What is varnish and where is it used?

Varnish is a viscous liquid that is applied to the surface of a wooden product and covers it with a thin film. It hardens over time. This substance contains resins and various polymers, which are usually dissolved in special solvents.

Looking at the catalog of the best varnishes, it can be noted that thanks to them the following problems are solved:

- the appearance of the wood is preserved and emphasis is placed on its texture;

- surfaces are decorated;

- the tree is protected from putrefactive processes and damage;

- help improve thermal insulation.

This material can be used for internal and external work. Its properties and scope of application depend on the structure. If you need to create a solid base, then it is advisable to buy an alkyd-urea variety; to protect against moisture, buy an alkyd substance, and to cover surfaces subject to heavy loads, buy an oil one.

There are 5 categories based on the degree of gloss, as can be seen from the photo of wood varnish:

- regular matte gives less than 10% gloss;

- semi-matte 10-15%;

- semi-gloss 40-50%;

- glossy 80-90%;

- super glossy over 90% gloss.

Wood oil, composition and characteristics.

The oil acts as an impregnation. Wood is a very hygroscopic material (easily absorbs moisture). After several cycles of moisture absorption and drying, the wood begins to warp and crack. To prevent this from happening, we recommend periodically treating wooden products with special oil.

Deeply absorbed into the structure of the wood, it fills the treated material with substances that prevent the penetration of dust and water, and prevents abrasion and external temperature influences. Well protects against household pollution, spilled water, juice, coffee.

In addition to its protective properties, the oil improves aesthetic properties. After impregnation with oil, the structure of the wood is clearly revealed and natural shades are enhanced. Oils contain coloring components that can completely change the original color, imitating the colors and shades of other types of wood.

The oiled surface preserves the natural texture of the wood. Thanks to natural components (beeswax and carnauba wax), the oil provides good resistance to abrasion and mechanical stress. At the same time, it dries quickly after application and has a light, pleasant smell.

The composition of wood oils includes natural oils - linseed, sow thistle, soybean, sunflower oil, tung. Or artificial - tallow.

- Sunflower oil is not used in its pure form for wood processing, as it does not dry completely. Only after heat treatment for 2-3 hours and thorough cleaning is it used as an additive in impregnating oils and oil paints. Treat fatty oils that do not dry out completely.

- Flaxseed is a quick-drying, vegetable oil. Dries quickly and forms a film upon contact with oxygen, while forming a transparent film. It is considered one of the best components for wood processing. It is not used in its pure form, only after long-term heat treatment.

- Thistle oil is a plant familiar to all summer residents and is considered a weed. Sow thistle, rich in fatty oils. It is this oil that is used as a raw material for the production of drying oil, which is used as a component in impregnating oils for wood.

- Soybean oil contains the substance lethicin, which acts as an emulsifier. This feature of lethicin acting as a wetting agent upon contact with solids allows the oil to penetrate deeply into the structure of the wood.

- Tung oil is extracted from the seeds of the tung tree. It is very toxic and is used only in the production of paints and varnishes. It has good penetrating ability, which is why it is widely used as a component of oil impregnations and varnishes. Forms a matte, wear-resistant surface. There are no synthetic analogues of this oil. Dries faster than linseed oil. The resulting water-repellent film is more durable, even with a large layer application.

- Tall oil is a by-product obtained from pulp cooking.

For interior work

By covering wooden structures indoors with liquid, you not only provide them with decorative properties, but also protect them from external influences. There are special substances for parquet and furniture, as well as universal materials.

The floor covering must be reliably protected, because it is under constant load. At the same time, you can choose the effect you prefer by purchasing glossy or matte wood varnish.

You also need to select the composition for different rooms. After all, in the bedroom the load on the parquet will be less than in the hallway or living room. Therefore, in the second case, higher quality material with additional protection will be required.

Experts also recommend selecting parquet coatings based on the degree of transparency, consistency and method of application. Parameters such as resistance to ultraviolet radiation and stress are also important. Among the substances used for flooring, primer, water-soluble, polyurethane, alkyd, and formaldehyde types are popular.

