Polyvinyl chloride panels have long established themselves as a beautiful and durable material with a long service life. Therefore, covering eaves with siding is one of the best solutions for the exterior decoration of small buildings. Of course, it is best when the walls are covered with the same material, creating a single, holistic picture.

Covering eaves with siding in a private house

Why do you need a G-profile and other extras?

In addition to the wall panels themselves, there are many additional elements that simplify their installation and give the facades a complete look. They serve not only as decoration, but also perform the function of sealing those sections of the walls that cannot be covered with siding. Such extras include:

- starting profile from which installation begins and which fixes the first panel;

- connecting profile for siding, covering the joints between panels along their length;

- finishing strip framing the edge of the cladding under the cornice;

- internal and external corner profiles for designing the corresponding corners of the building;

- near-window strips for creating slopes, etc.

Scheme for using add-ons Source ukrpublic.com

Most of these elements can be replaced by a G-profile, which has a simple but universal design. And it is often preferred when they want to save on materials, since many accessories are significantly more expensive than it. During installation, all cladding elements are attached to the siding guides in one way, so such replacement does not complicate the work. But how equivalent it turns out depends on the place of application.

Frame for sheathing

Even if we are dealing with a flat façade plane, it is recommended to install decorative strips on a metal profile. A similar design made of wooden beams is more difficult to implement and less effective.

Unlike galvanized sheathing, it requires additional treatment with antiseptics.

A high-quality metal base can withstand heavy loads, so it is suitable for fixing metal siding.

Advantages of lathing

The main advantages of the frame are:

- the ability to visually align the walls of the house;

- ventilation façade equipment;

- insulation of walls, which will have a positive effect on the indoor climate and help save on heating costs.

Recommendations

For siding sheathing, the correct choice would be a profile with a cross-section of 2.7x6 cm with special sides, which act as a kind of stiffening ribs. When installing the base, it is necessary to take into account the dimensions of the main cladding elements. To fix the planks to a wooden frame, ordinary self-tapping screws are sufficient, and in the case of a brick or concrete wall, you cannot do without dowels.

The heavier the finishing material, the smaller the distance between the metal profile should be. According to the standards, the pitch between the lathing slats is 0.6 and 0.4 m for vinyl and metal material, respectively. The frame slats are installed perpendicular to the fixation of the decorative cladding.

Application of j-profile

According to its main purpose, the j profile is an end strip that covers the cut of the wall panels. Open ends not only spoil the appearance of the cladding, they completely defeat the purpose of protecting the walls from moisture. Precipitation and atmospheric moisture easily penetrate under the skin in such places, causing rot and corrosion. Vinyl G-plank, as well as a similar profile for metal siding, can easily solve this problem in a variety of places.

j-profile for metal siding Source aliance.online

Where and how such an accessory can be installed depends on its type.

Types of end profile

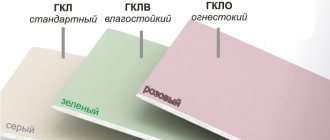

In total, there are 3 types of j profiles for fastening siding, or even 4 if you include a chamfered profile in this list.

- A regular profile has standard width and height dimensions, which may vary from manufacturer to manufacturer.

Profile for siding Döcke LUX BERGART Source roofos.ru

- A flexible profile, often called arched, with the same dimensions, differs from the usual one by the presence of notches on the rear shelf, along which it is easily cut and bent to the desired radius.

Flexible profile for framing radius openings Source azbuka-rem82.ru

- The wide profile has the same width as a regular one, but has an increased height, which allows you to cover the ends of the siding with a large gap between it and the wall.

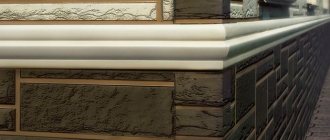

A wide profile is usually used as a platband Source marketudachi.ru

See also: Catalog of companies that specialize in finishing materials and related work

In addition to the standard j-profile for siding, an additional element very similar to it, called a j-plank, a wind strip or a j-profile with a chamfer, is also used. It is used to cover and decorate the edge of the roof - a wind board, or a deep window opening.

G-bar for roofing edge Source lesovik76.ru

Methods of use

The universal profile is installed in a variety of cladding units.

- In the upper part of the wall under the cornice - instead of a finishing strip.

- On the side inclined lines of the pediment to fix its cladding and give it a complete look.

- On the edges of horizontal eaves for attaching soffits - perforated siding panels.

- At the end of the wall when combining siding with other facing materials.

- At the corners of the house, you can also install two j profiles instead of special elements.

Replacing the corner profile with universal ones does not guarantee the tightness of the skin, but reduces its cost Source infradom.ru

- At the top and bottom ends of the corner profile for a decorative effect.

There are also places in the cladding where it is better to use special additional elements without replacing them with a G-profile. This is the line of fastening of the first siding panel, along which the starting strip is installed, and the line of joint of the panels along the length, which is best covered with a connecting H-shaped profile. If you install two universal profiles instead, the joint will still remain, and moisture and dust will get into it.

