The main enemies of a wooden floor are moisture and various kinds of bacteria and microorganisms. Under the influence of these factors, the construction material begins to rot, loses its original aesthetic properties and serves much less than it should.

How to cover a wooden floor

To prevent the occurrence of these problems, the wooden floor must be coated with a special protective compound. The modern market offers a large selection of products that not only help to increase the durability and other important performance indicators of wood, but also make its appearance more noble and attractive.

After reading the information below, you will get a complete understanding of the features of the selection and use of existing compositions, which will allow you to independently cope with this event.

How to cover a wooden floor in a house: choosing the best option

Wooden flooring in the home remains a very common choice for both private homes and apartments.

Pleasant appearance, environmental friendliness, good heat-intensive qualities, and affordable cost remain the undeniable advantages of this coating. Like all natural materials, a wooden surface requires special care and mandatory protection from damage, moisture and ultraviolet exposure. In addition, wood products allow you to enhance its natural color or give it the desired shade. For all these purposes, there are a number of special means - from various impregnations and stains to varnishes and paints.

Properties of wooden flooring

Each material has unique properties, wood is no exception in this regard. This material has the following positive features:

- beautiful appearance - the pattern of natural wood makes a pleasant aesthetic impression and fits well with a wide variety of interior types; ability to retain heat, high thermal insulation properties; environmental safety - the tree does not emit toxins, some species, on the contrary, have healing properties; availability of material - most types of wood are quite inexpensive; ease of processing - with the exception of particularly hard species, wood is a malleable material and even a non-specialist can lay such a floor covering with his own hands; durability - some types of wood can last for many decades.

But wood also has its disadvantages, which must be taken into account when choosing this material:

- instability to mechanical damage (with the exception of particularly hard wood, which is highly expensive); fire hazard - untreated dry wood is an extremely fire-prone material; ability to dry out and crack when exposed to sunlight; exposure to moisture - swelling, mold, rotting, loss of strength, aesthetic appearance (only some species, such as larch, respond well to humidity and become stronger); exposure to insect activity.

It is precisely in order to prevent and neutralize the possible negative consequences of use for a wooden floor that many care and protection products have been developed. Almost all types of new wood flooring must be treated with antiseptic solutions, insect repellents, and mixtures that reduce the flammability of the material. Also of decisive importance are the compositions that perform the finishing treatment - they are responsible for the main protective functions.

Features of pine floors

Pine is a tree with unique wood properties. The wood is very durable with a density of 520 kilograms per cubic meter (an average value and depends on the conditions in which the tree grew). Pine wood from trees that grew in dry places and acquired the most durable and reliable structure is especially valued among builders.

The texture and shade of pine lumber depends on what part of the trunk it came from. Closer to the center, dark red colors are obtained, and the outer layer (sapwood) has a light shade and the younger the tree, the paler the color.

For all its strength, pine has low hardness compared to oak or beech lumber, and therefore when laying pine board flooring, it is worth considering the places where heavy furniture or household appliances will stand, since deformations (dents) will definitely occur there.

At the same time, both the advantage and disadvantage of pine wood is its high resin content. From a positive point of view, resin can be noted as an additional moisture-resistant layer, but this component of wood tends to separate on the surface of lumber, which leads to inevitable damage to the appearance of the floor covering. Naturally, black spots will spoil any photo, and during a visual inspection questions will arise about the quality of the floors.

Types of wood coating products

If you choose the right product for covering a wooden floor, you can not only preserve all its positive properties, but also improve them. Often, when installing such floors, owners want to preserve the appearance and texture of the wood - this is an additional aesthetic point that gives a special atmosphere to the room. Therefore, many coatings are made transparent and only slightly change the appearance of the tree.

Oil

This type of coating has been known for a long time and is a traditional means of improving the properties of wood and extending its service life. The main feature of the oil is that it is completely absorbed into the pores and fibers of wood, giving a preservative effect without forming a hard surface. The water-repellent properties of the oil reliably protect the floor material from dampness, fungus and mold. Oil also has a positive effect on the strength and wear resistance of wood.

