If you are determined to build your home with a fashionable and functional flat roof, then it's time to think carefully about its enclosure! This way, the open area at a height will be safe, comfortable and suitable even for children’s games. Moreover, the roof parapet will simultaneously play an important aesthetic role, giving the exterior of the building a complete, logical and stylish look.

You will be surprised to learn how many types of parapets exist, what design masterpieces are made from them, and which option is most suitable for you!

The role of waterproofing in the composition of a flat roof

Without properly equipped waterproofing, a flat roof will leak - we found that out. But the water dripping from the ceiling is just the tip of the iceberg. In fact, there are many more unpleasant consequences. Moisture seeping into the under-roof space:

- destroys the base of the roof (concrete screeds and slabs crumble, wooden sheathing rots, metal components corrode);

- with an insulated roof, it saturates the thermal insulation layer, worsening its properties and destroying the structure;

- flows down the walls, contributing to their wear;

- leads to the growth of fungi and mold, which give a persistent smell of dampness in the house, and in some cases pose a threat to human health.

Properly installed waterproofing creates a barrier against moisture, preventing it from penetrating into the roof layers and preventing the occurrence of all the situations described above.

How is vapor barrier different from waterproofing?

These two types of insulation are mandatory in residential construction, since each of them solves a specific problem.

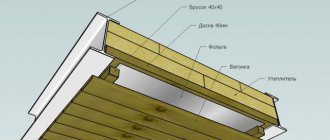

Waterproofing is located in the upper part of the roofing pie between the insulation and the finishing. The task of waterproofing is to prevent water from precipitation from penetrating into the room and to ensure the removal of water vapor from the house to the outside. The structure of the waterproofing can be represented as a set of funnels, directed with the wide side inward.

Vapor barrier is needed to prevent the ingress of moisture, which condenses from the steam passing from the house to the outside through all layers of the roofing pie. Therefore, the insulating qualities of such materials must be maximum. The lower the permeability, the better. This insulation is placed on the inside of the flat roof between the ceiling trim and the insulation.

Flat roof parapet

How and with what to paint a wooden floor in a house; review of suitable paints and varnishes.

Last edition: 18.05.

The parapet can be seen on the roof quite often. It may be a nondescript design with a strict geometric shape, but sometimes it is a beautifully designed creation of a talented craftsman. The main function of a flat roof parapet is protective. Unlike frame-type roofs, roofing on a flat surface especially needs protection from the wind. At high altitudes, its gusts can reach enormous force.

Flat roofs can be used or not. The features of the parapets on each of them, as well as some requirements, will be discussed separately in this article.

Parapet - brick fence

Brick parapets are most often found on multi-story buildings. The height of such a parapet sometimes “jumps” over the 1 m line, but it should be at least 0.45 m - it all depends on the height of the building and the function of the roof. They are laid out before installing the roofing around the perimeter of the building on the load-bearing walls.

Brick parapets have several purposes: they serve as a fence for people working on the roof and protect the roof from damage. A U-shaped protective casing made of metal is mounted on top of such a parapet. Treated with a special coating, such a cap does not corrode for a long time.

In winter, the presence of a parapet eliminates the possibility of ice build-up and snow falling from the roof surface. But this applies not only to brick parapets.

Metal fencing

Metal parapet is also used on flat roofs and, recently, more and more. It is made of thick steel and coated with a compound that increases its shelf life. Such a metal can resist the effects of the environment on it for a long time.

The purpose of such a parapet is not much different from a brick one, in combination with which it is more common.

Dimensions and requirements

Parapets may differ in design and composition, but there are general rules from which it follows that the height of the parapet on the roof is different.

From the building codes and regulations (SNiP) the following conclusion can be drawn - for buildings whose distance to the eaves exceeds 10 m:

- buildings whose roofs are used by people (exploited) - the parapet must be at least 1.2 m high;

- buildings with unused roofs - a fence and (or) parapet with a height of at least 0.6 m is required, a combined option is allowed. For example, the height of the parapet is 0.45 m, plus the metal fence is 0.15 m. The total is 0.6 m.

Note! For buildings with a flat roof, the height of which is less than 10 m, the installation of a parapet is optional

Device and installation

The presence of a protective parapet on a flat roof is mandatory. To achieve maximum efficiency, the installation of a parapet made of block or brick is carried out before roofing work, directly on the ceiling.

At a certain distance from the base, a groove is made in the form of a groove. Later, when the roof is covered, the roofing carpet will be tucked into this recess. This will prevent water from getting under the coating. To avoid destruction of a brick or block, the top of the parapet must be covered, for example, with a metal apron.

Note! All connections, joints and junctions must be sealed!

The metal parapet and fence must be made of thick steel and treated with anti-corrosion compounds. They must have oblique stops and withstand heavy loads.

In addition to the function of fencing and protecting the roof from the wind, a parapet on a flat roof can also perform other tasks, for example, holding water flows on the roof during heavy rain.

Roof fencing is an important safety feature on the roof.

A roof fence is a safety element installed around the perimeter of the roof, in the form of a railing or curb, and designed to prevent people from falling.

The roof fence consists of posts installed along the edge of the roof and horizontal slats mounted on these posts in several levels. The height of such a fence is regulated, and for ease of movement on the roof it can be installed on a transition bridge for the roof. When choosing a material for a roof fencing, you should take into account the design and material of the roof itself, as well as its operating conditions. For aggressive environments, structures made of stronger and more durable materials are used. Regular inspections of the fence should also be carried out, the frequency of which depends on the conditions in which they are used. The choice of roofing material depends on various factors. There are many types of it, suitable for certain conditions. Walkways, for example, have two main functions: ensuring safe movement along the edge of the roof and preventing ice and snow from falling off the sloping roof. The length and width of such a bridge can be increased if necessary, and to ensure greater safety it can be equipped with railings.

