- Metal grid

August 7, 2019

3840

When laying floors during renovation or during the construction of a new building, leveling of the floors is always carried out at the final stage. As a result, the top layer becomes more neat and even. To give the surface strength, you need a floor screed mesh of various geometric sizes; it is used for high-quality reinforcement.

Reinforcing mesh for floor screed has many applications. But its main industry is construction.

- It can be used when arranging ordinary floors in non-residential industrial buildings

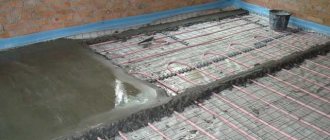

- When installing a specialized heated floor in a modern apartment or country house.

Installing a reliable screed mesh can significantly increase the service life and make the floor almost eternal.

You should choose and purchase the screed mesh correctly. It must be of proper quality. If the material is chosen incorrectly, the floor will quickly begin to deteriorate, and you will have to repeat the floor leveling procedure. This is a waste of time and money.

In this article we will look at the main features of choosing a mesh, as well as the correct laying technology.

What is a floor screed in simple words

The topmost layer of the base is called the screed. This layer consists of a high-quality concrete mixture and additional material for reinforcement (strengthening). After screeding, the surface will be quite flat, which will allow all kinds of coatings to be laid on it (tiles of various sizes and shapes, laminate or linoleum).

The main components of the screed are usually sand, cement and water. These elements are mixed in certain proportions to prepare a mixture of a consistency suitable for installation. In addition, various additives and additional components can be added to the composition, which speed up the drying process and add strength.

The number of components can be adjusted at your discretion. But it is worth remembering that sand is the main thing, it is what gives strength. If you add little of it to the mixture, the screed will begin to crack and collapse over time. To increase the strength characteristics of the floor, first a mesh for floor screed is first evenly laid out on the base, and then it is filled with concrete mixture until completely immersed.

The video shows in detail how to make a cement-sand screed, how to place beacons and pull the mortar over them. The next day, the screed from the solution must be rubbed

Fiber fiber

The principle of using fiber as reinforcement for screeds is significantly different from mesh reinforcement.

Fiber - fibers of basalt, glass, polypropylene, metal, in dry form are added to the ingredients of mortar or concrete. When the floor hardens, the fiber gives the effect of a durable monolith, protects the floor surface well from microcracks, but will not save you from significant mechanical impact.

The fiber-reinforced screed is laid and leveled along the beacons, just like concrete or mortar for other types of reinforcement.

If fiber is used simultaneously with metal or polypropylene mesh, a super durable coating is obtained.

When working with fiber, you need to add it in small portions to the mortar mixture, waiting until the fibers are completely distributed in a concrete mixer or other container. If you add all of it at the same time, the fiber can bunch up into a shapeless lump.

Reinforcing the screed is a simple way to make the floor last forever

The main purpose of reinforcement is to increase the strength of the structure, as well as improve the load-bearing capacity. Thanks to this, deep cracks will not appear on the floor surface, and bending loads will also be reduced. An increase in the strength characteristics of the screed is achieved by introducing reinforcing materials into the structure that have high strength indicators.

To screed the floor covering, two types of reinforcement are used:

- Mesh is used as the main material for strengthening. The essence of this method is that the material for strengthening is laid on a pre-prepared base and filled with cement mortar;

- Micro-reinforcement using various industrial additives. Fiber, steel filings and wire are used here.

The procedure for reinforcing the screed is not always mandatory, but on most construction sites, building codes require the laying of a reinforcing layer. With this procedure, the floor will be more monolithic, and the likelihood of cracking will be significantly reduced.

There are small cracks on any concrete surface. If you do not see them, then wet the surface a little - the cracks will become clearly visible. Such defects are not critical. The most important thing is that the entire concrete structure is single and monolithic, and not assembled from separate fragments. It is the reinforcement that ensures the integrity and solidity of the entire structure.

The mesh for pouring the floor with concrete is laid over the entire area, and after filling with mortar it turns the entire top layer into a durable slab. Under the influence of external forces, small cracks will still appear, but the mesh will not allow individual fragments to move freely. If you install quality reinforcement materials, your floor will last forever.

