Varnishing exterior or interior walls is a good way to make them more attractive. In addition to being decorative, wall varnish performs another important function - it provides reliable, long-term protection for building materials from the negative effects of the external environment and other unfavorable factors. Thanks to varnishing, the service life of a wooden, concrete or brick surface is significantly extended.

Today in stores you can see a huge variety of paints and varnishes that are used for various finishing and painting works. Glossy, semi-gloss and matte varnish are sold, there are colored and colorless transparent varnish mixtures, and you can also purchase pearlescent, craquelure composition, and even varnish with glitter. You can choose a universal varnish solution, as well as one specifically suitable only for processing metal, wood, brick, concrete or drywall.

Advantages of varnishing

Using wall varnish provides many undeniable advantages. You can varnish both external, concrete or brick walls, and internal surfaces, thanks to this the following goals are achieved:

- moisture and water cannot penetrate deep into the building material from which the walls are constructed;

- the surface is reliably protected from exposure to sunlight and ultraviolet rays, so the material does not fade or lose its shade;

- the structure of the building material is strengthened, therefore its service life is extended and it deteriorates much more slowly;

- the base acquires protection from the influence of chemical detergents and other aggressive substances, as well as from physical and mechanical stress and damage;

- the walls become visually attractive.

To reliably protect walls and ceilings, it is necessary to choose the right varnish, taking into account various nuances.

Conclusion

The process of painting over varnish is completely acceptable. However, in order for the new finish to be durable, you need to make sure that there is good adhesion between the base and the old coating. In addition, it is extremely important to follow the technology that we discussed above.

For more information on this topic, watch the video in this article.

Finishing of the surface often ends with varnishing. This provides it with protection from mechanical stress, atmospheric disasters and resistance to water. Different substrates are treated with formulations based on various liquid resins. The choice of the desired one is dictated by the type of base being processed, taking into account whether it is painted, the CM on a water or non-aqueous basis, and the place of varnishing. Since many surfaces are coated with water-based paint, the question comes to mind: is it possible to varnish water-based paint?

How to choose the right varnish

When choosing a varnish solution in a store, you need to understand what indicators it should meet and what properties it should have. For example, if varnish for walls and ceilings will be applied in the bathroom, then it is necessary to choose a composition that has maximum moisture resistance. And if a bedroom or children's room is to be varnished, it is important to select the safest solution, without toxic components, for example, acrylic varnish for walls. Also, when choosing, you need to take into account what type of material will be varnished, for example, brick, concrete, wood, plaster or some other material.

If varnish for walls or ceilings will be applied indoors, public, residential or non-residential, then the safest are water-based compositions - aqualacs. Acrylic mixtures that contain water are in great demand these days, although they are not cheap.

Protective layer for acrylic base on car body

Varnishing a car body begins with checking the compatibility of the dye and the selected varnish. The degree of its rigidity is also taken into account. The number of layers during varnishing depends on it. The jar is marked:

- Hard type – HS. A coating of 1.5 layers is performed. Contains solid particles. Refers to economical materials. It is used when painting the surface of a car at the factory.

- With a soft structure – MS. The body is processed in 2-3 layers. Each subsequent layer is thicker than the previous one. The material spreads on the surface, so you need to work with it carefully. Can be polished and processed better. The car is varnished with the composition yourself.

The body, painted with acrylic auto enamel, is covered with a two-layer varnish coating, which masks all defects and enhances the shade. The main functional purpose is to protect the base layer.

- Cars painted with metallic, pearl, nitro enamel, or alkyd dyes must be varnished. Acrylic varnish in this case is used as a universal product. Car varnish dries quickly. Complete drying occurs in approximately 2 hours. Most often, an aerosol composition is used for self-varnishing. The can is kept at a distance of 25 cm.

Matte automotive varnish materials have become increasingly popular. They further enhance the strength of the paint coating and penetrate into the smallest cracks, thereby stopping corrosion processes. After the topcoat has dried, the car body does not need to be sanded.