The simplest and most common type of roofing material is a simple metal fence. Its design is elementary: it is represented by vertical supports, securely fastened to the edge of the roof, and horizontal crossbars, usually two. The sizes are individual, as is the material used, and the price mainly depends on these two factors. In Europe, this type of fencing is a necessary requirement, and its installation is mandatory, but in Russia this has not yet been achieved.

There are many other types of fencing, and they all fall into two main groups. Roof fencing for useable roofs is intended for houses and office buildings in which the roof is used as a useful space. This is most popular now in large cities suffering from a lack of free space. On such roofs, observation decks, open spaces, gardens, etc. are arranged. Of course, in this case, a more reliable fence is required, the strength of which is determined by standards. Safety characteristics are regulated by GOST roofing GOST 25772-83, which determines the strength, material and height of the fence. The latter is calculated based on the height of the building itself, which is associated with increased wind strength at the top. The roof railing can also be reduced in height if it is installed on a parapet.

In cases where the roof is not intended for permanent use, the requirements are not so strict. It is necessary that the height of the fence be at least 60 centimeters for a safe stay on the roof during repair work. The main material from which roof fencing is made is galvanized steel due to its strength and resistance to corrosion.

Types of fencing and materials

Waterproofing under metal tiles is a necessary stage of roof installation

Fencing devices for equipping high-rise buildings are made from monolithic slabs, bricks, reinforced concrete blocks, and metal. To provide greater protection, they are covered with concrete slabs, profiles or galvanized steel. The profile, in turn, has a gable, single-pitch or horizontal surface. In modern construction, it is customary to distinguish the following parapet products:

- standard brick fencing;

- durable metal grilles and caps.

A parapet in the form of a metal fence is much more reliable and safe, in contrast to a conventional brick one.

The appearance of protective structures directly depends on the structural features of the facade. The front part of the building can be represented by a figured, radial, straight, or combined design. As for protective aprons, they are made from thin sheets of metal, differing in the method of fastening. In view of these features, the following types of parapets are distinguished:

- simple;

- curly;

- flat;

- complex;

- in the form of a skate.

As for the shaped devices, they are very similar to railings, complemented by many curves and complex lines. A simple design is represented by the combination of two slopes and a standard rectangular dropper. The complex version is distinguished by the fact that the droppers are slightly bent inward and are protected by a visor on top; it is considered the most durable and reliable. Flat models are equipped with drips located around the perimeter. As for ridge-shaped parapets, a special covered canopy is built above them.

A parapet is a building structure that has certain requirements. Its presence is mandatory in multi-storey buildings. When creating a protective structure on a high-rise building or office center, a metal apron must be installed to protect the building from precipitation.

Arranging a parapet on a residential building

Additional supporting and auxiliary structures are made from steel, aluminum and wooden profiles. If you prefer wood, the bars should be at least 30 mm thick, plus treat them with bio- and fire retardants.

If you consider metal substructures more reliable, then take a steel profile or stainless aluminum. Ideally, it will be the same metal as the parapet, otherwise consider the compatibility of such materials.

By the way, in Russia most often parapets are simply glued together. For this purpose, special adhesives are produced for fixing metal products to almost any surface. Those. the parapet, cornice and flashing can be securely fixed to a concrete, wooden or brick surface.

For this purpose, most often moisture-resistant plywood is laid on the load-bearing base of the roof perimeter and secured. This base for the parapet is almost ideal, and the metal is secured with glue from Enke. This method, unlike others, allows not only to achieve a flat surface and provide the necessary noise reduction in the wind.

By the way, the simplest option for arranging a parapet is to cover it with mastic or modern liquid rubber:

What is a parapet

Flat roof installation, roofing installation

Parapet

In essence, it is a continuation of the wall, however, as mentioned above, options are possible. The creation of such structures is regulated by the requirements of SNiP, according to which parapets are required for any building with a roof slope of up to 12 percent and a height of more than 10 meters. Obviously, most of the modern residential buildings built in large cities fall into this category, while suburban housing, on the contrary, needs fencing only in exceptional cases.

According to the same SNiP for pitched roofs, the use of fences is provided for at a height of more than 7 m. Such fences are made in accordance with GOST 25772. The parapet can be created using the following materials:

- Concrete blocks. Typically, light varieties of this material are used here. These are compositions obtained using cement binders, sand and aggregate. Their main difference from the so-called heavy concrete is that the aggregate here has a low density. There are also various types of porous concrete, where the low weight is achieved due to the large volume of air bubbles within the material.

- Monolithic reinforced concrete. If the blocks can boast that they are light in weight, and it is not difficult to lay them with some skill, then the second option is the lot of those who use special equipment during the construction process and focus on reliability and strength. Using monolithic technology, it is possible to obtain a structure of any type and shape, and the strength characteristics will be very high. The roof parapet is created as follows: formwork is installed, reinforcement is performed with steel rods, and then liquid concrete is poured.

- Brick. Masonry materials of this type have proven themselves well when used in difficult conditions. Of course, the parapet will be somewhat heavier than a structure made of concrete blocks, but this is compensated by very high strength, as well as reliability and durability.

- Metal fencing is also found, but the difference here is that the parapet is not made solid, but in the form of posts connected to longitudinal rods. This type is used on both pitched and flat roofs.

The minimum height of the structure starts at 20 cm, but the maximum can reach 1.2 m. This parameter is selected taking into account the purpose of the roof. For example, the minimum height may be due to the need to create an additional waterproofing carpet that will extend 25 cm or more onto the surface of the side.