The tree completely retains its appearance, while the variety of types of oils allows you to choose any shade, or choose a transparent composition. The disadvantage of this impregnation is the need for constant maintenance and regular updating. Also, oils do not tolerate high temperatures and temperature changes. Oil is a flammable material, which negatively affects fire safety.

The features of the product do not make it possible to use it in open spaces, for example, on a veranda. Waxing is not recommended in places with constant high humidity - due to the fact that the inner layers of the wood are not soaked through, it will inevitably swell. It is also better not to use wax in areas where wet cleaning using household chemicals is often required.

Mastic

A special type of coating based on resins - natural or polymer. Rubber-based compounds are also often used. Mastic is excellent for parquet floors, acting almost the same as liquid wax, but better protecting the surface from damage. The peculiarity of mastic is that it forms a hard film - either due to the evaporation of alcohol solvents, or as a result of the natural solidification of the hot composition.

The property of mastic is to add shine to the floor covering; it is often used in interior spaces, excluding rooms with high humidity and frequent temperature changes. This is a practical and very beautiful covering that will decorate your living room or bedroom. Mastic does not require as frequent renewal as oil or wax.

There are two types of varnishes most often used:

- one-component - easy to use, but have a shorter service life; two-component - require a more complex application procedure, are more expensive, but will last several years longer.

Varnishes can be water-based, alcohol-based solvents, even oil-based - the latter must be mixed before starting work. Alcohol varnishes dry the fastest, oil-based varnishes will require a long time to dry and take about two weeks to gain strength. Water-based varnishes are considered the most unreliable, but in fact they are in no way inferior to other options and create a very durable coating. At the same time, the composition itself does not have a strong odor and dries quickly.

Dye

The last remedy differs from all of the above in its main feature - the opacity of the layer. The paint can be of a wide variety of shades, imitate the color of wood or be in a completely opposite color spectrum - this allows you to choose the composition and color for any type of interior. Paint can preserve the texture of wood, especially if applied in one or two layers; with significant thickness, you can achieve a smooth surface.

This product has the following advantages:

- ease of use and application - usually there is no need to prepare the composition; it can be applied with a brush or roller; durability and strength of the coating; good moisture insulation; affordable price; widest choice of colors.

What product should I use for the floors?

The boardwalk of a veranda at a summer cottage can be covered with several coating options. They differ in their cost, external aesthetics and color palette. Let's talk about each next.

Enamel: giving the floor a solid color

Enamel compositions are often used for painting metal and wooden structures.

This product has a high density, so it will completely hide the natural texture and pattern of natural wood. Therefore, it makes sense to use floor enamel if the boards have defects that need to be hidden.

Using this material, you can get wooden floors that are monochromatic in color.

Antiseptic composition: we protect the boardwalk from harmful bacteria

This is a very useful tool that significantly extends the life of wooden structures. It helps to increase the wood's resistance to excessive air humidity and prevents the formation of mold, mildew and rot.

In the future, the floors should be painted or varnished, because the antiseptic, regardless of its cost, will not visually give the wood any additional aesthetics and will not protect it from mechanical or atmospheric influences.

Varnish for wooden surfaces

The wooden floor of a country house requires additional protection from external factors that have a negative impact on the wood. These are high humidity in the room, small rodents, mold, bark beetles and other insects. And for this purpose, varnish is very widely used.

Its aesthetics can be glossy, matte or semi-matte. Each of the described types is characterized by a certain aesthetic effect.

The glossy varnish composition has a bright shine, but over time it can wear out from frequent walking on the floor of the veranda.

Matte and semi-matte varnish does not shine. But this product is highly resistant to impact and perfectly protects wooden structures from negative environmental factors.

According to many experts in the field of construction and interior decoration, varnish compositions are more practical to use.

How to cover a wooden floor

Author: Nikolay Strelkovsky

The main enemies of a wooden floor are moisture and various kinds of bacteria and microorganisms. Under the influence of these factors, the construction material begins to rot, loses its original aesthetic properties and serves much less than it should.

How to cover a wooden floor

To prevent the occurrence of these problems, the wooden floor must be coated with a special protective compound. The modern market offers a large selection of products that not only help to increase the durability and other important performance indicators of wood, but also make its appearance more noble and attractive.

After reading the information below, you will get a complete understanding of the features of the selection and use of existing compositions, which will allow you to independently cope with this event.

