Frame construction has a number of undeniable advantages over conventional houses. It allows you to quickly build, does not require special professional skills, and is characterized by the simplicity of the design of houses. In addition, heat saving indicators are high.

In this article we will talk about how to arrange the heating of a frame house, what requirements are imposed on the heating system and which one should be preferred. It must be said that frame houses allow you to organize heating of any type in them - from a traditional Russian stove to convectors.

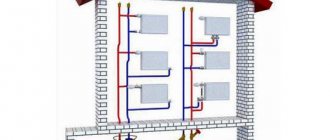

Heating system for a frame house

There are numerous options for organizing heating in a frame house, which occurs due to the good heat conservation of such types of buildings. Any coolant can be used. The choice of heating system depends on the personal preferences of the home owners and the budget allocated for this matter.

A frame house can be heated:

- Using gas (natural, liquefied), diesel fuel;

- Solid fuel;

- Electricity;

- Systems that receive energy from the earth or the sun.

The best option is to install a combined type frame house heating system. This approach will allow you to heat your home regardless of environmental conditions.

Combined heating may include an electric boiler, a solid fuel fireplace, air heating of a frame house and solar panels on the roof. At night, the house will be heated with water in an electric boiler and in a heated floor system, which will allow the use of a night tariff to calculate electrical energy; in the evening, you can use a solid fuel boiler, and when there is no precipitation, solar panels. In addition, some of the system elements are replaceable with analogues. For example, radiators can be used instead of heated floors, and a gas boiler can replace an electric one.

What difficulties arise in frame structures?

This type of house has cavities that are an integral part of the building's structure. And this causes significant heat losses and imposes additional conditions on the heating system.

Additional insulation inside or outside the building, as well as the installation of modern multi-chamber windows in plastic or wooden frames, will help reduce heat loss. It is worth installing the heating system after all insulation measures have been carried out - this will provide significant savings during further operation.

Heating system installation procedure

Before starting work on installing a heating system, you need to decide on its type. Afterwards, you need to draw up a project for placing its elements throughout the house, purchase the necessary equipment and materials for installation.

Thanks to the frame structure, laying heating pipes can be carried out at the very end of construction work. But if you don’t want to disassemble the wall cladding, then you should think about the heating system in advance.

As a rule, heating pipes are mounted on top of the frame and finishing; placement between the wall and sheets of drywall is often found. The external option is preferable, since it will not be necessary to perform any actions with the structure of the house, and access to communications will also be provided in case of their breakdown.

If you plan to install a combination boiler, you will need to strengthen the foundation under its location in advance, since the unit has considerable weight. In addition, it is necessary to consider a fire extinguishing system in case of an emergency. In this regard, a combination boiler is a rather problematic option.

Classic fireplace design

The standard version of the fireplace consists of the following parts:

- the firebox is a place in the fireplace that is U-shaped and framed by a portal. For better combustion of combustible material, a grate or hearth is installed in its lower part;

- perval or otherwise smoke tooth is a special narrowing to the chimney that provides better draft;

- chimney - provides fairly good removal of combustion products and excellent air supply.

The modern version of the fireplace provides the most accurate non-standard heat exchange system, which increases the efficiency of the device and ensures the preservation of a certain amount of air in the room. Thus, the air under the grate is not collected from the room, but comes from outside. Special holes are formed in the floor of the room, which supply air to the channels from the back wall of the firebox. This heated air begins to move to the tubular heater a little below the pass, and only then into the room. As a result of this, the air will take heat from the combustion products and transfer it to the room and reduce the temperature of the exhaust gas.

Although, this solution does not fully compensate for the air gap from the room. For example, it is not recommended to install fireplaces in frame houses in rooms with a volume of less than 30 m2?

This is especially important for modern houses with sealed windows and doors of increased density

Foundation for a classic fireplace

The weight of a classic fireplace of 15 tons poses a significant problem for different types of foundations. All projects of frame houses with fireplaces include the installation of a special, more powerful base under the hearth or stove. If this foundation was not planned, then you can safely forget about installing a fireplace in a frame house.

The frame house itself is light in weight when compared to a brick building. Therefore, the foundation for it is usually made lighter, for example, a shallowly buried strip. A stone fireplace is another matter; under it it is necessary to install a monolithic concrete slab, around the entire perimeter 30 cm larger than the original dimensions of the fireplace. The foundation must be buried below the freezing level of the soil and ground and not connected to the foundation of the house. A strip foundation can swell when the soil freezes and thaws, but monolithic ones will not react to this in any way, which is why it is prohibited to connect them into one single system.

