Hello, dear readers! Recently my team and I finished working on a large project. When choosing building materials, we tried to take into account many details and experiment a little. Now there are two clear leaders in the market for drywall manufacturers - Volma and Knauf. There is no clear opinion which material is better. We decided to conduct our own experiment - in the room we made a ceiling based on Knauf gypsum boards, and in the hallway we used Volma. What came out of this and what conclusions I came to – read in this article.

The properties of gypsum plasterboard are determined by the following indicators:

- The strength and quality of sheets for walls, ceilings, floors or decorative finishing.

- Sufficient degree of moisture resistance and fire resistance.

- Availability of branded hangers and metal profiles for installation and its manufacturability.

- Quantity and quality of installation tools.

- Availability of branded materials for surface finishing.

- Price and quality of the entire range of work.

Installation of metal frame and guides

If we compare which is better: Knauf or Volma plasterboard based on the above properties, then one of the main technological points is the assembly of metal structures for installing sheets. The consumer of this product, having paid the costs, should know that he received high-quality metal structures for the frame of a wall, partition, frame for the ceiling or floor.

These structures during operation are dangerous to the life and health of a person and his family.

Drywall Knauf

Knauf produces and sells all the necessary frame sets for walls, partitions, and floors in its stores. All clients are offered specialized tools for performing technological processes. In addition to the tools, all mounting materials are available. Knauf employees have developed educational and methodological material with step-by-step instructions.

This centralization of building materials stimulates the emergence of specialized construction teams with good quality work. This trade policy of the Knauf enterprise is the main advantage in the building materials market.

Drywall Volma

Volma Corporation does not supply metal frame structures to our market. The absence of branded profiles, fasteners and tools does not mean that Volma construction plasterboard is inferior to competitors.

If the consumer finds out that he needs this product, then metal frame structures are available for sale in large quantities.

Carry out work on installing a frame for Volma sheets, possibly from profiles from any manufacturers, including the Knauf concern.

Tools and components for drywall are also produced and sold by different manufacturers. Standard sizes of plasterboard sheets from all manufacturers comply with the product certification system in the Russian Federation.

What are the negative reviews based on?

Some of the complaints and claims are the consequences of manufacturers’ competitive struggle for the sales market. Creating negative advertising for a competing product increases your chances of selling your product.

It is not uncommon for low-quality products of Asian origin to be sold under a well-promoted and popular brand. Previously, counterfeit products could be identified by their characteristic chemical smell. The installation and operational properties of such drywall, as well as its environmental safety, raise reasonable doubts.

The low quality of even the branded material KNAUF moisture-resistant small-format plasterboard may be a consequence of improper and prolonged storage. The construction market is saturated with plasterboard products, so material with large price markups is sold with long delays. Naturally, panels that have spent the winter in a damp warehouse cannot meet the original characteristics.

Covering the frame with plasterboard

When determining the effectiveness of installation work on the installation of partitions, interior walls and ceilings made of plasterboard, it is necessary to evaluate the estimated cost of finished products without finishing work.

If we take partitions and ceilings measuring 9 m2 for analysis, then after drawing up the estimated cost for gypsum board Knauf and gypsum board Volma, an effective material will be determined. We will determine the cost based on the cost of the sheets, since all other volumes of materials will be the same.

Knauf plasterboard ceiling

- Putty “Fugenfoller” consumption – 3.6 kg, cost 77.4 rubles.

- Primer for drywall “Tifengrunt” consumption – 0.9 l, cost 56.16 rub.

- Total 9 sq. m. – 133.56 rub.

The quality of Knauf products is high. This determines the high price of Knauf drywall and all components.

Despite this, production and sales volumes are increasing every year. But one cannot ignore the need for low-budget Volma products.

Inferior in quality to drywall after small financial costs, as a rough calculation has shown, you can achieve quite decent final results.

Of course, the Volma plasterboard material is not a defective product. The company specializes not only in sheet plasterboard, but also plasterboard blocks. The consumer should choose which building material to buy depending on the construction location and financial capabilities. In any case, both types of gypsum concrete are a cheap type of finishing of buildings and structures.

source: //gipsokarton-blog.ru/instrument-i-materialy/gipsokarton-volma-ili-knauf.html

Drywall, which has gained considerable popularity in the Russian market of finishing building materials, is produced by a number of manufacturers. The brands “KNAUF”, “Giprok”, “Lafarge”, “Rigips”, “Belgips” and others are widely known. Among the manufacturing enterprises is the VOLMA company, formed on the basis of the Volgograd gypsum plant with a network of branches. In terms of sales volumes, VOLMA gypsum board ranks second in Russia, second only to KNAUF products.

