Planken is a wooden board, the distinctive feature of which is a chamfer on all sides. This material is a favorite among craftsmen involved in façade installation. This cladding has more rounded edges than a regular planed board and perfectly imitates timber. Planken facades are made from trees such as larch, spruce, merbau, teak, dahoma, etc. Most of the names are unfamiliar to the average resident of our country. Building materials made from them are even more rare in our country, so we will dwell on the description of what is available in abundance on our market.

Advantages of installation and methods of fastening

The main advantage of installation is the material’s resistance to environmental influences. The technical gap maintained during installation (2-10 mm) allows the material to contract and expand, which protects it from deformation. Additionally, the gaps between the boards provide air flow to the structure, which affects its service life. The plank is attached in two ways:

- The simplest method is considered to be open using self-tapping screws;

- With a closed installation method, hidden fastening elements are used.

Open way

With the open fastening method, the boards are screwed through with self-tapping screws to the sheathing elements. This installation is considered the most durable and simplest. Each board can be quickly fixed to the sheathing, and if it is necessary to replace it, you do not have to disassemble the entire structure. Not using special fasteners significantly reduces the cost of the installation process, so it is most convenient to sheathe a house in this way. To avoid the appearance of rust on a wooden surface, it is necessary to use galvanized hardware. The use of black self-tapping screws requires covering their heads with putty. The only disadvantage of the open method is the visibility of the material fastening.

Closed method

The use of closed installation is more expensive and complex than the open method. Its advantage is that it hides visible mounting elements on the outer surface of the cladding. For closed fixation, special metal plates are used.

Snake

For the Snake, metal plates 15 mm wide with drilled holes are used. The length of the plate depends on the width of the planken:

- For a width of 70-110 mm, use a plate 145 mm long;

- For a width of 110-150 mm, use a plate 190 mm long.

When laying the material, per one element of the lathing, there are two plates located parallel to each other. Therefore, the optimal lag width will be 40 mm. Before installation, the boards are laid out with their backs facing up and markings are applied for the plates at the points where they are attached to the joists. Using two self-tapping screws, screw the plate across the board so that both edges protrude by 10 mm.

The first board is screwed to the sheathing with self-tapping screws, the next ones through a hole in the metal strip. Planken is laid alternately, placing one edge of the fastener without a hole under the fixed board. The second edge of the fastener is screwed through the hole with a self-tapping screw to the joist.

Key

Flat mount The key has a cone-shaped pin with serrations and a rectangular head with a hole on which a tenon with a stop is located. At the beginning of installation, the first board is secured to the joist with self-tapping screws. Next, take the Keys and place them relative to the log at an angle of 45-60°. Using a hammer, the key is driven into the joist so that the pin fits into the wood up to the head. The cap remaining on the surface is bent with a hammer to the planken and screwed on with a self-tapping screw, with the tenon positioned parallel to the joist.

This operation is performed on all connections. After installing all the Keys, lay the next board, hammering it onto the tenons of the Keys. The entire installation procedure is repeated until the cladding is completely completed.

Crab

The metal plate Crab is used to fasten a plank with a straight profile having a 9 mm groove. The crabs are installed in the groove of the first board where it is attached to the joist. The next board is placed with a groove on the Crabs and tapped with a mallet. In the resulting technological gap, holes will be visible in the Crab's support wings, through which they are screwed to the joist with self-tapping screws.

Bridge

The metal plate Bridge is used for fastening a plank with a straight profile having a groove of at least 7 mm. Its installation is carried out similarly to the Crab fastener. Their difference lies only in the shape of the plate.

- Crab and Bridge Plate Mount

- fastening key

- fastening the board using fasteners Key

- Fastening with metal plates Snake

Cat

This type of fastener belongs to the tenon fasteners and is a bit like a “cobra”. Designed for hidden quick fixation of terraces and facades made of straight plank, which is made of any type of wood. It has a stopper to provide a ventilation technological gap, as well as a hole and two multi-directional spikes for reliable fixation of the plank.

| Thickness, mm | Width, mm | Length, mm | Material | Additional fasteners |

| 2 | 30 | 40 | Galvanized steel | Screws |

Unique features and other advantages

Planken is famous for a number of unique characteristics and positive qualities

The material is usually divided by profile type. Today there are three types of planken, each of which is interesting in its own way.