A more correct option would be a regular fireplace in a frame house on screw piles. Swelling when the soil freezes does not affect this foundation at all, and the base of the fireplace and walls can be connected.

In a frame house with a foundation on screw piles, additional metal sheets are laid under the fireplace, which are tied together with a channel and special sheet metal 10 mm thick.

This steel platform under the fireplace can fully withstand a certain load.

This method is used in the construction of special outdoor stoves or barbecues.

Fireplace safety

The fireplace is an open type structure, that is, access to the fire is open all the time, and this, of course, creates a characteristic threat. In order to reduce it, the fireplace is installed in compliance with a certain number of rules.

Consider these rules below:

- The walls of the fireplace and chimney should not come into contact with the frame and insulation material. The vapor barrier layer and sheathing at the joints are protected with special heat-resistant building materials.

- The fireplace is built in and mounted into the internal partition, made of sand-lime brick in this place. This is the best option.

- The fireplace sits on its own concrete base. The danger zone in front of the firebox is covered with a special fire-resistant coating, for example, brick, tile and stone, it all depends on the building material of the main flooring.

- The chimney pipe is removed in compliance with all fire safety rules: the pipe must be insulated and insulated at a certain intersection of ceilings or walls.

Electrical heating

Heating for a frame house using electricity is a fairly popular option, but the cost of constantly heating the building with its help is relatively high. Its installation does not require obtaining any special permits, it can be carried out in any conditions, and there is no need to spend money on consumables.

The electric boiler is installed according to the rules for installing any other electrical equipment. Wiring is calculated based on the power of the equipment with a reserve for overloads and requires reliable insulation.

An important condition for using electric heating

Most importantly, to use electric heating without spending too much money, it is important that your home is very well insulated! This is extremely important! That is why the inhabitants of the right frame houses use ordinary electric convectors and chuckle when looking at the inhabitants of brick and block cottages sighing about the exorbitantly high heating bills!

When is it more profitable to use electric convectors, and when is it more profitable to use an electric boiler with radiators or heated floors?

Some customers ask us which electric heating option to choose, electric convectors for each window or an electric boiler with radiators?

Our answer is:

If you are building a garden or country house in which you live only from spring to autumn, then the choice is obvious - electric convectors! They are indifferent to sub-zero temperatures, they will cost less, and their installation can be done by anyone without a degree in electrical engineering. In case of failure, the convector is simply replaced with a new one. Their cost is almost the same as that of heating radiators, and they do not require pipes, pumps, or a boiler.

The disadvantage of electric convectors is that inexpensive models dry the air, not everyone likes this.

If your home is intended for permanent residence, and you prefer heated floors, then the choice is definitely an electric boiler with water heated floors.

In other cases - according to your taste.

Warm floor

The underfloor heating system is installed on subfloors. It is first necessary to install a vapor barrier on the surface to protect the floor from moisture. Next, heat-reflecting material is laid to prevent heat dissipation, after which heating mats are laid. Finally, finishing and installation of heated floor control systems are carried out.

The advantage of the solution is that warm air rises up from the surface of the floors and is distributed throughout the entire space of the room, and cold air falls to the bottom, where it also warms up.

Latest generation systems

Many people have heard about “warm baseboard” or “contour” class systems. Such heating, in fact, is built according to the classical scheme of heating and coolant circulation, but differs in slightly different standards, namely:

- the amount of coolant in the system is small;

- the circulation rate is high and occurs forcibly with the help of pumps, whereas classical systems can use natural convection circulation.

- As a result, contour systems have the following advantages:

- can be installed by hand without significant amounts of construction work;

- often do not require the creation of technical areas where heating equipment will be located.

However, heating with contour systems also has disadvantages:

- the initial period of warming up the house lasts a very long time;

- when the heater is turned off, the system temperature drops quickly;

- electricity consumption is necessarily higher, since even circuits using gas heaters use circulation pumps.

It is possible to build a “warm baseboard” or “circuit” system using only electric heaters, but the cost of using such a solution is very high.

Electric boiler

You can install an electric boiler yourself, but a number of nuances should be taken into account:

- The cross-section of the wires must comply with the requirements specified in the documents for the equipment;

- The switch may only be placed in the same room as the boiler;

- If you plan to use a boiler, then it should be located above the electric boiler;

- Wiring in a frame house must be done in advance;

- Installation of electrical equipment requires strict adherence to safety precautions in order to avoid electric shock;

- The boiler must be regularly inspected for leaks and damage to the insulation.