Finishing

To further compare the cost of a completely finished partition and ceiling surface, we will consider the option of overusing finishing materials by 20% due to the poor quality of the front surface of Volma plasterboard.

The process of finishing drywall Volma Partition Knauf:

- Putty “Kniflot” consumption - 13.5 kg, cost 540 rubles.

- Finishing putty consumption - 10.8 kg, cost 691.2 rubles.

- Total 9 sq. m. -1231.2 rub.

Ceiling Knauf:

- Putty "Fugenfoller" consumption - 3.6 kg, cost 77.4 rubles.

- Primer for drywall "Tifengrunt" consumption - 0.9 l, cost 56.16 rubles.

- Total 9 sq. m. - 133.56 rub.

Partitions Volma: 1231.2 rub. + 246.24 rub. (20%) = 1477.44 rub. Ceiling Volma: 133.56 rub. + 26.72 rub. (20%) = 160.272 rub.

Product range

The VOLMA company produces the following types of plasterboard:

- standard plasterboard;

- moisture-resistant gypsum board (water absorption no more than 5%);

- fire-resistant gypsum plasterboard (minimum time of resistance to open fire - 20 minutes);

- moisture-resistant fire-resistant GKLVO (combines the properties of moisture-resistant and fire-resistant plasterboard).

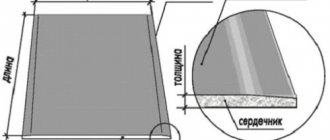

Sheets of all types have the same standard dimensions (in mm):

- length – 2500;

- width – 1200;

- thickness: GKL and GKLV – 9.5 and 12.5, GKLO and GKLVO – 12.5.

At the request of the customer, the company can produce sheets 3000 mm long, which are used for finishing walls and constructing partitions in rooms with high ceilings. The thickness of these sheets is 12.5 mm.

Volma or Knauf: which is better?

For cladding walls and ceilings, experienced professionals recommend choosing high-quality plasterboard from well-known manufacturers Volma and Knauf, which occupy leading positions in sales.

In terms of technical characteristics, they are close, so it is very difficult to make a clear choice. The difference in choosing Volma or Knauf gypsum boards will be visible when comparing them in detail.

Drywall Knauf - German quality

The Knauf company was founded in 1932 and specializes in the production of thermal insulation and gypsum building materials. Currently, it occupies a leading position in plasterboard sales in Europe due to the use of high-quality raw materials in the manufacture, the introduction of innovative technologies and the availability of a wide selection of specialized lines.

Knauf plasterboard sheet has the following advantages:

- precise adherence to the geometry of the sheets, which significantly simplifies installation;

- perfectly smooth surface with increased adhesive properties;

- optimal edge shape, ensuring tight joining and the possibility of applying plaster without special processing;

- the presence of reinforcing fibers, which significantly increase the strength of the material;

- balanced strength characteristics ensuring high strength and lack of fragility;

- the level of moisture absorption does not exceed 5%;

- absence of toxic substances;

- the material is able to provide an optimal microclimate in the room due to air exchange with the external environment.

Knauf gypsum boards have the following disadvantages:

- the difficulty of processing sheets due to the presence of reinforcing fibers, which significantly complicate the production of complex geometric shapes;

- high cost of the material, which exceeds analogues by an average of 15-20%.

Volma plasterboard - domestic high-quality material

Volma plasterboard has been produced in Russia since 1999 after the reconstruction and modernization of the Stalingrad gypsum plant. Due to the presence of our own gypsum mining enterprises, it was possible to establish inexpensive production of the material at modern facilities using unique technologies. In terms of cost and quality, Volma plasterboard is the best among all manufacturers present on the market.

The modern production base has made it possible to establish the production of specialized types of plasterboard and virtually completely cover the needs of the domestic market. In terms of its technical and operational characteristics, Volma gypsum boards are in no way inferior to their foreign analogues, thanks to which these products have become the most popular in the domestic market.