Below we will look at several types of abutments for various parapets, which will allow you to understand in more detail how abutments are created.

Dimensions

- The building must be equipped with a parapet if its height exceeds 10 meters and the slope angle is up to 12%.

- When the roof slope angle exceeds 12%, the building height requirements are reduced to 7 meters.

- With regular use of the roof, it is assumed that a parapet with a minimum height of 1.2 meters will be installed.

- If it is assumed that there will be no actual use of a roof with a flat roof located on a building below 10 meters, then for protective purposes it is sufficient to install a metal fence. In such situations, the absence of a parapet is acceptable. However, if the building is higher than 10 meters, then installation of a fence is required.

Roof parapet 200 mm

In this case, a side made of thermal insulation boards, for example ISOVER, is laid between the protruding part of the longitudinal wall and the roof. They are glued to the concrete base using a special compound, and they must fit tightly to the vertical wall. Next, a layer of roofing material is laid. The roll coating lies in several layers. The lower one is a reinforcement that extends to a distance of 2 m from the parapet. Above it is the base layer. They both go along the inclined edge made of insulation to the top of the concrete wall and break off only at its edge. The third layer is represented by the same roofing material, but its lower edge is only 35-50 cm from the beginning of the rise formed by the ISOVER layer. The upper part of the parapet is protected by a metal element, which is fixed using special dowels, for example, 3.7x70 mm. Along the lower part of the metal apron on the roof side there are crutches with a pitch of 600 mm.

Possible repairs near the site

The waterproofing layer of roofing felt must be tightly glued to the parapet wall, roof plane and side using hot bitumen mastic. As soon as the first layer has cooled, a second layer of waterproofing is glued on top of it. The abutment of the roofing covering to the plane of the parapet is carried out by laying the upper edge of the roof in a pre-made groove, or directly on the upper plane of the fence.

To fix the roofing materials in the groove, a pressure strip is mounted on top of it and dowels are screwed in. Both the seam and the strip are coated with silicone sealant and painted. The steel apron, which will be installed on top of the parapet, is also attached to this strip.

As an option, the junction of the parapet and the roofing is treated with hydrophobic mastic materials. Thus, a continuous sealed coating without seams is obtained.

What you need to know

Roof waterproofing is divided into two types: with a soft covering and a hard covering. The use of soft roofing is mainly limited and is used as waterproofing for a concrete roof or any other flat surface. To install waterproofing for pitched roofs, so-called hard coatings are provided, such as: ceramic and polymer tiles, corrugated sheets, galvanized sheet steel, corrugated asbestos-cement sheets. But in some cases, soft coverings can also be used for pitched roofs. An example is bitumen-polymer shingles, which are laid on moisture-resistant plywood along the sheathing.

Due to its low cost, soft roofing has found its application not only in industrial buildings, but also in public ones. And the simplicity and small amount of accompanying materials allow roofing work to be completed in the shortest possible time. Today you can choose several options for soft roof waterproofing:

- Installation of roofing felt roofing material. It is one of the oldest and most labor-intensive methods, as it requires a device of 3-4 layers, as well as the constant presence of hot bitumen.

- Installation of coatings from bitumen roll materials. Laying of the coating is carried out by fusing onto the insulated surface. Ideal for metal surfaces, such as garage roof waterproofing.

- Bitumen-polymer shingles. Identical in composition to bitumen roll materials, but has a higher cost and aesthetic appearance. Used for pitched roof structures. On flat surfaces, where the textured part and “scales” are not visible, the use is not advisable.

- Bulk rubber-rubber and bitumen-mastic compositions. This is a new stage in the development of soft waterproofing. Today it is the simplest method of waterproofing, as it does not require a “hot process”. Due to the ease of installation, waterproofing a roof with your own hands does not require significant experience and skills. The bulk composition is poured over the surface and leveled using a needle roller, or sprayed using a spray bottle.

Rolled waterproofing roofing

When installing roof waterproofing yourself, or with the involvement of specialists, you need to take into account several important factors:

- It is necessary to choose one or another waterproofing material.

- Roof waterproofing, which varies in price within a fairly narrow range, is quite cheap. But first you should familiarize yourself with the average cost in order to avoid deception by dishonest sellers.

- When installing roofs using hot bitumen, a paid permit from environmental services may be required.

- Craftsmen working with weldable materials must have a certificate allowing them to work with vessels under high pressure. This is due to the fact that when depositing materials, they work closely with propane-butane mixtures.

The process of fusing rolled waterproofing

Design requirements

Junction unit to the parapet for a single-layer roof.

The design of the parapet is very simple, it consists of the main part, the so-called shelf, and figured or straight bends located at an angle of 90 degrees.

The basic requirements for parapets are as follows:

- — The height of the structure should not be less than 1.2 m for roofs in use.

- — For unused flat roofs (buildings below 10 m), the absence of a parapet or the construction of a decorative metal fence is allowed. For a building height of 10 m or more, the presence of a parapet is mandatory.

- — At the junction of the parapet and the roof, it is necessary to install a waterproofing carpet made of galvanized metal; fastenings are carried out with special crutches.

- — If the roof covering is PVC or TPO membrane, then the drip line should be welded to an additional waterproofing carpet.

- — A roof parapet with a height of 45 cm or more must have a protective apron secured with a metal clamping strip with self-tapping screws. All joints must be protected with sealant.

Device principle

In fact, the installed protective fence on the roof is not an absolute guarantee of safety for the roof and people. If there are minimal inaccuracies in the connection of the roof with the selected parapet system, the entire structure may become loose. If the initial building material is chosen incorrectly, resistance to corrosive and atmospheric processes is reduced to almost zero.

