Modern multi-storey buildings do not have good sound insulation. Many residents carry out isolation measures on their own. Fortunately, today the building materials market allows you to select materials that meet the parameters and characteristics of the buyer. Depending on the intended work, you can select the appropriate sound insulation in a panel house.

@Panel'nii dom

Reasons for poor sound insulation of panel houses

The main reason for poor sound insulation of panel houses is non-compliance with construction technology. Many developers, in order to save money, do not include soundproofing measures in the construction plan, which is why the residents of these buildings suffer.

Panel houses consist of reinforced concrete structures, which, despite their small thickness, perfectly conduct various sounds. If, for example, someone is renovating a house, then even on the top floor you can hear it as if work is being done behind your wall.

@Panel'nii dom

Also, do not forget that each panel block is manufactured quickly enough, and few people worry about cracks and cracks, but it is through them that many different sounds pass. Solving the problem with developers is problematic, since everything in the documentation presented is as it should be, but in reality it is very difficult to determine whether there is sound insulation or not. Everything will be revealed after you move into the apartment...

In order to ensure the most comfortable conditions in your apartment, it is necessary to deal with sound insulation even at the stage of rough renovation, especially since the variety of building materials allows you to choose exactly what you need.

Sealing seams and joints

If in new buildings the problem is the poor quality of filling joints, then in old houses this is compounded by cracks resulting from deformations and displacement of elements.

These defects allow sounds to pass through structures freely. A sound insulation device without eliminating through gaps will not provide confidence in the final result, since the protective layer will be insufficient. If work is carried out on a bare floor base, then you should carefully evaluate the joints between the panels and the interface lines of the wall panels and the ceiling. If cracks or chips are detected, the cement or other sealing filling is removed to the base material, and the resulting void is filled with polyurethane foam or non-hardening construction sealant.

Treatment of joints and cracks in floor panels.

When improving the properties of an existing coating when performing repairs without completely dismantling the base, it is recommended to open it along the perimeter to the base, fill the joint with sealant and cover it with a cement-sand screed under the level

Sometimes they do not pay attention to the passages of pipelines through the floor panels located in the bathrooms and kitchen. By eliminating through gaps around them, they reduce the penetration of sounds and uncontrolled air exchange, which is a source of extraneous odors and affects the indoor microclimate

Soundproofing methods

To determine soundproofing methods, you should first understand what sounds disturb a panel house and what you need to protect against. There are two main types of noise that are found in panel houses: impact and airborne. Speaking of airborne noise, it is transmitted through the air.

As a rule, these include a loud TV, a quarrel between neighbors behind the wall, or the operation of household appliances. As for the shock, its origin depends on whether the house is being renovated or not. It is transmitted over hard surfaces of the structure, and getting rid of it is much more difficult than airborne.

There are currently three main soundproofing methods recognized:

- Frame;

- Frameless;

- Floating.

The frame installation method is the installation of a frame base made of wooden beams or an aluminum profile. According to the technology, plates that absorb sound waves are placed between the guides of the structure. Afterwards, sound-reflecting materials are installed, which provide maximum protection from various noises and sounds. In some cases, the outer layer is not a reflective, but an absorbing surface.

@Panel'nii dom

As a rule, this finishing option is used for recording studios and similar premises. The main advantage of this method of sound insulation is its effectiveness. It is possible to reduce the noise level in the apartment as much as possible, while the cost of such insulation will be relatively low and quite affordable. The only downside is the loss of space in the room. If similar work is done on each wall, floor and ceilings, then the overall square footage may suffer by several square meters.

The frameless method of sound insulation involves the use of special slabs, panels and membranes of small thickness. In this soundproofing technology, the material is attached or glued directly to the surface of the wall and ceiling. The final stage of work is the use of finishing or thin cladding panels. If you carry out soundproofing measures correctly, you can create optimal conditions with minimal loss of space. In addition, without using a frame base, you can save on materials.

You can read more about this soundproofing method in this Article.

@Panel'nii dom

The floating method is suitable exclusively for flooring. The essence of insulation is that soundproofing material is laid on the subfloor, and a screed is made on top of it. Due to the fact that the floor base does not come into contact with the walls, a good soundproofing effect is obtained. Using this technology, you can not only get a floor through which no sound passes, but also achieve complete sound insulation by combining various technologies.

@Panel'nii dom

Of course, you can protect one wall through which sounds are constantly heard, but such work will not be considered effective, because only with combined insulation can the necessary results be achieved.

Reference data

To make it easier for you to navigate when deciding whether to soundproof an apartment in a panel house, we provide data on the Rw values of building structures made of various materials, the requirements for sound insulation of various rooms and the level of noise created in everyday life by various sources.

Rw value for the most common materials used in construction

| Installation material and format | Thickness in mm | Rw, sound insulation index | Application area |

| Brick (one and a half bricks) | 380 mm | 56 dB | External and load-bearing walls |

| Brick (one brick masonry) | 250 mm | 54 dB | External walls, inter-apartment partitions |

| Brick (half-brick masonry) | 125 mm | 47 dB | Apartment and interior partitions |

| Hollow-core reinforced concrete slab with a thickness of 22 | 220 mm | 52 dB | Interfloor ceilings |

| Vibration-pressed reinforced concrete floor slab 16 | 160 mm | 52 dB | Interfloor ceilings |

| Vibration-pressed reinforced concrete floor slab 14 | 140 mm | 51 dB | Interfloor ceilings |

| Monolithic reinforced concrete | 200 mm | 53 dB | Support frame |

| Monolithic reinforced concrete | 250 mm | 55 dB | Support frame |

| Gypsum concrete panel | 80 mm | 40 dB | Bathroom box |

| Foam block D400-15 | 150 mm | 41 dB | Apartment and interior partitions |

| Foam block D400-12 | 120 mm | 40 dB | Apartment and interior partitions |

| Foam block D400-10 | 100 mm | 39 dB | Apartment and interior partitions |

SNiP 23-03-2003 requirements for sound insulation of some premises

| House category | Minimum required Rw, dB | Impact noise level Lnw, dB (for floors) |

| Overlappings between apartment premises and separating apartment premises from staircase halls and used attic spaces | ||

| Category A | 54 dB | 55 dB |

| Category B | 52 dB | 58 dB |

| Category B | 50 dB | 60 dB |

| Floors between apartments and shops located underneath them | ||

| Category A | 59 dB | 55 dB |

| Category B, Category B | 57 dB | 58 dB |

| Floors between rooms in an apartment on two levels | ||

| Category A | 47 dB | 60 dB |

| Category B | 45 dB | 63 dB |

| Category B | 43 dB | 66 dB |

| Overlappings between apartment premises and restaurants, cafes, and gyms located underneath them | ||

| Category A | 62 dB | 55 dB |

| Category B, Category B | 60 dB | 58 dB |

| Floors between apartment premises and administrative premises and offices located underneath them: | ||

| Category A | 52 dB | 58 dB |

| Category B, Category B | 50 dB | 60 dB |

| Walls and partitions between apartments, between apartment premises and staircases, halls, corridors, lobbies: | ||

| Category A | 54 dB | — |

| Category B | 52 dB | — |

| Category B | 50 dB | — |

| Walls between apartments and shops: | ||

| Category A | 59 dB | — |

| Category B, Category B | 57 dB | — |

| Partitions between rooms, between the kitchen and the room in the apartment | ||

| Category A | 43 dB | — |

| Category B, Category B | 41 dB | — |

Soundproofing base

Some people call the soundproofing base a floating floor. Essentially, this design separates the finished floor from the floor panel. Sound insulation in this technology is provided by soundproofing material in the form of slabs; the most common today are: mineral or basalt wool, as well as extruded polystyrene.

