The popularity of flat types of roofing in Soviet times was due to one reason: such roofs were considered more durable compared to pitched slate roofs, and then this was practically the only roofing material available. Today this problem has lost its relevance, but flat roofs remain in demand - primarily because of the ease of their arrangement. But such roofing structures are subject to special requirements, including the correct organization of drainage.

Types of drains

In the case of a pitched roof, organizing a drainage system does not present any difficulties - the water flows down the inclined plane on its own, and you only need to collect it.

With flat roofs, things are different - the required slope is absent or minimal, so you have to manage to prevent water from stagnating.

Currently, the internal drainage system of flat roofs is one of two types of design: siphon or gravity.

Gravity or gravity structures require a slight slope, with water collected in special water inlets leading into the building.

Siphon systems work differently - there is no slope, and water can accumulate, including in the funnel area. The principle of operation of such structures is based on the pressure difference in the sewer riser - due to the resulting vacuum, all the water in the funnel area is sucked in and discharged out. At the same time, the internal drain does not necessarily have to be equipped with a heating system - in southern and temperate latitudes, water does not freeze, since the risers are heated by the internal heat of the building. In the northern regions, flat roofs for residential buildings are not common at all due to the likely freezing of water both directly on the roof and in the riser. Here, only non-residential buildings are equipped with flat roofs.

In any case, drain funnels must be equipped with protective nets to prevent debris or animals from entering the riser.

Features of internal drainage

Since a flat roof does not have a slope for the natural drainage of precipitation, special requirements are placed on the drainage design. In principle, organizing the internal drainage of a flat roof from the point of view of labor costs is much more difficult than the external one, which differs little from the drainage of traditional pitched roofs. But at the same time, the internal drain has a number of undeniable advantages over the external one, and the principle of collecting water is slightly reminiscent of that used in the bathroom - it flows in the direction where the resistance to liquid flow is the least, that is, towards the funnel. The water then drains into the sewer pipe and flows into a standard sewer drain. An atypical scheme involves collecting water in a reservoir for its further use (for technical purposes).

Let's look at the main advantages of a flat roof with internal drainage:

- no freezing effect of wastewater, since the pipes are hidden inside the building;

- the high aesthetics of such systems is due to the absence of pipes and other drainage elements on the roof and facade of the building;

- The drainage efficiency of the internal drain is higher than that of the external drain.

The complexity of organizing internal drainage lies in the fact that its elements must be provided for at the design stage of the building. It is not possible to implement an internal drainage system in a finished building without dismantling part of it. The second difficulty is to ensure protection of the drain from clogging, since the sweeps and filters used for these purposes should not interfere with the intake of liquid.

What is it ↑

Free flow of water from the edge of the roof to the ground occurs due to the appropriate slope of the slope. At the same time, there are completely no structures for its organized collection and transportation.

This model is attractive due to its minimal costs for arranging the roof and the simplicity of its construction. However, it is also necessary to take into account negative aspects that will inevitably affect the condition of the roof and the entire building as a whole.

- Gradual destruction of the foundation. Even in regions with little rainfall, water from the roof will gradually penetrate into the foundation structure. This will inevitably lead to a deterioration in his condition. To avoid this, it is necessary to make additional underground drainage to remove moisture from the soil.

- The basement part will also be exposed to precipitation. Therefore, it is necessary to periodically update the waterproofing layer on its surface.

- External unorganized drainage contributes to possible damage to the facade walls. During their construction, it is necessary to provide an additional layer of waterproofing material.

Considering these shortcomings, a fair question arises: is it necessary to make a roof without an organized drainage system? To answer this you need to refer to SNiP 31-06 standards. The contents of this document clearly describe the features of the building in which unorganized drainage can be left.

Installation of a standard design of internal drainage for a flat roof

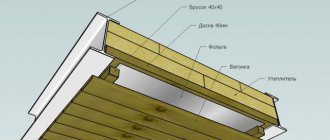

The standard design of an internal drain consists of a cover and a glass. The lid is usually made removable, and a mesh is installed between it and the glass to protect the drain from various debris.

A layer of waterproofing material is installed under the cover to prevent water from flowing into the building, bypassing the drain.

The diagram of a typical internal drain funnel, shown in the figure, consists of:

- external coarse filter;

- internal air filter;

- pressure flange (most often metal);

- waterproofing layer;

- a receiving funnel connected to the sewer pipe;

- thermal cable.

The design of the glass may include a base that facilitates a more dense and reliable waterproofing arrangement. The number of funnels on the roof should be reduced to a minimum, at the same time, the distance between adjacent funnels should not exceed 45-50 meters. The optimal diameter of pipes for water drainage is 85-200 mm. The internal drainage system must provide for the possibility of its inspection (cleaning); usually such structures are located in the lower part of the drain.

