In accordance with SNiP, depending on the characteristics of the finishing and the technology of work, plaster can be simple, improved and high-quality. Compliance with the regulated requirements and recommendations of manufacturers of dry mixtures will allow finishing by machine without unnecessary costs for rework.

| Plaster tolerances | Simple | Improved | High quality |

| Deviation from the vertical by 1 m, no more | 3 mm | 2 mm | 1 mm |

| Irregularities of a smooth outline per 4 m2, pcs. | 15 mm | 10 mm | 5 mm |

| Maximum deviation from the vertical for the entire height of the room | 3 pcs. | 2 pcs. | 2 pcs. |

| Depth of unevenness | 5 mm | 3 mm | 2 mm |

| Deviation from horizontal by 1 m. | 3 mm | 2 mm | 1 mm |

| Deviations of window and door slopes by 1 m. | 4 mm | 2 mm | 1 mm |

| Deviations of slope width from design, mm | 5 mm | 3 mm | 2 mm |

| Maximum deviations of window and door slopes for the entire element, mm | 10 mm | 5 mm | 3 mm |

| Deviations of the radius of curved surfaces, for the entire element, mm | 10 mm | 7 mm | 5 mm |

| Substrate moisture | 8% | 8% | 8% |

SNiP and SP for plaster

Currently, plastering work is regulated by the Code of Practice SP 71.13330.2017 “Insulating and finishing coatings”.

This document is an updated version of SNiP 3.04.01-87. GOST for plaster is not currently used. The set of rules SP 71.13330.2017 was approved by the Ministry of Construction and Housing and Communal Services and contains rules and general principles regarding processes in order to ensure compliance with the requirements of technical regulations.

A code of practice is a normative document that recommends technical solutions or engineering survey procedures for construction, design, construction and installation work and the manufacture of construction products, as well as the operation of construction products and determines ways to achieve their compliance with the mandatory requirements of building codes, regulations and standards.

Introduction

The set of rules was developed by the team of authors of the Federal State Budgetary Educational Institution of Higher Education "National Research Moscow State University of Civil Engineering" (Candidate of Technical Sciences A.P. Pustovgar,

Candidate of Technical Sciences

S.A. Pashkevich

,

S.V. Nefedov, I.S. Ivanova

,

F.A. Grebenshchikov

) with the participation of the non-profit organization “National Roofing Union” (Candidate of Technical Sciences

A.V. Voronin

), Association "ROSIZOL" (

E.Yu. Ivlieva

,

A.M.Deev

), BUT Association "ANFAS" (

S.A. Golunov

), Association "Union of Dry Construction Mixture Manufacturers" (

N.A. Glotova

,

A.V. Zabelin

,

B. B.Vtorov

), PSK Concrete Engineering LLC (

AMGorb

).

Amendment No. 1 to SP 71.13330.2017 was made by the team of authors of the Joint Stock Company “Research and Development (PhD. I.P. Savrasov

, Ph.D.

tech. Sciences I.M.Drobyashchenko

, Ph.D.

tech. Sciences S.V.Kotov

,

N.V.Barannik

).

SNiP plaster. Code of Practice (SP)

In SP 71.13330.2017, the requirements for plastering work are specified in Chapter 7 “Finishing work”. This document applies to both internal and external work, including plastering the plinth and facade. It defines the requirements for the technology of work, the presence and control of errors in plastering.

Below are the main extracts from this document regarding plastering work.

7.1.1 Finishing work in premises should be carried out at an ambient temperature and surfaces to be finished from 5°C to 30°C, relative air humidity no more than 60%, unless otherwise specified by the material manufacturer. This temperature and humidity regime in the room must be maintained around the clock during the entire period of finishing work and at least 2 days before the start and 12 days after the completion of work.

7.1.8 Before applying each subsequent layer, it is necessary to remove dust from the surface being treated and, if necessary, treat the base with a primer to reduce or level its absorbency.

7.2.6 Plaster mortar based on cement or lime-cement binder can be applied either in one layer or in layers according to the instructions of the material manufacturer. When installing a multi-layer plaster coating, each layer must be applied after the previous one has set. Depending on the type of work, the plaster mortar, the type of base, the unevenness of the wall and the thickness of the layer, if provided for by the project, a plaster mesh is selected, if necessary, and attached to the wall.

7.2.7 When performing internal plastering work with gypsum-based solutions, it is allowed to carry out work without using a plaster mesh. Gypsum-based plaster solutions are applied in one layer, unless otherwise specified by the material manufacturer.