The advantages of Volma plasterboard sheets include the following:

- high accuracy of sheet geometry, which makes it possible to simplify installation work and obtain hermetically sealed joints;

- optimal ratio of strength and ductility of sheets, providing the ability to cover surfaces of complex shapes;

- ease of cutting drywall with high quality edges that are not subject to crumbling;

- the ability of the sheet to absorb the load and distribute it evenly along the entire surface due to the use of gypsum sintering technology at a temperature of +200°C;

- low price of material and excellent technical characteristics;

- almost ideal durable surface with excellent adhesion thanks to the use of multi-layer cardboard.

Drywall produced by Volma has the following disadvantages:

- lack of marking lines, which complicates the process of aligning sheets during installation;

- slight surface waviness due to the characteristics of the production technologies used.

Comparison table between Knauf and Volma drywall

In order to figure out which drywall is better, you can use the table comparing products from Knauf and Volma.

| Parameter | Knauf | Volma |

| Sheet sizes | Width 0.6 or 1.2 m, length from 2 to 4 m. Standard sheet size 2.5x1.2 m. | Standard sizes are 2.5x1.2 m or 3x1.2 m. |

| Drywall thickness | From 6.5 to 16 mm. | From 9.5 to 12.4 mm. |

| Material Density | Up to 30.6 kg/m3. | Up to 30.6 kg/m3. |

| Flammability class | G1 | G1 |

| Type of edge used | Semicircular thinned. | Rectangular thinned edge. |

| Main product lines |

|

|

| Presence of reinforcing fibers | Yes. | No. |

| Moisture absorption level | Up to 5%. | Up to 5%. |

| Presence of antifungal impregnation | Yes. | Yes. |

| Possibility of forming surfaces of complex shapes. | No. | Yes. |

Review and cost comparison

Recommendations from professionals for choosing

It is quite difficult to determine unambiguously whether Knauf or Volma, since in specific cases, due to installation features or technical operating conditions, some materials may win and others lose. Therefore, it is recommended to use the following recommendations from professionals when choosing a specific manufacturer:

4 tips

- Knauf should be chosen for covering walls and ceilings that are subject to external mechanical influences;

- if it is necessary to apply a decorative layer without plastering or with a minimum amount of applied mortar, then the choice is obvious in favor of Knauf due to the possibility of choosing the color of the base, the absence of irregularities and the high adhesion of the cardboard;

- Volma plasterboard will allow you to save on surface covering due to the optimal cost, but with characteristics similar to Knauf products;

- It is recommended to create complex surface shapes, for example arches, using Volma gypsum plasterboard due to its flexibility and lack of fragility.

A comparison shows that Knauf offers a wide selection of sheet sizes and their high strength, while Volma allows the formation of complex surfaces when sheathing.

Which drywall is better?

Which drywall is better can be determined from the comparison table, taking into account the requirements for its installation and budget.

- If we look formally, the winner is Knauf, as it offers high-strength wear-resistant material with a wide range of standard sizes, as well as an almost ideal surface.

- However, with a limited budget, it turns out that Volma is better, since its cost is on average up to 30% cheaper than Knauf, due to the use of domestic raw materials in production. Volma is also more attractive for cladding arches and forming suspended ceilings due to its simple processing and optimal flexibility.

shopmat.ru

Description and marking

“VOLMA” plasterboard is produced with a thinned edge, thanks to which the joint of the sheets becomes invisible after puttying. The shape of the ends is rectangular, the surface of the sheet is perfectly flat.

By choosing manufacturers of building materials that are well-known and familiar to you, you guarantee yourself complete success in the work performed.

Colors of facing cardboard and markings

| Type of plasterboard sheets | Cardboard color (front surface) | Cardboard color (reverse surface) | Marking color |

| standard | grey | grey | blue |

| moisture resistant | green | grey | blue |

| fire resistant | pink | grey | red |

| moisture resistant fire resistant | pink | green | black |

Drywall markings include the following designations:

- name “VOLMA-List”;

- letter abbreviation indicating the type of drywall: StP for GKL, StPV for GKLV, StPO for GKLO, StPVO for GKLVO (StP - building board);

- type of longitudinal edge;

- a series of numbers corresponding to the length, width and thickness of the sheet, expressed in mm;

- TU number.