Namely:

- There is a straight planken. Installation of this material is carried out in an open way;

- Beveled or slanted material is also common. The main advantage of using such a profile is that the edges are beveled, due to this the joining gaps are hidden without any problems. Thanks to this feature, moisture will definitely not get inside the facade; accordingly, the cladding will retain its original appearance for a long time and perform its functions.

If you compare planken with some other material, lining immediately comes to mind - although there are many interesting proposals for cladding facades. To connect it, the tongue-and-groove method is preferred. In the case of planken, everything is different - it’s more convenient to work here, there’s more choice.

All work can be done independently - especially if you have some experience in construction

The lining often swells and dries out - as a result, the material begins to warp, and elements may also twist. That is, this type of fastening does not cope well with humidity and temperature changes. Another drawback is that if you need to replace any part of the lining, it will be difficult.

Planken copes well with drying out or swelling, and if necessary, any part in the facade cladding can be easily replaced on its own.

Changing planken parts is actually very easy - there are minimal difficulties here, especially if the fastening method is open. The hidden method will also not cause problems, except that you will have to disassemble that part of the cladding that is higher than the board that needs to be replaced.

The products are ready for installation work and are waiting in the wings

From an environmental point of view, planken is completely safe. Condensation does not accumulate in the gaps, so the service life is not reduced.

The material has high waterproofing and thermal insulation properties. Installs easily. In stores there are solutions with different textures, the color palette is also rich.

Thanks to this, it will be possible to choose the desired shade even for those customers who are very demanding and are looking for something specific to implement their design ideas.

RESULTS

ROOM RESULTS °ÑÑÑ Ð² завиÑимоÑÑи Ð¾Ñ ÐºÐ°ÑеÑÑва изделий.

RESPONSIBILITY, RESEARCH, RESEARCH ¸ Ð¸Ð·Ð´ÐµÐ»Ð¸Ñ RESULTS и долговеÑноÑÑÑÑÑ. RESULTS °ÑивнÑм воздейÑÑвиÑм.

RESULTS и “Ðконом” кДаÑÑа в ÑÑÑÑÑкÑÑÑе д RESULTS ½Ñе ÑÑеÑинÑ, ÑÑÑки, ÑмолÑнÑе каÑмаÑки.

RESULTS RESULTS еÑÑÑ.

RESULTS no problem. registry Ñ Ð¾Ñ 550 ÑÑб/кв.м и завиÑÐ¸Ñ RESULTS.

RESULTS ROOM, ROOM доп RESULTS. ROOM OPTIONS OPTIONS виР´ RESEARCH кой имиÑаÑией бÑевен. RESULTS › ›

Installation methods

If you prefer larch planks for finishing the building, then the question will arise of how to install the material. Let's look at the main mounting options.

- Open method - a wooden frame or metal sheathing is prepared in advance. Self-tapping screws are fixed through the sheathing elements. In order for the hats to be less swept up, they are recessed deeper and then painted. If you want to avoid rust, it is better to use galvanized products.

- The closed method is more complex and expensive. To make the fastening invisible, special metal plates are used.

To cover the corners, you need to ensure that the finishing material is properly secured. Then it can be used for a long time even in adverse weather conditions. It is better to mount two boards at once on the corners. At the ends, cuts are made at an angle of 45 degrees. Then they are fastened at 90 degrees using metal corners. The resulting structure must be installed and secured to the sheathing.

Practical advice

- When designing the arrangement of planks on the facade, try not to place more than three of them in a row.

- To paint or process the ends of boards, use a small sponge rather than a brush or roller. The work will be more accurate.

- When using nails for fastening, choose ones that are resistant to corrosion, and protect the surface from it with a paint coating. Otherwise, rust stains will inevitably appear on the surfaces.

- The nails used can be made invisible, or almost invisible, by hammering each of them into the bar and depriving it of its head (cut off with wire cutters). Then it is driven deep into the wood with a small drift. The remaining small dents can be hidden with wood putty (if the final painting of the facade is planned with opaque paint).

- You can use homemade putty to hide nail indentations. Mix one part of transparent varnish (which will cover the surface later) with one part of sawdust from the wood of this plank (easy to collect when sawing off excess pieces of boards at corners, in niches). The mixture is used to cover the dents with a construction knife or an artistic palette knife.

Peculiarities

Essentially planken is a hardwood board (larch, pine, oak, cedar). It differs from edged by chamfering at the corners. Thickness 20-25 millimeters. Width 14-15 centimeters. Sometimes found 7-8 centimeters wide. Typically used for home interiors. The length depends on the manufacturer and the specific variety.