A layer of waterproofing is laid on a flat surface of the ceiling, on which insulating boards are laid. Then a leveling screed is applied to the slabs, which will be the basis for the floor covering. The thickness of the screed should be at least one and a half centimeters. This installation technology ensures maximum sound insulation of the floor, while no sounds will reach you, and your steps or jumps will not be heard by the neighbors below. In addition to soundproofing characteristics, the effect of thermal insulation will be obtained, since the porous structure of the plates helps to reduce thermal conductivity.

You can also use dry screed as a base. Fine-grained expanded clay is used as bulk building material. Thanks to its characteristics, it effectively protects the coating from the penetration of noise and cold. In apartments, sound insulation with dry screed is rarely used, since the existing space is lost due to the height of the layer, however, if a new house is being built from scratch, then this option is the best value for money.

Soundproofing the floor

The first step is to remove the skirting boards that surround the floor. Remove them carefully so as not to damage them, as they will then be installed in their original place. If the flooring is an old budget material, for example, linoleum, sound insulation can be done on top of it.

The new covering is dismantled, and after the soundproofing work is completed, it is laid again.

Soundproofing a floor begins with a layer of fiberglass flooring. Be sure to wear gloves and take care of eye protection. This material consists of tiny fibers that have an irritating effect on the skin.

Wood blocks are laid on the fiberglass layer at a distance identical to the width of the insulating boards, leaving a margin between the tips and walls.

Wooden blocks do not need to be fastened - rigid fasteners will allow noise to be transmitted through the wood, since its sound absorption level is low.

The next step is laying mineral wool in strips between the wooden elements and sealing with gypsum fiber boards, which are laid in a double layer.

Important! Lay the joints between the slabs and the walls with sound-absorbing tape. All that remains is to lay the finishing coating of your choice on the rough soundproofed floor

All that remains is to lay the finishing coating of your choice on the rough soundproofed floor.

Materials for soundproofing an apartment

In order to insulate an apartment, it is necessary to choose the appropriate soundproofing materials correctly. Today the market provides a huge selection of building materials that can be selected not only by characteristics, but also by cost. Depending on the expected budget, you can choose the most suitable sound insulation.

Do you know? It is impossible to achieve one hundred percent sound insulation in an apartment. You can ensure that noise does not affect your peace of mind and sleep.

Rolled soft sound insulation

Due to its soft porous structure, the product copes well with various types of noise. Roll insulation has a relatively small thickness, so it is suitable for both frame and frameless sound insulation methods. Sound waves are distributed throughout the product without entering the room in full.

@Panel'nii dom

Cotton slabs

Mineral wool is considered one of the options for insulating materials. Basalt or ecowool are also often used. All products have a fibrous structure, due to which this effect is achieved. The fibers are randomly arranged, and the product has excellent vapor permeability. Different cotton slabs differ in the production method and raw materials used. As a rule, such boards are used for frame sound insulation, but they can also be glued directly to walls and ceilings. If mineral wool is installed in a frame, it is important that the slab fits tightly into the guides. The slightest cracks and voids reduce the level of acoustic protection.

Read more about Rockwool company materials HERE

@Panel'nii dom

Cork insulation

Cork building material is considered an ideal sound insulation option. It is worth noting that it is made from natural raw materials, crushed cork bark, and cannot have a negative impact on the human body or pets. The porous structure guarantees good sound insulation and also has a noise-absorbing effect. Essentially, cork is an ideal soundproofing layer that provides sound absorption and sound insulation. The only thing that is not entirely acceptable is the cost of the product.

@Panel'nii dom

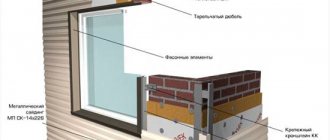

Layers of the cake

The amount of noise protection in panel houses depends on the wall material :

- reinforced concrete and concrete;

- SIP panels;

- sandwich panels;

- single-layer or three-layer.

And also on the method of protection - external or internal.

Considering that creating effective protection for the walls of a house will require a fairly significant amount of financial investment from its owner, before carrying out noise and sound insulation measures, it would be more correct to carry out special measurements of the level of noise pollution and their sources. Then it will be possible to accurately select the composition of the protective cake and the thickness of its layers.

External noise protection is carried out in conjunction with thermal protection . At the same time, for modern panel designs, such as SIP, sandwich, three-layer concrete, the installation of additional external and internal noise protection is not required, since the thickness of the internal protective layer according to GOST provides it completely. It may be necessary to protect the connecting seams if the technology for their installation has been violated.

For single-layer wall panels, the choice of pie and the thickness of the layers depends on the thickness of the panel. If the latter does not exceed 250 mm, then the cake must have at least 100 mm.

The insulation material depends on the height of the building; for multi-storey panel buildings, acoustic Penoplex and mineral wool with a frameless installation method are mainly used. For buildings up to 3 floors, the above-mentioned insulation with acoustic characteristics, installed on a ventilation frame, is also used.

If the owner decides to carry out internal noise and sound insulation of panel walls, for heated rooms the insulator is selected without a heat-insulating component, so its layer can be reduced to 50 mm. Preference is given to frame systems, since they are adjusted to specific conditions of noise pollution and are able to absorb it up to 70 dB or even more.

The frame technology of internal protection has proven itself well for any panel walls, since there is no direct contact with the insulated working plane, which guarantees the ability of the insulator to dampen impact noise from all kinds of sources.

Protective pie of internal insulation of walls made of panels from noise pollution in the case of using the frame method:

- Vibration isolation to prevent the transmission of mechanical vibrations to system components.

- The noise-absorbing layer is acoustic mineral wool.

- Sound-reflecting shell or membrane.

- External protective layer of plasterboard.

On the side of the source of sound pollution, an air gap remains behind the drywall.

Soundproofing walls in an apartment

The primary method of preparation is to identify cracks and cracks in the wall surface. If there are defects, they need to be covered with putty. It is worth understanding that even through a small crack, sound and noise can enter your apartment.

The optimal solution for walls is the use of plasterboard structures in which soundproofing boards or rolled sheets are installed. A layer of waterproofing film is installed on top of the sound insulation. This insulation option is suitable for large apartments, since as a result of the manufacture of the profile structure, some space is removed.

If the apartment is small, then it is better to use frameless installation technology and less thick slabs as an option. Thanks to this method of sound insulation, you can not only create optimal conditions, but also save the available space.

Preparing the walls

Before starting work, you need to carefully check the wall surface for cracks and crevices. If they are present, they should be covered with putty or soundproofing sealant.

After carrying out such activities, clean the surface from dust and debris, and then coat it with a layer of primer. Priming walls is one of the important procedures, since the coating composition has components that protect the surface from the formation of mold and mildew. The completely dried surface is completely ready for further sound insulation.

Types and sources of noise

Before we begin soundproofing an apartment, let's understand the types and sources of annoying noise. After all, to get rid of noise, sometimes it is enough to isolate a certain element of the apartment’s structure and not spend money on complete sound insulation.

There are two types of noise:

- Wave noise - transmitted through the air, from the source to the eardrums, using sound waves. Wave noise includes loud music, loud conversations, barking dogs, and so on.

- Vibration noise - transmitted by vibrations along the walls emanating from the source. Vibration noise includes a sledgehammer hitting a wall, the operation of a hammer drill or a washing machine.

Now let's look at the sources of noise:

- Noise from the street comes mainly through the windows. The sound of squealing brakes, the voices of screaming children and grandmothers, the hum of a flying airplane - all this is noise coming from the street. You can get rid of street noise by installing high-quality windows with triple glazing. Curtains made of thick material can serve as an additional soundproofing element.