An example of marking of moisture-resistant fire-resistant sheets GKLVO with a thinned edge of the UK, length 3000, width 1200 and thickness 12.5 mm:

Comparative characteristics, features and differences

Unlike other brands, VOLMA plasterboard is produced not according to GOST, but according to specifications, which is associated with the improvement of a number of parameters (strength, surface density, vapor permeability, water absorption). During production, non-traditional materials such as sugar and starch are added to the liquid gypsum mixture, which improve the adhesion of the gypsum core and facing board. In terms of application, VOLMA gypsum boards do not have any special differences from other brands of plasterboard. Attention should mainly be paid to the need to make a deeper cut, otherwise a break will result in an uneven edge.

It is recommended to seal joints only with joint putty, as it does not shrink. When using finishing putty, a recess may subsequently form.

What is the difference between these materials

Despite all the similarities, there are differences that are important to consider. The whole point here is how exactly the drywall will be used, and what result you want to get in the end. Understanding this and the difference between these two options, it will be possible to choose the optimal material for certain jobs.

Here's what makes the materials different:

- Volma is more affordable.

- Volma is more environmentally friendly.

- Knauf cuts better and can take a rounded shape.

- Knauf has better acoustic properties.

- Knauf has good dielectric properties.

The surface of Knauf drywall is smooth and even . But Volm's is wavy . In addition, there are no marking lines. This makes Knauf a more convenient material to use. At least in general.

Hence the slight difference in technology . Volma slabs must first be marked. It's not difficult if you have experience. But otherwise it will take quite some time. Yes, Volma products are quite resistant to various bends, however, still not as much as Knauf.

The difference is that Knauf is suitable for a greater number of tasks. For example, due to greater flexibility. So if a person is looking for some more or less universal option, it’s worth paying attention to Knauf.

At the same time, Volma is more environmentally friendly and economical. And this is also important. But aesthetically the material is not as good as Knauf brand products. And of course, given all these differences, the question inevitably arises of what is better to buy.

Reviews

Reviews about plasterboard sheets from the VOLMA company are quite contradictory; some buyers are not satisfied with the quality. The main complaints come from the wavy surface, which has to be carefully plastered and puttied, and the greater weight. At the same time, many believe that the unevenness of the sheets is a consequence of improper storage in the store’s warehouse, and in general, VOLMA plasterboard is not inferior to the products of its main competitor, the KNAUF company, and is also cheaper.

source: //mrgipsokarton.ru/wiki/volma

The constant need to reduce the cost of money, time and effort spent during repairs led to the emergence of such a material as tongue-and-groove slabs. For statistics: one GWP during the construction of a partition in a building replaces 20 ceramic bricks and 14 sand-lime bricks. PGP “Volma” are intended for the construction of partitions in public and residential buildings in which the ceiling does not exceed 4.2 m.

Hollow gypsum slab “Volma”

Such slabs are small in width (80 - 100 mm) and have a significant side surface. The latter have a special tongue-and-groove connection. This increases the stability of the masonry being built and contributes to the formation of a flat surface, since the slab fits into the groove and forms a reliable connection.

Which is better PGP Volma or Knauf? We select for tasks

Remodeling apartments with plasterboard is becoming increasingly popular among the population. Which is better: PGP “Volma” or “Knauf” is probably the main question that puzzles people who carry out such redevelopments. In recent years, brick has not even been considered as a competitor. Firstly, partitions made from it are significantly heavier, and the load on the floor slab may be higher than the calculated one (this is especially true in high-rise buildings of old buildings, where such alterations are strictly prohibited). Secondly, laying it is much more difficult, longer and dirtier than using tongue-and-groove slabs (TGP). An alternative in the form of blocks, for example, aerated concrete, meets the same objections: although this building material is lighter in weight than brick, it is slightly less difficult to lay easier, but the work still remains longer and dirtier. Such problems do not arise with PGP: they are installed quickly (even faster than the recently popular frame-plasterboard partitions), quite clean, and there is no need to wait for the solution to set.

The most important thing: you can handle the installation yourself. Another huge plus: the walls of the PGP do not need to be plastered, you can immediately start finishing. But in terms of price, there is no comparison: in any case, with all the additional nuances, it will cost less than laying out an internal partition from brick, for example.