Available types of wood treatment compounds

Reliable and effective protection of wooden structures from harmful external influences can be ensured using the following compositions:

Polyurethane varnish Pallmann IS 90 Sport for wooden floors

Each option mentioned will give the wooden floor an attractive appearance, while at the same time ensuring increased resistance of the material to various types of influences and loads and helping to extend its service life.

Hard wax oil for wooden floors Saicos

Next, you are invited to familiarize yourself with a description of the basic properties of varnish, wax and oil, as well as study the technology for applying each of these materials. But first you should definitely understand the procedure for preparing the surface for subsequent processing.

Marmoleum

Different types of marmoleum

Natural and environmentally friendly finishing materials play an important role when choosing them

When choosing a floor covering, you should pay attention to marmoleum - a material that appeared in the last century and is based on natural materials - chalk, jute, cork, wood flour.. Thanks to its natural composition, the scope of application of marmoleum extends to educational (schools, universities ), medical and health institutions, kindergartens.

Thanks to its natural composition, the scope of application of marmoleum extends to educational (schools, universities), medical and health institutions, and kindergartens.

The main advantages of marmoleum:

long service life - up to 20 years; composition of marmoleum - natural ingredients; resistance to chemical components (acids, salts, all kinds of reagents); fire resistance; antistatic; bactericidal properties (especially important for families with children); resistance to physical impact. A square meter of marmoleum can withstand up to 160 kg of load without consequences; UV resistance; the material is also not afraid of high humidity: when interacting with moisture, its properties do not change; economical due to self-sufficiency: this flooring does not require additional hydro, noise and thermal insulation; the price per square meter of the product is on the same level as laminate; simplicity of laying the material, allowing you to carry out the process yourself, without the help of professionals.

The disadvantages of marmoleum include its fragility; therefore, when choosing marmoleum, you should carefully check each element for cracks or other deformations. Transportation and transfer of the material should be carried out with the utmost care, avoiding deformation of the edges of the product. The material cuts quite poorly.

The disadvantages of marmoleum include its fragility; therefore, when choosing marmoleum, you should carefully check each element for cracks or other deformations

Transport and transfer of material should be carried out with the utmost care, avoiding deformation of the edges of the product. The material cuts quite poorly.

90% of marmoleum produced is in rolls. The standard width reaches 2 m, the thickness limits are 2-2.5 mm. For objects with increased load, the thickness of the product is 3.2 and 4 mm.

Instructions for preparing a wooden floor for coating

The procedure depends on whether you are working with a new floor or a previously used structure.

Guide for a new floor

First of all, check the condition of the fasteners that secure the deck boards. The heads of screws and nails need to be “sunk” into the material by about 2-3 mm. Next, the remaining recesses are covered with a sealing agent. Instead, you can use a special putty designed for wood processing. It is important that the color of the material matches the color of the boards as much as possible.

Drive in the nail heads and apply putty.

Cover the deck with starter varnish and let it dry. The drying time is determined by the moisture content of the boards. If the material humidity is more than 12%, the varnish will dry for a very long time - up to several months. If the boards have been well dried, the waiting period will be reduced to 2-3 weeks.

Apply varnish to the floor

Guide for old floor

If the existing deck boards are in good condition and do not require replacement, preparation begins by removing the existing paint or other coating. If you find defective boards, be sure to replace them before starting work.

Old paint should be removed

The paint can be easily removed using a sanding machine. But it is not advisable to buy this unit for single use. If your place of residence does not provide such tools for rent, use the old and proven manual method.

Prepare the following:

Proceed to remove the old paintwork. Place paper on the base and place a well-heated iron on top of it. As a result of this treatment, the paint will come off the floor and stick to the sheet. Remove the remaining areas of the coating with a spatula and knife. If paint has become embedded in the floor material, apply a stripper according to the manufacturer's instructions.

Remove the thin top layer of material from the cleaned boards. An electric plane will help you with this. Make sure that the fastener heads do not protrude above the boards.

Important! The work is quite dusty, so for your own safety, wear a respirator and safety glasses.

Sand the surface using a grinder with the previously mentioned attachment and sandpaper. Collect the dust, but do not throw it away - it may be useful to you in the future.