Straight variety

For production, high quality wood is used, without defects, inclusions that spoil the appearance (knots, resin inclusions, etc.). Manufacturers coat the underside of the boards with compounds that protect them from rotting and moisture.

A universal material, used for finishing walls, ceilings, partitions, fences, decorative elements inside and outside the house (as facade cladding), and used in the construction of terraces. It has a specially processed front surface (makes walking comfortable and safe), and a back surface (with longitudinal grooves to prevent warping due to moisture). This is also what the variety for interior decoration of baths, saunas, and swimming pools looks like.

Straight type end parts

Criterias of choice

- First of all, the choice of planken should depend on the wood used. Choose only oak or larch. You need to be prepared for higher prices for these types of wood, but it is better to overpay once than to change the facade every 3 years. It is unknown what will be more expensive.

- Next comes the choice of planken shape. As mentioned earlier, this can be a beveled plank, a straight plank and a straight plank with a groove. You need to choose depending on your own taste preferences. Planken is primarily a finishing material, so you need to choose what you like.

- The choice of form may be influenced by the location of application. You can use any plank for the facade, but, for example, only a straight plank is suitable for a fence. Simply because other forms of planken will look inconspicuous in this place.

- Planken surface. The surface of the board in production can be given a rounded or wavy shape. It goes without saying that such delights will add value to the final product. But you can spend money on finishing.

- Planken processing. Not all manufacturers treat their products with an antiseptic. Some people just release boards. Therefore, you should be prepared for the fact that instead of processed planken, they will try to sell you a blank.

About planken and cladding

Types of planken

Facade board planken straight

The profile that has a plank for the facade can be of three types - straight, straight with grooves and beveled (oblique plank).

- The angle on the beveled plank can be different, from 35⁰ to 70⁰. The width of the plank ranges from 70 to 90 mm, the thickness from 15 to 22 mm, and the length of the board reaches 4 m.

- The most common wood for making planken is Siberian larch. We can say about the material that it does not rot easily, it does not deform when changing air humidity and temperature conditions, and it is also much cheaper, because the price of larch is lower than decorative tree species.

- There are two ways to install plank on a wall - open and closed. Instructions for them will be given below, as well as photo and video materials.

Ventilated façade for planken

Beam 100×60 mm

It is best to install planken on a suspended ventilated façade so that moving air currents dry both the cladding and the wall itself. Also, ventilated facades require the installation of insulation, which is very important for the northern regions. To make a lathing for planken with your own hands, first of all, you need to find out the width of the insulation. For any mineral wool (stone wool, slag wool, glass wool), the most common width is 60 mm. If you use this exact size, then the distance between the sheathing profiles will be 58 cm - the insulation should fit tightly between the bars. For the façade ventilation subsystem you need at least 20-30 mm, so the timber must be thicker than the façade insulation. If the sheathing is the same thickness as mineral wool, then after insulation you should sew additional slats to create a ventilated space.. Mushroom dowel

Mushroom dowel

- After installing the beam, lay layers of insulation between it, but before securing it with dowel mushrooms, cover the wool with a wind barrier, a water barrier, or simply a thick, dense cellophane film. Install the dowels through the insulation.

- To install dowel rods, you will have to drill a hole in the main wall through the mineral wool, and it will wrap around the drill bit. To prevent this from happening, take a piece of any (metal or plastic) tube with an internal diameter that is 3-4 mm larger than the thickness of the drill. Insert this tube through the wool to the main wall and drill through it.

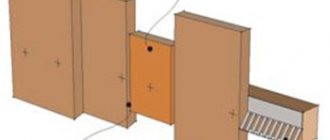

Closed and open methods of installing planks

Mounting strip

- For closed plank fastening, special strips are used, 15 mm wide and 145 and 190 mm long. A fastening with parameters 145/15 mm is used for boards with a width of 70 to 110 mm, the same strip 190/15 mm is suitable for a wider board from 110 to 150 mm. Also, this method of fastening can be carried out in a cross way, when the planks are installed in the letter X. Marking the plank for attaching the snake

- In order to prepare planken boards for the closed fastening method, they should be laid out on the floor (on the ground) along the height of the wall being sheathed. Then, onto the laid out field, transfer the size of the frame (sheathing) to which these boards will be attached. Moreover, it is better to draw the contours of each beam completely so that you can clearly see its width.