If you have the slightest doubt about the correct execution of the parapet with your own hands, you should entrust this procedure to professional builders. Specialists accurately determine the dimensions of the parapet; when selecting materials, they take into account the load exerted by water on the structure from above, and determine the average annual rate of climatic precipitation.

If you do not have sufficient experience, it is better to entrust the construction of the roof parapet to professionals

An additional structure on the roof, made of brick, is usually a continuation of the load-bearing main wall made of the same building material. The protection is completed upon completion of installation of the necessary floors. Even during the design process, the height of the future brick “side” must be accurately determined. After all, a special groove is created under it, which will serve as the junction of the parapet with the roof being installed. In order to extend the service life, caps made of durable metals are installed on protective structures, in particular:

- sheet copper;

- galvanized steel;

- aluminum;

- The more expensive options are oxidized and patinated materials.

Copper sheet is used as a protective cap for the parapet to extend its life.

Benefits of operation

In order to impart heat resistance to the described devices, they are subjected to heat treatment. After this, they are not afraid of the negative effects of the environment, and the service life increases. The advantage of universal protective fences is that they can be painted in any shade, logically complementing the overall appearance of the building being equipped.

Parapets made of metal are in demand due to their ease of installation, while at the same time they cope with the assigned tasks perfectly. Pre-cut metal sheets are laid on the fence; at the joints they are folded according to the principle of seam locks. The result is a sealed structure, devoid of any gaps or holes. As for parapet covers, they are manufactured in a variety of shapes using specialized equipment.

Parapets made of metal sheets are the easiest to build

During long-term operation of the building or without proper installation of protective aprons, the fences wear out and require repairs. Replacing outdated materials and providing new insulation extends the service life of parapets, increasing their functionality and giving a presentable appearance.

Installation in accordance with SNiP

Current building regulations state that it is mandatory to install a protective fence on the roof of an object whose height exceeds 10 m and whose slope reaches 12%. With an even greater slope, the described structure must also be erected on low buildings. The minimum height of the parapet is considered to be 45 cm, the maximum permissible value is 1.2 m.

Important! The installation of a protective fence is a personal desire of the developer. If the roof is not subject to operation and any work is performed on it only during periodic maintenance or major repairs, there is no need for a parapet

It is known from practice that summer cafes, observation decks, and recreation areas are often set up on the roofs of high-rise buildings. In this case, protection is necessarily created for people at altitude.

Installation Tips

To ensure that the installation of the parapet takes a minimum of time and is carried out correctly, it is recommended to take into account the following nuances :

- Before installation, you need to calculate the roof area , determine the average amount of precipitation during the year and clarify the load per square meter: these indicators will be required when determining the amount of materials for the arrangement of the parapet itself.

- Installation requires climbing equipment and skills in high-altitude work, so the task of installing a parapet can only be entrusted to professionals who have the appropriate equipment and a license for such activities.

- Often the structure is a continuation of the wall, so its construction is carried out during the construction phase of the building . This means that the system needs to be thought through at the design stage of the house.

If there is a parapet, waterproofing is done with overlaps of a certain height Source 2gis.ru

Metal parapets are considered very popular: they are strong, lightweight, resistant to temperature fluctuations, moisture, mechanical loads, and have a long service life. It is possible to cover the structure with a metal profile; the connections are made seam to ensure maximum tightness. In addition, the building can be equipped with parapets, for example, made of armor-resistant glass or especially durable plastic: the supports are made of metal, and the space between them is covered with sheets of such material. The apron on the roof, which serves for drainage, is usually made of galvanized steel.

Methods of attaching a parapet roof

It is recommended to make parapets from a metal profile and install them with a slope of 3° towards the roof. In this case, the height of the parapet and the extension beyond the roof depend on the height of the building. There is such a thing as the height of a parapet roof.

Let's look at each type of parapet roof fastening.

We are talking about special products made from steel strip 40-60 mm wide and 4-5 mm thick. These strips are welded into a T-shaped profile, which is quite labor-intensive, but the most practical, because this increases the contact area.

But crutches have such disadvantages as low corrosion resistance, which is why rusty streaks appear on building facades, plus the need for a large number of point fastenings. And this leads to loosening of fasteners, tearing off of the profile in strong winds and frequent need for repairs.

The main requirement for installing crutches is tightness:

The parapet roof is also secured to false planks made of stainless and galvanized steel with a thickness of at least 1 mm. This method requires welding, but is more reliable in windy conditions, because here the entire load is evenly distributed over all corners.

For parapet widths of 600 mm or more, parapet covers are glued to the base in combination with T-profiles or false strips. This type of fastening is most resistant to wind load and moisture, because there is already an additional layer of waterproofing - glue. Glue based on rubber, bitumen and polyurethane fills the pores of the base.

In combination with gluing and false strips, a UDS connector and a backing profile are also used.

Here's another good example where sticking is used:

Only gluing helps when foam is used as a parapet roof. This method is often resorted to when the parapet itself is a continuation of the load-bearing wall of the house, and then it can serve as a cold bridge. Even more: condense moisture!

Here's how to make such a roof:

- Step 1. Connect the planks at the corner joint using assembly adhesive.

- Step 2. Also place the foam strips themselves on the glue, and cut off the excess from the street side.

- Step 3. Stitch excess foam from the top and sweep away any debris.

- Step 4. Cover the inner and outer corners with electrical tape and apply foam on top.

- Step 5. Cut the roofing membrane into pieces of the desired size, and apply it over the foam.

- Step 6: Carefully seal all seams.

- Step 7: Hand smooth the entire surface.