Which is better: Volma or Knauf, it is perhaps not entirely correct to wonder. Despite the fact that both companies produce the same type of products, there is still a difference in the assortment. And when choosing, you need to start from what goals you set for yourself, what are the objectives of the work being performed? We will talk about this and other important selection criteria in our material.

This German company has long been a leader in the building materials market. The quality is, of course, German. This also applies to tongue-and-groove slabs. Their standard sizes produced by Knauf are: 667x500 mm with a thickness of 80 or 100 mm. Possible claims made against products are usually associated not with the manufacturer, but with the following links in the chain along the way of constructing the partition:

- Improper storage in conditions of too high humidity, which leads to a decrease in the quality of the tongue-and-groove slab.

- Deformations and damage during transportation.

- Errors during the installation process.

- Agree, the manufacturer has nothing to do with it. In many cases, when the installation of such structures caused criticism, the crews involved in this installation were to blame. The only thing that can be questioned is the too high cost of plasterboard tongue-and-groove slabs. But, obviously, this is the price of the quality of the product produced.

This Volgograd brand is the only domestic real competitor to the Germans that deserves close attention. “Peshelan” or “Magma” lag far behind it both in terms of assortment and quality of products produced (this was noted by repairmen who dealt with them). The builders admitted that compared to the Knauf PGP, the Volma has some disadvantages, but very minor ones. The main dimensions of the element are the same: 667x500 mm. However, there is no choice of thickness: the Volgograd plant offers only 80 mm slabs. For many repairmen, this thickness is insufficient, and they turn their attention to 10-centimeter Knauf products. The front surface is not smooth enough. In some cases, for example, when wallpapering is intended, finishing plastering may be required. During the production process, fiberglass is added to the filler for additional reinforcement. On the one hand, this is a plus, since the material becomes much stronger and more resistant to temperatures. On the other hand, cutting and fixing the slabs becomes noticeably more difficult, which thus acquire an additional level of rigidity. However, Volma has a direction that distinguishes its products from the offers of its main competitor. The plant also produces hollow slabs, which are not in the assortment of the German Knauf. In structure, they differ in that they are not monolithic, like ordinary ones, but have longitudinal cylindrical voids. The advantages of such plates:

- Lighter weight. A solid tongue-and-groove ridge weighs from 27 to 32 kg, a hollow one - 20-22. The maximum weight is for hydrophobic options. The advantage of lightness is not only less load on the floors, but also in transportation. When delivering solid building materials, it can be loaded into a standard truck in the amount of 240 square meters. A hollow one can already fit 300 sq.m., which reduces transportation costs.

- “Void” has higher heat and sound insulation properties due to the air gap in the slab.

- It is also worth noting that all these advantages are provided without loss of the strength characteristics of the slabs themselves, which is important for potential buyers making repairs. Thus, hollow core slabs, as the lightest but most durable (and cheaper) material, are being chosen by an increasing number of repairers - as an alternative to the more expensive German manufacturer, which, moreover, does not yet produce hollow core slabs.

Based on all the comparisons made, it can be understood that there are not so many fundamental differences between the products of Knauf and Volma. It is necessary to give preference to someone specific only in certain cases:

- If you need a wall thicker than 8 centimeters, there is nothing left to do but purchase German tongue-and-groove slabs, since the domestic plant does not produce such.

- If you want to remodel your apartment using hollow slabs, no one will provide them to you except Volma.

- If you intend to paint a new wall, it is better to buy Knauf - this way you will avoid intermediate puttying. If you plan to lay tiles or hang shelves on the wall, take the stronger Volma. Remember fiberglass reinforcement? A wall with such reinforcement can actually withstand even quite a serious load.

If there are no special conditions, when faced with the choice of which is better: Volma or Knauf, people often choose a domestic manufacturer. If the quality of our products is no worse (and in some ways better) than German ones, then why overpay? One has only to take into account that when purchasing tongue-and-groove slabs from one company, all accompanying materials must be purchased from its own production.

remtra.ru

Characteristics of GWP

The material is produced using special casting technology. In production, gypsum grade G-4 or G-5 is used. Gypsum used in construction is an environmentally friendly substance that allows air to pass through. Therefore, the erected partitions meet the established sanitary and hygienic requirements, which regulate the quality of materials used for finishing work. To increase the strength and performance characteristics, special plasticizing substances are added to the composition. The slabs are distinguished by hygroscopicity: moisture resistant and conventional GGP. Water absorption is reduced by adding Portland cement and granulated blast furnace slag to the raw material composition. Moisture-resistant gypsum board is painted for visual distinction in a different color, like gypsum board, green.

