.

Teak oil for wood

It is distinguished by its versatility of use; it can be used for outdoor and indoor impregnation. Harmless to humans. It is unacceptable to dilute the product; stir it thoroughly before applying it.

It is distinguished by its versatility of use; it can be used for outdoor and indoor impregnation.

Tar oil for wood

This natural product has been used for a long time, but cannot be applied indoors. The protective layer is reliable and durable.

This natural product has been used for a long time, but cannot be applied indoors.

Linseed oil for wood

Flaxseed oil is an affordable option that has high water resistance. The downside is the long drying time.

Flaxseed oil is an affordable option that has high water resistance.

Vaseline oil for wood

You can soak a wooden base with Vaseline without losing its natural color; it is transparent. Does not crack or change structure over time.

You can soak a wooden base with Vaseline without losing its natural color; it is transparent.

Sunflower oil for wood

Sunflower impregnation takes last place in the product rankings, due to the low degree of moisture protection and the inability to dry the surface completely. The advantage is accessibility and low cost.

The advantage is accessibility and low cost.

Mineral oil for wood

It is rarely used to cover a product with your own hands. It is usually used to coat materials used in woodworking on an industrial scale.

Polymerization does not occur, and it is also impossible to wash off the product afterwards.

It is usually used to coat materials used in woodworking on an industrial scale.

Tinting oil for wood

It is distinguished by obtaining a beautiful external surface finish and can be used for any type of wood.

It is distinguished by obtaining a beautiful external surface finish.

Danish wood oil

Can be used for different types of substrates, creating a durable barrier against moisture. The finish will be glossy.

Can be used for different types of substrates, creating a durable barrier against moisture.

Coconut oil for wood

A little-known substance that can give the material a glossy effect, emits a pleasant smell, and creates a reliable barrier from external factors.

Can give the material a glossy effect.

White wood oil

White oil makes a wooden object lighter. It is also used to create a film-like layer on the base and improve the appearance.

White oil makes a wooden object lighter.

Oil-wax for wood

If wax is applied to the product, then, if desired, the natural pattern is preserved. There are color options. The product protects the texture of the material from many harmful influences. Propolis can be added as a component.

The product protects the texture of the material from many harmful influences.

Whether it is possible to process wood by mining is a question that causes a lot of controversy.

There are both supporters and opponents of this procedure.

Wood processing pros and cons

We have already looked at the pros and cons of impregnating wood with oil; what is the difference between wood processing and processing?

Used motor oil for wood has the following advantages:

- it, like any other oil, helps protect wood from mold, rot, pests, strengthen and extend the life of wood

— at the same time, wood processing is a cheap process. Used oil costs you nothing

- treatment as an antiseptic for wood perfectly repels moisture

- prevents further destruction. Treating wood with waste oil helps stop further deterioration of already damaged wood.

It would seem, what kind of controversy could arise about the benefits of used oil with so many positive qualities?

Let's look at the disadvantages that using used oil has:

— impregnation of wood with waste material can be hazardous to human health. The thing is that used engine oil accumulates toxic and carcinogenic substances that negatively affect people's health. In addition, used oil has a persistent unpleasant odor.

— wood processing has a negative effect on the appearance of the material. The wood changes color and it is no longer possible to restore it.

— parts that are coated with waste cannot be further processed with other compounds and are difficult to paint.

- increased fire hazard. Although this is also a controversial point. Some experts argue that used oil, on the contrary, reduces the fire hazard of wood since its composition initially includes components that reduce its flammability.

What used oil can be used and what can be treated

Used passenger car oil is ideal. These are mainly oils with a mineral composition. The unpleasant aroma and harmful substances are removed from such oil in just a few days and it can be used with minimal harm. It is strictly forbidden to use oils from heavy equipment, oils that were used in an industrial area, as well as transformer and transmission oils. The content of carcinogens in such oils is simply off scale.

Processing is used to protect wood that will be used in non-residential premises. These could be garages, sheds, outbuildings, wooden fences, poles, etc. Also, processing of wood by mining will be relevant for hidden parts of the facade of the house and rough covering.

Usually, not all the wood is impregnated with waste, but only those parts of it that come into contact with the ground or are susceptible to particularly strong moisture. The remaining parts are coated with compounds that do not spoil the appearance of the tree so much.