In some cases you can’t do without a mesh

Reinforcing screeds is a somewhat labor-intensive and financially expensive process. It is better to fill the screed without a mesh. But there are situations when it is impossible to obtain a concrete layer leveling the base with a long service life - it will crumble a few years after the installation of the floor.

Among them:

- flooring on the ground (garage, private house). In this case, layers of crushed stone, gravel or expanded clay, which are not stable, are poured under the screed. Any slight movement of the soil under the influence of frost, water and other natural factors will inevitably lead to the destruction of the floor pie;

- absence of direct contact of the screed solution with the concrete base, i.e. a so-called floating screed is made - a waterproofing film (bitumen), a layer of insulation or noise-proofing material is laid between it and the ceiling;

- pouring a rough screed;

- the thickness of the poured layer of mortar is more than 5 cm. It takes a long time to dry, as a result of which a network of small cracks appears on the surface. The reinforcing mesh for the screed prevents their further growth;

- “warm floor” device - under sudden temperature changes, concrete is constantly in motion: it either expands or returns to its original linear dimensions. And these are more and more cracks;

- Excessive load on the floor is planned: oak furniture, stove, fireplace.

Attention: when pouring a 3-4 cm thick screed onto a reinforced concrete floor, no tensile loads leading to deformation occur in the leveling layer. Therefore, reinforcement is not performed in such cases.

What types of materials are used to strengthen floors?

There are the following types of reinforcing elements that are used in the construction industry:

- Metal grid. It is mounted most often and gives the structure high levels of strength and reliability;

- Plastic and fiberglass reinforcement. These elements have fairly low strength indicators, and these materials also have poor fire resistance;

- Fiber – steel microfibers.

During the construction of industrial and residential buildings, in most cases, steel mesh is installed as a reinforcing material for the floor. It allows you to correctly form the load over the entire surface and avoid deformations under sufficiently large loads and bending forces. If you use steel mesh for reinforcement, you are guaranteed decades of reliable operation.

Features of floor mesh production

Floor mesh is produced at specialized enterprises from prepared VR-1 wire. This is a cold-drawn wire made of high-quality low-carbon steel. Depending on the geometric dimensions of the cells and the intended purpose, the wire diameter can vary from 2.5 to 6 millimeters. The wire is cut into individual rods and welded into a special mesh using spot welding.

The rods have special notches along their entire length, which are applied every 3 millimeters. They are necessary to provide stronger adhesion to the concrete mixture.

The cells have equal sides (square shape) with clearly fixed dimensions:

- Mesh with geometric cell dimensions of 50×50 millimeters. This is the minimum cell size for the production of these products. The minimum cell size requires the use of a large volume of steel rods. Accordingly, the strength characteristics will be significantly higher. It is used for laying conventional floors in industrial buildings, as well as in garages for heavy trucks;

- Grid with geometric dimensions 100×100 millimeters. The main area of application is the arrangement of floors in shopping centers and warehouses;

- Grid with geometric dimensions 150×150 millimeters. Here the size of one square cell is 150 millimeters. It is used for laying floors in residential premises and industrial workshops where there is no heavy load;

- Grid with geometric dimensions 200×200 millimeters. This is the largest cell size produced. Used to install a leveling layer in rooms where there is no heavy load.

Products with thinner wire and small cell sizes are supplied from the manufacturer's factory in rolls. Products made from large thick wire are quite problematic to roll into rolls, so they are supplied in cards. Twisted rolls are much more convenient to transport.

Popular manufacturers

Mesh for screed reinforcement is produced at many enterprises. The most popular among them:

Armplast produces fiberglass reinforcement for heated floors. The light weight of the mesh and the size of the cells allow it to be used for plastering work. Product advantages:

- does not corrode in the alkaline environment of the CPR;

- long service life;

- high strength - twice as strong as steel reinforcement of the same diameter;

- has almost the same coefficient of expansion as concrete;

- does not conduct electric current.

Tenax specializes in the production of polypropylene fittings. The product is characterized by increased strength and flexibility. It does not deform when the screed shrinks, has high resistance to aggressive chemicals, and is easy to cut. According to experts, plastic mesh is the best option for a 7-8 cm thick screed when installing electric or water floor heating systems.