To protect furniture, high-quality and expensive analogues are used. They must maintain the natural appearance of wood. Therefore, the polyurethane type of material is most often used. It is also permissible to use oil, alkyd, acrylic and alcohol compounds.

It is important that the coating does not retain odor and that the film hardens quickly. Therefore, quick-drying wood varnish when processing furniture can be indispensable when carrying out urgent work.

Distinctive features

There are several varieties of such materials, the use of which depends on the area of application of wooden products and the requirements for their finishing coating:

| Polyurethane |

|

| Alkyd-urethane |

|

| Acrylic |

|

| Alcohol | When applied, they ideally adhere to the surface being treated, creating a durable coating that has a high degree of resistance to mechanical stress. But since the price of such compositions is not affordable, their scope of application is limited to use in the processing of musical instruments. |

White wood varnish can be applied with a brush

Preliminary preparation and working conditions

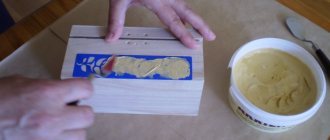

To apply the material to the surface, use a brush, roller or spray. In this case, the surface should be pre-prepared.

Tip: to achieve the desired result, the material should be applied in three layers.

Before starting work, the surface must undergo pre-treatment, the instructions are as follows:

- it is cleaned of old coating, as well as dust and dirt;

- after cleaning, the surface is polished;

- cover with a primer with your own hands, which can significantly reduce the consumption of the base material.

Tinted wood varnish Colorit

Tip: Repeated sanding after applying the primer will help give the surface an ideal smoothness.

To achieve the greatest efficiency, you need to ensure that the average air temperature indoors or outdoors is 20˚C, and the air humidity does not exceed 50%. However, each subsequent layer should not be applied earlier than every other day.

Coloring

Wood is a natural material that is easily damaged by adverse factors, which makes it very vulnerable. Therefore, products and structures made from it require increased protection, which can guarantee that they will last a very long time. One of them is varnish, regardless of whether it is colored or colorless.

Wenge wood varnish XB-784

As mentioned above, tinted material performs not only a protective function, but also a decorative one, giving the surface the desired shade. For this reason, it is not used on valuable woods such as beech or oak. For these purposes, colorless varnish, oils and other decorative and protective agents that can highlight the natural beauty of the wood structure are ideal.

Advice: since the use of tinted materials helps solve two problems at once, one of which is protection from damage, and the other is giving the wood a touch of nobility, they are used to process inexpensive species, such as pine.

Instead of paint

Gloss

In most cases, wood has a porous structure, which is characterized by good absorption. Therefore, even if you apply glossy varnish to an unprimed wooden surface, it will remain matte.

The second layer will not be absorbed as much, so the wood may receive the necessary gloss. If the structure of the material is highly porous, it will have to be applied in three or even more layers.

What colors of wood varnish are used?

If, after applying the first ball, the desired color is obtained, but there is no gloss, a colorless varnish is applied on top of this layer. In this case, the number of layers will depend on obtaining the desired degree of glossy shine.

White matte varnish for wood from Tikkurila

Texture

You can focus on the texture of the wood, that is, emphasize the natural pattern, by applying varnish to a surface that has not been previously primed. In this case, the decisive role is played by the different degrees of absorption inherent in individual sections of the tree.

The degree of absorption will significantly decrease when treating a surface coated with a primer, so this effect cannot be achieved. And if it is a colorless varnish, all efforts to provide contrast to the natural pattern on the surface of the wood will go to waste.

Color properties

- The initial color of the wood will be practically unaffected if the colored material is applied in one layer.

- However, each subsequent layer will increase the hiding power, leading to a smoothing of the textured wood pattern.

- If you use dark wood varnish, a thick layer of this material can give the same effect as paint. There may be a feeling that the desired varnish color does not match the actual one. For example, the sample indicated on the can looks as it should, but in reality, when the varnish is already applied to the surface, it may look different. This is due to the translucency of the varnish, which allows the natural grain of the wood to be visible.