Sanding a wooden floor

Fill cracks and other flooring defects. If you do not have a special primer of a suitable color, use a mixture of PVA glue and wood dust. Add dust until the desired color is obtained. If you use the second option, be careful and attentive: any excess glue that appears must be immediately removed from the surface. This is easily done with a damp cloth.

For putty, mix sawdust and PVA glue

Finally, all you have to do is apply a starter varnish to the floor and let it dry. The recommendations are similar to the previous case.

How to paint the floor correctly

You can paint the floorboard at home with your own hands. The technology for this process looks something like this:

- Clean the coating from dirt, dust and grease.

- Fill all cracks and defects with putty.

- Carefully sand the treated areas to make the surface uniform.

- Apply an antiseptic or primer solution to the floor covering. Wait until completely dry.

- Paint.

If necessary, the floorboard can be processed in several stages.

Procedure for applying varnish

Various tools are used to apply varnish. So, for example, quick-drying water-soluble compounds are applied with rollers of the highest quality. The performer must distribute the material over the surface using exclusively translational movements. First, the product is applied across the flooring, after which it is leveled in the longitudinal direction, i.e. the surface is varnished “crosswise”.

Procedure for applying varnish

You can use a spatula to apply the first layer of material. The performer makes fairly quick S-shaped movements, evenly distributing the composition over the base. This technology allows for higher coating strength.

If using a brush, the material should be applied in neat U-shaped strokes. In this case, the new stroke should slightly overlap the previous one.

How to coat a wooden floor with oil

How to coat a wooden floor with oil

The oil penetrates the wood structure, protecting the material from the inside and without creating a continuous film on top of it. As a result, the wear resistance of the wooden floor increases significantly. An additional advantage of the oil is its environmental friendliness. As a rule, such coatings do not contain solvents or are present in insignificant quantities.

Solid oil for wooden floors

It is important to know that on a floor covered with oil, material defects will be much more noticeable than if varnish is used. Therefore, the work must be carried out step by step and in strict accordance with the manufacturer’s recommendations. A general requirement that is relevant for all such compositions is the timely removal of excess oil from wood. Otherwise, the floor will be covered with unsightly dark spots.

It is impossible to provide specific instructions for covering a wooden floor with oil, because... the procedure is largely determined by the manufacturer's recommendations. We can only describe the general sequence:

On average, the oil hardens for 12 hours. After this, the material will need to be given another 3-4 days to gain strength.

Wood oil extends the life of the floor

Important! After the first treatment of a wooden floor with oil, the surface will become very dirty. Such marks will stop appearing only after the material is completely saturated, which on average takes several years.

If necessary, such a coating can be restored without much effort: the damaged area is simply sanded and re-impregnated with oil.

Using oil you can reliably protect the floor from moisture

Oil treatment of wood

To treat wooden floors, oil is used, made from both natural substances and artificial components (for example, oil that contains polyurethane). During processing, the oil passes deep into the wood, leaving a thin coating on the outside. After applying the oil, the flooring acquires greater strength and a slight shine.

When choosing an oil, you must pay attention to its composition. Do not use products that contain solvent to treat wood.

It is also worth paying attention to the viscosity of the oil:

- Thick (this composition contains 90% natural oil);

- Average (40-50%);

- Liquid (20-40%).

It is worth talking about the scope of application of the oil. It is best used in high traffic areas (for example, corridors). In addition, oils are well suited for cold rooms, open areas and areas where there is constant contact with moisture (in the bathroom or near the pool).

Using wax to coat wood floors

Rubbing oil-wax into wood

The main advantage of wax is its absolute environmental friendliness and safety for human health. Wax can be used both as an independent coating and in combination with the previously discussed oil.

Floors covered with hard wax look as natural as possible.

The technology for applying wax is extremely simple and straightforward:

Experts recommend renewing the wax coating twice a year. Otherwise, the frequency of such processing remains at the discretion of the owner.

Now you know what can be used to cover a wooden floor and how to handle each material considered.

Video - How to cover a wooden floor

Did you like the article? Save so you don't lose or share with friends!