- The noise from the entrance comes through the front door. In order not to hear the sounds of a working elevator or neighbors arguing on the landing, it is enough to soundproof the front door. In addition to covering the door with sound-absorbing materials, it is necessary to install seals between the door leaf and the frame, otherwise noise insulation will be ineffective.

- Noise from adjacent apartments comes through walls, through sockets and cracks between floor slabs. Noise from neighbors is the most common reason for wanting to soundproof an apartment. If there is only one source of constant annoying noise, then it is enough to soundproof the walls adjacent to the source. If you are unlucky and noisy neighbors surround you on all sides, then in this case you will have to completely soundproof the apartment.

- Noise from your apartment reaches your neighbors in the ways listed above and annoys them. If you often have noisy groups, if you are a musician rehearsing at home, if you have children who love to jump and have fun loudly, then for the sake of maintaining good relations with your neighbors, it is better for you to soundproof the walls, ceiling and floor without waiting for the visit of the local police officer.

The procedure for soundproofing apartment walls made of different materials

The technology for installing thin materials is quite simple and does not require special skills; it’s a different matter when it comes to thick sound insulation, and this issue should be dealt with in more detail.

Before you begin, you need to silence all the holes for sockets and switches with mineral wool. It is recommended to use gypsum as a putty composition, as it dries quickly. After the sockets, the same must be done with the communication pipes.

When the preparation is done, you can install the frame. In the vertical direction, profiles are installed at a distance of 60 cm from each other. It is important to maintain this distance, since it is comparable to the dimensions of the insulating boards. To fix the frame to the wall, it is important to use a vibration pad to prevent vibration noise from penetrating into the room.

Soundproofing boards are installed into the resulting frame, and they must fit tightly without leaving voids or gaps. The seams between the plates must be sewn with special tape, which will prevent sound penetration. Next, waterproofing is installed using a construction stapler.

@Panel'nii dom

The canvas is spread over the entire area and fixed. The last stage of installation is installing plasterboard sheets. Depending on the room, the type of sheets may be different. When the sheets are installed, you can proceed to finishing the walls.

Decorative panels

If sound insulation is carried out using panels, then finishing is not required, but it is important to carry out all work carefully and cleanly. The most effective sound insulation is the one that combines several types of materials. The cost of such sound insulation will be rather large, but the result will be noticeable. Using the correct installation of modern soundproofing materials guarantees coziness and comfort in the house.

About how to create a Beautiful interior using decorative panels in this Article

@Panel'nii dom

Gluing roll sound insulation to the wall

The technology for installing roll insulation is similar to that used for slabs. For gluing without lathing, a layer of glue is applied to the wall and additionally secured with dowels using fungi. In terms of time, this method is more profitable, since even a beginner can do everything quickly and efficiently.

@Panel'nii dom

Electrical distribution boxes.

These boxes, in which the electrical wiring is connected, are usually installed at the top of the wall. Often you may not be aware of them because they are hidden behind the wallpaper. It is very easy to find by lightly tapping. Exactly as in the previous example, the holes for installing distribution boxes are through and are covered with a thin layer of plastic on top.

Tip: Soundproofing electrical distribution boxes can be done in the same way as electrical outlets. We strongly recommend that you contact an electrician, since fire safety depends on the correct wiring!

Soundproofing the ceiling in an apartment

Soundproofing of ceilings is carried out in the same form as walls. If the apartment is undergoing major renovations, then everything can be done quickly and efficiently. If there is a renovation and you just need to do soundproofing, then it’s easier to negotiate with your upstairs neighbors and install a floating floor in their apartment at your expense.

More details about ceiling soundproofing HERE

A popular method of sound insulation is mineral wool slabs.

Today, mineral slabs are quite popular due to their characteristics and relatively low cost. If we consider this material as sound insulation, then for installation you will need a frame and sheets for sewing up the surface. The procedure is not complicated, but it requires a lot of time and effort to achieve the expected result.

Other ways to insulate the ceiling from extraneous noise

In addition to the main types of insulation, additional options can be used. One of the most suitable is the use of a stretch fabric ceiling. Such canvases have sound-absorbing properties, which in turn are ideal for working in an apartment.

Noise protection materials

Acoustic mineral wool is considered the most popular external noise insulator for panel walls.

When laying SIP panels or a three-layer concrete slab in the core, its level of street noise absorption reaches 60-70 dB, which is a very good indicator.

To protect single-layer mineral wool panels, it is installed using the “ventilated facade” option , which further increases the degree of noise insulation to 65 dB. The advantage of mineral wool is its versatility.

It provides protection against heat loss and street noise, fire resistance, vapor permeability, at a low price level, with environmental and biological safety and with a long period of operation.

The disadvantages include the difficulty of laying the slabs due to the need to take increased safety measures, as well as the weak structure of the insulation, and therefore the material may sag over time.

For external noise protection, Penoplex 100 mm thick is also used , installed in a frameless manner for buildings of any number of storeys. In terms of noise insulation, Penoplex and mineral wool are almost on the same level, and it is easier to work with.

For these purposes, choose the Penoplex brand - Comfort 100 mm, the ability to absorb noise up to 60 dB. The advantages of the material also include its low weight, ease of installation, high heat and sound insulation characteristics, versatility, the ability to use both inside and outside walls, as well as increased biosecurity.

Disadvantages include high price, exposure to ultraviolet radiation and chemical solvents, low degree of fire resistance, the material does not burn, but smokes with the release of toxic materials.

For internal sound protection of panel walls, the market offers many more options for both frame and frameless installation.

User ratings for high quality soundproofing materials:

- MaxForte SoundPRO, roll insulator 5x1.4 m, 12 mm, with the highest level of protection against shock and air layers. Protection is provided by specially placed aluminosilicate fiber.

Pros: non-flammable, does not take up free space in the room, universal, for any type of surface, environmentally friendly and not afraid of mold and parasites.Cons: high price 1190 rubles. for 1 m2 or 8550 per roll.

- Minvata can protect against 95% of airborne and especially impact noise.

Pros: universal for any type of installation, fire-resistant, durable, with a low price of 773 rubles. per package.Cons: Cannot be installed in damp rooms due to high hygroscopicity and complex installation process.

- MaxForte ECOstove with a protection level of 67%, based on basalt with a high sound absorption index.

Advantages: high density, does not collapse during installation, homogeneous structure, non-flammable material, universal action for all types of wall panels.Disadvantages: Not recommended for installation in wet rooms without a vapor barrier layer in areas with high humidity, high cost - a 2.4 m2 package costs 750 rubles.

- Thermosound insulation - three-layer protection against noise pollution with a thickness of only 14 mm and can absorb 30 dB. The inner layer is made of fiberglass canvas, compressed and sealed into a protective shell of propylene.

Advantages: environmentally friendly, quick to install, fireproof, has high thermal resistance and is not afraid of moisture, temperature and biodamage.Cons: high price RUB 3,800. per roll 15 m2, difficult to install due to large dimensions.

- Isoplat — protection from natural wood fibers, protection level up to 30 dB.

Positive qualities: environmental safety, provides additional strength and long service life, simple installation.Cons: very high price 630 rubles. for 3.24 m2, not well represented on the construction market, cannot be installed in wet rooms.

When installing internal sound insulation on frames, it is necessary to use acoustic fastenings with elastic shock absorbers. Before installing the massive cladding, a vibration tape is glued to the contour of the frame, which prevents the transmission of mechanical vibrations to the panel and increases the overall protective index Rw of the system.