In the photo - furniture varnish for wenge wood

- To obtain a lighter shade than that indicated in the sample, a thinner is used, which is the substances that make up the base of the varnish. For example, acrylic varnish is diluted only with water.

- You can get a darker shade if you apply the varnish in a thick layer. But here we must not forget that with an increase in the number of layers, the hiding power also increases.

- The final color of the varnish depends not only on the added color pigment, but also on the binders included in its composition. For example, the element added to bind alkyd varnishes is resin, which always gives the final color a yellow-brown tint. Acrylic varnishes do not have this drawback. The water included in their base cannot in any way affect the final color, therefore it always forms an absolutely transparent film.

External use

To protect structures located outside the home, a more durable coating is required. Therefore, the selected material must guarantee resistance to external weather factors and mechanical damage. They cover facades, gazebos, decking, fences, log houses, etc.

A variation of this group can be alkyd-based yacht varnish for wood. It is harmful and is used only for processing wooden ships, but not for interior work. Safer is the yacht look based on urethane-alkyd.

Water-based acrylic varnishes

This category of varnishes is considered to be the most environmentally friendly paints and varnishes. The material does not emit odors and is completely safe, therefore it is used even when decorating children's rooms.

The disadvantage of varnish is that it takes a long time for surfaces to dry:

- The varnish will finally harden a couple of weeks after application.

- In addition, it is not very suitable for outdoor use, not providing the required level of moisture resistance.

- And in terms of abrasion resistance, the varnish has not proven itself very well.

Oily

This type of paint and varnish is widely used in interior finishing work, but is not suitable for flooring. Contains oil and resin. Fatty and medium-fat mixtures perfectly cover the surface, protecting it. But materials with a fat content of less than 50% serve only the role of decorative finishing.

Increasing the amount of resin speeds up the hardening process, but this reduces strength. The color of the substance varies from yellowish to brown. Drying time 24-72 hours.

Oil or varnish?

Oil and varnish are intended to protect wooden surfaces.

They can be colorless or colored, matte or glossy. The choice in favor of oil or varnish is always based on the purpose of the room and its traffic. What is wood oil, what is it for, what does it consist of and how does it differ from varnishes? Wood oil, used for wooden and parquet floors. There is also a special category of oil used in baths and saunas. What does oil do to a tree?

For example, thematic equipment https://arbero.ru/produktsiya , for children's centers and open playgrounds, is made of wood materials. Under the influence of the environment, precipitation, temperature, sun, without special protection, these materials may soon become unusable. Special paints and varnishes will help avoid this.

Acrylic

This is the safest type of paintwork. Water-based acrylic varnish for wood is odorless and highly fire-resistant. The resulting film is not sensitive to ultraviolet radiation, but is exposed to moisture.

It is not recommended to use in traffic areas with floor loads. The time for the film to completely cure is about 14 days.

How to make the right choice of odorless varnish

Today the market offers a wide selection of paints and varnishes. In order to purchase quality products, you need to pay attention to the following points:

- Compound. This is what you should pay attention to first. Because the presence or absence of varnish odor directly depends on what components are included in the composition.

- Drying. High-quality varnishes dry quite quickly. If you need to apply two or three layers of coating, then each of them must be allowed to dry for at least two hours.

- Wear resistance. It is necessary to choose materials that are resistant to mechanical friction and damage. They must have high strength, especially if the floor is to be varnished.

- Shine. Both glossy and matte varnishes are available for sale. Both types have special advantages. For example, gloss gives a beautiful shine, and matte hides all minor damage and scratches.

- Moisture resistance. Polyurethane has the best water-repellent properties. Therefore, for rooms with high humidity, it is more advisable to choose varnishes that contain this component.

Nitrovarnishes

Such mixtures are weakly resistant to ultraviolet liquids, the use of which is limited to internal work. Can be used for processing different types of wood. Penetrate into the product and create a strong protective film.