A carefully thought-out design of the drain will allow the system to function without the occurrence of insoluble problems throughout the entire life of the building, so the design stage should be treated with due attention.

Calculation of internal drainage for a flat roof

Since errors here are difficult to correct, a diagram and drawing of the internal drainage system are drawn up at the design stage of the entire house.

If this is a siphon-type system, it is important to make the drainage system in such a way that water easily flows into the funnel even when there is no wind - usually it creates the necessary pressure drop in the system.

When drawing up a plan for internal drainage in the case of using a flat roof, the following factors must also be taken into account:

- average annual precipitation in the region of residence;

- features of the roofing structure;

- the possibility of backflow of liquid;

- dimensions of the roof structure and drainage funnels.

Usually the calculation of the roof funnel area is carried out so that for each square. a centimeter of pipe was approximately 1 square. meter of roof area, based on this the number of funnels is calculated.

If there is more than one funnel, each should serve approximately the same roof area - this is important, since the slope of a flat roof is absent or minimal. The minimum distance between adjacent storm drains must exceed 1 meter, between drainage basins - 60 meters. If the roof has a slight slope, the distance between the catch basins can be reduced to 45 meters.

For residential premises, the design should include two funnels for each residential section. There are also standards for the distance from gutters to external walls: it should exceed 1 meter, although usually it is much greater.

It is advisable that the drainage system be installed in technical rooms; it is prohibited to place pipes above equipment for which contact with water is strictly contraindicated. Typically, internal drainage is installed in shafts or niches; they can be installed next to the pipes of heating/ventilation systems. It is not prohibited to place them in the corridors of living rooms.

Material for drainage elements

Industrial gutters presented in the retail network are quite diverse designs that may differ in the materials used, the shape and size of the gutters, etc.

The most economical option for internal drains are systems whose pipes are made of galvanized steel. By the way, they are easiest to make yourself. Typically, galvanized drainage is used in multi-story construction, but such pipes are also used in private buildings.

Recently, plastic pipes have become increasingly common, which are even cheaper, but have a number of specific requirements for joining with other elements of the internal drainage system. Copper pipes are rare - this is an expensive option, although it is the most reliable and durable.

To ensure that the elements of such a system are in harmony with the roof and interior of the building, they are painted in a suitable color. Coating them with a layer of polymer is also becoming popular.

When choosing a material, it is worth considering the type of roofing: slate goes well with metal, and flexible tiles go well with pipes and elements made of PVC.

Functional purpose of drainage systems

Gutters, the appearance of which can be seen in the photo, belong to the engineering structures necessary for each building, regardless of its purpose. What type of drainage system (internal or external) to install is determined based on the structural features of the roof.

Living in a climate zone where there is a change in weather conditions depending on the time of year explains the need to comply with a number of requirements for the reliability and strength of gutters, which must function flawlessly in conditions of frosty and snowy winters and very hot summers. Therefore, experts note that internal gutters of buildings are more practical and convenient, since their operation does not depend on sudden temperature changes, but this applies to flat roofs in use.

To avoid problems with the functioning of external drainage structures on a single or double slope, hipped, gable, or sloping roof, you can design and install an electric heating system.

Installation features

Drawing up a drawing with calculations and selecting high-quality materials is good, but the installation itself is an extremely responsible matter. Any mistake made at this stage can lead to serious consequences in the future, and it is often impossible to correct them.

To help precipitation flow to the funnels, it is advisable to arrange a slope of at least 5° on flat roofs. Such a minimal slope is organized using cement screeds; it is also permissible to use suitable thermal insulation material for this. It is important to ensure the unimpeded flow of water into the funnel, and if the thermal insulation layer interferes with this, the funnel is raised by placing it on a wooden beam. It must be treated with a high-quality antiseptic.

For siphon systems, the pairing of pipe sections located vertically and horizontally is carried out using special adapters. This way you will ensure direct flow of liquid from one pipe to another.

Since the funnel is usually located above the freezing point, it is advisable to ensure its heating in winter. For example, electric heaters. If the drainage structure is located at a distance of more than a meter from the heated part of the building, it is recommended to provide heating for horizontal pipes, especially in regions with severe winters. The common belief that drainage is not needed in winter is incorrect: without it, the conditions for leaks to occur on the roof are approximately the same as with asphalt, so it is better not to neglect this rule. Heating also protects system elements from deformation and premature failure.

On buildings with a multi-level roof, each level must have its own internal drainage system. Particular care must be taken to calculate their number and location if the difference between levels exceeds 4 meters.