Here's what the process looks like:

Single rebate is one of the most popular methods, which is suitable for profile widths up to 450 mm and ventilated spaces.

Double rebate is recommended for parapet widths of 600 mm and above and for ventilated spaces. Another type of fastening with such initial data is prohibited, because here temperature fluctuations and additional stresses easily arise, and, as a result, the nodes become loose.

This method is suitable for adhesive connections, a ventilated base and a profile width of up to 600 mm.

One of the most reliable ways to protect a parapet is to wrap it with a PVC membrane. This must be done in such a way that the PVC membrane either extends 80-100 mm onto the horizontal surface, or onto the outer surface of the parapet:

- Step 1. First of all, you need to secure it with a metal strip.

- Step 2. Cut the metal strip to the required length and fix it to the parapet.

- Step 3. Secure the membrane strip to the parapet between the metal strips.

- Step 4. Lay membrane tape over the parapet.

- Step 5. Cut special corners from the membrane and secure them using stitching rollers and a welding machine.

- Step 6. Using the same tools, process all the edges and folds of the membrane.

- Step 7. Lay the canvases at the bottom of the parapet in two layers.

- Step 8. Cover all corners additionally.

This membrane can be left just like the rest on the roof surface, or it can be additionally covered with metal covers:

And finally, one of the most reliable ways to equip a parapet is to fuse rolled roofing materials onto it using a gas burner:

Let us also mention the modern fashion of using a flat roof with a parapet for practical purposes, arranging recreation areas and additional open space for personal tasks. In this case, a special glass fence is attached to the parapet:

Technical requirements and building standards

With a minimum or zero angle of inclination, the metal parapet is able to withstand increased atmospheric loads.

Modern parapets are made of copper, aluminum and titanium-zinc. Depending on the material of manufacture, the method of connecting the profile is selected: riveting, double seam, welding and high- or low-temperature soldering.

For a copper profile, it is necessary to install a cornice with a size of 50 mm or more. Separately, we also note titanium-zinc, which has its own installation rules: installation with a slope of at least 3°, and up to 15° you need to lay a separating layer with a drainage function.

In Russia they are rare, but there are still wooden parapets. Naturally, it is also necessary to install a cover on top of them, but this time with an anti-condensation super-diffuse membrane. To do this, you need to install strips on which the top covering will be attached. Next, a part of the membrane is laid on the corner.

Now metal strips are also installed on the sides of the parapet, which will protect the tree. A lid is made from a metal sheet (in this case titanium-zinc is suitable):

To connect parapet profiles end-to-end, you need a standing, double or lying seam, as well as overlay strips. Abroad, some rules for arranging a parapet recommend connecting the attic corners by welding, or cutting out the attic corners from a single sheet, while others say that only internal corners should be made from two parts. In a word, to some extent, both options are acceptable.

The main thing is to take into account the linear expansion and contraction of the metal, because the parapet is located in the open air, and of all the house structures it heats up the most in the heat and rapidly loses temperature in the cold.

Therefore, if you fix the roof parapet too rigidly, for example, using a standing seam, or directly place metal profiles on the edge of the roof, then distortion of the material cannot be avoided.

This is why, if the standing seam technique has already been used, it is also necessary to use overlapping joint strips and expansion joints:

Roof connection

When the floors have already been erected and the roofing pie has been laid, it is necessary to take care of the reliability of the junction points. There are two basic rules that allow you to make a quality connection:

- with a fence height of 50 cm, the groove is made 25 cm in size, the insulating material is fixed at the level of the groove height and fixed with a metal strip;

- if the height of the fence is less than 50 cm, a waterproofing carpet is laid over the entire area of the side surface, and the top is treated with mastic.

More details about the construction of high-quality flat roof connections can be found in the video clip

If the roof is of a soft type, then the connection is quite difficult to complete; the weak point of such a structure is the presence of a right angle between the fence and the roof. For a high-quality connection device, experts recommend reducing the angle of inclination to 45 degrees. This action will help avoid deformation, cracking and freezing of the entire roof structure. Pouring a concrete cast at 45 degrees is done using a wooden plank, which is pre-treated with antiseptics. At the final stage of the work, the plank and flashing are covered with insulating material, which is laid overlapping.

Parapets perform a protective, fencing and aesthetic function. The presence of this structural element of operating buildings allows not only to protect the life and health of people, but also to minimize the risks of destruction of the insulating material and load-bearing elements of the structure. With high-quality connections, the roofing plane will provide reliable protection against possible leaks and cracking of the roofing material.

One of the important issues in the construction of buildings is ensuring safety during maintenance and carrying out the necessary roof repair work. For this purpose, even during the construction of the building, the roof perimeter is fenced with appropriate structures. Structurally, all roofs are divided into pitched and flat, and among the latter, they are divided into exploitable and, accordingly, non-exploitable.

What determines the height of the fence?

Buildings with a viewing area in the roof area require higher fencing.

They help protect people from the possible danger of falling or tripping. Here it is necessary to install additional handrails. You can lean on the railing while taking in the surrounding views.

Features and Functions

Relatively recently, parapets on buildings served only an aesthetic function. Now these devices are mandatory attributes of the roof, and this rule is prescribed in the relevant GOSTs.

The main task of each type of fencing is to protect a person on the roof from falling. The secondary function is to protect the building from precipitation and any climatic influences. But the constant improvement of design solutions has allowed the low wall running along the perimeter of the edge of the roof to also serve as decoration for architectural buildings.

Parapets are installed on both pitched and flat roofs. In the first case, the structure is erected above the cornice and from below (from the ground) is clearly visible from all sides. In the second case, a low barrier completely blocks the roof from human view.