Oil radiators

Heating a frame house using oil radiators is not fundamentally different from heating with convectors. The device consists of spirals located in a tank with oil. During operation of the radiator, the coils heat up very much, but the surface of the device remains warm (about 50 degrees). This eliminates the burning of oxygen and the formation of soot from dust.

It is impossible to set the exact room heating temperature when using a radiator, even despite the presence of a thermostat. However, due to the large amount of oil, the device accumulates heat and continues to heat the rooms after being turned off.

Since oil radiators are not equipped with fans, natural air movement occurs. Therefore, an overheating zone forms around the device, and as you move away from it, the air temperature drops sharply.

Gas heating

Heating a frame house with gas is the most popular method. A gas boiler has long served as a reliable source of heat in the house.

It should be noted that gas supply to the house is not so fast and not so simple. You will first need to obtain permits from various authorities over the course of several months.

Gas heating can be installed only with the help of special equipment, which is not cheap. Installation and commissioning work is just as expensive, which is why many people prefer electric heating systems.

However, if we consider the long term, gas heating will be much cheaper than other types of heating. The low price of gas covers the cost of installing equipment. In just a few years, you will “recoup” all the money spent.

Video description

In our video we’ll talk about heating in a private country house. Our guest is the author and presenter of the Teplo-Voda channel Vladimir Sukhorukov:

Oil radiator

Considered uneconomical - critics argue that it should not be used as a heating device due to high energy consumption and low output. But it is this type of device that has one of the highest efficiency - about 98%. That is, it converts almost all electrical energy into heat (the law of conservation of energy has not yet been canceled), and those minor losses of 2% are due to the resistance of the internal walls of the radiator to the coolant. Yes, it is inertial - it takes a long time to warm up, but it also takes a long time to cool down.

On a note! Accordingly, when using an oil radiator, the room in which it is used will warm up for a long time.

But this is a property of all batteries, including water heating, in which the main method of heat transfer is radiation, which works slowly.

The main disadvantage is the “rough” power control and the use of mechanical thermostats. And such inaccurate control of temperature conditions makes an oil radiator ineffective when trying to optimize the cost of heating with electricity in a private home. And yet, it has a rather high body temperature when operating at full power, which is dangerous if there are small children in the house.

In defense of oil radiators, let’s say that these are still devices for temporary local heating and high energy efficiency has never been required of them.

There are models of oil radiators that can be hung on the wall Source b-sector.ru

Fan heater

It is often written about a fan heater that it burns oxygen. But “oxygen combustion” is nothing more than an oxidation (combustion) process, and the maximum that can burn at a fairly low temperature of the coil is organic dust in the air. Therefore, it is incorrect to talk about burning oxygen (after all, it’s not wood that burns) since this insignificant volume must be replenished as a result of mandatory ventilation of the room.

The efficiency of such a device is slightly lower than that of an oil radiator (part of the electricity is spent on operating the fan), but it is not very different, considering that the power of the fan motor itself is small (about 50 W out of a total of 1 or 2 kW). The advantage is that the room warms up very quickly. Disadvantages are a constant noise level (albeit insignificant) and dust transfer throughout the room. And the main drawback of these household appliances is manual power adjustment and the illusory possibility of creating an automated heating system based on fan heaters

A fan heater is the most compact heating device, and it is great for heating a small area Source romb.ua

Therefore, it is necessary to emphasize once again that the main reason why some types of electric heaters are not suitable for heating a home is not the efficiency (almost all of them are above 95%), but the impossibility of automating system control. It is this factor that does not allow optimizing the operation of the heating system, and without this it is impossible to heat a house with electricity cheaply.

Stove heating and fireplaces

Heating a frame house without using gas can be done using a stove or fireplace. Since time immemorial, people have loved to look at fire, which gives a feeling of coziness and comfort. Modern solutions offer many ways to contemplate “live” fire. Their use makes it possible to create a feeling of comfort in the house, and the fireplace itself can act as a heater.

Among the advantages of a fireplace are high heat accumulation and its uniform distribution. The materials for making fireplaces are presented in a wide range, so everyone will find something to suit their taste. Of course, fireplaces are not without their drawbacks. The most tangible is the need to purchase firewood to keep the fire going. In addition, when using it, it is very important to follow fire safety rules.

An alternative option is stove heating of a frame house. If you constantly add firewood as needed, the stove will maintain the required level of heat in the house for a long period of time. In addition, the premises will be heated already five minus after kindling. There are also very different options for the implementation of stoves; the unit can be placed in a corner, near a wall and in other places. In addition, the oven can be used for cooking food.

Video description

Video about infrared heaters:

There are three fundamentally different types of infrared heaters:

- reflectors in which the filament coil is enclosed in a quartz glass bulb;

- panel - a heating element is “soldered” in a ceramic monolithic slab;

- film - with carbon coating on a polymer film.