Advantages and disadvantages of acrylic varnishes

Water-based acrylic varnish for walls has the following advantages:

- is an environmentally friendly and safe product, since it does not contain organic solvents;

- does not emit an unpleasant, pungent odor;

- forms an elastic, but at the same time durable protective film on the material;

- has no color, a completely transparent, colorless solution, which even after several years does not begin to turn yellow, due to which the natural color of the building material does not change, especially for wooden surfaces;

- can be tinted in any colors you like;

- varnishes are produced with different degrees of gloss, for example, matte, glossy, semi-matte and semi-gloss;

- is a non-flammable solution;

- very easy and simple to apply using a roller, brush or spray;

- the applied layers dry quickly enough;

- can be used for various building materials from which ceilings and walls are made, for example wood, stone, brick, metal, plastic, and others.

Despite all these advantages, acrylic varnishes have some disadvantages. For example, they take a very long time to polymerize; the surface can be used only after one and a half to two weeks. In addition, acrylic varnishes wear off quite quickly, but this drawback applies more to the floor than to walls or ceilings.

Application of varnish composition

After choosing a varnish, you can begin decorating the room. To do this, you first need to prepare the materials at hand that will be needed during finishing.

Most often, varnish is applied to plaster, so you must first clean the surface. To do this, use a stiff brush, which will lightly sand the surface, eliminating small chips. Clean the coating with a sponge, removing dust and other contaminants. After this, you can apply the primer in one or two layers with a roller.

When working with a wooden surface, you first need to clean it and repair cracks in the wood, which can lead to the mortar flowing in, and cover the material with a primer.

Then begins the procedure of grinding the surface and applying putty, which levels the surface before varnishing begins.

Pay attention to: Concrete varnish: types and advantages of compositions

The varnishing itself takes about an hour:

- Wear protective clothing and protect your respiratory system with a respirator. Due to the aggressive composition of the varnish, do not allow it to come into contact with the skin.

- Place newspapers or film on the floor to prevent the varnish from getting on it. Skirting boards and ceilings can be protected with masking tape.

- Use a spray bottle to apply varnish. Apply a layer that is not too thick, but do not leave streaks that will look untidy after drying.

- Paint areas where using a sprayer is not possible using a roller of varying thickness. It is not recommended to use a brush as it often leaves streaks.

The varnish usually dries in a few hours, but some compositions harden only after a couple of weeks, which is why you need to pay attention to the manufacturer’s instructions.

After finishing work, you can clean the floors and ceilings of protective materials, since varnishing is usually carried out in one layer, maximum - you can apply a second, finishing one.

The process of applying varnish to a wooden surface

Polyurethane varnish

Scuba gear is made not only from acrylic, but also from polyurethane. One of the best options is to coat the walls with polyurethane-based varnish, either a one-component or two-component solution. They have the following advantages:

- are produced odorless, these are absolutely non-toxic, harmless substances for humans;

- dry quite quickly, after 2-3 hours you can apply the next layer, and after a couple of days you can start using the varnished surface, be it floors, walls or ceilings;

- applied in an even layer, very easily and quickly;

- has a high rate of adhesion to various building materials;

- is very durable, abrasion-resistant and durable;

- excellent resistance to chemicals;

- It is universal and can be used for different types of coatings.

One of the significant disadvantages of polyurethane varnishes is their high cost. However, this is fully justified by the long service life and excellent technical characteristics.

Color selection

The choice of shade is important, because you will have to be in the created environment for a long time.

Designers highlight a pearlescent shade. It can be the main design element or used to highlight the main background.

A glossy decorative layer does not hide wall defects well. The matte finish hides them from view. This quality of varnish is used in house construction, where it takes a lot of effort and money to level the walls, and the result is far from ideal.

Colorless LM is chosen as an independent protective film or as a backdrop for a rich tone. In the design of a room, it does not take all the attention.

Treatment of external walls

If you need to protect an outdoor wooden, concrete or brick wall, then you should not choose a water-based aqualac, for example, an acrylic composition, because it will not last long. For outdoor surfaces, it is better to use varnish solutions based on organic solvents.

One popular option is alkyd varnish composition. It has a high level of moisture resistance and weather resistance, but its disadvantage is its long drying time. But if the alkyd solution is mixed with a special hardener, the drying period will be significantly shortened.

In addition to alkyd, other types of varnishes are used, which create a durable protective layer that is resistant to harmful external influences. They are resistant to temperature changes and ultraviolet rays, are easy to apply, have almost no color, and make the surface visually attractive. Among such compositions based on organic solvents are:

- urethane;

- nitro varnishes;

- oil;

- bitumen;

- epoxy;

- shellacs.