To prevent the parapet from being destroyed by strong winds and precipitation unfavorable for building materials, this elevation is covered with a special apron made of galvanized or copper sheet metal and equipped with drips, thanks to which water that gets on the building is easily drained. Drip caps also eliminate the possibility of water entering protected areas of the parapet.

A properly assembled fence protects the roof from gusty winds, the force of which can deform and tear off the cladding

No less important is the decorative use of the parapet. It improves the roof of high-rise buildings, hiding air conditioning units and other communications

To understand which version of the parapet to install on the roof, you need to find out all the possibilities of this design.

In addition to the functions listed, the following points include:

- The parapet is used as a fire protection system that prevents the fire of roof materials.

- It evenly distributes air flows along the entire perimeter of the roof, and the pressure on it is distributed accordingly. The parapet prevents strong winds from lifting its edges.

- Does not allow various debris, branches and anything else that may be lying on the roof to fall down.

- Hides from people's view equipment and devices located on the roof, which can disfigure the appearance of the roof.

All parapets, without exception, have the same structure:

- shelf - main part;

- overhangs - are perpendicular to the shelf;

- drippers (placed on the sides of the parapet) - are responsible for draining rain and melt water.

Types of parapets by shape, configuration

Let us examine in more detail what types of protective elements there are in appearance and structure.

Simple

A simple element has no additional bends. Consists of two slopes. The photo above is an example of fixing a simple parapet on the roof.

It is fixed at the joints to prevent moisture from penetrating into the roofing pie or fence span. Available for sale in a wide range of colors. The most popular are galvanized steel or PVC coated.

Difficult

The more complex structure of the parapets allows precipitation to be discharged from both sides. The drip caps are made in such a way that they are folded under the visor.

This design eliminates the risk of water flowing under the structure, providing better sealing and moisture drainage.

Decorative

Decorative elements, in addition to their protective function, add aesthetics to the building and go well with the architectural picture.

The traditional design can be complemented by forging, made in an unusual color scheme, from combined materials.

Decorative parapets are indicated in the building drawing. They are most often installed on pitched roofs (to ensure a safe approach to the chimney), fences, and other buildings.

Figured

The figured type is made in the form of a railing. Such parapets protect balconies, loggias, observation platforms on the roofs of multi-story buildings, and industrial buildings.

They are made of metal, a combined type - of metal and wood. Installation should only be entrusted to experienced professionals in compliance with all safety requirements.

Skate

Ridge parapets have additional fastening from below. The top is covered with a visor. Equipped with two droppers on the sides.

They have a long service life.

Mounted on the roofs of residential buildings and industrial buildings. The main function is to protect the roofing pie from precipitation and extend its service life.

Flat

The surface of such a parapet is truly completely flat. It has drips on the sides, which are responsible for draining water.

The droppers are made in a rectangular shape. Flat parapet elements are easy to install. They perfectly protect fences and the outer parts of facade walls from external influences.

Parapet height 450 mm

Parapet 450 mm

Such solutions are also used for flat roofs. In this case, there is also a three-layer protection and a layer of insulation, but the arrangement of these elements is somewhat different. The first thing to note is the height of the insulation layer, which turns out to be even less than in the case when the height of the parapet on a flat roof is only 200 mm. If in the above example the layer of triangular cross-section with its upper part touched the horizontal part of the concrete side, here it is barely a third of the height.

The situation is similar with the first two layers of roofing carpet. They end on the insulation material, only in contact with the concrete wall. Only the third layer goes under the apron, which, as in the first example, stretches 35-50 cm towards the center of the roof. The metal apron has also undergone certain changes. Now it has only small protruding parts and covers not the entire parapet on the roof, but its upper part. Fixation is done with two dowels, but there is one more difference.

For roofs of this type, special metal fences are used, which are installed on top of the concrete side. The height of the side itself is 450 cm, but together with the fence it already reaches 600 mm. The structure is created using steel strip crutches, which, as for the 200 mm side, go in increments of 600 mm.

Purpose of the design

Installation of a parapet is possible on any roof, regardless of its size, degree of inclination, shape and material of manufacture. Main functions of the product :

- Protecting people who walk on the roof, carry out construction work or repairs there, from falling to the ground.

- Retaining snow masses sliding under their own weight , their one-time collapse, which can harm the life and health of passers-by, as well as property.

- Visual camouflage of pipelines, air ducts, cooling equipment and other items that detract from the appearance of the building.

- Additional resistance to strong wind loads , which is especially important in regions with harsh climates.

- Improving the waterproofing properties of roofing structures, protecting joints from leakage.

- Possibility of creating a safe and beautiful observation deck if the roof has a flat structure with a zero angle of inclination.

A properly installed parapet on the roof will protect the structure from precipitation, hurricane winds and other external influences, and will also become a decorative decoration of the building itself.

If the parapet is part of the wall, then even gas pipes are attached to it Source kak-sdelat-kryshu.ru

Joining the roof to other surfaces

Scheme of the junction of the roof to the parapet

In cases where it is necessary to seal the joints of the coating with other surfaces, a slightly different technique is used. For example, if there is an abutment of the roof to the parapet, the latter must be insulated.

In this case, the walls are insulated by laying a layer of mineral wool. At the junction with the parapet, an additional layer is fused onto the roofing carpet.

The insulation sheets are covered with cement bonded particle boards or flat slate. A side at an angle is made from a rigid mineral wool slab. It is glued onto hot bitumen directly into the corner.

The first layer of roofing is folded onto a horizontal plane by 15 cm, the second layer should overlap the previous one by 5 cm.

Next, a steel apron is made that will drain rainwater onto the roofing surface. After these steps, the junction of the roof and the parapet will be securely and permanently sealed.