Heating a house with electricity of the first type refers to heaters operating in the short-wave range of infrared radiation.

Such devices can be used as an additional heater, but not as a basic element of the heating system of a private house with electricity.

Disadvantages - the lowest efficiency (due to the visible part of the radiation), lack of precise temperature control and high case temperature.

The second type of device operates in the soft long-wave range. The maximum temperature of the ceramic panel does not exceed 90°C, but on the body it is even lower. There are two types of control - mechanical and electronic thermostat. The first option involves manual control and its accuracy is low. Using electronic thermostats, you can set the temperature with an accuracy of 1°C.

The infrared panel is so safe that it can be hung on wooden walls Source centr-tepla.in.ua

The peculiarity of film heaters is that they heat not the air, but the objects in the radiation zone (and the objects then the air). Therefore, it is not practical to use them at home as the main heating system. Knowing this property of heating films, you can use them in the right place - where a person is located directly at this time, on open verandas, garages. I turned it on, and it was immediately warm; when I left, I turned it off, so as not to heat up the street or the garage where no one was there.

Installing films in the bedroom is uncomfortable: if you are in the zone of action of the heater, it will be hot, if not in the zone, then it will be cold. The best option is to use them as part of a heated floor - this is most comfortable for a person when his feet are warm and his head is cool. Operation is controlled automatically using a temperature sensor-thermostat pair.

If there is not enough space on the floor, then the film heater can be mounted on any free plane Source otdelka-expert.ru

Using a solid fuel boiler

Heating for a frame house using a solid fuel boiler is the best option for houses without gas supply. It allows you to use a wide variety of raw materials for heating - firewood, peat briquettes, wood and paper production waste. In a solid fuel boiler, not only the raw materials themselves are burned, but also the gas released during the process, which can significantly increase the efficiency of the equipment.

The principle of operation of a solid fuel boiler is as follows: through the heat exchanger pipes in the boiler, the air mass is heated, which subsequently enters the premises of the building. The convection process makes it possible to increase the temperature in the house to the required values within a short time.

Equipment operating on solid fuel supports several operating algorithms:

- Stage-by-stage heating of the house;

- Fast heating;

- Maintains the set temperature for 12-15 hours.

Convectors

A convector is a metal body of a certain design with an inlet and outlet to create the effect of air convection. There is a heating element inside the convector. Heating elements come in several types (in order of technical evolution): needle-shaped with filaments, heating elements, X-shaped monoliths, and monoliths with “scales” - Hedgehog. The inlet channel is closed with various types of filters to protect against dust, the outlet - with a decorative grille to protect against the ingress of small objects and more uniform distribution of heated air.

The convector body not only serves as protection for the heating element, but also increases the speed of the upward flow. Due to this, with the same power, the room is heated faster than from a water heating battery.

The stylish convector panel looks great in a modern interior Source teplo-vsem.ru

Convectors have three types of thermostats - mechanical, electronic and, more recently, inverter.

A mechanical and electronic thermostat is a thermal relay that turns the convector on and off depending on the temperature set on it. In a mechanical thermostat, the temperature is set by a manual regulator, often “by eye”; in an electronic thermostat, by touch buttons with a digital indication of the temperature value.

The inverter thermostat (control unit), unlike the mechanical and electronic thermostat, which operate in on/off mode, controls the operation of the convector according to a different principle - with automatic change of heating power, which allows achieving high energy efficiency indicators. Such savings can reach 40-70% of electricity compared to the usual on/off convector.

The reason for this saving is in such a thing as hysteresis: this is the temperature difference at which the thermostat turns the device on and off. Convectors with a mechanical or electronic thermostat turn on and off not when the set temperature is reached exactly, but with an error predetermined by the manufacturer. This is done so that the heater does not turn on and off at a high frequency (the lower the hysteresis, the higher this frequency). In this case, the automation would quickly fail. Therefore, such convectors always have a difference of several degrees between turning on and off, no matter how accurately they measure the temperature. And these extra degrees on/off of convectors consume extra electricity.

A convector with an inverter thermostat operates according to a different algorithm: it does not have parameters such as the temperature at which the heater turns on and off. The inverter thermostat does not turn off/turn on the heating, but automatically reduces/increases the heating power depending on the temperature difference and the rate of change of this temperature.

Nuances and conclusions

To ensure maximum effect from the heating system, the frame house must be properly insulated. At the same time, not only floors and walls require thermal insulation. According to research, the greatest heat loss occurs through ceilings. To avoid this, you need to insulate not only the ceiling, but also the attic space, if there is one in your house.