Soundproofing the floor in an apartment

To protect the flooring in an apartment, a floating floor is the optimal solution. Sometimes there are situations when renovations have just recently been completed and you don’t want to start all over again. To do this, you can use various insulating items in the house to achieve the expected result. For floors, a full-length carpet would be an excellent option. Thanks to its porous structure, it will absorb sounds, creating optimal conditions for humans.

@Panel'nii dom

Types of materials for sound insulation

Today, the abundance of materials is so great that you can choose according to various parameters and characteristics. Depending on the method of work and the intended budget, you can choose the optimal solution. The most effective sound-insulating layer is considered to be mineral wool, the fibers of which perfectly retain sounds. If you use a combination of membranes and slabs, you can achieve maximum soundproofing effect.

Sealing seams and joints

In the soundproofing process, sealing seams is considered one of the most important, since sounds and noise can penetrate through the seams. To solve the problem, you can use a soundproofing sealant, which guarantees effective protection.

Soundproofing substrates

To choose a substrate, you should first decide what material will be used. Depending on the available budget, the most correct solution is selected. The underlay ensures proper operation of sound insulation. There are many types of material and you can choose anything.

Soundproofing of beam floors

As a rule, roll or tile products are used to soundproof beam floors. The procedure is carried out in the same way as walls using a frame method. The only difference between them is that you do not need to build a separate structure; everything is available.

Sound insulation under floor screed

For flooring, the best option for sound insulation is a floating floor system. With the help of technology you can achieve the expected effect. The work is not difficult, but it forces the master to work.

Sound insulation of floors on joists

Floor insulation work is carried out using a substrate and appropriate material. GKL and GVL boards, as well as chipboard, are ideal. Insulating membranes are installed under coverings to increase the retention effect.

Soundproofing floors under laminate

As previously stated, the underlay for laminate flooring should not only complement the style of the interior, but also be an effective building material. After installation, creaks and broken locks of the products should not appear. With the right substrate, you can achieve the optimal solution.

@Panel'nii dom

Soundproofing floors under tiles

Ceramic tiles are considered one of the best types of flooring materials. A solid base with proper insulation can last for decades without losing its quality and features.

Soundproofing floors under linoleum

When choosing insulation for linoleum, it is important that the surface is not too thick, otherwise the surface of the material may become deformed and lose its appearance. The best option for linoleum would be a hard layer of sound insulation.

A cool article came out on this topic READ HERE

Features of wall and ceiling treatment

In terms of price-quality ratio, the best option for soundproofing walls in monolithic houses is plasterboard. It is installed on a metal frame. Apply 2-3 layers of gypsum plasterboard; soundproofing material (most often mineral wool) is placed in the spaces between the profiles.

Particular attention is paid to the structure of the frame. It is fixed around the perimeter to the fencing structures (you can use fastenings to the wall)

Further work is carried out in this order:

- When fastening to the wall, the outer surface of the metal profile is covered with sealant.

- The frame is mounted to the floor and ceiling using anchors and dowels. To improve sound insulation in monolithic houses, it is advisable to use soundproofing suspensions.

- The cavities formed by the frame are tightly sealed with mineral or specialized acoustic wool. (The latter option is preferable).

- They lay communications inside the sound-absorbing layer, sealing the exit points.

Wall cladding is carried out using a combination of soundproofing materials. The structure of two layers of plasterboard sheets, covered with gypsum fiber board, is characterized by excellent performance. GKL joints should not be combined in different layers. The lower level joints must be covered with the upper ones and covered with non-hardening sealant or putty.

There is an alternative solution for soundproofing walls in a monolithic house: sandwich panels, ZIPS panels. The products are mounted directly to the wall.

To protect against sounds, a vibration-independent metal frame on suspensions is assembled from the rooms above. The empty space between it is filled with mineral (or acoustic) wool and lined with soundproofing panels with quartz sand. At the final stage, the ceiling is finished with plasterboard sheets.

Soundproofing doors

Doors to an apartment, like any other part of the structure, are capable of transmitting sounds. To solve this problem, you can change the door leaf and seal all existing holes in the wall. It is important to remember that doors with glass elements do not retain sound well, so it is better to use homogeneous panels.

Door soundproofing options

Soundproofing doors can be done in several ways. The most common way is to tape around the entire perimeter of the door frame. A universal threshold can also be installed as an option. And, of course, it is possible to fill the canvas structure with soundproofing material.

Read more HERE

Window.

Few people know that through the windows not only the noise of the street or traffic intersection, but also the sound from your neighbors’ home theater can penetrate into the apartment. If you replace old frames with modern metal-plastic structures, the problem will be solved very quickly. But sometimes minor edits to the old stuff can give a more effective result. It should also be noted that very often one can hear complaints that after dismantling a wooden window for metal-plastic ones, some types of extraneous noise become more audible. The reason for this is the so-called “masking effect”, which was created due to street noise.

Advice: To soundproof an old structure, first of all you should replace the glass, which was previously 4 mm thick with thicker, modern ones - 5-6 mm. Immediately after dismantling, coat the frame structure with transparent silicone sealant. The installed window must be strictly in size. Place the glass tightly into the silicone seam, then press it with glazing beads and remove any protruding excess.

It is very important to attach a special rubber seal around the entire perimeter of the sash, which has a section in the shape of the English letter “D”. Today on the construction market you can find a great variety of different seals for such purposes.

If, after the operations performed, the window sash closes with force, then it is better to seek recommendations from a carpenter, who will determine in which places the layer of wood needs to be removed.

Before installing metal-plastic windows, you need to understand that thicker double-glazed windows (3 glasses) do not provide higher sound insulation compared to standard single-chamber options with the same total glass thickness.

| Note. We advise you not to use drywall when leveling slopes, due to the fact that resonance phenomena in the air can reduce the noise insulation index of the window structure. It is correct to use cement mortar for these purposes. |

Soundproofing pipes in an apartment

As you know, sewer and water pipes make a lot of noise. Using polyethylene foam, you can wrap up noise sources and make your apartment more comfortable and quiet.

Pipe insulation methods

There are also special casings that can be placed on top to insulate pipes. Such boxes are made of polyurethane foam and provide high performance. The only thing that is not particularly attractive is the cost of the product.

And you can read about the intricacies of soundproofing pipes in THIS ARTICLE

Price of work

The total cost of soundproofing work with materials is quite significant and ranges from 2000 to 4000 m2 , with most of it accounting for the purchase of insulation and consumables.

Work on installing a sound insulation system in panel houses depends on the chosen scheme, the number of storeys of the house, the technical condition of the panels and the type of insulation.

Average prices for work:

| Name of works | Price RUR for 1m2 |

| External sound insulation ventilated facade, mineral wool | 1650 |

| Wet facade Penoplex | 1150 |

| Internal frame sound insulation of load-bearing panel wall | 800 |

| Internal frame insulation of panel partition | 670 |

Soundproofing of air ducts

The air duct can also produce excess noise, and the problem can be eliminated by covering the pipe body with soundproofing material. By wrapping all sides and gluing the material tightly, you can be sure of the quality of the work done.

@Panel'nii dom

You can create ideal conditions in your apartment if you use comprehensive sound insulation. Every element of the apartment needs processing and preparation. Only quality work will ensure complete comfort and coziness in the house.

Read more about soundproofing a hood in a kitchen or production area in this article.

Sound insulation of PGP partitions

How to soundproof a laminate floor?

How to make insulation - step by step procedure

Before the initial stage of installing soundproofing protection for panel walls of any design, both outside and inside, surface is thoroughly prepared . Not only are they cleaned of dust and dirt, it is important to check all butt seals and completely waterproof them. We also repair various cracks, chips and any damage to concrete surfaces.

Outside

On multi-storey panel buildings, frameless protection is installed.