Source

Finished floor installation

Most often, to install a finished floor in a wooden house, a board processed on a milling machine and having a tongue-and-groove lock is used. The first board is laid with a groove against the wall, leaving a compensation gap of 1.5 cm. The tenon of another board is inserted into the groove and hammered with a mallet. Reinforce the boards with self-tapping screws, screwing them into the center of the board and joists. The self-tapping screw should be twice as long as the thickness of the board.

The second fastening option is to screw the screws into the tenon of the board at an angle of 45 degrees. To prevent the board from splitting, holes are drilled in it in advance. Finished floors are laid after finishing the interior finishing of the house.

Choosing what to cover wooden floors with

Wooden floors make your home interior more comfortable and family-friendly. In addition, natural wood always looks very stylish and expensive. The overall style of the room is not important here - wooden floors look very rich in both modern and more classic styles. Even with the abundance of numerous innovative floor coverings on the construction market, wood does not lose its popularity. More and more people are choosing wooden floors for their appearance and environmental friendliness. In addition, a floor made of natural wood has good thermoregulation - it is very warm in cold winter, and quite cool on a hot and sultry day. You can walk on this floor without fear even barefoot. Wood is also highly durable with the proper level of care. Let's find out how to cover a wooden floor to get the longest lifespan and avoid problems with it.

So, how to treat such a floor in an apartment or private house? Where to start and how to process? First of all, you should choose the appropriate material. Previously, ordinary oil paint was considered the most popular coating. And only recently coatings have appeared on the market that do not hide the wood grain and give the floor a rich color and shine. Often, these compositions not only perform a decorative function, but also protect the coating from various environmental influences. How to cover a wooden floor? There are a lot of products - varnishes, mastics, all kinds of oils, wax and much more.

Parquet floor creaking

Creaking is one of the most common problems with old parquet floors. Unfortunately, in many cases, it is possible to completely get rid of it only by completely replacing the coating in compliance with all the necessary technologies. However, in some situations, you can eliminate the squeak yourself, and without any special financial costs. To do this, you need to try to “wedge” the parquet along its perimeter.

Before carrying out wedging work, it is recommended to check the humidity in the room. If it is above 40%, then the probability of a successful result after the work is extremely low.

The first step is to remove the baseboards and remove the old wedges, which most likely no longer fulfill their function. In their place we drive new wedges, at a distance of about half a meter from each other. For a week, we “knock out” the wedges every day and check the floor for squeaks. If the creaking does not disappear within a week, then, alas, this method cannot be eliminated.

As you can see, it is quite possible to carry out minor parquet repairs yourself, without turning to specialists for help. But if your parquet flooring does not yet require repair, remember that the best way to maintain its attractive appearance for many years is timely and proper care.

Preparatory work

Before you start covering a wooden surface with any protective compounds, it is necessary to carry out preparatory work. The work differs for new and old floors.

If the floor is new

First of all, check how deep the nails or screws sit. The caps of fasteners must be 1-2 mm inside the surface of the floorboard. Next, these same caps should be covered with sealant or putty.

The color of this putty should approximately match the color of the board. Then, the surface is covered with starting varnish and dried. How much time to dry depends on the degree of drying of the boards. If they are wet enough, then the process can take a significant amount of time - 3-4 months. In this case, it is best to carry out this preparatory stage in the fall, and then leave the surface to dry until spring. If a dry board was used during the installation process, 3 weeks will be enough for the varnish to dry.

Old floor

It often happens that the owners of old apartments or houses, where the wood of the floor was covered with paint, want to give a second life to the floor and, having cleaned the paint, see that the wood is in excellent condition. Here, just a couple of layers of paint will be enough and then the floor will delight the owners with its ideal texture. And you will no longer need to think about how to cover the floor in your apartment.

How to remove paint? This process is simple, but requires serious investment of labor. However, with the help of a scraping machine everything will turn out much easier. For a one-time event, it makes no sense to purchase a car, but renting one is a good solution.

If you need to remove the paint manually, then you should prepare:

The first step is to remove everything that covers the floors in the apartments. This is done using paper and a hot iron. All the paint will stick to the paper, and the residue can be conveniently removed with either a knife or a spatula. In those places where the paint is very deep, a wash will help.