The facade plank is installed on the sheathing in a closed way

Place the metal strips on the facade plank so that they protrude beyond the edge of the board by at least 10 mm. Now you need to screw them on with at least two self-tapping screws each. The protruding ears of the planks will serve as clamps, and the lower one will be inserted between the beam and the board, and the upper one will be attached to the beam using a self-tapping screw.

Self-tapping screws for open mounting must be made of stainless metals

There is also an open method of installing planks, which is the fastest and cheapest, which is fastening the boards to the joists with self-tapping screws. Of course, such fixation is more reliable than the closed method, but judge for yourself, what kind of load will be required to tear off the board?! It will be impossible to destroy any of the fastenings by the wind, but only with targeted efforts.

Façade finishing with planken

When a planken façade is installed, the corners should be covered with the same material. Moreover, it is better to install not one board at a time, but two at once, having previously fastened them with screws at an angle of 90⁰.

RESULTS

Â

RESULTS:

SÑÑадиÑионнÑй (клаÑÑиÑеÑкий);

пÑÑмой Ñ Ð¿Ð°Ð·Ð°Ð¼Ð¸;

коÑой ´ Ñглом).

RESULTS планкен. RESULTS ми, повеÑÑноÑÑÑ Ð²ÑглÑÐ´Ð¸Ñ Ð¸Ð´ÐµÐ°Ð»Ñно Ñовной.

RESULTS RUR 45-70 RUR.

RESULTS sir. RESULTS, RESULTS RESULTS µÐ¿Ð»ÐµÐ½Ð¸Ñ.

RESULTS но, Ñак и веÑÑикалÑно, но Ð ±Ð¾Ð»ÐµÐµ ASSURANCE °Ñ Ñкладка.

RESULTS CONTACT US °, sloping µÐ½Ð¸Ñ мейка.

RESULTS WITH RESPONSIBILITY ¾Ð¼Ð¾Ñи кÑепежей оÑÑ Ð¸Ð»Ð¸ Ðаб.

Originality, warmth and comfort: planken in the interior

In photos of houses on the Internet, facade planks significantly transform any structure, making it at the same time solid, neat, and interesting. But this facing material provides even greater opportunities when creating interiors. Natural wood provides special coziness and comfort in the room, positively influencing the physical and psycho-emotional state of household members.

If for external cladding there are only two ways to decorate a façade with planken - horizontal and vertical, then inside the board can be fixed not only using the two methods listed above, but also to create separate planes and fragments located at different angles and inclinations in relation to the main surfaces.

Today, planken can be found not only on the facades of buildings, but also in the interior.

Using various options for placing planks, you can visually increase the height of the room (vertical fastening), visually expand the boundaries (horizontal fastening), and make a large rectangular ceiling in the living room interesting by using fragmentary installation. You can “play” with the structure of planken when decorating the ceiling in a room with complex architecture, for example, if there are niches, ledges, etc. Sometimes painted planken is used to create a certain interior composition.

The requirements for the quality of the material for the manufacture of planks for interior decoration are somewhat relaxed; it could very well be pine. The shade of wood cladding should be selected in accordance with the overall size of the room and the design style. For small rooms, light colors with an inexpressive wood pattern are suitable. When decorating large rooms, there are no color restrictions related to size.

Using planken you can finish the floor, ceiling, walls and other surfaces

How finishing is carried out

You can start with the fact that the planken façade board can be placed on the surface vertically, horizontally or at an angle. The course of further work will depend on the chosen type of fastening - you will need to assemble one of the types of sheathing, differing in the arrangement of the elements. In principle, it is possible to fix the cladding directly to the walls. But, in this case, it will not be possible to create an additional layer of insulation, which is why everything is most often started.

Having chosen the location of the parts, install the frame. It consists of wooden or metal elements fixed vertically or horizontally to the wall, to which the finishing coating is attached. Next, the insulation is laid and covered with a windproof membrane. After this, if necessary, a counter-lattice is constructed with elements located perpendicular to the intended direction of installation of the plank.

All that remains is to attach the outer covering. This is done in two ways: for hidden installation, a “snake” fastening is used, and for open installation, the planken-type façade finishing board is simply screwed with self-tapping screws or nailed to the frame. The open version is no different, but the installation method with a snake fastening requires more careful consideration.