After carefully preparing the walls and sealing the seams, the walls are well primed. The insulator boards are installed on glue , which is purchased dry, in accordance with the brand of the protective board.

Beacons are installed to ensure that the insulator does not move. Lay the slabs from the corner, the second slab from the opposite side.

The second and subsequent rows are laid with offset seams so that cold bridges do not form. After the glue has dried, the slabs are additionally secured with 5 dowels. on one sheet.

A perforated metal corner is installed on the corner of the wall. Level the surface of the slabs with glue so that the dowel heads and corners are not visible. A reinforced mesh with an overlap of 100 mm is installed on the glue and covered with a layer of 3 mm of glue. After it dries, apply another layer and level it with a spatula. The surface is primed and painted, additional plastering can be done.

From the inside

Work on installing internal sound insulation, regardless of the type of insulator chosen, is carried out in a strictly established sequence :

- Dismantle the previous finishing layer from the walls: wallpaper, paint and facing panels.

- Dismantle the electrical equipment and extend the wires for a new installation and wrap them with electrical tape for safety.

- Install wooden or metal sheathing.

- The frame is filled with soundproofing boards.

- If the composition of the cake requires a vapor barrier, install it, leave a ventilation gap and cover the system with acoustic plasterboard, securing it to the frame with self-tapping screws.

Permissible noise standards

In different regions of the Russian Federation, requirements for noise levels in residential premises may differ. On average, you cannot make noise from 22-23.00 in the evening until 7-8.00 in the morning, including quiet time for children from 13.00 to 15.00. On holidays and weekends, silence must be observed until 10.00 am (with the exception of New Year's Eve).

Maximum permissible noise levels for residential premises in apartment buildings:

From 8.00 to 22.00 (daytime) – 40-55 dBA,

From 22.00 to 8.00 (night) – 30-45 dBA.

Important: permissible noise levels in rooms are set with standard ventilation (with open vents, transoms, narrow window sashes).

Maximum noise levels day and night

How noise affects human health

Noises affect a person on a mental and physical level. By affecting the psyche, they lead to nervous disorders, insomnia and stress. Constant stress destroys health and shortens life. According to doctors, they can take away 8-12 years of our stay in this world.

Noises, even not very loud, but prolonged, change the frequency of contractions of the heart muscle, lower and increase blood pressure, and reduce blood flow to the brain.

Scientists have found that after 10 years of living in a noisy city, people become more susceptible to various diseases. They have an increase in gastrointestinal diseases (gastritis and ulcers), hypertension, and coronary heart disease.

Soundproofing of central heating risers

According to regulations, central heating pipes passing through the floors must be installed in special sleeves. These are large diameter pipes that perform the function of sound insulation. If the standards have not been met and the sleeve is missing, the owners will have to insulate the risers themselves.

Work progress:

- Remove the cement slurry from around the pipe.

- Wrap the freed pipe with mineral wool or glass wool.

- Cement the space between the pipe, ceilings and insulation.

- Cut off any remaining soundproofing material.

- Carefully putty the surface and smooth out any unevenness.

Price

High-quality long-term sound insulation is not cheap. The calculation takes into account the type of room and working surface (walls, floor, ceiling), noise source, materials, base strength and area volume.

If installation work is carried out by professionals, the cost will double. On average, turnkey sound insulation can cost 2,200 rubles/m² (without delivery of materials). Many websites of companies providing sound insulation services have an online calculator for accurately calculating the cost of work.

For high-quality sound insulation of a room, it is not enough to treat one wall or ceiling; an integrated approach is required. It is advisable to carry out work at the initial stage of repair.

Consider sound insulation for a suspended ceiling

The most important thing is to vibration decouple the ceiling.

In simple words, you need to assemble a new ceiling that is not rigidly connected to the floor slab. This is accomplished through special vibration suspensions with a Silomer.

Vibration stop SLIM

Vibration stop SLIM is a vibration-isolating mount designed to combat impact noise penetrating floor slabs and walls. As an elastic element, a special polyurethane Silomer (made in Austria) is used, which has the ability to retain vibrations and durability.

Working with VibroStop SLIM vibration suspensions is similar to installing conventional KNAUF direct suspensions. Fastening to the ceiling is done with two anchor wedges or dowel-nails measuring 6 x 40 mm. Each vibration mount is designed for a load of 15 kg and the average consumption is 2.7 pieces per 1 m2.

In these suspensions, the design is made so that the metal that is attached to the ceiling does not interact in any way with the metal that is attached to the metal profile. Also, due to the fact that it is an elastic (damping) suspension, it acts as a shock absorber in a car and, due to this, dampens the shock wave from above.

Important: you need to use suspensions with the Silomer material; cheap suspensions with an elastic band will not work here.

Along the perimeter of the ceiling, the guide profile must be attached through a damper tape in 2 layers. To ensure that the metal profile does not adhere rigidly to the walls and vibrations are not transmitted to it.

Damping tape

Self-adhesive tape made of chemically cross-linked polyethylene serves to isolate structural noise, as well as seal and compensate for uneven surfaces of the floor, walls or ceiling at the junction of the guide profiles of the plasterboard structure frame.

The use of tape can significantly reduce the vibration load on profile elements and eliminate sound bridges along the perimeter of the soundproofing cladding in places where the cladding sheets adjoin adjacent surfaces.

Initially, the guide profile is attached to self-tapping screws, but after the entire frame is assembled, the fire itself will be held in place and the screws will definitely need to be unscrewed so that there are no sound bridges.

Next, the sheathing is done. All empty space must be filled with basalt fiber slabs. They work as a sound-absorbing material, protecting against airborne noise (voices, screams, TV). Sound absorption occurs when the formula mass - elasticity - mass is met. Between the floor slab and the finishing layers of gypsum fiber board and gypsum board there must be a fibrous, absorbent material.

Maxforte Ecocooker PRO

Sound-absorbing slabs Maxforte Ecoplite PRO are made of volcanic rock and do not contain volatile resins and phenol-formaldehyde binders. The boards are resistant to moisture and do not rot. Due to its low thermal conductivity, the material can be used as a thermal insulation material.

The plates effectively absorb noise even in the most problematic “low frequency” range.

And at the last stage, the entire structure is sewn up with GVL (gypsum fiber sheet) and gypsum board (gypsum plasterboard sheet). They work on the principle of mass. The heavier the finishing layer, the better the sound insulation works. Therefore, everything is sewn in 2 layers.

You can calculate the materials and their cost by following the link >>

The next type of sound insulation is acoustic, that is, it is a suspended ceiling with special perforation, the structure and size of which prevent sound waves from being reflected. As a result, noise is dampened in the room. The operation of such ceilings is approximately as shown in the following photo:

Perforated acoustic sheet is made exclusively from fabric. The base is a polyester mesh, which is filled with polyurethane. This fabric is subjected to 250 thousand micro-punctures, thanks to which it becomes a sound-absorbing membrane. The fabric base is much stronger than the PPC film. You can, of course, make perforations on the film, but this will cause the ceiling to lose some of its strength, since the film is thin and quite delicate. Most major manufacturers offer this type of acoustic ceiling. The widest range of products is represented by Clipso and Cerutti, by the way, and customer reviews speak in favor of these manufacturers.

The ceiling acoustic system from Clipso is completed with a stretch ceiling acoustic system, a proprietary mounting molding made of polyvinyl chloride with a complex cross-section and a sound-absorbing layer using Schumanet-BM slabs. This ceiling system most effectively eliminates echo and is suitable for people who are used to watching TV in acoustic comfort without disturbing the peace of their neighbors. The system is used in conference rooms, offices, and service areas to optimize sound.