7.2.13 The quality of plastering work is assessed according to the requirements:

| Simple plaster | Improved plaster | High quality plaster | |

| Deviation from vertical | No more than 3 mm per 1 m, but no more than 10 mm over the entire height of the room | No more than 2 mm per 1 m, but no more than 10 mm over the entire height of the room | No more than 0.5 mm per 1 m, but no more than 5 mm over the entire height of the room |

| Horizontal deviation | No more than 3 mm per 1 m | No more than 3 mm per 1 m | No more than 1 mm per 1 m |

| Surface irregularities of a smooth outline | No more than 4 pcs. per 1 m, but not more than 10 mm for the entire element | No more than 2 pieces, depth (height) up to 3 mm | No more than 2 pcs., depth (height) up to 1 mm |

| Deviation of window and door slopes, pilasters, pillars, etc. from vertical and horizontal | No more than 4 mm per 1 m, but no more than 10 mm for the entire element | On area 4 no more than 4 mm per 1 m, but no more than 10 mm for the entire element | On area 4 no more than 2 mm per 1 m, but no more than 5 mm for the entire element |

| Deviation of the radius of curved surfaces from the design value | No more than 10 mm for the entire element | No more than 7 mm for the entire element | No more than 4 mm for the entire element |

| Deviation of slope width from design | No more than 5 mm | No more than 3 mm | No more than 2 mm |

Read more about each type of plaster according to SP in the articles: simple, improved and high-quality plaster. In addition to the requirements for deviations and tolerances, there is a difference in the technology of work. Simple plastering can be done without beacons, but for improved and high-quality plaster it is necessary to use beacon profiles.

The requirements of SP 71.13330.2017 regarding the quality of plastering work correspond to the German standard for plaster DIN V 18550 “Plaster and plastering systems”. This European Standard contains a set of recommendations for the preparation and assessment of surface quality depending on the different types of finishing coatings from the lowest Q1 to the highest Q4.

In addition to the current Code of Practice, there is a draft National Standard of the Russian Federation GOST R 57984-2017/EN 13914-1:2005 “Plaster for external and internal work. Rules for selection, preparation and application. Part 1. Plasters for external work”, but at the moment this document has not come into force.

General requirements for plastering

The basic rules include the following points:

- The room is protected from precipitation. Interior finishing is carried out at air temperature ≥ 10 ºС and humidity up to 60%. Such conditions are created and maintained continuously 48 hours before the start of work and at least 12 days after completion.

- Brick walls are moistened before plastering if the air temperature is more than ≥ 23 ºС.

- Hydro-, heat-, sound-insulation and floor filling have been completed; all seams in the walls have been sealed; doors and windows installed.

- Water supply and heating pipes have been installed and tested.

- Embedded products for sanitary systems are installed after plastering.

- Finishing of facades begins after the roofing, waterproofing is completed, and fasteners for drains are installed.

- The surface for plastering is prepared: there is no rust, oil or bitumen stains, or efflorescence.

- The base must be no less durable and the finish.

- The joints between wooden and brick (concrete) surfaces are plastered over a metal mesh; wooden walls - on stuffed shingles.

- Protruding parts of the facade and plaster stucco molding are made with reinforcement (reinforcement or mesh).

General information about plaster

For work, various types of mixtures are used, which are used depending on their purpose. It is also necessary to take into account the climatic conditions of the region, room temperature, humidity, etc. The plaster mixture is designed to protect walls and other structures of the house from the influence of the external environment.

When choosing plaster, all conditions should be taken into account. In addition, the composition must have waterproofing and acoustic properties. Ready-made mixtures are used for decorative finishing. However, you can prepare the composition with your own hands, and you need to select the right ingredients and dye, according to a special recipe.

To apply plaster to a stone base, complex solutions are used. Cement mortar is applied to the concrete wall. In this case, the concrete must first be scored. A lime-gypsum mixture with additional elements is suitable for a wooden surface.

If it is necessary to cover the surface with a layer of plaster 20 mm thick or more, a reinforcing mesh is used. It is also used for plastering architectural elements made of concrete and brick. Mesh is often used at the junction of walls, especially if they are made of different materials. This procedure will prevent future cracks from appearing on the coating.