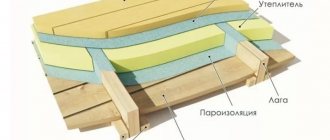

Floors on joists

The installation of a floor in a wooden house on joists is identical to the installation of a subfloor. There are differences in the methods of attaching the joists. They are fixed to the base and grillage. They are located at a distance of 2 cm from the walls.

First they make the strapping. The logs are attached to it with anchors, but not rigidly, but only slightly fixed so that they do not wobble. The step between the lags is 40-60 cm.

Skull bars are attached to the bottom edge of the joists. Boards are laid loosely on the bars.

Polyethylene film serves as waterproofing. The joints are fixed with a stapler. The film goes onto the wall.

Insulation is laid over the waterproofing.

The vapor barrier membrane is installed in the same way as waterproofing. A counter-batten is nailed onto the vapor barrier layer. It creates a ventilation gap. You can lay sheets of chipboard or boards on the logs.

By the way, such floors can be insulated from below.

Single layer floor

Single-layer flooring is laid in two versions:

- on brick supports. Beams are placed on them, and flooring in the form of boards or sheet materials is laid on top;

- along the beams. Brick supports are not used. The beams are embedded in the walls. The distance between them is large: about a meter. Therefore, the flooring is attached to the sheathing. The sheathing is made from square timber. It is fixed with nails. It is necessary to ensure its horizontal position so that the coating laid on the logs is even. If you plan to install only boards, and the finishing coating: laminate, linoleum will not be laid, then the boardwalk is considered finished. At the end of the work, the floor is varnished.

Double floor

A double floor consists of a rough and a finishing coating.

Skull bars are nailed to the bottom of the installed logs. Boards are placed tightly between the skull blocks.

Moisture-proof material is laid on the boards. Then the insulation and vapor barrier membrane are laid. Tongue and groove boards of the finished floor are laid on it. To ensure that the space between the finished and subfloor is ventilated, vents are made in the corners of the finished floor and covered with decorative grilles.

Types of varnish: shine and gloss

If varnish is chosen as the finishing coating, you should remember that only highly specialized parquet varnishes are suitable for these purposes. Only they are able to give the surface the necessary shine, and can also fill small gaps.

It is also necessary to take into account that not every varnish is suitable for a particular floorboard. For example, for pine floors, only those products that are designed for soft wood are suitable.

Water-soluble varnishes

A water-based product has many benefits. The varnish is odorless, dries well and quickly, and has good adhesion characteristics. There are one-component or two-component formulations. The difference between them is the service life - a composition based on one component will lose its quality after 2 years, while a two-component one can be used for up to 10 years.

To get excellent results, the conditions must be met. It is best to purchase only the highest quality rollers, and during application the room must be kept at constant humidity. When performing work in winter, a humidifier is necessary. This is a good choice, especially if you consider what floors are used in apartments of old construction.

Alkyd varnish

This product can perfectly highlight the unique structure of wood, but it takes a very long time to dry. These varnishes are relevant on moving bases, that is, where the boards move due to loads.

When working with these varnishes, it is very important to use them no more than the norm calculated by the manufacturer. Otherwise, the coating will wrinkle. Also, at the time of drying, the surface should not be exposed to sunlight.

Waterless polyurethane varnishes

Such coatings have excellent wear resistance. They can be used even in those rooms where people wear shoes, shoes, and boots. These funds are relevant for restaurants, theaters, cafes. If you think that this is the right product to cover the floor in an apartment, then the capabilities of polyurethane varnishes are too excessive for an ordinary city apartment, so they should not be used for your own home.

Heating

We lay a vapor barrier on the laid subfloor, and fill the gaps between the joists with insulation (mineral wool). Penoplex or foil polyethylene foam is placed on top. We use polyurethane foam at the junctions of walls and floors. Before laying the finished floor, we lay a layer of vapor barrier material on top. The laid clean layer can be additionally covered with thickened linoleum or carpet.

For many residents, such a scheme is enough to preserve heat, but some also need heated heated floors. Installing heated floors is becoming more and more attractive in home improvement and increasing its comfort.

Heating options:

- Supply of hot water to heating pipes;

- Heating by electric heating cable;

- Heating by infrared radiation.