Note! When the roof is adjacent to a chimney, it is advisable to use special strips. Please note that the pipe passes not only through the finishing coating, but also through the attic and ceiling

Therefore, sealing must be performed at all three pipe passages.

In places where the ceiling and attic pass through, you can use silicone sealant, where the pipe passes through the roofing - strips.

It is recommended to install the chimney itself on the roof closer to the ridge strip. The pipe cannot be installed in the valley, since it will be almost impossible to connect it to the roof with reliable sealing.

On a roof covered with asphalt shingles, it is best to use an adjacent flashing. It will press the knots tightly against each other and prevent water from getting inside.

If the roof is covered with metal tiles, use a vaka strip. Wakaflex is placed under the strip, then the strip is closed and carefully sealed with sealant.

Wakaflex is a rolled self-adhesive material that can also be used to process roof joints with walls, parapets and chimneys.

Reinforced for added rigidity and available in a variety of colors, the material is ideal for a variety of sealing applications.

When covering with metal tiles, it is advisable to use external and internal metal strips. Joints finished in this way will last a very long time without the need for repairs.

In this case, the seams will not leak, and the abutment roof assemblies will last for 25 years or more.

The connection between the roof and the wall protruding above the roof must also be processed.

A groove is made into which part of the roofing covering is inserted. Next, everything is sealed with bitumen-based sealant. This sealant can be used even on wet surfaces.

The end walls complicate the operation because the roof adjoins them at an angle. Therefore, when sealing such joints you need to be especially careful and careful.

To seal joints between ceramic tiles, it is recommended to use corrugated aluminum tapes.

The wavy profile of the material will repeat the shape of the tiles, and the bitumen poured further will give the seams absolute tightness. These tapes can also be used in the case of bituminous shingles. A wide selection of material colors will allow you to choose the desired shade to match the color of the roof covering.

Popular types of metal parapet

There are other types of roof fencing. Here are some of them:

- flat ones are equipped with drips responsible for draining water, which are routed in opposite directions;

- ridge caps are attached from below and covered with a visor;

- complex ones are equipped with double-sided drainage from different sides, and with drips tucked under the visor;

- simple with two slopes;

- curly, outwardly reminiscent of railings.

Regardless of the material, shape, size and design, each parapet has a set of constituent elements:

- shelf - the main element of the parapet;

- bends or overhangs - parts located at right angles to the shelf;

- side drips are designed to drain water.

Example of profiles of parapet strips that have a protective and decorative function: Example of profiles of parapet strips that are subject to external load: For the manufacture of parapet strips I use industrially produced metal profiles with a polymer coating to match the color of the building facade according to the RAL table (this is a German color standard, where each color corresponds to a digital value). I mark the profiles in accordance with the required dimensions (according to the width of the building wall) and bend them on a machine into the required shape.

I advise you to decorate houses in the high-tech or modern style with profiles of parapet strips, which have both a protective and decorative function. This will make them look powerful and stylish.

But garages and outdoor utility rooms for equipment can be decorated with standard profiles, which are created only to perform protective functions without any decorative note.

Types of metal aprons

But what kind of aprons are there if you suddenly need to install such a product:

- "carrying" The structures delay the avalanche-like descent of snow and melt water. They do not allow gusts of wind to damage the integrity of the roof. Such systems are more resistant to wind and are attached to the building with corrosion-resistant brackets and fasteners. They have different shapes and designs and are made of metal profiles with a thickness of more than 1.25 mm;

- "non-load-bearing". They decorate the roof of the building, hide unsightly communications and ventilation holes. These systems are mounted on supporting and auxiliary structures, which are usually made of wood or metal with an anti-corrosion coating. I choose the profile thickness in the range from 0.4 to 0.8 mm.

Overview of junction nodes

Such connections on different roofs will be radically different. A parapet-type roof must be equipped with a side fence of at least 45 cm in height, covered with reliable waterproofing on top. This material is fixed to the surface using bitumen and mastic.

If the height of the enclosing element is more than 50 cm, the groove is made at a distance of approximately 25 cm relative to the surface of the roof base. In this situation, the waterproofing is installed up to the groove into which the edges of the insulating material are placed. As for the junction, it is sealed again with bitumen or mastic.

The parapet elements must fit together precisely to ensure the tightness of the structure is achieved.

Soft roofing involves the creation of a reinforced and durable waterproofing layer. On a guided roof, the rolled roof covering is laid with a good overlap on the vertical parapet wall.

When using roofing felt as a waterproofing scaffold, it is fixed to the enclosing wall, side and roof using hot bitumen mastic. The next layer of insulation is applied only after the previous one has completely cooled.

This is interesting: the red line of development in urban planning.

The principle of operation is as follows. The top edge of the insulation is placed over the structure or inserted into the created groove. Next, it is secured with a special galvanized bar, which is fixed in place with dowels. The joining areas are treated with sealant, which must dry completely, after which a layer of paint is applied. Upon completion of such actions, an apron made of steel or other material is applied to the bar.

Safety fencing on pitched and flat roofs is an important design. It is carried out in accordance with current standards and regulations. The connection of the additional structure to the roof is carried out efficiently and using the necessary materials and devices. The parapet assembly is the weakest point on many roofs; the service life of the roof and the protective fence, respectively, depends on its reliability and strength.

Roof installation work

Making a parapet is quite simple; for this you need to prepare:

- brick, mortar for connecting bricks (regular concrete);

- reinforcing metal rods;

- clamping bar;

- metal apron;

- waterproofing (roofing felt);

- metal caps and screws.

Laying begins after the floors are ready and the main roof covering has been laid. Each row is reinforced with metal rods, the height of the masonry should not be less than 50 cm (in this case it will be necessary to install metal fences; for a full-height parapet, no fences are installed).