Snake - simple metal plates with several holes. They are screwed to each board from the inside so that a small part of the plate with a hole protrudes above the top edge. The plates are arranged in a checkerboard pattern so that the parts do not interfere with each other when mounted on the frame. Between the rows of fastenings it is necessary to maintain the same distance as for the sheathing elements. To make it easier to work, apply lines on the back side of the plank that correspond to the middle of the beam on which the sheathing will be attached and place the fasteners either on the right or left side of these lines.

The mounting plates will have to be secured to all installed sheathing elements. Moreover, it is necessary to ensure the location of the fasteners and not to confuse the edge of the plate with and without a hole - the hole should be on the side of the part that will protrude from the top side of the board, and the edge without a hole should protrude from the bottom.

Installation is very simple: first, the first board is attached. It is fixed through the bottom and through the mounting hole of the mounting plate. In order for the bottom edge of the next board to be securely fastened, the protruding part of the fastener without a mounting hole is inserted behind the already screwed part. This creates a kind of lock that will reliably hold the bottom edge of the part. The top one is fixed with a self-tapping screw, similar to the first part. This is how the entire wall is covered.

ARENA

Features and advantages of facade boards

Planken is a universal profile in the form of a facing board for external and internal decoration. It can be mounted vertically or horizontally, diagonally. When installed in an oblique way, the effect of a “herringbone” or one-sided oblique pattern is obtained.

There are three types of planken:

- Classic - straight, the end of the board in projection is a rectangle with smooth edges. This planken is assembled with a gap.

- Beveled - it has beveled sides. The sheathing of this type of planks is assembled overlapping or in special grooves.

- With grooves - grooves are made along both sides of the plank.

This finishing option has a number of advantages:

- additional protective properties, the ability to hide defects;

- long service life;

- resistance to temperature changes;

- resistance to any precipitation;

- aesthetic appearance;

- wide choice of design, color and shape;

- simple installation and easy maintenance;

- low probability of deformation during operation;

- environmental Safety;

- fire resistance;

- resistance to mold and mildew;

- multifunctionality.

Planken is used for:

- covering walls, house facades;

- ceiling and floor finishing;

- construction of fences;

- improvement of gazebos;

- landscape design.

It may seem that planken has something in common with lining, but there are clear differences. Unlike lining, planken does not allow water and dampness to accumulate in the wood. Due to this, its service life is significantly increased. In addition, the plank is installed with a small gap between the boards.

An important advantage of planken over lining is that if the board is deformed, only this element can be replaced, and not the entire structure. The following wood is used to produce planken:

The following wood is used to produce planken:

- pine and spruce;

- larches;

- cedar;

- dahoms;

- merbau and teak.

Kinds

However, planken is quite popular on the market, so it makes sense to consider all its varieties. The aesthetic value of such a board is slightly higher than that of lining.

Straight

Straight planken is the most common board, treated with an antiseptic and varnished. But, in fairness, such boards look quite impressive, giving the buildings the appearance of a Scandinavian mansion.

This type of plank is used to create fences, furniture, canopies and decorative grilles. The scope of application of any planken is limited only by the imagination of the builder or designer.

Despite all the aesthetic value, from a practical point of view, such planken has the worst performance properties. The joints between the boards are not covered with anything, and therefore quickly become clogged with dirt and dust. Because of this, constant maintenance of the board is required. But when installing a facade, rarely does anyone intend to wash and clean it once a month, so the value of this type of plank is rather questionable.

Beveled

Beveled plank is a board whose edges are cut at 45 degrees. The cross section of such a board is a parallelogram. The use of such boards makes the house look like a ship from the time of great geographical discoveries.

Beveled planken

The beveled edges prevent dust from penetrating to the edges of the board, which makes the planken more practical. In addition, such a cross-section facilitates hidden installation, which pleases many Russian designers.

This type of plank is most often used for building cladding.

Straight plank with grooves

Straight planken with grooves combines all the advantages of the previous types. It is quite beautiful and has grooves for quick installation. Dust cannot get in and will be fixed in the grooves due to the tight fit of one board to another.

Step-by-step instructions for covering the facade with planken

Let's look at the step-by-step instructions for installing the planken.

Tools and materials

Materials required

- Fasteners

- Planken

- Beams 50x50 for sheathing or guides made of metal profiles.

- Antiseptic

Tools needed:

- Screwdriver

- Jigsaw

- Laser and hydraulic level

Frame installation

The frame is a familiar lathing. A similar design is made for attaching drywall. Guides are installed in 60 cm increments, onto which the board will then be attached.