Necessary conditions for plastering

Practically, perfectly smooth surfaces are difficult to find in residential buildings or public buildings. Before you begin finishing the walls, they should first be leveled. If you plan to plaster yourself, there are a few things you should consider to ensure that no problems arise during the process.

Standards for plastering walls, as well as permissible deviations for plastering can be found in SNiP. In order for plastering to take place according to technology, as well as to create normal working conditions, the readiness of the territory must meet special rules.

Important. If plastering work is carried out in winter, the temperature in the workroom should not be lower than +10°, while the humidity should preferably not be higher than 70%.

To prevent the cold from penetrating into the building, all openings, vestibules and other openings are insulated. You also need to monitor the humidity of the walls. For brick and stone foundations it should be no higher than 8%.

Areas of special attention

It is worth carefully inspecting the areas around sockets, switches, the places where door frames adjoin the wall, ceiling and floor skirting boards. If the walls there are uneven, then the baseboard will not fit tightly and a gap will form.

Experts recommend checking the quality of putty in the dark using a flashlight. The light is directed parallel to the plane being tested and, if there are irregularities on it, they will immediately give a shadow. In daylight, it is more difficult to identify such defects, since diffused light will not provide shadows.

Source

Features of plaster according to SNiP

Advice. It is better to purchase fittings installed in the walls of the house from stainless steel so that they do not become rusty. Otherwise, dirty spots may appear on the parts attached to it.

Wet plaster has many benefits. It is considered universal: by selecting the desired composition, it is used under different conditions. However, like any building material, it also has its disadvantages. The main disadvantages of plastering are the labor-intensive and long process of the work performed. Wet plaster is divided into simple, improved and high-quality plaster.

What materials are used

Particularly stringent requirements are imposed on materials for high-quality plaster. When choosing, their quality, strength, and resistance to the influence of factors in the internal environment of the room are assessed. To perform high-quality plastering, you must purchase the following materials:

- primer;

- antibacterial solution;

- plaster mixture;

- finishing mixture;

- protective plaster mixture.

The plaster mixture may include components such as sand, quartz chips, polymer components, clay, lime, gypsum, cement.

Acceptance of plastered surfaces according to SP 71.13330 (SNiP)

These requirements must be observed during the production and acceptance of plastering work performed in buildings and structures. (In particular, when accepting apartments, private houses and cottages completed for “fine finishing”).

Let us highlight the most important points of these requirements that must be monitored when accepting plastered bases.

clause 7.2.13 The quality of plastering work is assessed according to the requirements presented in table 7.4. The surface quality category is established by the project and assessed according to Table 7.5. Surface quality categories K3 and K4 are established only for high-quality plaster.

clause 7.3.7 After plastering and (or) putty finishing work, the quality of the resulting surface must correspond to the design and meet the requirements presented in Table 7.5.

Table 7.4 - Requirements for plastered bases

Control (method, volume, type of registration)

Deviation from vertical

No more than 3 mm per 1 m, but no more than 10 mm over the entire height of the room

Horizontal deviation

No more than 3 mm per 1 m

Surface irregularities of a smooth outline

On an area of 4 m2 no more than 4 mm per 1 m, but no more than 10 mm for the entire element

Measuring, pattern, at least three measurements per element, work log

Deviation of window and door slopes, pilasters, pillars, etc. from vertical and horizontal

No more than 4 mm per 1 m, but no more than 10 mm for the entire element

Deviation of the radius of curved surfaces from the design value

No more than 10 mm for the entire element

Deviation of slope width from design

Deviation from vertical

No more than 2 mm per 1 m, but no more than 10 mm over the entire height of the room

Horizontal deviation

No more than 3 mm per 1 m

Surface irregularities of a smooth outline

No more than 2 pieces, depth (height) up to 3 mm

Measuring, pattern, at least three measurements per element, work log

Deviation of window and door slopes, pilasters, pillars, etc. from vertical and horizontal

On an area of 4 m2 no more than 4 mm per 1 m, but no more than 10 mm for the entire element

Deviation of the radius of curved surfaces from the design value

No more than 7 mm for the entire element

Deviation of slope width from design

Deviation from vertical

No more than 0.5 mm per 1 m, but no more than 5 mm over the entire height of the room

Horizontal deviation

No more than 1 mm per 1 m

Surface irregularities of a smooth outline

No more than 2 pcs., depth (height) up to 1 mm

Measuring, pattern, at least three measurements per element, work log

Deviation of window and door slopes, pilasters, pillars, etc. from vertical and horizontal