The question of whether mining can be used for wood processing remains open. Each owner finds the answer for himself. Irina Zheleznyak, Staff correspondent of the online publication “AtmWood. Wood-Industrial Bulletin"

How useful was the information for you?

Selection of oils by type of work

This material is put under pressure by various factors, they are different, because the conditions on the street and in the house are different. Therefore, you need to protect objects with suitable elements.

You need to protect objects with suitable elements.

Interior work

The painting process inside the structure must be harmless; the substances must not be toxic. In a house, walls may be affected by humidity, temperature changes, and biological formations. Use formulations suitable for application under given conditions.

The painting process inside the structure must be harmless; the substances must not be toxic.

Exterior works

For work outside, the use of reliable products that are resistant to natural factors is required. They must have a long service life, vapor permeability, and elasticity.

For work outside, the use of reliable products that are resistant to natural factors is required.

How to oil interior wooden surfaces: detailed instructions

So, how to treat wood with oil? There are two ways to apply it - hot and cold. Both options require compliance with the same rules, the difference lies in the temperature of the oil composition. When using cold technology, the applied substance is at room temperature; when using hot technology, the composition is heated to a temperature of +80 °C. In addition, when using hot technology, the surface to be treated must also be heated using a special thermal pad, since the heated oil will not be absorbed into the cold wood and will remain on its surface.

Regardless of what technology you decide to use to treat wood with oil, the work is carried out in several stages:

- Apply the first coat of oil composition using a brush or cotton cloth. Make sure that the oil lays on the surface in a thin, even layer.

- It is necessary to remove excess composition immediately, otherwise the dried impregnation will form a crust that is difficult to remove. To remove excess oil, wipe the area with a dry cloth until the cloth no longer collects oil. If it is not absorbed into the wood, but lies on its surface, you can collect its excess into puddles using a rubber spatula, and then remove it with a rag.

- Then the surface of the wooden product is polished using a soft cloth. When finished polishing, wipe all wet areas dry with a cotton rag.

- If you decided to treat the wood with oil using cold technology, then re-application of the composition is possible after at least five hours, in some cases it is worth increasing this time to twelve hours (depending on the type of oil). A second treatment with hot oil is possible after two or two and a half hours, since its drying time is much shorter.

- Re-application of the oil composition is carried out in the same way as the initial one, but do not forget about the need to grind each layer. The number of layers is influenced by the condition of the wooden surface, the type of wood, and the type of oil. In most cases, the effect is achieved through two- and three-layer processing.

The surface will dry completely only after two to three weeks; a combination of the factors mentioned above influences the indication of a more precise period.

Review of manufacturers

The construction market offers a wide range of oils suitable for processing materials. For home processing, we can highlight: Borma Wachs, OSMO, Adler, American Wood Oil, Varathane, Tikkurila. For external ones, the following brands can be noted: Belinka, Tikkurila, Borma Wachs, OSMO.

The construction market offers a wide range of oils suitable for processing materials.

Deciding what we need from the oil

Oils for processing and impregnation of wood can be classified according to the following criteria:

- Purpose - for external or internal work, for what types of wood, only for protection or also to add shade.

- Composition - natural or synthetic, how many additives it contains.

- Drying abilities.

The following are treated with an oil protective coating:

- Wooden products used for cooking: cutting boards, spatulas, spoons, bowls, etc.

- Wooden furniture and household items that must be safe: cribs, wooden toys.

- Wooden surfaces to protect against moisture, abrasion and pests.

Therefore, the composition of impregnations varies from completely vegetable to chemical - from an industrial laboratory.

The former are safe when ingested by the human body and in contact with skin, and when working with some synthetic oils it is necessary to wear a protective mask. The manufacturer indicates precautions when working with products on the label.

To process products used for cooking, 100% tabletop vegetable oils and industrial safe high-quality impregnations are used.

All natural vegetable oils dry (polymerize) slowly - about a week, or even longer. Therefore, during construction and repairs, ready-made industrial compositions are more often used. They dry in a few hours.