After completion of the masonry, the fence and roof are connected. Such a connection should be smooth; the roofing material is attached at an angle of 45 degrees to the inner side using sand-cement mortar. Roofing felt is laid on top in two layers and coated with bitumen.

After drying, the insulation layer is fixed with self-tapping screws, then a pressure strip and a metal apron are installed. The cap can be of various types (flat, gable, decorative), it is also attached with self-tapping screws.

Price list: price of parapet slab

Parapet slabs. GOST 6786-80

Parapet slabs. series 1.238.1-2

Parapet slabs. series 1.438-1

Cornice slabs. series 1.138-3 v.1

Price of reinforced concrete cornice slab

| Name | Size | Weight, tons | price, rub. |

| KR24-10 | 2390*1000*90/70 | 0,48 | 2 690 |

| KR12-10 | 1190*1000*90/70 | 0,24 | 1 370 |

| AK21-10 | 2080*1000*90/70 | 0,425 | 2 380 |

| AK12-10 | 1180*1000*90/70 | 0,24 | 1 350 |

| AK 12.8 | 1180*750*90/70 | 0,24 | 1600 |

| AK 18.10 | 1780*1000*90/70 | 0,35 | Great Dane |

SitaTurbo adapter for zinc pipe

Number of parts, dimensions and articles

* di = inner diameter (mm) ** da = outer diameter (mm)

Capacities according to DIN EN 1253 in l/s - with round pipe adapter and zinc pipe adapter connected to a zinc riser

Material : zinc-titanium

SitaTurbo adapter for zinc pipe , made of zinc-titanium, for the transition from an adapter to a round pipe of a zinc vertical riser, from 6 or 5 parts. The length of the inserted part is 50 mm.

Types of parepets

Figured . Its appearance bears a close resemblance to a railing. It is characterized by intricate contours and curls.

A simple design with two slopes.

Complicated structure . In this situation, drainage is provided in two different directions. As for the drippers (this is an element that performs the function of safely draining water from the edge of the roof into the gutter), they must be fitted under the protective protrusion.

The roof parapet is in the shape of a ridge , that is, it has a fastening at the bottom, which is covered with a visor.

With a flat surface . It is equipped with droppers responsible for drainage, which are placed in opposite directions.

VARIETIES OF PARAPET APRONS

There are a wide variety of options for making aprons and they are generally selected for each object individually, based on the size, direction of drainage, and other parameters. The most common apron options are listed below.

| "FP-1" | "FP-2" |

| "FP-3" | "FP-4" |

Installation of parapet covers

For fastening use:

- roofing screws;

- rivets;

- anchors;

- screws.

Nails can be used for fixation on wooden structures, but in this case the reliability of fastening is reduced. Straight-line products are installed using standard fasteners. If you plan to install a pitched steel roof on a parapet with a flat surface, internal structures are used - guides of different configurations on brackets. They are fixed on a rough basis using anchors. A galvanized steel sheet is installed on top. Installation is carried out using screws or rivets.

There is another option: the sheets are attached to special plates, previously fixed to the rough base. This installation method is used when it is planned to install products in the shape of an accordion (with a slight slope of the drains, a specific configuration of drips - reminiscent of a zigzag or accordion).

Such strips protrude slightly beyond the parapet. This is necessary so that you can use a hidden fixation method without screws or other fasteners. At the last stage, the galvanized steel parapet is installed - it is slightly stretched to the sides in order to be placed on top of the plate.

Traditional insulation method. Installing insulation between rafters.

Thermal insulation, usually mineral wool, is installed between beams or rafters, which act as cold bridges.

- the thickness of the rafters must correspond to 4 times the thickness of the insulation (due to the low thermal insulation capacity of the wooden rafters). In fact, the thickness of the rafters does not exceed 150-200 mm. At the same time, the area of such cold bridges in the roof area is 7.7% (with a rafter pitch of 650 mm under slabs of 600 mm).

- Mineral wool at sufficient angles of inclination of the roof can slide and sag over time, forming voids not filled with insulation - a direct path to heat loss

- Fiber thermal insulation needs to be insulated from water vapor so as not to accumulate water.

- Fiber insulation has an irritating effect on the skin of small fibers when working with it, and in a poorly ventilated attic space (for example, when installing insulation from the inside) - on the eyes and respiratory system.

complex correct installation of thermal insulation between rafters installed at non-standard spacing.

As a result, the roof's thermal insulation barrier is not continuous, which, in addition to increased heating costs, can negatively affect the interior decoration over time.

Traditional insulation method. Installing insulation between rafters.

Thermal insulation, usually mineral wool, is installed between beams or rafters, which act as cold bridges.

- the thickness of the rafters must correspond to 4 times the thickness of the insulation (due to the low thermal insulation capacity of the wooden rafters). In fact, the thickness of the rafters does not exceed 150-200 mm. At the same time, the area of such cold bridges in the roof area is 7.7% (with a rafter pitch of 650 mm under slabs of 600 mm).

- complex correct installation of thermal insulation between rafters installed at non-standard spacing.

- Mineral wool at sufficient angles of inclination of the roof can slide and sag over time, forming voids not filled with insulation - a direct path to heat loss

- Fiber thermal insulation needs to be insulated from water vapor so as not to accumulate water.

- Fiber insulation has an irritating effect on the skin of small fibers when working with it, and in a poorly ventilated attic space (for example, when installing insulation from the inside) - on the eyes and respiratory system.

As a result, the roof's thermal insulation barrier is not continuous, which, in addition to increased heating costs, can negatively affect the interior decoration over time.