Conventional gypsum blocks are installed in buildings with a typical humidity level. In rooms that are constantly exposed to moisture, a moisture-resistant board is recommended.

The 8 cm thick PGP provides a high level of thermal insulation. For comparison, it is equal to the thermal insulation provided by a 40 cm concrete partition. The noise insulation coefficient is also surprising; it varies between 34 and 40 dB.

The plates are resistant to fire. They are able to withstand an open flame for three hours and not lose their strength, which affects the reliability of the structure.

KNAUF putties reviews and prices

See all prices

Gypsum putty Knauf Fugen, 25 kg

Name:

Ruslan

Review:

Perhaps the best gypsum putty both in the Knauf line and among other manufacturers presented in the Leroy store.

I have been working with her for a long time and constantly. Superplastic, excellent application, layers of application both to peel and up to 5 mm, very finely ground, perfectly smoothed into “glass”, better mixing of layers. Allows work “wet on wet”. For example, when you pass a wall parallel to the floor, then return to the beginning and immediately pass perpendicularly (lattice method), without waiting for complete drying, and so on until the desired degree of leveling. Very durable, with proper preparation of the wall before filling and a good primer after filling, it never comes off with the wallpaper, does not dissolve from the primer, and even holds ceramic tiles well. It is also used for laying PGP, gluing gypsum boards, paint corners, sealing joints of gypsum boards and dissimilar walls with paper tape, etc. Among the disadvantages: it is difficult and inconvenient for beginners to work with - it is very demanding on proper kneading, cleanliness of dishes and tools. Do not return the putty back to the bucket after working on the surface. With the right approach, the composition works for an hour, an hour and a half, and even two. The color of the walls is different shades of beige, spotted in places. It sands disgustingly (very sticky), so you need to make a smooth surface “immediately” and always “under the light”. Under expensive painting and thin light-colored wallpaper, it is definitely necessary to apply a superfinish with sanding on top in order to “whiten” and eliminate minor defects. Advantages:

A very worthy product

Disadvantages:

requires “correct” work with it, color, “spotting”.

Name:

Alexey

Review:

For the first time I tried this putty for filling walls. I really liked it, very elastic. It sets very slowly, making it very pleasant and easy to work with.

Name:

Mikhail

Review:

Ignorants and amateurs who write reviews, learn the equipment, don’t disgrace yourself, it’s better not to take on repairs, but trust the professionals!

1. Color depends on the plant and not only Fugen. 2. This is not a finishing putty, it should not be white and plain, for this there are finishing polymer putties, Rotband Paste, for example. 3. Fugen is primarily a putty for sealing seams; strength and minimum shrinkage are important here; only flawless Uniflot is better. It is also good as a putty, it is convenient to work with, but it is stronger and dries a little faster, as a result. 4. Learn to work with clean tools and mix with clean water. 5. Learn to prime before applying any coat. Advantages:

Only Uniflot is better for seams, Rotband Paste for finishing.

Disadvantages:

Trust the repair to a professional.

Name:

Mikhail

Review:

Ignorants and amateurs who write reviews, learn the equipment, don’t disgrace yourself, it’s better not to take on repairs, but trust the professionals!

1. Color depends on the plant and not only Fugen. 2. This is not a finishing putty, it should not be white and plain, for this there are finishing polymer putties, Rotband Paste, for example. 3. Fugen is primarily a putty for sealing seams; strength and minimum shrinkage are important here; only flawless Uniflot is better. It is also good as a putty, it is convenient to work with, but it is stronger and dries a little faster, as a result. 4. Learn to work with clean tools and mix with clean water. 5. Learn to prime before applying any coat. Pros:

Best of its kind.

Disadvantages:

Do what you studied for.

Name:

Yuri

Review:

let the consumer somehow understand what color is in which bags

Advantages:

good quality, it’s a shame that it’s not white

Disadvantages:

I took two bags, both pink, for 2 liters of water the life of the mixture is 35 minutes, you have to mix in small portions.