Each of these varieties has its own properties and technical characteristics; coating walls with organic solvent-based varnish is used mainly for treating external surfaces of brick, plastic, concrete, foam concrete and wood.

Kinds

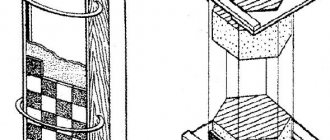

Depending on the composition, one-component and two-component varnishes are distinguished:

- In one-component versions, only acrylic is the binder, to which stabilizers, plasticizers, and antiseptics are added. One-component compositions are quite strong, the resulting transparent layer will effectively protect the wood from fading, deterioration, and mechanical damage. However, a constant humid environment will significantly shorten the service life and make the varnish less durable. Therefore, one-component compositions are more often used in decorative and applied arts rather than for covering floors and other surfaces subject to significant loads.

- In two-component compositions, the additional binder is polyurethane. Its addition increases the elasticity and strength of the final coating, resistance to mechanical loads, which makes it suitable for flooring in public places with a large influx of visitors.

Depending on the resulting decorative effect, the varnish can be matte, semi-matte, or glossy:

- Semi-matte gives the surface a smooth, non-shiny finish. After hardening, it has a silky texture, unevenness and defects on the surface become less noticeable.

- The product, coated with glossy varnish, acquires a bright shine. The use of a glossy composition requires an almost ideal surface, as all its imperfections will appear. Parquet is often treated with glossy varnish to achieve a “mirror effect”. Parquet varnish is inferior to matte in durability.

- Semi-matte combines the advantages and disadvantages of matte and glossy compositions. It will emphasize the texture of the product, give it a subtle shine and shimmer, but will also show surface imperfections.

Decorative properties

Most often, consumers choose glossy or matte varieties of varnishes, for example, polyurethane or acrylic compounds. However, if any special components are added to the varnish mixture, the surface can be made unique, very attractive and decorative. For example, for a wooden structure, you can use the technology of tinting, artificial aging, and also enhancing the natural texture. The following types of varnish compositions are used for decorating surfaces:

- Craquelure varnish solutions are most often applied to a layer of plaster, on which they create the appearance of an aged surface on which cracks have appeared. These cracks occur when the composition is applied in two layers, after which the network of cracks is patinated;

- Mother-of-pearl mixtures are an excellent finishing option that creates a unique spectral shimmering effect. Mother-of-pearl solutions are produced on the basis of acrylic components, they are safe for humans, and are applied to wallpaper, plaster, wood and mineral materials;

- Glitter varnishes have an acrylic base with glitter and are intended for finishing application on walls. Decorative components are made in various shades and are purchased separately. Glitter is independently added to the varnish mixture, resulting in an original and unique coating.

So, there are many varieties of varnish, each consumer chooses the most suitable composition for his room. Many people ask how to varnish a brick wall, how to varnish a concrete or wooden surface? To do this correctly, you must adhere to the technology specified in the instructions. And if you do not have the necessary knowledge and skills in the field of repair and finishing, then it is better to entrust this work to professional craftsmen.

Manufacturers

In construction markets, it is quite difficult to decide on the choice of paint and varnish material due to the wide range and large number of manufacturing companies.

There are several popular companies that produce quality products:

- Optimist is a large Russian manufacturer of paint and varnish products with a twenty-year history. The company strictly adheres to quality standards and uses high-quality materials in its work.

- VGT is a Russian company specializing in the production of varnishes, paints, enamels, pigments and other acrylic materials. The company has its own research center. Construction stores offer a wide range of products from this company.

- Tikkurila is one of the leading companies in the production of paints and varnishes in Finland, Sweden and Russia. Acrylic varnishes of this brand are in wide demand among consumers.

- Pinotex - the products of this company are famous for their quality, are in demand throughout Europe, and produce universal, waterproof, wear-resistant acrylic varnishes.

- "Lakra" produces parquet and tinted varnishes with a UV filter, the products have quality certificates.

After the primer has completely dried, paint the surface.

- First, prepare the coloring agent and mix it well. If necessary, pigment is added to create the desired color. To thoroughly mix the pigment and paint, use a construction-type mixer.

- Then they begin to paint the surface. Apply a thin layer of paint with a brush; no streaks should form on the surface. Instead of a brush, you can use a roller.

- When the first application dries, proceed to the second coating.

After this, the surface is considered prepared for varnishing.