In modern renovations, plasterboard is often used to cover walls, ceilings, and create a variety of structures and partitions. Its use guarantees the resulting smooth surfaces without flaws.

As a reinforcing material or decorative design of surfaces, fiberglass can be glued to drywall.

This coating is a modern material that helps hide minor defects in both walls and ceilings. The technology for laying it is almost no different from working with paper (vinyl) wallpaper, but certain nuances should be taken into account.

What is fiberglass?

The material is a canvas used for painting or putty. It is made from fiberglass threads, which are pressed during the production process. Fiberglass has the appearance of a mesh. It is also called differently the cobweb.

Fiberglass and glass wallpaper are considered environmentally friendly; they protect the wall from the appearance of fungi and mold.

The material protects surfaces from cracks.

The product is presented on the market in the form of rolls, the width of which is 1 m, and the length can be 20 or 50 m. The density of the structure ranges between 20 - 60 g/m2.

Fiberglass has two sides that differ from each other. The back has fibers that increase the adhesion of the material to the surface. The front side is smooth, which makes it easy to carry out painting work.

Even if the sides of the fiberglass are mixed up and used for other purposes, there will not be much difference in the finishing.

Fiberglass can be with simple and complex weaving. The first type is used to prepare the surface for plastering, the second - for painting.

Cost of services

Gluing glass wallpaper with your own hands, as you can see, is a very difficult task. If you are afraid of ruining a rather expensive material, use the services of professional craftsmen.

You can order glass wallpaper gluing at a price of approximately 140 rubles/sq. m., and the price for painting is 100 rubles/sq. m.

For those who like to do their own renovations in their own apartment, we suggest watching a video on how to glue glass wallpaper. We hope that gluing glass wallpaper will not cause you any trouble, and the walls after repair will delight you with their ideal appearance.

Advantages

Fiberglass wallpaper is considered environmentally friendly, since synthetic raw materials are not used in its production. Their advantages also include the following:

- Moisture resistance - due to their structure they do not absorb moisture.

- Fire resistance - the material does not burn.

- Strength - the tensile strength of glass wallpaper is several times better than that of a simple vinyl sheet.

- Durability – service life reaches 25 years.

- Practicality - installation will not cause any difficulties.

Fiberglass protects walls from the formation of fungi and mold. It can be painted more than once. The integrity of its structure is not compromised by such influences. The cost of fiberglass is optimal, which further increases its popularity.

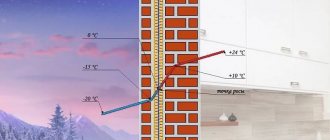

The scope of application of the material is quite extensive. It is effectively used in finishing rooms with high air humidity and low temperature conditions.

Application for decorative finishing

Fiberglass can be painted or coated with other materials only after it has completely dried. If the paint is applied directly to the fiberglass, the web structure will show through the finish. But this technique will give the surface an original look.

To obtain a perfectly flat base, you will need to first level the fiberglass with a layer of putty.

Typically, dry mixtures are used for work, which are stirred in water until the desired consistency is obtained. Apply the composition in a thin layer, not exceeding 1.5-2 mm, using a spatula.

Next, the surface is grouted, but before that you need to make sure that the material is completely dry. The work is carried out with a special grater or grinding machine, where abrasive paper is attached.

Important! If two or more layers of putty are to be applied, each layer must dry well. Moreover, the next layer must be applied to the surface no earlier than 12 hours after applying the previous one.

Installation methods

Fiberglass or glass wallpaper are rolled materials. Their installation is carried out only using adhesive solutions. You can also use simple glue for non-woven or vinyl wallpaper.

The choice of product directly depends on the quality characteristics of the surface being coated.

Fiberglass is glued to drywall using an adhesive solution, as well as non-woven and vinyl wallpaper.

If you need to install fiberglass on plasterboard walls, it is better to use specialized products. They will help securely secure the material.

Further care instructions

Upon completion of gluing fiberglass on the surface of plasterboard sheets, it is necessary to care for the material as follows:

- It is mandatory to color it.

- After painting, surfaces covered with fiberglass can be cleaned and wiped with a damp sponge.

- Sharp objects should be avoided near the material, as they can cause serious damage to it.

Having carried out all the steps correctly, the fiberglass on the pasted surfaces will last for many years, and its color, which has become boring over time, can be changed at any time if necessary by carrying out a new coloring.

For some, performing the steps described above seems too complicated, but this is far from true if you look at it. The steps that should be carried out before and during wallpapering are in many ways similar to those that are usually performed before and during wallpapering, only in this case the surface acquires greater strength and resistance to damage.

So, after familiarizing yourself with how to glue fiberglass to drywall, and observing all the above steps in the correct sequence, there should not be any special difficulties even for those who for the first time decided to glue walls or ceilings with this material with their own hands.

Video:

Preparing drywall for installation of glass wallpaper

The work process will not cause any difficulties. It is necessary to clean the surface of the gypsum board from dust and other deposits.

Detailed analysis: how to make a plasterboard box in the toilet yourself

After this, the surface is plastered. It is necessary to properly process the joints of the material using a special sickle tape. All surface defects are covered with putty. And after it dries, sand it with sandpaper.