On an area of 4 m2 no more than 2 mm per 1 m, but no more than 5 mm for the entire element

Deviation of the radius of curved surfaces from the design value

No more than 4 mm for the entire element

Deviation of slope width from design

Table 7.5 - Requirements for surface quality depending on the type of finishing coating

Surface quality category

Requirements (control methods)

Surfaces for which there are no requirements for the decorative properties (surfaces are intended for finishing work with various types of tiles and sheet materials)

The presence of scratches, holes, burrs, tool marks with a depth of no more than 3 mm is allowed (complete visual inspection). Shadows from side light are allowed (no control is carried out)

Scratches, holes, and burrs no more than 1 mm deep are allowed (full visual inspection). Shadows from side light are allowed (control is carried out if necessary to bring the surface quality to category K3)

Surfaces for which increased demands are placed on the decorative properties (surfaces are intended for finishing work with small-piece and transparent elements, applying decorative plasters with a grain size of less than 1 mm, for applying non-structural matte paints and coatings, gluing wallpaper on paper and non-woven bases)

The presence of traces of abrasive used when grinding the surface is allowed, but not deeper than 0.3 mm (complete visual inspection). Shadows from side light are allowed, but they must be significantly less than for surface quality of category K2 (control is carried out if necessary)

Surfaces for which the maximum requirements are imposed on the decorative properties (surfaces are intended for glossy cladding, for example, metal or vinyl wallpaper, application of glossy paints, glazes or coatings, application of polymer, thin-layer, Venetian plaster or other types of high-quality gloss, for painting surfaces with thin-layer semi-matte or glossy coatings using airless sprayers, for gluing the thinnest metallic wallpaper and glossy photo wallpaper).

Recommended when installing side lighting

Scratches, holes, burrs, tool marks are not allowed (complete visual inspection). Shadows from side light are not allowed (solid visual assessment using a hand-held side light)

Source

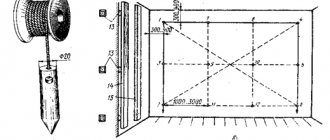

Bringing out corners

In order for the furniture to fit well into the corners, they must be strictly 90°. But it is not always justified to make absolutely all corners in the apartment straight. As a rule, this value is important for the bathroom, kitchen, and rooms with built-in furniture.

The angle is checked with a regular tape measure. To do this, you need to remember the school geometry course. The two diagonals of the room should be equal in length. It would also be correct to check with a construction square with a side length of at least 0.5 meters. The square must be applied along the entire height of the angle at equal intervals, moving it continuously from bottom to top.

Regulatory framework for interior and exterior decoration

Designing the interior decoration of houses and apartments will include a large list of documents. For each operation there is a separate legal regulation - GOST, SNiP, instructions.

The construction services market contains offers from various organizations, where craftsmen perform work in full compliance with GOSTs and SNiPs. Each property owner who needs such services is able to independently check the level of qualifications of third-party craftsmen.

Why do you need SP (SNiP)

SNiP (SP) for plaster

A number of requirements for plaster are specified in SP 71.13330.2017, and specifically in Chapter 7. This standard applies not only to internal and external surfaces, but also affects the plaster of the basement and facade parts of buildings. Here are the requirements for the technology of work, including control of permissible errors in the plastering process.

The normative document SP 71.13330.2017 corresponds to the German standard DIN V 18550. The European legal act contains recommendations regarding the preparation, as well as assessment of the quality of finished coatings, based on the type of finishing surface - from Q1 (lowest) to Q4 (highest).

The main purpose of plastering is to create the correct geometry of the premises. This is, first of all, setting strictly right angles (90°), reducing the width of doorways (including slopes) to optimal values and a number of other operations. In general, you should get a single and even plane.

| Plaster parameters | Simple | Improved | High quality |

| Deviations relative to the vertical | No more than 3 mm | Up to 2 mm | Maximum 0.5 mm |

| Maximum vertical deviations in relation to the entire height of the premises | 15 mm | 10 mm | 5 mm |

| Maximum number of irregularities per 4 m2 | 3 mm | 2 mm | 2 mm |

| Maximum Defect Depth | 5 mm | 3 mm | 2 mm |

| Limit deviations relative to the horizontal at 1 m | 3 mm | 2 mm | 1 mm |

| Maximum substrate moisture level | 8% | 8% | 8% |

| Deviation of slope width from design (for the entire element) | 5 mm | 3 mm | 2 mm |

The document that specifies the finishing quality criteria is SNiP 3.04.01-87. Tolerances in accordance with SNiP should be taken into account as a guide to action.