This concludes our review of the most popular options for heating a frame house. Any solution has its own list of pros and cons. When choosing a heating system, you should take into account the area of the building, whether it is possible to supply gas and other nuances. However, the most rational option would be to use a combined type of heating.

— Why not install cheaper wall convectors?

It would seem - indeed, because convectors do not require installation of a boiler, pipe routing, and so on. One-time costs are lower. At the same time, their energy consumption is similar to that of a system with an electric boiler. But we shouldn’t discount the following fact: if we install an electric boiler, the cable is connected to the boiler - and we get one potentially dangerous point. If we are talking about convectors, then the number of such connection points is equal to the number of convectors. That is, their operation requires very competent electrical wiring. All cables must be twisted very tightly, the cable must be copper, the twists must be insulated, and all this must be in fireproof casings.

Manufacturers of heating devices

Many domestic and foreign manufacturers offer their products on the heating equipment market. In order not to get confused in companies and brands, it is worth knowing those who have proven themselves on the positive side.

Italy has long remained the leader in the production of aluminum radiators. Large corporations such as Global, Sira Industrie, Fondital and Ferroli produce high-quality products equipped with the latest technological developments. Cheaper, but no less reliable devices are produced by Konner and Smart. Russian companies, some of which operate under the control of European concerns, also supply decent equipment. These include Orana, Royal Thermo, Rifar and AlBerg. Most of these manufacturers have started producing bimetallic batteries. You can add the German brand “Tenrad” and the Chinese “Oasis” to the list.

Production technology of Italian heating radiators

"Minsk Heating Equipment Plant" offers classic cast iron radiators made using traditional technology. This giant supplies Belarus, Russia and the CIS countries with sectional versions of the MS-140. Eurocast iron is produced by the Chinese concern Konner and the Russian STI Nova. Exclusive designer models made of cast iron can be found in the Czech and English “Carron” lines. Their products are designed for consumers with a decent level of income and, accordingly, with increased requirements for appearance.

When choosing steel panel radiators, you should take a closer look at devices from the German, Finnish “Purmo”, and Czech “Korado”. Several factories are actively operating in Turkey. Of these, the largest one, operating under the control of German owners, especially stands out. Russia also produces high-quality panel batteries, for example, under the Conrad brand. Tubular options are less in demand among Russian buyers, but stores offer a sufficient assortment of Swedish “Zehnder”, German “Kermi”, and Italian “Delonghi”. Among the domestic manufacturers, we can highlight the “Kimry Thermal Equipment Plant”, which produces the “Harmony”, “Effect” and “Esthete” series.

Don’t overpay for brand recognition; check the technical specifications – inexpensive radiators may well meet all the requirements.

Price range

Given the variety of radiators available, it is difficult to summarize price offers from different manufacturers into one table. The cost depends on the country of manufacture, technical equipment, heat transfer, design and even on the region of sale. We will indicate approximate prices for 1 section with an interaxial distance of 50 cm.

| Model, manufacturer | Cost, rub |

| Aluminium, Europe | From 550 |

| Aluminum, China | From 430 |

| Aluminum, Russia | From 500 |

| Bimetallic, Europe | From 670 |

| Bimetallic, China | From 480 |

| Bimetallic, Russia | From 600 |

| Cast iron MS-140 | From 420 |

| Eurocast iron, Europe | From 640 |

| Eurocast iron, China | From 550 |

| Steel panel, Europe | From 450 |

| Steel panel, Türkiye | From 300 |

| Steel panels, Russia | From 300 |

| Steel tubular | From 500 |

When choosing a radiator, you need to pay attention to its heat output, since this is a determining indicator. At first glance, a cast iron battery will cost much less than its bimetallic counterpart. However, when carrying out calculations to determine the required number of sections, the difference is significantly reduced: to heat the same room, a larger number of cast iron sections will be needed. It is also worth considering the equipment of the device: some manufacturers supply their products with an installation kit, while others offer to buy it separately. This means additional costs that may offset the perceived benefits.

Selection of radiators - what are they?

Probably, many remember that recent period when cast iron radiators were installed in all apartments and houses. For a more presentable appearance, it was necessary to paint the radiator unit once every 1–2 years. But, despite this main drawback, today they have the leading ability to withstand high pressure. They can also boast a long service life.

If the main thing when choosing is price, then you can pay attention to steel radiators. They look quite attractive. In terms of performance, they have good heat transfer and convection. Due to their price and positive characteristics, they have become widespread. But their main disadvantage is their susceptibility to corrosion.