What everyone should know

There are no materials that can be placed under laminate and achieve at least any increase in sound insulation. This is a common myth that people cling to in the hope of improving sound insulation with little cost. Accepting this fact will allow you to save money and avoid making pointless designs.

No claims to noise protection. In principle, tenants are not allowed to have a specific right to soundproofing in their apartment. The tenant of an old apartment cannot, without a special contractual agreement, in principle demand that the landlord provide the apartment in accordance with the current state of construction technology upon conclusion of the lease, explains Roperz. It is different if the landlord undertakes structural changes that result in noise nuisance.

Sheet pressed from natural cork chips

Under the ordinance, renters are entitled to standard shock protection of 53 decibels. However, the requirement for enhanced impact protection with a limit of 46 decibels only exists if the landlord has made a corresponding commitment.

For protective materials of this kind, a characteristic indicator is measured in dB. The second indicator is the degree of sound absorption, which is measured from 0 to 1. The closer this degree is to unity, the better the material. As already mentioned, thick walls themselves protect the comfort of our home from extraneous sounds. However, increasing the massiveness of walls and ceilings is a task too difficult for the average person, and also ineffective.

In most cases, the rigid material is plasterboard - its thickness is optimal for interior work, when it is important to preserve as much living space as possible. Drywall plays the role, while a layer of soft material takes on sound absorption

As already mentioned, these include glass wool, mineral wool, polyurethane foam and other cellular formations. For effective sound absorption, the layer of material in a multilayer structure must be at least 50 mm and constitute at least half of the entire structure.

The task, also in the house, is performed by an acoustic ceiling - also a multilayer structure that reduces the energy of sound vibrations and absorbs them. To do this, it is necessary to create an air space between the ceiling itself and the ceiling area - it is filled with compressed mineral or fiberglass slabs.

After all, there is cheaper polyethylene foam! Quite often, laminate flooring manufacturers offer it along with their products. Polyethylene foam is used both for soundproofing floor coverings and floating floors, and for sealing joints. It is resistant to almost all solvents and has good contact with cement and other finishing materials. However, by humidifying a space filled with polyethylene foam, good conditions are created for mold colonies. In addition, prolonged loads lead to a loss of material thickness (up to ¾ of the original value), which in turn leads to a loss of sound insulation properties.

The composite material, consisting of two layers of polyethylene film and polystyrene foam granules, is an improved version of the use of polyethylene. The top layer provides protection against moisture penetration into the structure. The bottom film allows air and steam into the space between the films, but from there they escape through the seams. Such ventilation prevents the accumulation of moisture and the formation of mold. The composite material does not deform and lasts quite a long time - from 20 years. When laying, the use of adhesives is not required.

The cork rubber backing consists of granules of cork and rubber. This material perfectly dampens vibration of household appliances and other devices. Such a substrate can be effectively laid under both elastic and hard floor coverings: linoleum, parquet, laminate, tiles. However, the cork rubber coating needs additional protection from moisture, since it serves as a medium for the occurrence and development of mold.

Club of Defenders of Silence

Ever since I encountered the problem of poor sound insulation in a panel house (137 series), I have become very interested in the topic of audibility in apartment buildings, especially in standard buildings. I was surprised, is this really how all people live, is it really possible that you can hear stomping and voices everywhere? I spent almost a year moving. And for the search, all available information on the Internet was searched, thousands of conflicting reviews about different types of houses were read. You know, it is very difficult to get rid of the illusion that there are “high-quality brick houses with good sound insulation” and there are “terrible panel houses with high audibility.” These cliches were so ingrained in my brain that it seemed to me that if I moved into a brick house on the middle floor, it would be better than the last floor in a panel house. And I admit that if I could quickly sell my old apartment, I would move to a brick house on the middle floor. This was the biggest mistake, because the stomping of neighbors from above does not depend on the type of house, but on the flooring, which neighbors can install in any way (laminate, linoleum), and also in many houses that I looked at in apartments, one of the walls of the rooms was not made of brick, and from double slabs of plaster. But then I had illusions and didn’t know about it, I wanted to leave the panel hell for any house, as long as it wasn’t a panel.

First of all, I want to note that when we talk about soundproofing an apartment, we are not talking about the fact that the apartment can be as quiet as a crypt. In any case, it will be quieter in a private house without neighbors. The apartment will be a compromise in any case. Previously, I read with skepticism recommendations that if you want silence, go to a private house. And when I began to study the soundproofing capabilities of standard building materials, it became clear to me that the apartment would be quiet as long as the neighbors were normal. No house can protect you from violent neighbors. Moreover, violence can manifest itself in many aspects. Neighbors don’t have to be antisocial, drink, rowdy, throw parties, sing karaoke to make life miserable. Some set up almost mini-productions at home for the manufacture of chairs and other nonsense, annoying for years (although these cases are rare). Some neighbors may practically not leave the house (being, for example, a housewife) and run around all evening, driving their heels into the floor like hooves. Nothing illegal, but you won’t be able to live in comfort. The neighbors may have a small dog that will bark all day long, and there will be no way to save it. Or maybe a hyperactive child, always running around and dropping everything. It is impossible to get rid of all noise for adequate money, so any apartment is a big risk. The risk is so great that I personally am even scared of the prospect that in the future I will have to move somewhere again or that the neighbors will change, and I want to light a candle in the local church for the adequacy of my neighbors and my health. But at the same time, I do not agree with the statement that sound insulation depends only on the neighbors, that all apartments are the same, etc. In my old apartment, the neighbors were adequate, but there was no life in it. So how do you find an apartment with good soundproofing? What to look for?

1. The main rule is to choose the correct location of the apartment: Only the top floor. For our forum, the advantages of the last floor are obvious. But if you read the Internet, you can find so many terrible stories about the top floor that it becomes embarrassing: - The elevator will break down, it’s like walking (or the lights will be turned off) - The roof will leak - The sun will heat the apartment like hell, much more than on the middle floor — Elevators and other engineering equipment will interfere with you. — Pigeons, etc.

In my opinion, the following fears can be fully justified: - If there is no technical floor, then there may be pipes on the ceiling in the corridor, which somewhat spoils the aesthetics. But I haven’t seen such a problem in houses with a technical floor. — Elevator noises. This problem is possible, I came across it a couple of times on the Internet, that supposedly the operation of the elevator motor can be heard throughout the apartment. But, in my opinion, this is a big exception to the rule. Most likely, the installation (or location) rules for the motor have been violated. If everything is done correctly, you won't hear the elevator at all. — It’s hotter on the top floor on the sunny side. If there is a technical floor, then of course the roof has no effect and the hot roof is unlikely to heat the apartment on the top floor. Rather, the factor here is that in many apartments on the top floor the sun is not blocked by anything, so it can burn from morning to evening. Not only the residents of the top floor, but also many apartments, even starting from the fifth floor, suffer from such sun. It’s easy to judge this, you can just look at the facade of a house facing West and see how many blinds, reflective films and blackout curtains are located on the balconies and loggias. Most of the heating comes from the sun shining through the window, rather than from heating the walls or ceiling.

You and I, of course, know the main advantage of the last floor: no one stomps on your head. Unfortunately, this does not eliminate the presence of neighbors on the side or below. The stomping of neighbors below or to the side can also be heard, although quieter than above (2-3 times). However, like loud music or TV, they penetrate the walls like a knife. Therefore, it is very important to minimize the number of neighbors; it is better to border on the elevator hall or staircase than on neighbors. It is advisable to look for an apartment with 1 border with neighbors.