GOST for plaster

In addition to SNiP, the legislation of the Russian Federation provides for GOST R 57984-2017/EN 13914-1:2005, which affects interior and exterior decoration. It also contains features of the selection, preparation and application of solutions. However, at the moment the document has not entered into force. But there are other GOSTs depending on the binder component of the mixtures:

As a rule, these GOSTs are used for the production of building mixtures on an industrial scale. But a number of companies for the manufacture of their products, in addition to the basic documents, are supported by the requirements of the Technical Specifications.

Construction project

Improved wall plaster: we follow the requirements of SNiP

Plaster can be the most ordinary, advanced and especially high quality. Contrary to popular opinion, these definitions do not refer to the quality of the material, but to the methodology for performing the work and the properties of the cladding, which are regulated by the requirements and rules of SNiP and GOST. Let's look at the differences between improved plaster and other types of finishing using plaster and the requirements that it must meet.

Differences between different plaster options

Performing regular plastering is possible when the requirements for the quality of the finished coating are not very high. This type of cladding requires the application of only two layers - spray and primer - and is very often used in non-residential premises.

When medium or large demands are placed on wall coverings, advanced plaster is done. It is used in cases where a remarkably smooth base is not required, and a structured final coating will be applied to the plastered surface or tiles will be laid. The technology of work involves the presence of 3 layers: spray, primer and cover.

Beacon plaster has a similar application technology to the improved one, however, it requires at least one additional primer layer. Coating with plaster of this level makes it possible to obtain a surface that is perfectly leveled horizontally and vertically.

Advanced plaster: thickness of layers

All requirements for the work and the quality of the resulting coating are specified in the document SNiP 3.04.01-87 “Insulating and facing coatings”.

According to the technology, improved plastering is done in 3 layers. The thickness of any of them depends on the base and mortar material and is prescribed in the SNiP rules.

- Spraying is needed to increase the adhesion of materials. A solution with the consistency of liquid sour cream is used for it. The thickness of the continuous layer applied to brick or concrete bases should be within 5 mm. For wooden bases, the maximum layer thickness increases to 9 mm, taking into account shingles or mesh.

- The soil is used to level the surface of the walls. If there are significant unevenness of the walls, it is allowed to apply the primer in stages. The thickness of each individual soil layer should be within 5 mm for cement-based mortars and 7 mm for light lime and gypsum-based mortars.

- The covering layer is the final stage of finishing using plaster, which is rubbed down using a trowel and serves to obtain a smooth and even coating. Its thickness can be no more than 2 mm. When using plaster for decorative work, the coating usually has a thickness of up to 7 mm.

Advice: the technology for performing advanced plastering does not require the mandatory use of beacons, however, for the convenience of surface leveling and control over the thickness of layers, beginners are still recommended to work with beacons.

Each layer is applied only after the previous one has set. The total thickness of the material varies within 2 cm. When this figure needs to be exceeded, a metal mesh is placed on the base. Experts also advise using it when plastering walls made of aerated concrete, while working on wood and metal. The reinforced mesh helps eliminate the appearance of cracks in any situation.

The current SNiP does not have regulations for attaching mesh for plastering work, and its mention in documents is a recommendation.

Possible deviations for advanced plaster

In accordance with SNiP 3.04.01-87, plastered surfaces may have deviations that are not considered a violation of the standard:

- the coating usually has a deviation from the vertical and horizontal of no more than 2 mm per 1 m of length;

- over the entire height of the wall, the surface can be deflected by no more than 10 mm;

- slopes of doors and windows, pillars, pilasters, husks can be deviated no more than 2 mm from the vertical and horizontal per 1 m of length;

- the radius of curved surfaces can be deviated by 7 mm from the value mentioned in the project (control is carried out using a pattern);

- The width of the slope differs from the design by 3 mm.

Important! SNiP for improved plaster does not allow the presence of peelings, cracks, sinkholes, efflorescence, and also noticeable traces of the tool used for grouting on the surface.

Requirements for the quality of applied plaster compositions

Qualitative control of the material used and the mortar is carried out on the basis of GOST 28013-98 “Building mortars. General technical conditions".

According to GOST, a solution for improved plaster must meet the following requirements:

- The solution, which is intended for spraying and soil, must pass through a mesh with a cell diameter of 3 mm.