"Gridex". The company supplies construction organizations and retail chains with basalt reinforcing materials. Product Features:

- impregnated with acrylate - improves adhesion to the central fiber board;

- standard cell size 25 x 25 mm;

- ideal for various “warm floor” systems;

- not afraid of the alkaline environment of concrete;

- does not conduct heat, unlike metal.

"LenStroyDetal". The company welds metal mesh for the screed (mesh size 100x100 mm) from galvanized rods with a diameter of 4 mm. Galvanizing steel significantly increases the service life of the metal inside the alkaline environment of concrete, and with it the screed.

Technology for correct installation of reinforcing elements. Expert advice!

Before you begin installation, you must thoroughly inspect the purchased products for any possible defects, if you did not do this when purchasing. Correct installation technology is performed in a few simple steps:

- First you need to prepare the base on which the screed will be laid. All visible defects are eliminated and treated with a special primer solution. Then the entire surface of the prepared base is covered with a special waterproofing material. The walls around the entire perimeter of the installation must also be covered with damper tape. This will completely eliminate the possibility of deformation as a result of thermal expansion. The walls are pasted to a height of approximately 10-12 centimeters.

- Next, the grid is laid out. It should be arranged in strictly parallel layers, with an overlap of no more than 10 centimeters allowed. The mesh should not lie close to the wall. The required gap is 3-4 centimeters.

- It is also necessary to raise it 2 centimeters above the surface. This is done with the aim of uniformly distributing the mesh in the poured concrete mixture. To do this, additional stands are made from bricks or pipe scraps.

- Check the evenness of the laid out mesh. A level is used for this. In places where unevenness is identified, it is necessary to make additional linings from scrap materials.

- Next, a special concrete solution is prepared and placed on top of the previously prepared layer. The reinforcement elements must be completely in the solution, none of the edges should be visible on the surface. Afterwards the surface is leveled.

I hope this article will help you understand which floor screed mesh you need!

Why does the foundation need to be reinforced?

Reinforcement allows you to increase the power and strength of the concrete base several times. Of course, a durable structure that will withstand gigantic loads and will be timeless can be obtained without the use of reinforcement.

For example, during the construction of the famous Colosseum, the builders of that time had no idea about additional strengthening of concrete with reinforcement, but the building stood for thousands of years, despite its location in an earthquake-prone zone. What is the mystery of such strength? Archaeological research has shown that the depth of the monolithic concrete slab is 9 meters, thickness - 13 meters. That is, the Colosseum is “alive” only thanks to this colossus.

However, today it is not economically profitable to build such a foundation. The development of the metallurgical industry makes it possible to significantly reduce the cost of construction through the use of a simple and effective method - pouring a concrete mass onto a frame made of metal reinforcement or mesh. The result is a reliable reinforced concrete foundation, thanks to which your building will last, if not millennia, then definitely a couple of centuries.

After hardening, concrete becomes rigid and inelastic, so it can deform when uneven pressure is applied to the surface. The reinforcement laid inside takes on all vertical loads and distributes them evenly over the entire base area.

The use of reinforcement is associated with additional costs, so some people refuse to install it. If you also doubt the need for reinforced mesh, make design calculations, analyze the feasibility, consider a number of factors: the composition and characteristics of the soil, groundwater level, degree and depth of freezing.

If you are constructing a building from light materials (logs, beams, frame-panel structures), it is not necessary to reinforce the base. As for heavy building materials (brick, concrete block, foam block, gas block, cinder block), in this case it is risky to refuse to lay the reinforced mesh. Concrete without reinforcement does not work well in bending and tension, so the foundation will deform or shrink, which will lead to the formation of cracks in the walls and premature destruction.

Carrying out repairs

It is important to strictly follow the mesh laying technology, especially when using heated floors. A special condition is that the screed must be completely dry before starting the heated floor. Otherwise, due to uneven drying of the solution, cracks may appear on the surface.

If the mesh is used to repair a cracked floor, then it is worth performing the work in the following sequence:

- Clean and prime the surface so that there is no dust.

- Apply the tile adhesive solution using a notched trowel. This mixture has good binding properties.

- Then lay the polymer mesh.

- Remove excess solution.

- When the glue dries, you can begin pouring the self-leveling floor. A small layer will be enough.

In the future, the reinforced surface will not become covered with cracks.