Separately, it is worth discussing the material of the guides. It is more environmentally friendly, of course, to use wood. But for the façade there is no particular difference in the ecology of the material. But there are differences in corrosion processes. Wood deteriorates faster, so it is better to give preference to metal guides.

When using beams for sheathing, they must be treated with an antiseptic.

Material fastening methods

There are two fastening methods:

- Open. This is how a straight plank is most often attached. For open fastening, decorative nails are used, which are driven into the plank along one line. How beautiful it is - everyone decides for themselves.

- Hidden way. This method involves the use of hidden fasteners. The most commonly used fastener is a snake fastener. To replace a board laid in a hidden way, you will have to dismantle the entire facade, which lies above the point of damage. There are no such problems for the open installation method.

Planken installation

Let's look at the hidden installation of the plank.

- A 50x50 beam is installed in place of the future first row of the board. This jurus will support the second row and will allow you to mount the façade beautifully and evenly.

- There are 4 snakes attached to the board, two on each side. The upper snakes are attached to the sheathing using self-tapping screws. The lower ones remain in limbo for now. As a result of fastening, it turns out that the upper fasteners are a small strip with a hole for a self-tapping screw, and the lower ones are wedges for inserting into the board of the lower row

- The third row is attached in the same way as the second.

- After installing the entire facade, the block is removed from the first row and a board is attached in its place.

Planken installation

Planken cannot be called a real revelation in the field of finishing materials. The same lining costs less and exists for a much longer period of time, which means it has been tested over the years. Nevertheless, the material has the right to life. High-quality processed boards look quite impressive, especially in connection with the growing fashion for environmentally friendly and natural materials.

Fasteners for planken

- The hidden snake fastener for planken is a plank specially designed for installing planken, with which it is possible to install façade boards taking into account the gap. Thanks to the use of a perforated snake strip, the gap will always be the same size. The snake is attached to the back of the board, and then the plank with the strip is installed on the sheathing.

- The fastener for planken planfix is L-shaped, made in the form of a plate, thanks to which it is possible to fasten planken with a thickness of more than 18 mm, this is facilitated by the presence of a spike. Planfix is considered a hidden fastener, thanks to which a perfectly flat plane of the external wall is obtained. Its advantage also lies in the fact that installation with the participation of planfix is very simple.

- Self-tapping screws for planken are used either from stainless steel or with an anti-corrosion coating. This is necessary so that metal fasteners do not oxidize in a humid environment and do not leave black marks on the plank. Otherwise, the facade will lose its attractiveness.

Planken finishing of facades: advantages and disadvantages

Summarizing the information about planken presented in the article, for the sake of objectivity and completeness of the presentation, it is worth highlighting not only the positive qualities of this material, but also its problematic characteristics. The main disadvantages include the following:

- High price. And not only for lumber, but also for fasteners. and the latter are needed in large quantities. Saving money by making it yourself is also not an option, since the parts require perfectly even dimensions, which cannot be created without special equipment.

- The installation features of the planken cannot provide complete protection of the heat-insulating material from the penetration of moisture and ultraviolet radiation, so additional protection or expensive insulation is required.

- Such facade coating does not provide significant additional thermal insulation for the building.

Finishing the facade of a building with planken has many advantages

The disadvantages are certainly significant. However, looking at photos on the Internet of finishing facades with planken wood from larch, oak and even cheaper pine, I want to omit the problems and concentrate on the advantages. And this material has a lot of them:

- Planken, with any installation method, provides the maximum possible ventilation, which helps maintain the safety of the facing layer, insulation and the structure as a whole;

- the absence of grooves and pockets where moisture can accumulate significantly extends the life of the boards;

- Features of the fastening method make it easy to replace damaged plank elements;

- all of the above advantages ensure the shelf life of facades for 15-40 years;

- The gaps that must be between the planks give contour to the structure, making it visually larger and more voluminous.

With all types of stability and density indicators, wood remains a living, natural material. And only with proper adherence to processing technologies, taking into account the specifics of installation and selecting the appropriate fasteners, can you achieve maximum aesthetics and ensure the durability of the exterior of the house.

Tips for choosing material: how to distinguish pine from larch

As mentioned above, for the durability and aesthetics of the exterior design of the house, it is necessary to choose the right material, in particular planken. Even financially secure people try to manage money wisely and save whenever possible. Taking advantage of this, unscrupulous sellers can pass off pine boards as larch lumber.