- The solution for the covering layer must pass through a mesh with a mesh size of 1.5 mm.

- The sand used to prepare the solution must contain grains; their size will not exceed 2.5 mm in solutions for soil and spray and 1.25 mm for finishing.

- GOST also changes technical parameters such as mobility, delamination, water retention and stability.

An additional requirement of GOST is that the solution must have a document indicating:

- number and time of preparation;

- brand of solution;

- quantity;

- mobility;

- binder;

- standard.

Classification of plaster according to SP

According to Russian SNiP 3.04.01-87, which is devoted to finishing and insulating coatings, the classification of surface plaster includes three main classes:

All requirements, as well as the list of construction standards for plastering work, specified in the relevant documentation, apply not only to the manual technique of applying mortars, but also to the use of machinery. The same applies to the classes mentioned above. They have a number of differences and requirements, depending on the specific situation.

Simple plaster

Unlike the next two classes, a simple finishing technique is used in rare cases, since it is suitable for situations where there are no high requirements for the quality of finishing. In particular, this applies to these places:

If deviations are acceptable after painting the walls or wallpapering, all irregularities are clearly visible. For this reason, this is not the best solution for decorating the rooms of an apartment or country house.

Gypsum or cement-sand mortars are suitable for work. The thickness of the laid coating varies within different limits, based on the degree of curvature of the base. As a rule - 20 mm. But you should also take into account the recommendations of plaster manufacturers. However, in this case there are some mandatory requirements:

Simple plaster does not require the use of reinforcing mesh. A 3 or 4 cm coating holds well without reinforcement. But when the thickness of the plaster exceeds 5 cm, it is no longer possible to do without reinforcement.

Improved plaster

Among all classes, the most popular finish is considered to be improved

its variation. The surface after processing the base is strong and smooth. Suitable for both walls and ceilings. Here the work is carried out according to beacons. Unlike simple plaster, the improved version gives a better result.

For the first layer, a liquid consistency of the composition is prepared in order to increase the adhesion of the material during subsequent processing. The primer layer requires a thick composition to level the surface and smooth out unevenness. The cover acts as a finishing coating.

High quality plaster

At the next mandatory stage, the surface is treated with a primer. You can use a roller or spray.

Next comes an important responsible process - fastening the beacons and setting up the corner profiles. Without such preparation, the wall cannot be made sufficiently even. The joints of surfaces made of dissimilar materials, as well as the tops of door and window openings, are reinforced with fiberglass or metal mesh to prevent cracking. With further use of putty for painting, the mesh can be attached to the entire surface depending on the type of base.

After completing the preparatory stage, the main part of the work is carried out - applying the plaster mixture. When the coating has set a little, the beacons are removed and the remaining furrows are sealed. Finally, the surface is leveled.

How to check the quality of plaster for a person far from this issue

Sometimes unscrupulous plasterers can, taking advantage of the customer’s insufficient experience, deliver poorly performed work. And this will become clear only when it comes to wallpapering or other wall work. By then it will be useless to look for the culprits, so it is better to check the work right away, and in the presence of the craftsmen.

You can do this without special knowledge if you know the basic requirements for plastering work. The first layer is applied rough plaster, then comes the starting putty, on top of which you can glue the wallpaper. But if you plan to paint the walls, apply decorative plaster or glue thin wallpaper, then you will also need finishing putty.

Plaster thickness

The finishing technology requires observance of the thickness of the plaster layer, adhering to the framework. This depends on the specific type of mixture used and in each case the indicators vary. For example, the thickness of the layer of Knauf MP-75 gypsum composition varies from 8 to 50 mm when applied by machine in one pass. If a thick surface is needed (more than 5 cm), the plaster is applied in two layers with intermediate drying of each. In this case, after drying, the first layer must be primed before laying the next one.

Specific values are selected depending on the degree of curvature of the surfaces. Relevant information is contained in the descriptions of the materials. To familiarize yourself with them, it is better to visit the manufacturers’ electronic resources.

Features of plaster according to SP

Plastering work is carried out in accordance with a set of rules in order to avoid unwanted nuances. In particular, it is worth highlighting the following features:

To install gypsum products on walls, it is necessary to create a reinforcing frame from reinforcement in advance. Thanks to this, the structure lasts for a long time. The fittings should be selected from stainless steel to avoid rust and stains throughout its life.