With the water method of floor heating, heating pipes are placed in the concrete screed. These can be polyethylene, metal-plastic and copper pipes through which hot water transfers thermal energy.

A simple solution for supplying hot water to these pipes would be to connect to the general heating system in an apartment building, but this is administratively difficult. Obtaining such permission from utility services, ordering a project and agreeing with the building management is far from an easy task.

In a private house, solving the issue of installing a warm water floor, you can get a safe, durable and cost-effective scheme for maintaining a comfortable thermal regime.

In electric heating systems, a shielded heating cable in combination with temperature sensors is used as the main heat source.

Infrared floors are a thin film with carbon strips between its layers. These strips, receiving power from the electrical network, emit infrared thermal radiation, which heats the space around them.

Oil: beauty and strength

Coating wooden floors with oils has been used for a very, very long time by architects and parquet specialists. They knew what to cover the floor with so that it would survive to this day.

Modern products for covering wooden floors are based on natural oils, synthetic polymers, and hard waxes. All these substances have excellent preservative properties for wood and significantly increase wear resistance. Wood treated with oil compounds perfectly withstands environmental influences. Such a floor will not swell or dry out, but after such treatment it is no longer acceptable to varnish it.

Oil coatings will help preserve the natural color of the wood or slightly change its shade. Unlike varnishes, the product penetrates the wood much deeper. The composition penetrates into the pores of the wood and creates a thin film on the surface. This floor, which is treated with oil, has high wear resistance and takes on a natural appearance.

Any modern oil composition that is intended for application to a wooden floor will contain polyurethane and wax, which immediately have all the necessary strength characteristics. In addition, the product can create gloss, matte, and silky matte. If you are wondering what to cover your floors with, oil is a great choice. Durability and natural color of wood - what else is needed for a home?

Methods of applying protective agents

There are two methods for treating wood with protective agents:

- Surface treatment . This method allows you to preserve all the decorative properties of the tree and at the same time protect it from various influences. This operation is carried out in any private construction, from finishing wooden beams in houses to any wooden buildings.

- Deep processing . The implementation of deep coloring is possible only in production, where there are special industrial devices. The essence of this treatment is to penetrate the product deep into the wood fibers, thereby ensuring high-quality protection of the entire part.

Wax based protective coating

Compositions on this basis are applied as a protective layer. A similar product consists of beeswax, flaxseed or any other natural oil, as well as other additives. All these ingredients are found in different proportions depending on the manufacturer.

Waxed floors have a noble matte finish, a distinct wood texture, and a golden color. They have high resistance to moisture. However, the product does not protect the wooden surface from mechanical stress. In addition, such coating requires professional maintenance. Such compositions are practically not used in residential premises. But there is nothing better than waxing wooden floors in public buildings.

Floor covering using Scandinavian technology

This option is suitable for those who appreciate and love the pristine characteristics and advantages of natural wood. Also using this method, the wood will not be subjected to any processing.

In Scandinavian countries, carefully sanded wood floors are not coated with any protective or decorative compounds. It is simply cleaned regularly with soap solutions, using ordinary laundry soap. Over time, the solution will be absorbed deep into the wood pores and any dirt will be easily removed from the surface.

It doesn’t matter at all what you use to cover a natural wood floor. The main enemy of wood is moisture. Even a carefully treated and maximally protected wooden surface should not be wetted unless absolutely necessary.

If you constantly remember this, then such a floor covering can be used for a very, very long time. And yet, there is no other finishing floor covering that would give as much warmth, coziness and maximum comfort. And only wood can generate aesthetic pleasure.

Source

Tools

With large surfaces it is faster and more economical to work with a roller, but a regular paint brush will also be needed. You won't be able to paint near walls and in corners with a roller. Therefore, it is better to go through hard-to-reach places with a brush and then use a roller.

If your walls are not painted or wallpapered, then you don’t have to worry too much and get to work. But if you need to protect the walls, you will need to purchase masking tape and cover them, and remove it after completing the work.

To impregnate the roller with paint, it won’t hurt to buy a paint bath. Of course, you can get by with, for example, a cut-off water bottle, but a bathtub is more practical and convenient.

For work you will need: tape, roller, brush, paint tray (tray)