To avoid deception, it is safest to ask for a certificate or other document confirming the truth of the verbal characteristics of the product offered by the seller. If this is not possible, then you should rely on your own knowledge. General information about larch as a building material is as follows: the wood core has a light pink tint; the sapwood is wide, yellowish or light pink; The annual layers are clearly visible, the boundary between late and early wood is easily determined.

In order not to purchase a pine façade plank instead of a deciduous one, it is worth conducting a careful visual inspection of the material:

Planken made from larch has a more pronounced structure and darker color

- Fresh pine wood is much lighter than larch. The first turns yellow over time, the second acquires a dark red-brown hue.

- Larch has a much more noticeable structure.

- When you run your fingernail crosswise across the surface of a pine board, a barely noticeable mark will remain; this will not happen with larch.

Important! Larch lumber does not have a characteristic resinous odor.

Advantages

- Increased resistance to external factors, including changes in temperature and humidity.

- Planken has an increased service life compared to other wood cladding materials. This is due to the peculiarities of production technology, which involves the elimination of sapwood, knots and some other defects.

- Large selection of shades and textures, the ability to combine with other materials.

- Simple installation of facade planks is carried out without the use of special equipment and devices. Moreover, depending on the conditions of use, it can be either closed or open.

- Possibility of installing a ventilated facade system.

- High hydro- and thermal insulation qualities, which allows us to call planken an energy-saving material.

- Good maintainability. Replacing a damaged product is quick and painless.

- Due to the fact that the workpieces do not fit together rigidly, this cladding “breathes”. Finishing facades with planken significantly increases the service life of additional coating layers (for example, insulation), and prevents the occurrence of processes such as moisture condensation and subsequent rotting of materials. A favorable microclimate is created in the home, which significantly increases the level of comfort.

There is also a special type of this product. During the manufacturing process, planken thermowood boards are subjected not only to drying, but also to special treatment in an autoclave under conditions of high humidity. The temperature in the chamber can be from 170 °C or more. This technology ensures additional processing of raw materials and the complete destruction of all “destroyers” of wood.

The most popular in our country is façade board made from Siberian larch. These products are in no way inferior in their characteristics to products made from rare, exotic (and expensive) wood species. The board is processed to perfect smoothness on all sides. Standard thickness is 20-22 mm.

Features of larch plank

- The products have a high density and also contain a specific resin, which eliminates the possibility of damage by wood-boring insects. That is why in our country larch is traditionally used in house construction.

- This facade cladding board can be used even in conditions of high humidity, as it is resistant to rotting. When wet, wood becomes even stronger. In this it is similar to oak, although it is cheaper. It is not for nothing that experienced craftsmen recommend making the mortgage crowns of log houses from this tree. Unlike planken from other rocks, the material does not require systematic impregnation with antiseptic compounds.

- The board is not subject to deformation under the influence of external factors during its entire service life.

- The profile features allow the installation of boards without the use of numerous and expensive fasteners, which reduces both the time required for this and the overall cost of the cladding. In addition, finishing can be done independently, without involving professionals, which also reduces the cost of the work.

- Not inferior to exotic wood species in performance characteristics and appearance, it costs much less. Even people with relatively modest incomes can buy larch planks.

- The boards have up to 10 shades, which allows you to make the best choice.

Prices

The cost depends not only on the size (primarily thickness) and type of wood, but also on additional design.

For example, 22 mm larch (95x140 mm with a length of 2 - 4 m) will cost per 1 m2: grade AB - 750 rubles, A (Prima) - 1,150; Extra – 1,350. If texturing is necessary, it costs 300 rubles/m2, coating the board with oil (ultraviolet protection) – 560 rubles/m2.

Products made from thermowood are more expensive. For example, Angara pine up to 4 m long (20 mm, width from 90 to 150 mm) will cost 2,200 per m2. An increase in thickness by 2 mm increases the price by 200 rubles. For a plank made of Far Eastern cedar (18 mm, width 90 - 110 mm, length from 60 to 140 cm) you will have to pay 2,485 rubles/m2.

Plankens made from exotic wood are also sold on the market. The cost of such products is much higher, and they are not designed for the mass consumer. For example, the price of planken boards from Indonesia (teak, keruing, balau and some other species) ranges from 3,570 to 7,597 rubles/m2.

What is this

What is planken essentially? This is a material made from natural wood, intended for interior and exterior decoration. Compared to a regular wooden board, planks have no sharp edges. Instead, they are beveled or rounded.