The content of natural oils and other ingredients in them varies depending on the tasks: protection from moisture, pests, adding shine, etc. Thus, G-Nature natural oil contains linseed, tung oil, rosin, and wax. They can be used to process countertops and cutting boards. And Osmo UV-schutz-Ol is used for garden furniture; it protects wood from sunlight.

Natural oils harden at different times. Sunflower takes longer to polymerize than others; it is sometimes called semi-drying. And there are oils that do not dry out at all, for example castor oil.

Popular oils for interior and exterior use:

- mineral;

- linen;

- woody;

- coconut;

- from several components.

Application technologies, features and nuances

It is important not only to choose the right oil for wood processing, but also to use it correctly. Then the protective layer will be durable and will not lose its properties.

It is important not only to choose the right oil for wood processing, but also to use it correctly.

Preparatory work

Preparation begins with inspecting the surface for defects; if large defects larger than 5 mm are identified, they are eliminated. Afterwards, the product is sanded, cleaned of dirt and a primer solution is applied.

There are solutions that do not require the application of a primer; you can read about this on the packaging.

Preparation begins with inspecting the surface for defects; if large defects larger than 5 mm are identified, they are eliminated.

Algorithm for applying oil

When the primer layer dries, proceed to saturating the surface with oil products. Typically, the tool of choice is rollers and brushes. To avoid the formation of strong smudges, apply the composition along the fibers. It is acceptable to use fabric swabs to treat the surface with the composition.

To avoid the formation of strong smudges, apply the composition along the fibers.

Impregnation technologies

According to the working technology, you can choose from two methods: coating and soaking. The second technique can be performed only when working with small products. For large ones it will be difficult to find a suitable container.

According to the working technology, you can choose from two methods: coating and soaking.

Preliminary stage

With any method, they begin by removing the old layer, if any. The wooden base is sanded, cleaned of dirt and primed if necessary. Primers serve to improve adhesion and reduce material consumption.

Primers serve to improve adhesion and reduce material consumption.

Coating

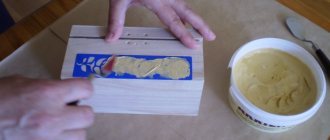

Using a brush with natural wax or a soft cloth soaked in oil, treat the entire surface with the first layer. After 15-20 minutes, excess parts of the product are removed. After drying, apply a second layer of impregnation.

Using a brush with natural wax or a soft cloth soaked in oil, treat the entire surface with the first layer.

Soaking

Soaking helps to get good soaking. Oil is poured into the selected container, into which the item that needs soaking is placed. It can remain in it for a long time; the release of bubbles can serve as a guide to the completion of the process.

Soaking helps to get good soaking.

Number of layers

Usually 2-3 layers of the substance are applied. Here it is better to look at the instructions from the manufacturer, and the condition of the surface; if it has deeply absorbed the product, then another layer is needed.

Usually 2-3 layers of the substance are applied.

Drying time

It takes at least a day for the composition to dry completely. For this reason, driers are often used to reduce the time. It is advisable to refer to the manufacturer's instructions to determine the drying time for a particular substance.

It takes at least a day for the composition to dry completely.

Consumption

To calculate consumption, you need to know the area of the surface being treated and the average consumption indicated on the packaging. The average consumption is 100 g/m2. If wax is present in the impregnation, then less substance may be needed - 75 g/m2.

The average consumption is 100 g/m2.

How to dilute

Finished products are rarely diluted, they are produced in the required consistency, they are thoroughly mixed before use and that’s it. But some tree species must be treated with more liquid substances. You can add turpentine, other oil, white-spirit.

Finished products are rarely diluted, they are produced in the required consistency, they are thoroughly mixed before use and that’s it.

Wood treatment oil will help to obtain a reliable layer from moisture and other factors. But it is important to choose an acceptable option for specific working conditions. The article described the characteristics of the species, they should help make the right choice.

Impregnation of wood at home

Let's look at this process using linseed oil as an example, as it is the cheapest and most accessible to the average craftsman. To work you will need a small list of useful things:

- natural hair brush, foam sponge, soft cloth, rags,

- oil, a stick for stirring it,

- construction hair dryer, metal brush - to remove old coating,

- sandpaper to bring the surface to a perfectly smooth state,

- broom for removing dust from the surface,

- gloves to avoid getting dirty.