To ensure normal adhesion of fiberglass and drywall, the entire rough surface must be treated with putty.

After this, layers of primer are applied. They should dry well and saturate the plasterboard. If there is old finish on the surface, it must be removed. Then perform plastering, puttying, sanding and priming.

Preparing the work surface

In order for the process of gluing the canvas to be successful, you will need to prepare the workspace in a special way, i.e. drywall. To do this you need to do the following:

Putty sheets

- remove the old finishing coating from the plasterboard sheets;

- clear the room of construction debris and furniture so that they do not interfere during gluing;

- treat all joints with serpyanka;

- level the surface on drywall. To do this, use putty and sandpaper. It is especially important to putty the entire surface if the installation of drywall was carried out using a frameless method;

- Prime the ceiling and walls with a deep penetration primer. This will prevent the material from peeling off in the future.

Next, we calculate the amount of material required. To do this, measure the height of the walls. Multiply it by the length of one wall. We multiply the resulting number by four (the number of walls). We determine 10% of the amount received for unexpected expenses. We sum everything up and get the final figure for the purchase. After this, you can start gluing itself.

Types of installation

There are two ways to glue the material: joint to joint or overlap. Their choice directly depends on the light source in the room. It is necessary to immediately assess the situation and determine what will be less noticeable: the joints or seams of the fiberglass strips.

The glass sheet must be glued to the plasterboard surface, joint to joint.

This is due to the fact that the rough surface made of HA perfectly absorbs moisture. After impregnating the fiberglass with glue, its structure will begin to swell. In some places there may be excess material that needs to be trimmed. It is better to avoid such modifications, as the structure of the canvas is disrupted. This will lead to loss of technical characteristics of the material.

Manufacturers

Fiberglass for ceilings is produced by different manufacturers in rolls 1 m wide. The most popular are the following:

- Wellton is a company from Finland. The glass fiber produced by it tolerates staining well;

- Oskar is a company from Russia that produces durable and affordable materials;

- Nortex is a manufacturer from China. Its products attract with low prices and good quality;

- Spectrum is a brand from Holland.

As for the cost, the price of cobweb depends on its density. The cheapest materials are offered by China - 600 rubles per roll with a density of 50 g/m², the most expensive - Wellton (1065 rubles per roll of web with a density of 45 g/m²).

All materials produced by the above brands are produced using standard technology, so their properties are almost identical to each other. Whom to give preference is up to you to decide.

Tools for installing fiberglass

You can carry out work on gluing the surface of the HA yourself. To do this you will need the following tools:

- roulette;

- rollers and brush;

- pencil;

- scissors;

- container for mixing the adhesive solution.

You will also need a rag to remove excess glue from the surface of the material.

One roller is used to apply the solution to glass wallpaper and the wall, the second is used to smooth the material on the surface. It must remain dry.

Application area

Fiberglass is used in polyvinyl chloride panels used for wall decoration, as well as in polymer materials used for roofing.

In addition, canvases can protect pipes from corrosion when creating drainage systems.

But more often fiberglass is used for finishing. It is used to reinforce drywall before applying putty. In this case, the web can easily eliminate minor flaws on the surface of the base.

In addition to the above, this material is also used before wallpapering ceilings, so that the base coating can better adhere to the material.

Work process

The first step in installing glass fiber will be preparing the adhesive solution. If it is presented in the form of a concentrate, you must add a certain amount of liquid to it (indicated on the product packaging). Ready-made mixtures are much more effective and practical.

Next, rolls of fiberglass are prepared. Pre-measure the height of the room. Strips of material are cut according to this parameter. It is worth considering that the ceiling height in the room may fluctuate slightly. It is for this reason that it is better to cut the rolls after applying them to the wall surface.

When choosing an adhesive for installing fiberglass, it is better to give preference to ready-made mixtures; they are more effective.

Glue is applied to the surface of the glass fiber and the back side of the fiberglass. The product should be absorbed into the structure of glass wallpaper and drywall.

Some repairmen advise not to spare the adhesive solution when applying. This should not be done, since HA will absorb excess moisture. Bubbles will appear on its surface, which will negatively affect the quality of finishing work.

The impregnated fiberglass is then applied to the wall and pressed tightly. It is necessary to smooth it with a rag and a dry roller. It is better to start the gluing process from the top of the wall, gradually lowering.

It is necessary to glue the material onto the GC with small gaps between the strips - 2 - 3 mm. This is due to the fact that the structure of the fabric has the ability to expand when exposed to moisture. Once the adhesive solution dries, these gaps will not be visible. The fiberglass will be distributed evenly over the drywall.

It is necessary to take into account that the room must have an optimal temperature when carrying out work. Drafts must be avoided, as they can cause the glass sheet to move away from the wall over time.

Pasting the ceiling for painting

Considering that the work is carried out indoors, the use of interior paints will be the best design option. They are able to favorably highlight the structure of the material, dry quickly, and also do not have any foul odors.

The best result when painting fiberglass is achieved using a medium-pile roller, well soaked in paint. To ensure that all bulges and depressions are evenly covered with paint, the roller is passed alternately in the horizontal and then vertical directions. To achieve a durable and especially beautiful surface, the next layer of paint should be applied to the dried layer.