The use of planken allows you to perform high-quality installation, fit your house into the overall suburban landscape, and emphasize the naturalness of the material used. It is not at all necessary that your house be built of wood. Any modern material, from brick to foam blocks, can be lined with planken. This way you will be able to achieve a full-fledged imitation of a wooden house, although traditional building bricks, for example, will be hidden under the plank.

Production nuances

The advantages, which we will talk about a little later, are due to exactly how planken is produced. This material can have different sizes, but installation is still easy to do with your own hands. To achieve this, manufacturers use several features in the production of planken:

- Special automated lines process raw materials, that is, wood, in order to achieve maximum quality and precision in the production of the material;

- At intermediate stages of production, mandatory quality control is carried out, which does not allow planks with flaws, defects and other damage that do not correspond to the class of the product to be sent for packaging;

- Modern planken is made from strictly defined tree species. Not every type of wood has the characteristics to become planken;

- Each workpiece is carefully studied, therefore, by purchasing about 5 m2 of material, you can be sure that all 5 m2 of planken will be of high quality without signs of defects.

Varieties

Depending on the method of cutting chamfers, there are 3 types:

- straight (mounted end-to-end while maintaining small gaps);

- beveled (has the shape of a parallelepiped, laying is done end-to-end);

- straight with pages (equipped with a special “crab” or “bridge” type fastening).

Depending on the type of material, there are:

- “Extra” class boards are of the highest quality, do not have chips, damage or resin pockets on the surface;

- “Prima” products – minor surface flaws and cracks are acceptable;

- board class “AB” - in addition to cracks, other flaws are found, for example, knots;

- “VS” boards – significant surface defects, the presence of knots, dark areas.

Planken can also vary depending on the material used. Larch products are widely used and are characterized by their ability to withstand high humidity well while maintaining their parameters and geometry. Moreover, under the influence of moisture and high temperatures they acquire additional strength and hardness.

This type of wood is not susceptible to attack by insect pests, which is why the finished board retains its integrity. These characteristics ensure durability; the service life of larch planks is 25 years.

They go well with other materials, be it parquet boards or artificial stone.

Canadian cedar and pine are also used for cladding. Strong, durable, with a characteristic pattern, the product becomes a worthy option for interior work and facade decoration.

The wood-polymer composite (WPC) version has high performance characteristics. Its basis is pine rock ground to crumbs, which is filled with polymers. Thanks to this composition, it is possible to obtain a material that is completely not susceptible to rotting, characterized by weather resistance, moisture resistance, and a long period of operation. WPC planken tolerates both high (up to +70C) and low (up to -50C) temperatures, as well as thermal shocks.

Finally, heat-treated planken is also isolated, which, thanks to special treatment, has high biostability, is not subject to deformation and is characterized by lower weight.

Differences in quality

The cost of lumber is affected by:

- Dimensions.

- Wood.

- Variety

Pine has 2 grades: A and AB. Grade A material has no knots and is characterized by a homogeneous composition. AB grade products may have more knots and have a less uniform wood composition. Larch lumber is divided into 4 grades: AB, BC, prima and extra. The latter variety has perfect wood without knots and a beautiful natural pattern. There are no defects or defects. Available class is BC. Low-grade wood is used in production, so the finished product is not aesthetically pleasing.

Fastening systems

Many people are puzzled by the question of how to attach the plank. There are two main types:

- using self-tapping screws. Installation is simple, no special fastening systems are required, facade cladding takes less time than with hidden cladding. The disadvantage of this method is the visibility of the screws.

- using hidden fastening systems - a more complex and time-consuming installation method. The main advantage is the beautiful, aesthetic appearance of the house, with invisible fasteners. In this case, finishing will take longer and will cost more if the installation is carried out by hired builders.

The specific method of fixing the plank depends on a number of factors, the main of which are the type of boards, budget and requirements for the aesthetic appearance of the cladding.

Scope of application

There are many areas of application for planken:

- Fencing: decorative and functional. Despite all the shortcomings of planken, we must admit that fences made from it look amazing.

- Separately, it is worth noting decorative fences, which are often installed on personal plots. Planken provides an opportunity for a landscape designer to more interestingly shape the space for specific needs, zoning the garden area.

- Garden furniture is made from planken. Benches made of thick textured boards look quite impressive and at the same time calmly withstand the effects of the weather.

- Facade cladding. The most popular way to use planken.