2. Type of house. The most common types of houses: - brick - monolithic - frame-monolithic - panel - block.

BRICK HOUSES. This type of house is valued more in terms of sound insulation than other types of houses. It is believed that brick is an ideal sound insulator. When I first started looking for an apartment to move to, I only considered brick houses. The legend of 100% soundproofing of brick houses has lived in us since childhood. If you briefly read the information from the Internet, you can find a hundred articles, identical in content, where they clearly put brick houses in first place, without mentioning any of the nuances that can negatively affect the sound insulation of an apartment in a brick house. Let's try to understand the pitfalls in brick houses. First of all, you need to understand that brick houses are completely DIFFERENT. Let's make a conditional division of houses by year of construction: - Old building before 1917 - Stalinka - Brick Khrushchev - Brick Brezhnev - Brick houses of the 90s-early 00s - Brick houses since 2000.

What is each type of house? — Old foundation before 1917 These houses are the most unpredictable in terms of quality and sound insulation. You need to study the house plan and technical documentation of the house in detail. Many houses have wooden floors (good vertical audibility). Often the walls with neighbors are made of thin partitions (shingles). Therefore, in addition to expensive repairs, you can get excellent audibility. - Stalinists. Many types of Stalin buildings are more expensive than modern economy or comfort class houses. This is due to their advantageous, for the most part, location, high ceilings and prestige. Disadvantages: lack of an elevator, or the presence of one small passenger elevator. Communications may not be designed for the power of modern electrical appliances. The ceilings in many Stalinka buildings are wooden. The variety of layouts has led to the fact that in Stalin buildings there are also many apartments where the wall between the apartments is made of shingles or half a brick, which is why you can hear the neighbors on the side very loudly. — Brick Khrushchev buildings Even in this standard series there are many modifications: for some, all the walls are made of brick, as I had in the 1-528KP series (including the bathroom and interior partitions), and for others, even the wall with the neighbors is made of a double wall made of plaster panels through which everything can be heard. You need to study the apartment plan and tap all the walls to make sure that the walls between neighbors are solid. — Brick Brezhnevka. Initially, the apartment layouts were very monotonous. The apartments were divided into rectangular sections; as a rule, the walls were all thick. But at the same time, the apartments were one-sided, i.e. All the windows in the three-room apartment faced either the courtyard or the street. It wasn't very convenient. And it was decided that all apartments should have at least one window facing the street or avenue, i.e. to the front of the house. As a result, as now, one-room apartments usually have all 2 windows facing the street, two-room apartments and three-room apartments have two-sided apartments (i.e., facing the courtyard and onto the street). Two-room and three-room Brezhnevka apartments are rarely one-sided anymore; apartments with a “open-wing” layout are appearing. The layout is becoming very popular when one of the rooms faces the opposite side of the house. And this room is bordered on both sides by neighbors. A logical solution in terms of sound insulation would have been to make two thick walls on both borders with neighbors, but even then, in order to save money, they began to use double hispolite panels (panel thickness 8 cm + air gap between the panels). The audibility between these panels is very high: I heard the drone of the TV, which is not audible through the 14cm reinforced concrete panel, for hours on sad nights in an old apartment in a panel house, unable to sleep. And then it seemed to me that this was only possible in budget terrible panel houses. But, as it turned out, exactly the same walls were used in brick houses. Saving on bricks led to a practice that survived the Soviet Union and continues to this day in all types of houses, including brick ones. A further desire to save money leads to the fact that many series of houses appear in Moscow, where only the external cladding is made of brick, and both a monolith and reinforced concrete panels were used inside. For example, this is the Vylukha tower and II-29 series. You can easily find many more series using the same technology. This is reminiscent of today's monolithic brick houses: the house looks like brick from the outside, but in terms of internal filling and sound insulation it is similar to panel houses of the same period. — Brick houses from the 90s and early 00s. In fact, these houses are not remarkable for anything special. Very often, the walls between apartments are made almost entirely of brick, as in Brezhnevka buildings. However, very often in open-plan apartments, one of the rooms borders its neighbors through a partition made of lightweight materials, which has low soundproofing properties. This does not depend on the elite quality of the house; even in houses with expensive apartments this can occur. — Brick houses since 2000. In the mid-2000s, energy efficiency standards were adopted that made the construction of brick houses unprofitable. The walls had to be thickened; even the masonry of 2.5 bricks (65 cm) no longer met the standards for thermal insulation. This led to the fact that practically no houses were built purely from brick. Like the “Vylukha towers,” it is very common to see externally brick houses with reinforced concrete slabs or pylons used inside. The problems with sound insulation are the same: the houses are essentially no different from panel houses or brick-monolithic houses and they can only be called brick only conditionally.

Which type of home would I choose based on these characteristics? If I were choosing a 2-3 room apartment in a brick house now in St. Petersburg, then it seems that the following would be completely adequate in terms of sound insulation: 1. Most brick Khrushchev buildings (where the inter-apartment walls are made of brick) 2. Brezhnev brick houses 528KP-40 (Nadezhina point ), 528KP-80, 528KP-81, 528KP-82 (“Icebreaker”) and some modifications (for example, the “Architect” series). 3. Brick houses built from 1991 to 2002 (you need to study the layout of the apartments so that all the walls with neighbors are brick, at least 25 cm thick).

The main problem with brick houses is vertical audibility. First of all, it should be noted that the same floor slabs are used in panel and brick houses: 16cm solid or 22cm hollow-core. Unlike panel houses, even if all the walls in the apartment with neighbors are 1.5-2 bricks thick (38-51cm), then lightweight materials are still used as interior partitions. This can be a thin wall made of brick laid on edge (6.5 cm thick + plaster), it can be a half-brick hollow brick (12 cm thick + plaster), or it can be plaster ringing partitions (exactly the same ones that were used in panel houses of that same period). In modern brick houses there may be partitions made of ringing PGP (8 cm thick), aerated concrete (10 cm). All these partitions perfectly transmit sounds from vertical neighbors: both air and percussion. Acousticists advise soundproofing such walls, or demolishing them and building modern multi-layer walls with sound insulation. Otherwise, impact sounds and airborne sounds from neighbors below will be heard at the level of a frame-monolithic house.

MONOLITHIC HOUSES. Monolithic houses became widespread 20 years ago. If you look at the information superficially, you will immediately find many articles that highly value the sound insulation of monolithic buildings. But in essence, a house made of a pure monolith is not very different from a panel house: the same reinforced concrete walls with a similar density of materials, in most cases the same wall thickness (on the upper walls the standard wall thickness is 16 cm). Theoretically, a cast, single monolithic structure without joints should provide better protection from airborne noise than panel houses. But at the same time, structural sounds (repairs) will spread even further than in a panel house. Complaints that renovations from the 20th floor can also be heard on the first floor, as if renovations are taking place in a neighboring apartment, are common for a monolith. The whole house “enjoys” the renovation. Also, it should be noted that almost no one is building completely monolithic houses now. Ideally, a monolithic house should have completely monolithic facade walls and all inter-apartment walls. But even in this case, the house contains non-load-bearing partitions, which are currently being erected from lightweight, ringing materials such as aerated concrete and PGP. As a result, the problem of re-emission of sounds from neighboring apartments (both percussion and airborne) arises. These partitions need to be soundproofed or demolished.