An important advantage is the drying speed - only a few hours. The composition contains toxic solvents, so work is carried out only in a respirator.

Varnish color palette

It would be wrong to assume that the choice of varnish coatings is limited. The color palette is quite wide - from light yellow to dark brown.

A less common option is clear varnish.

- But even when applying colored varnish, the shade will be quite weak.

- To achieve a more intense color, three to five coats will be required.

- In addition, colored varnish becomes discolored over time when exposed to ultraviolet radiation.

Polyurethane

They may have a two-component structure of a base and a hardener or additionally contain a solvent. They are characterized by increased adhesion, but have a pungent odor and harden within 15-20 days. The hard film protects surfaces from moisture, corrosion and chemical components. Therefore, varnish is used to treat yachts and ships, gazebos, and parquet.

Water-based polyurethane varnishes

Such materials have become an improved copy of acrylic varnish.

They are characterized by:

- Resilience;

- Elasticity;

- Durability;

- Environmentally friendly;

- Durability.

The only downside will be the high price of the material.

Polyester

They are distinguished by their multicomponent nature; the resin of the same name is used as a base. It is applied to the surface with a special gun.

As a result, a durable transparent film is formed on the processed parts, which is particularly durable, moisture-resistant, and resistant to elevated temperatures and chemical reagents. It is used to coat objects that require a glossy effect, such as musical instruments.

We prepare oil and wax for wood ourselves.

Wax, wax solvents and colors are often added to oil. Such mixtures also have a protective and aesthetic function. Suitable for highlighting the natural structure and even simulating other, more expensive types of wood.

You can find ready-made oil and wax formulations on sale, and they are also easy to prepare yourself at home. You need to take linseed oil, beeswax and a little rosin; white spirit is usually used as a solvent. For children's furniture, wooden toys, wooden dishes, it is recommended to use just such mixtures. You can watch the video in detail on how to prepare oil-wax:

Epoxy

These are moisture-resistant, impact-resistant paintwork materials, having a two-component composition based on epoxy resin. They cover flooring, doors, and solid floors. For example, epoxy varnish for tikkurila wood is popular.

When processing wood when carrying out interior or exterior work, you should use high-quality paints and varnishes. They must be selected depending on the type of structure, operating conditions and the expected external visual effect.

What varnishes have a smell? Is it harmful to human health?

Paints and varnishes based on organic solvents are endowed with a pungent odor that causes headaches, nausea or allergies in humans. Such symptoms indicate pathological processes in the body. Paintwork materials with a strong odor are certainly harmful. Such products must be used for their intended purpose, in specially equipped rooms with fresh ventilation.

Odorless, water-based wood varnish is an absolutely safe product for humans. Water-soluble varnishes are very popular today. They are environmentally friendly and have excellent technical characteristics. The coating is aesthetically pleasing, lasts a long time, and does not crack under the influence of sunlight.

Photo of wood varnish

Various varnish shades

Oil varnish for wood is made in various shades; it can be light yellow or even dark brown. It is quite rare to buy a completely colorless, transparent oil varnish. However, even if a dark brown composition is applied to wood, its layer is very thin, so the shade is almost invisible on the wooden surface. But if you apply 3-5 layers to the structure, the dark color will be much more noticeable.

Typically, oil-based varnishes that have a yellowish or brown tint will discolor after a certain period of time as they are exposed to the sun's rays. When the oil film dries, under the influence of ultraviolet rays, the applied layer becomes almost transparent, since it is very sensitive to solar radiation. Therefore, the presence of a certain shade in an oil varnish is not a disadvantage at all.

Advantages of varnish mixtures based on drying oil

These paints and varnishes are very popular today, they are used for application to floors, furniture, and other products. Drying oil-based varnish mixtures have the following advantages:

- are environmentally friendly and safe for humans;

- are moisture- and vapor-permeable, allowing the wood to “breathe”;

- are relatively inexpensive;

- are ubiquitous;

- very simple and easy to apply;

- provide a high level of protection to wood.