Installation on window openings

To frame window openings, take a wide j profile for siding, the dimensions of which allow it to be used as a platband. Installation is carried out on the frame before installing the wall panels, the edges of which are then inserted into the grooves of the profile. This method of finishing openings is used when they are not recessed into the wall and do not require the installation of slopes.

Installation of panels in the installed frame Source montazh-saidinga.ru

Advantages of the material

Sheathing the cornice with siding is a modern design solution. Siding for eaves is called soffit. The material has many advantages over other finishing options. Positive qualities usually include:

- Versatility: this type of siding is intended for cornices, but is also widely used for floors;

- Diversity. They sell various types of siding, as well as decorative additions to it. Wide color palette available;

- Does not require any additional coverage;

- Environmental friendliness of materials used in production;

- Resistance to various types of influence: biological, temperature changes and high humidity;

- Compliance with fire safety standards;

- Easy to install: even inexperienced builders can carry them out; you can work alone;

- Relatively low cost of material and finishing costs;

- Small mass of siding. The use of the material will not affect the overall weight of the structure and will not cause a risk of collapse;

Video description

Brief but very clear instructions for installing a G-profile around openings are presented in the video:

Gable installation

The gables of pitched roofs are often lined with siding, and the most problematic and unsightly place is the cut line of the panels under the roof overhang. The easiest way to cover it is with a universal end profile, securing it along this line before starting cladding work.

The installation itself is simple; the extension is simply fixed with self-tapping screws or nails into the holes of the nail strip. It is more difficult to “catch” the angle of joining of two parts under the ridge and accurately cut the facing panels so that the cut is completely hidden in the grooves of the profile. To cut parts accurately and without errors, it is recommended to first make templates from scrap material, as shown in the diagram.

Scheme for making templates for cladding the pediment with siding Source recn.ru

If the pediment is high, the length of one profile may not be enough. To build it up, you will need to trim one of the elements.

When fixing profiles, the topmost self-tapping screw under the ridge is screwed into the uppermost point of the mounting hole, the rest, as usual, into the center. The pitch between the screws is 25-30 cm.

Installation of spotlights with G-profile

The main purpose of the j profile in siding and where to install it is to line the eaves with soffits. If in other places you can use special additional elements, then only this one will do.

One row is attached along the wall, to which a horizontal wooden beam is nailed or screwed with self-tapping screws. The profile is fixed on its lower plane, lengthening it if necessary, as shown in the previous diagram.

On the opposite side of the cornice, the second row is fixed parallel to the first. Their grooves should face each other.

Then measure the width of the resulting cornice between the inner walls of the profiles and cut the soffits to size, subtracting 12 mm from the obtained value. This is necessary to provide clearance for thermal expansion of the panels.

Universal components

Fastening system : hidden.

Installation : both before and after installation of metal siding.

Type of siding : Shipboard, L-beam, L-beam XL, Woodstock.

Advantages : versatility of use.

Low tide

Size range: 150*30*2000 180*30*2000 210*30*2000 240*30*2000

Purpose : used to protect a window opening - this element is also called a window sill.

Rolling : on one side - the bottom of the part.

Base ebb

Size range: 50*20*2000

Purpose : protects the junction of the facade with the plinth from weather conditions.

Installation recommendation : depending on the selected type of siding, it is installed before or after installation of metal siding.

Rolling : on one side - the bottom of the part.

Small aquilon bar

Size range: 35*20*2000 35*20*3000

Purpose : used in conjunction with a 3D window strip or a simple or complex eaves overhang strip.

Installation order : first install the small aquilon strip, and then install the 3D slope strip (in the group of complex components) or eaves overhang strips (simple and complex). The result is a neatly executed assembly of the frame of the window opening.

Z-shaped

Size range: 32*15*3000

Purpose : used as a support strip when the last siding panel is trimmed.

*Manufactured only in 0.7 metal thickness and only in Polyester coating.

Video description

How to install the G-profile and soffits on the cornice, see this video instruction:

Framing corners

External and internal corner elements ensure the tightness of the corner joints of the siding panels. If desired, they can be replaced with j siding profiles, for which they are attached close to each other, each on its own side of the corner. But this solution has several disadvantages:

- insufficient joint tightness;

- simplification and deterioration of the appearance of the connection;

- the impossibility of neat and beautiful finishing of an indirect angle;

- the need to purchase two extras instead of one.

However, even two G-profiles are cheaper than one corner profile, which is why some developers prefer them.

Mounting points

In order for the cornice hemming to be correct and have the required aesthetic effect, you should know certain subtleties.

Types of pairing of load-bearing elements

By puff

In this case, the tie rod or the lower chord of the truss can serve as the lower part of the roof structure. In any case, you will need to decide on the pitch of the trusses. The approximate value of the construction pitch is from 50 to 80 cm. In this case, the length of the panel will be approximately 3 meters. If you carry out simple calculations, determine that the panel will need to be trimmed at the fastening points.

Installation Tips

Before buying extensions, guides and hangers for siding, you need to calculate the amount of all materials. Additional elements are calculated especially carefully, since you need a lot of them, they are not cheap, and no one wants to buy too much.