To prevent noise from water flowing through the pipes from disturbing, they are covered with a layer of soundproofing material.

Typically, the greatest difficulties arise at the stage of installing the funnel - here it is important to achieve the most airtight pressure to the base of the roof. To do this, it is customary to install a special glass in the hole for installing the internal drain, which will ensure the required tightness of the structure.

The glass must be installed after a layer of waterproofing has been laid on the roof surface - it is important that the upper edge of the glass is located above the waterproofing material, regardless of whether it is rolled or poured. The funnel is fastened using self-tapping screws; it is also advisable to additionally treat the glass with an adhesive composition. And only after this the installation of the main roofing material is carried out.

Let us describe the algorithm for making a hole:

- the roofing material is laid on top of the glass structure;

- if it is soft, cut a hole with a sharp knife, it is important that the cut exactly matches the edges of the glass;

- Now you can start installing the hood and filter system (in the simplest case, a regular grill).

Note that two-part funnels are considered the most practical, since they compensate for changes in the linear dimensions of the insulation during sudden temperature changes.

Another difficult point is connecting several funnels to a single drain, and this situation occurs quite often, based on the above standards for calculating the number of funnels per unit area. The fact is that for this you will have to install a system of horizontal pipes, and they must be located below the freezing point of the roof. Usually - under the floors of the building, but always above the ceiling. At the same time, even in siphon systems, to ensure guaranteed water collection, it is desirable to ensure their inclination at least at an angle of one or two degrees, for gravity flow systems - up to 5°. They also need to be covered with soundproofing material.

The heating element, or thermal cable, must be routed to the funnel area - this will protect the internal drain from pieces of frozen water, which often causes clogging of the entire drainage system.

Before designing, it is advisable to carefully study the full set of requirements and rules regarding the construction of internal drainage systems set out in the industry SNiP 2.02.01-85.

Gutter as one of the main and important components of the device

One of the main structural elements that receives water from the roof. There are several varieties of it: wall-mounted or hanging. Plastic, galvanized metal or copper are used for manufacturing.

Wall

It is localized close to the overhang of the roofing material at the very edge of the roof. The product is a side, up to 20 cm high and acts as a barrier to rainwater. Such gutters are installed at an angle to the overhang and directed towards the drain funnel. To connect the trays, glue or a double lying flange is used. Their tilt angle is 15 degrees, which prevents liquid from overflowing over the edge.

Rain or hanging

It is tightly attached directly under the roof overhang, which prevents accumulated liquid from flowing under the gutter. For fixing, steel hooks are used, shaped to match the product. Since this fragment does not bend, in order to avoid overflowing, a hole must be made in it in a pre-marked place. When calculating the slope in this case, the amount of precipitation that fell during the year is taken into account.

Classification of gutters

The following types of gutters are distinguished by shape:

| Variety | Characteristic |

| Semi-elliptical | Copes well with large flows of water, as it provides greater throughput |

| Semicircular | It is resistant to loads and has a high level of rigidity. This gutter is universal, as it is used on most roofing structures. |

Gutters are also classified according to the material of manufacture:

- Plastic. They have an attractive appearance, light weight and low cost. With proper fastening and use, the service life is 15-25 years. You can install them yourself. Such fragments are secured using couplings or latches with rubber seals. Sometimes glue is used for fixation. But such products have a high risk of mechanical damage and become brittle at subzero temperatures. Small scratches on the surface can be masked with acrylic paint.

- Aluminum. For connection, fasteners with rubber and silicone seals or specialized glue are used. Untreated material can quickly become rusty. A layer of varnish will help avoid this.

- Galvanized. They are metal products with pre-applied polymer protection. Characterized by a wide range of colors. For fastening, brackets with latches equipped with rubber seals are used. Such gutters are highly durable and do not corrode unless the polymer layer is damaged. The disadvantage is the frequent lack of the correct shape, which complicates the assembly of the system.

You can also buy copper products in stores. They are durable, rust-resistant, have an attractive appearance and a long service life, but they are expensive.

Copper rainwater is durable, corrosion-resistant, has an attractive appearance and a long service life, but it is expensive.

How to calculate gutters correctly?

The standard element length is 3-4 m. For small buildings, products with a cross-section of 70-115 mm are sufficient. On large structures, gutters with a cross-section of up to 200 mm are installed. It is necessary to calculate the specified fragment so that the distance between the nearest craters is 8-12 m.

Assembling the gutter design

If the length of the gutter is more than 12 m, then several fragments of fasteners connected to each other are required. After this, plugs are installed at the edges of the structure and it is fixed on the brackets.