FRAME-MONOLITHIC HOUSES: The most common type of house in large cities. On the Internet you can find dozens of articles almost identical in content, which claim a lot of advantages of this type of house over panel ones: - more durable (125-150 years versus 100 years for modern panel ones) - better sound insulation - more varied layouts - the possibility of building an underground parking

Currently, in large cities, frame-monolithic houses are built more often than panel houses. The main question is why? Of course, this is done for economic reasons. This is partly due to fashion, since panel houses gained a very bad reputation during the years of budget construction in the Soviet years. For some people, panel houses have automatically become the worst type of housing. Public information often indicates that panel houses are built 2-3 times faster than monolithic ones and cost 20-25% less than monolithic ones. Thanks to seamless technology, the facades of panel houses are sheathed with insulation and covered with plaster. As a result, modern panel houses can be practically indistinguishable from monolithic houses. In my opinion, the only tangible advantage of monolithic houses over panel houses is the possibility of building underground parking. But this does not explain why in remote areas they build budget brick-monolithic houses without underground parking, and sell apartments no higher than those of panel houses. Due to the rise in prices for building materials and the inability to increase prices for apartments, developers must find ways to reduce the cost of monolithic houses to the level of panel houses. Otherwise, it is unclear how the developer will make a profit. History goes in circles, and the desire to save money has been haunting minds since the times of the Soviet Union. First there were Stalin buildings with beautiful facades, then there were Stalin buildings made of cinder blocks, then they began to build Stalin buildings without finishing the facades (under Khrushchev), then they lowered the height of the ceilings and shrunk the layouts and made Khrushchev buildings out of brick. Then they switched to panel houses and made Khrushchev panel buildings. Then, at the end of the 60s, they began to build large-panel houses of the 1-602LG series, the essence of which was that they began to use longer panels. This not only made it possible to make the rooms wider, but also to save on building materials due to fewer load-bearing walls. Sections of load-bearing panels for 2 windows appear, and if in this section there were 2 rooms of different apartments, then they were divided by a light partition of 2 sheets of plaster. And it was profitable, so the 137 series, considered almost the best panel houses in the Soviet Union, were built according to this principle until the 90s. In the case of monolithic frame houses, the possibility of saving has reached its apotheosis: now there is no need for load-bearing walls at all, you can get by with load-bearing columns (pylons). The monolithic frame resembles a cage (reducing the mass of the structure saves on the foundation and building materials for the construction of walls). And here there is complete freedom of “creativity” to save money: you can make inter-apartment walls from a monolith or solid brick. But in reality, inter-apartment walls are starting to be made of aerated concrete and PGP partitions that do not meet sound insulation. And it is not surprising, understanding all of the above, to read thousands of complaints about audibility in modern brick-monolithic houses worse than in 50-year-old Khrushchev-era panel buildings.

Sound insulation, on the one hand, is a very complex science that needs to be studied for a long time in order to understand the principles of sound propagation. But sound insulation has simple laws, the principle of which is easy to explain. The main rule for good soundproofing of a room is the law of mass. The heavier the material from which the walls and ceilings are made, the better it insulates from extraneous noise. The use of lightweight partitions in monolithic frame houses cannot provide sound insulation even at the level of panel Khrushchev buildings (12 cm reinforced concrete walls of a Khrushchev building have higher sound insulation than a 20 cm aerated concrete wall of a monolith). I'm not saying that all frame-monolithic houses are built according to this principle. Nothing except the thirst for savings prevents the developer from building all the inter-apartment walls from a monolith, but a lot of budget houses are just like that.

PANEL HOUSES Back in Soviet times, panel houses earned a truly terrifying reputation as the most budget-friendly housing with a complete lack of sound insulation. It will probably take a long time before people will be able to talk about panel houses without negativity (if such a time comes). But contrary to general opinion, I believe that modern panel houses can actually be very good in terms of sound insulation, and now I will explain why. Can you find an apartment in a monolithic building in which all the walls with neighbors and all internal partitions in the apartment, except for the bathroom and ventilation duct, will be load-bearing reinforced concrete slabs 16 cm thick? I'm sure not. This is hardly an option, if only because the opportunity to remodel an apartment to your liking is very much appreciated. As a result, the minimum number of load-bearing walls is considered a big plus. But in terms of sound insulation, the load-bearing ones are 16cm. reinforced concrete walls have a gigantic mass (384 kg per 1 m2), a mass 4 times higher than that of aerated concrete, which is often used for interior partitions. Therefore, such load-bearing walls do not transmit ordinary household noise from neighbors above or below, as light partitions do.

But why are panel houses considered the worst in terms of sound insulation? In my opinion, this opinion was formed from several factors: 1. In Soviet times, panel houses were invented based on maximum savings and for quick construction. We saved money on literally everything. The first panel houses had thin walls 10-12cm thick. It was in panel houses that they began to experimentally make thin hipped ceilings (where the thickness of the floor slab was 6 cm), for example, in the series 606 and 507 panel houses in St. Petersburg. It was in panel houses that they began to lay linoleum on joists instead of floors, which is why vertical audibility became high. It was in panel houses that they used through sockets on the inter-apartment walls, through which, of course, neighbors could be heard. And imagine people who lived in brick houses (the same Khrushchev buildings), and then find themselves in a house where there is such audibility (lateral due to through sockets, vertical due to thin ceilings, and in later houses with linoleum instead of parquet with covered with sand). But if we remove these 2 negative factors: thin walls with through sockets and thin ceilings, let's try to objectively evaluate the sound insulation of a modern panel house. Horizontal audibility: a standard inter-apartment reinforced concrete wall 16cm thick has a sound insulation index of 52dB. For comparison, a brick wall made of solid brick with plaster on both sides has a sound insulation index of 53 dB. A difference of 1 dB can be estimated as follows: sounds through a brick wall will be 5% quieter. Those. the difference is practically unnoticeable. Vertical audibility: both panel and brick houses use the same floor panels: 16cm solid or 22cm hollow-core. Both floor slabs have a sound insulation index of approximately 52 dB. The only thing that makes sense is to have a good floating screed (or other type of sound insulation). Therefore, if in a panel house you can hear the neighbors from below (for example, how loud they are talking, or how the TV is grumbling), then first of all you need to check the heating radiators and the pipe connection sleeve. If the sound is not coming from there, then you need to make a floating screed and no longer hear such noise from below (a floating screed has a sound insulation index of 10 dB, which is higher than a Soviet floor on joists filled with sand). If you can hear your neighbors to the side, then you need to worry about moving the socket (you can do it in another place, you can make an external socket).

Compared to all-brick houses, panel houses have the following disadvantages: 1. The impact sounds of repairs travel further. Repairs can be heard 3-4 floors away from the sound source. In a brick building, sounds do not spread as much and will be heard on 2 floors. 2. In brick houses, some inter-apartment walls may be thicker than 1 brick. For example, 1.5-2 bricks. In this case, the sound insulation index of such walls is 56-59 dB (which is already 20-35% quieter than that of a reinforced concrete wall 16 cm thick).

Compared to monolithic houses, panel houses are in no way inferior. The only downside is the formation of cracks through which sounds can penetrate. But there may also be cracks in the monolith. This can be corrected if it occurs. On the other hand, in a panel, sounds travel over shorter distances (of the same repair), and there are more heavy load-bearing walls. However, when buying an apartment in a panel house, you also need to check all inter-apartment walls, as well as partitions. They can also be made of PGP or aerated concrete and re-emit sounds. In old Soviet large-panel houses in swing-open apartments, one of the rooms also has a light partition with neighbors in the form of a double plaster wall, which has very low sound insulation.

BLOCK HOUSES There is also a BLOCK TYPE of houses. But due to the low amount of information on these types of houses, it is very difficult to judge how good the sound insulation is there. In the first versions of cinder blocks, part of the inter-apartment load-bearing walls is made of blocks 40 cm thick (if we take into account the density of cinder blocks at 1600 kg/m3), we can say that in such houses the sound insulation should be high (at a level of 56 dB, as in a wall of 1.5 bricks). But for more modern series of block houses, the thickness and materials of the walls may be completely different. Reviews are also very contradictory. It is not entirely clear whether block houses are being built at all now. We are looking for monolithic frame houses with infill blocks. Most likely, block houses are practically no longer built.