Name:

Tatyana

Review:

bought 2 days ago, filled half the bucket, dried in five minutes. The putty was expired. Tried to clean the bucket, bent the trowel...

Advantages:

none

Disadvantages:

dried in the bucket in 10 minutes

Name:

Nick

Review:

Excellent putty, but for its color you can safely give it 1/5.

Anyone who has lived or lives in an apartment that is being renovated will understand me perfectly. Advantages:

In general, the putty is good, excellent adhesion, does not crack at the seams, dries quickly, very fine grain, easy to work with

Disadvantages:

I had to give it up because of the color. The color is dark gray, like a concrete wall

Name:

Vladimir

Review:

When puttying with a non-uniform layer (within 0.5-2mm), after drying, areas that are very different in color remain.

The entire wall is stained and will not be suitable for painting or thin wallpaper. The putty color is gray. The putty hardens quickly enough, you don’t need to mix too much. Advantages:

Durable, quite flexible.

Disadvantages:

Inhomogeneous color after drying, short solution life.

Name:

Ruslan

Review:

I will NEVER buy this again...I don’t recommend the product

Advantages:

none

Disadvantages:

dries quickly. Lumps appear when kneading with a mixer.

Name:

Mikhail

Review:

Bad putty

Advantages:

none

Disadvantages:

The putty was not mixed by the manufacturer before packaging! The bottom third of the bag is white plaster, the top is gray fillers. Hence the different colors when applied. The top of the bag dries in 3 days, the bottom in half an hour! Either mix the whole bag or don’t buy this g....!,

Installation of PGP

The temperature in the room where construction work is taking place should not be below 5 degrees above zero. Before erecting walls, plasterboards are given time (days) to adapt, leaving them in the room. To connect the boards, use glue of the same brand or a dry putty mixture. Procedure:

- Surfaces in contact with the partition are cleaned of dirt;

- Using a plumb line, markings are created and projected onto the walls;

- If the floor is uneven, it is leveled. For these purposes, a regular solution of cement and sand is suitable;

- Craftsmen advise mounting the slab horizontally, laying it on the large edge with the groove facing up. In this case, the glue used will be evenly distributed over the surface of the tongue and groove and will securely join them. The ridge is removed from the slabs laid in the first row. This is done with a jigsaw or a hacksaw blade with large teeth; the material is malleable;

- After assembling the first row of PGP, which is reminiscent of assembling children's Lego, check the horizontality of the structure with a level;

- Then it’s the second row’s turn. Mounting adhesive is applied to the ridge of the gypsum board being installed and into the groove of the already fixed slab in the first row. After applying the material, the slabs are carefully connected. For reliable fastening, use a rubber hammer, hitting the structure several times;

- Any glue that gets onto the front surface is immediately removed;

- When installing the slabs, do not allow the vertical lines to coincide; they must run apart. If necessary, additional elements are cut out;

- At each stage, the vertical is controlled with a plumb line;

- The final row is installed in a vertical position, placing it with the smaller edge. This will reduce material consumption. The space formed during installation between the ceiling and the plasterboards is filled with the same installation adhesive.

This installation is used in those structures that do not require a high level of sound insulation. Otherwise, use elastic joints of gypsum boards. The video will be useful for people interested in installing PGP from Knauf gypsum board.

Which plaster is better to choose?

Despite the wide range of ready-made plasters, choosing the right brand for construction and renovation is not easy. Stated characteristics do not always correspond to reality, and the abundance of products does not imply their quality. When purchasing, it is advised to take into account, first of all, the installation and operating conditions: base material, type and location of work, air temperature, level deviation and similar factors, and only then – from the price. Compositions with the required properties are sold by domestic and foreign manufacturers; the best reviews are from the brands Knauf, Ceresit, Unis, Bergauf and many others.

Review of plasters for facades and interior decoration

1. Cement-containing mineral - a budget variety, suitable for thick-layer leveling (provided it is reinforced with mesh) and forms a durable and moisture-resistant coating after hardening. PC compositions adhere well to walls and withstand significant mechanical loads; in some cases they are used as a supporting base for other brands. But at the same time, they are inferior in ductility, crack resistance, have a large weight and average permeability. The best reviews are observed for the Ceresit and Knauf brands.