In the case of the G-profile, it is necessary to decide where it will be installed and whether it will replace other accessories. Calculating the footage for finishing the gables or decorating the upper edge of the facade is simple: just measure the length of these lines, divide the result by the length of one profile and round up.

For installation of soffits and finishing of vertical corners, the resulting linear meters are doubled, since the profile will be mounted in pairs.

For the cornice, two perimeters are added - internal and external Source strojka24.ru

It is more difficult to calculate the number of profiles for openings. If on the pediment or cornice they can be increased in length, then the joined platbands around the window do not look at all aesthetically pleasing. Therefore, it is advisable to measure all the parameters of each opening and see how to finish them with solid planks with a minimum amount of scraps.

For choosing materials and self-installation, you may find other recommendations useful.

- Nails and screws for fastening the profile are selected with heads with a diameter of at least 8 mm.

- They are installed in the middle of the mounting hole to ensure free movement of the extensions during expansion.

- The fasteners are screwed in or not driven in all the way, leaving a gap of 1 mm under the head.

- When splicing profiles along the length, a gap of 6 mm is left between their fastening flanges so that when the plastic heats up and expands, the parts do not rest against each other and are not deformed.

- For the same reason, siding panels should not rest against the walls of the profile groove.

Rules for installing any siding elements Source stroika-portal.ru

- When choosing the color of profiles, it is worth remembering that dark ones heat up and expand more than light ones.

- When installing profiles on gables, they are attached with a slight offset from the corner to reduce heating from the roof.

Types of siding

Metal

Metal has a number of advantages over wood. It is stronger and more reliable. But metal siding is afraid of moisture: even despite the presence of a layer of zinc on the surface, red spots appear on the metal over time, where rust particularly affects iron. In addition to the aesthetic appearance, the strength of the material also deteriorates: the risk of damage to integrity in places where rust is located increases significantly. Buying copper siding will save you from this. Copper not only is not afraid of moisture, but also has a characteristic metallic luster. The main disadvantage of using a copper profile is its high price.

Wood

This material creates the illusion of high cost and adds aesthetics to the entire structure. Installation of wood siding does not require any special tools or special knowledge and skills. But wood has a big disadvantage: it absorbs all the moisture and is also susceptible to temperature changes, which is the main reason for the destruction of wooden structures even with special treatment.

Vinyl

Polyvinyl chloride is a material more resistant to high humidity. It is cheaper than all its analogues. These two factors make vinyl siding the best option for finishing eaves. In addition to them, they also note:

- Good strength characteristics;

- Wide selection of colors;

- Easy to install, installation does not require reading multi-page instructions, everything is assembled intuitively;

Separately, siding is not suitable for finishing the surface of the cornice. Builders use soffits for this purpose. They are PVC panels that may have perforations. These panels mainly serve to protect the cornice from accumulating moisture.

Based on the perforation method, soffits are divided into 3 types:

- Complete perforation of the entire surface of the panel;

- Partial perforation;

- Solid panels without perforation;

Perforation is required to ventilate the space near the eaves. Based on the degree of required ventilation and the expected moistening of the cornice, the type of perforation is selected already at the planning and design stage.

The most popular panels are those with a combined type of perforation. They provide sufficient ventilation, but do not allow water droplets to pass through.

Partially perforated PVC panels are especially useful in places where there are wooden or metal structural elements, since ventilation can allow condensation to leave the eaves space. Accordingly, metal will not succumb to rust, and wood will not rot.

Full perforation of the plates is appropriate in those buildings where the roof itself does not allow air to pass through, which will provide protection from the cold from the street. Solid panels are used in attics. There is no need to drain condensate.

Briefly about the main thing

If you carefully read the article, then you know almost everything about the GI profile for siding: what it is used for, what it looks like, what types of it are used for finishing openings, arched windows, ends and cornices. This universal additional element, which can replace many other siding components, is popular among buyers due to its affordable price. With its help you can beautifully decorate windows, gables, cornices and even the corners of a building.

Ratings 0

Let's summarize

We offer a wide range of components for finishing facades with metal siding in any color, configuration and even texture.

You can implement the most daring and unusual solutions on your façade. Especially if you “play” with contrast and use additional elements to metal siding of a different color. For example, when choosing light-colored metal siding, you can use dark-colored additional elements. This is a very well-known and popular maneuver in the design of facades.

Moreover, no matter what type of components you choose, the main thing is to adhere to and follow the Siding Installation Instructions, and everything will work out.

We hope our article was useful for you and helped you understand what parts are used for metal siding and why.

The categories mentioned in the article are:

Siding

Standard trim elements

Box finishing

Finishing the roof eaves with siding is carried out in several stages. And everyone is important. The filing of the cornice with siding is done on the box, and all the work begins with its manufacture. Covering the cornice with siding is done on the frame; the entire geometric shape of the structure depends on its correct execution. Therefore, in this matter you should be especially careful and take correct measurements and apply markings.

Attention: The frame can be made of aluminum profile or wood. If you choose the second option, then you should prepare the timber in advance and then treat it with antiseptics. It is available for free sale. Give preference to deep penetration liquid and do the treatment a couple of times. This will significantly extend the service life of the entire structure. After processing, all parts must be allowed to dry completely.

Making a box