2. Gypsum – quick-drying, lightweight, breathable. Due to high adhesion and ductility, they are better suited than others for finishing ceilings and inclined surfaces, and for thin-layer leveling. A distinctive feature is the short pot life - no more than 1 hour, the final strength when they harden is achieved after 1-5 days. The second feature is poor moisture resistance - you cannot plaster facades or basement walls. Knauf, Starateli, Volma, Yunis are considered trusted manufacturers.

3. Limestone – they allow air to pass through well, are easy to apply and have an affordable price. But due to their low moisture resistance in their pure form, they are practically not used; in any case, combined brands should definitely be chosen for finishing facades. There are excellent recommendations for compositions with lime additives Besto, Henkel and Osnovit.

4. Silicone ones are better than others for cladding external walls made of aerated concrete; they are valued for their resistance to dirt, moisture, UV, biological and mechanical influences, vapor permeability, lack of shrinkage and unchanged characteristics over a long service life (from 25 years). They are sold ready-made and stretch perfectly; even beginners do not have problems when applying and leveling them. The only limitation is the high cost - it is not practical to use them for thick-layer leveling or similar rough work; they are positioned primarily as finishing materials; prominent examples are Ceresit ST 174, Weber and Dufa.

5. Acrylic plasters - a diluted variety for protecting and decorating facades. Their advantages include a wide range of colors, elasticity, resistance to temperature changes and vapor permeability, while their disadvantages include an above-average price and electrostaticity. By analogy with silicone ones, they are not used for roughing and leveling work. Well-proven brands include Atlas, Weber Betonit, Baumit.

Of all the above compositions, combined (with a multicomponent binder) and pure gypsum and cement with minor additions of polymers are used for roughing and leveling. Expensive acrylic and silicone mixtures are optimal when thin-layer protection and finishing of any surfaces and facades is necessary. Only properly prepared structures need to be plastered; the quality of adhesion and the durability of the future coating depend on this.

Comparison of the most popular gypsum-based brands

When choosing plaster for leveling walls inside buildings, preference is given to quick-hardening and plastic compositions. These requirements are fully met by mixtures with minor additions of domestically produced plasticizers: Knauf Rotband, Starateli, Teplon, Volma. They have almost the same purpose; they are used for basic leveling of ceilings and walls in rooms with normal humidity. They are also united by common types of working base; they can be used to process concrete, brick and gas silicate masonry or already used gypsum or cement-sand surfaces.

The results of the comparison of characteristics are shown in the table:

| Indicator name | Knauf Rotband | Prospectors | Unis Teplon | Volma Layer |

| Consumption for a layer thickness of 10 mm, kg/m2 | 8,5 | 8-9 | 8 | 8-9 |

| Color | Grey | White | ||

| Recommended and maximum permissible layer thickness, mm | 5-50/50 | 5-50/70 | 5-30/60 | |

| Installation temperature, °C | From +5 to +30 | +10 to +30 | From +5 to +30 | |

| Solution lifetime, min | 30 | 20 | 50 | 45 |

| Drying time for a layer up to 10 mm thick, h | 72 | 24 | 120 | 24 |

| Special properties | Lightweight | Lightweight, thermal insulation | Lightweight | |

| Recommended application | Dry rooms with normal humidity | |||

Optimal choice of glue

High-quality glue is based on natural gypsum, which ensures a uniform consistency without forming lumps and excluding other inclusions. The volume of the mixture is increased by using purified sand, it will increase the strength of the solution. Performance indicators are improved by additives of mineral and polymer origin. They also affect the quality of the glue, improving it. These advantages are provided by the adhesive presented by the manufacturer “Volma”, which has a regular composition and is resistant to frost. The glue is a gray dry mixture, which before use is dissolved in water until it forms a homogeneous compound.

Advantages of adhesive backing

High-quality glue does not have a harmful effect on humans and the environment. It does not contain harmful or toxic additives, and it does not have a strong aroma. Advantages:

- No matter how much time has passed since the glue was applied to the connecting elements of the PGP, there will be no shrinkage;

- When constructing structures from PGP, glue is used sparingly;

- The plasticity of the material makes application convenient.

Volma assembly adhesive with a frost-resistant composition can withstand even fifteen-degree frost. Moisture-resistant plasterboard is attached using a similar method, and allows the use of both conventional adhesive and frost-resistant adhesive.

source: //gipsohouse.ru/questions/4811-pgp-volma.html

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials