Litokol has 5 types of epoxy grout:

Chameleon effect in the C.350 Crystal

- Starlike C.350 Crystal is a colorless mixture with a chameleon effect, suitable for grouting artistic and glass mosaics. The maximum thickness of seams is 2 mm. It looks most beautiful on transparent bases illuminated from within.

- Starlike Defender is a two-component acid-resistant epoxy-based grout with antifungal and antibacterial effect. Suitable for filling tile joints with a width of 1 to 15 mm, and can also be used for laying tiles and mosaics. Available in 7 color options.

- Starlike Color Crystal – for glass and artistic mosaics with joints less than 2 mm. Sold in 5 colors.

- Litochrome Starlike is a two-component epoxy grout for filling joints from 1 to 15 mm and laying mosaics or tiles on it. Can be used for interior and exterior work. There are 103 colors available, there are options with glitter, luminescent (glow in the dark), metallic (gold, bronze). To add optical effects to the base color, an additional additive component is purchased.

- Epoxystuk X90 is a two-component acid-resistant epoxy mixture. Suitable for filling joints with a thickness of 3 to 10 mm indoors and outdoors.

Night Vision collection glows in the dark

What parameters should you pay attention to?

When determining the consumption of grouting material, several parameters are taken into account:

- Tile sizes. The small size leads to the formation of a large number of connections per 1 m2. Thick tiles will require more grout.

- Connection width. It depends on the type of tile, most often it is 3 mm.

- Mass density. The composition of putties includes various components that affect their properties and density.

- Mastery of masonry. If defects form, more grout will be required to hide them.

To make the most accurate calculation, grouting agents must be of high quality, elastic, durable, and not susceptible to external influences.

High-quality, plastic mass will not flow down the vertical connection; filling occurs without the formation of air. Plasticity is important when connecting more than 6 mm, as it will maintain the integrity of the seam with little movement of the tile.

Attention is also paid to stability when exposed to humidity. If the mass is not moisture-resistant, then under the influence of moisture it will collapse, which will lead to high costs for the material.

Let's sum it up

The tile is ready

Working with epoxy grout is more difficult: the surface must be dry and clean, it is more difficult to clean the deposits, it is difficult to form internal corners in one day, you need to wash it with a lot of water. Due to the high price, strength of the seams and labor-intensive work, this grout does not leave room for error.

But on the customer’s side, the advantages of using such a mixture are obvious: the seams are easier to clean and dirt will not collect in them, they will not change color when wet, you can clean them with any chemicals. means. Externally, the seams will look like plastic with sand; many people do not like such a rough surface.

comments powered by HyperComments

Related posts:

- Grout consumption for tiles per 1 m²: calculation formula, calculator and standards

- Do-it-yourself tile grouting: selection of mixture and use

Standards of TOP manufacturers

The rate of putty requirement is calculated taking into account the mass density determined by the TM. The manufacturer calculates all standards taking into account that the tile is laid out on a flat surface and the joint is cleared of glue to a depth of 2 mm.

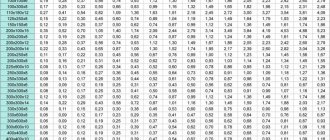

The table shows the consumption for tile joints per 1m2 from the best manufacturers:

| Tile size, cm | Seam depth, mm | Seam width, mm | Manufacturers | |||

| Ceresit | Litokol | Mapel | Saumalaasti | |||

| 10*10 | 6 | 2 | 0,42 | 0,37 | 0,38 | 0,4 |

| 20*20 | 8 | 2 | 0,28 | 0,25 | 0,26 | 0,3 |

| 30*30 | 6 | 2 | 0,14 | 0,12 | 0,13 | 0,2 |

| 40*40 | 8 | 2 | 0,14 | 0,12 | 0,13 | 0,2 |

| 60*60 | 10 | 2 | 0,12 | 0,1 | 0,11 | 0,1 |

If the dimensions of the tiles and joints differ from the standards given by the manufacturers, then the calculation is made individually using a certain formula.

Specifications

Technical characteristics of EPOXYSTUK X90

Technical characteristics of LITOCHROM STARLIKE

Technical characteristics of STARLIKE C.350 CRYSTAL

Chemical resistance table

Formula for grout consumption per 1 sq.m of tiles

A more accurate calculation of the required amount of grout mixture, taking into account individual parameters, can be made using the formula: P3 = M x K, where M (m/m2) is the length of the seam. K – flow coefficient.

The length of the seam is: M = (A + B) / A x B), where A is the length of the tile. B is the width of the tile.

The coefficient is calculated by the formula: K = W x D x R, where W is the width of the seam. G – seam depth. P is the density of the mixture.

It is recommended to increase the calculation result by a margin value of 10%.

We recommend videos on the topic:

Linear dimensions of the facing element

It is worth calculating the required amount of material, knowing what size the tiles will be laid. The amount of grout is directly related to the dimensions of the tile - the smaller the size, the more grout mixture will be needed.

Construction stores offer a huge variety of shapes and sizes of facing materials to choose from. When using mosaic tiles, especially round ones, the cost of grouting will increase significantly.

To avoid a large amount of waste, craftsmen choose cladding sizes that are multiples of the floor or wall surface.

We calculate the consumption of Ceresit grout

When calculating the required amount of Ceresit grout, a density coefficient of 1.75 is taken into account. It is the same for all types of mixture.

Thus, let’s calculate the consumption of Ceresite:

| Tile length, mm | 200 |

| Tile width, mm | 200 |

| Tile thickness, mm | 6 |

| Seam width, mm | 5 |

| Estimated area, m2 | 3 |

| Solution density coefficient, | 1,75 |

| Consumption, kg | 1,57 |

Ceresit mixture is sold in packages of 2 and 5 kg. So, for an area of 3 m2 it is enough to buy one package of 2 kg.

Intertile gaps

The average distances between tiles are: for floors – 3-5mm, for walls – 2-3mm (in practice they reach up to 3cm).

Sometimes an increased seam width is the result of a design idea. For budget cladding, the increased gap is necessary to equalize the difference in tile sizes.

The gap is expanded under certain circumstances: seismic activity, new construction. The enlarged seam protects the tile from cracking when deformed. At the same time, grout consumption increases.

Buyers' opinions on quality

Consumer reviews regarding Litokol epoxy mixtures are mostly positive. Experienced craftsmen believe that working with paste is difficult, but if you follow the instructions and recommendations of the manufacturer, the result will definitely please you. Buyers note that grouts are expensive and mistakes should not be made when working. Due to the short pot life (45-60 minutes), the paste must be processed immediately and the surface must be cleaned at the same time.

In terms of quality characteristics, epoxy compounds are much better than cement mixtures. The resulting seams do not fade over time, do not allow moisture to pass through, and are easily washed off from any contaminants. The brand's colored grouts have a stunning optical effect and convey the beauty of tile and mosaic compositions well. Litokol epoxy pastes compete with other materials and fully meet the stated characteristics.

Advantages of brand products

Based on the characteristics presented above, the features of this material include and highlight resistance to various adverse environments and numerous physical influences.

Another special feature is that it easily fills thin joints with a thickness of only 0.5 mm. To work, you will need a special rubber spatula with sufficient flexibility and moderate rigidity.

Reliability and resistance to damage and ultraviolet rays are also strengths of the brand's products. Thanks to the use of Litokol grout, you can delay the next repair, because the seams between the tiles will retain their original color after a very long time.

Density of grout mixture

The density of the substance is written on the packaging of the original fugue. The average value is 1.5 – 1.7 kg/dm3.

Scope of application

BioBlock technology, which is used in Mapei aggregate, prevents the appearance and spread of fungus and mold. Hydrophobic additives make the grout resistant to high humidity.

Drop Effect technology allows the space between tiles to be less exposed to contamination. And its coating becomes more durable. Waterproof and antifungal properties make the product an excellent solution for filling joints on facades, balconies, pools, terraces, kitchens or bathrooms.

Due to its increased resistance to stains, cement grout can be used to seal cracks between floor tiles in supermarkets, restaurants, gas stations and other public places.

Features of the material

Epoxy grout consists of two components - a paste based on epoxy resin and a liquid hardener, which are mixed immediately before use. When hardened, the mixture forms a translucent solid mass with a smooth surface, which, unlike its cement counterpart, does not absorb moisture at all.

Colors

Without the addition of dyes, epoxy resin is colorless and resembles glass in its transparency. The introduction of pigments into the grout makes it possible to obtain a material of various colors, and the addition of quartz sand helps to change the degree of transparency.

Litokol epoxy grout is available in a wide range of colors, including shades of all colors of the solar spectrum, as well as black, white, gray and beige tones. This allows you to choose a color that blends harmoniously with tiles of any shade. To achieve a shimmering effect, glitter can be added to the mixture.

Features and Benefits

Compared to cement-based compounds, epoxy grout has many advantages:

- High degree of adhesion with any facing materials without the use of additional means - primers, etc.

- High strength and durability. Its service life is at least 50 years, it is so durable that it is impossible to remove it without damaging the tiles.

- Absolutely waterproof.

- The durable, smooth surface with zero water absorption prevents the growth of mold and bacteria.

- Resistance to low and high temperatures (from -20°C to +100°C), aggressive chemicals, ultraviolet radiation.

- Hypoallergenic and environmentally safe. It can be exposed to contact with food.

- High aesthetic qualities throughout the entire service life.

- Easy to care for.

Application area

Due to its absolute waterproofness, mechanical strength and high decorative qualities, epoxy grout is used:

- for lining swimming pools;

- wherever moisture resistance and strength are required - in the cladding of countertops, floors exposed to high mechanical loads, rooms with high humidity;

- where chemical resistance to aggressive environments is required;

- in rooms with high requirements for cleanliness;

- for working with glass tiles and mosaics;

- where its aesthetic properties are important.

Application instructions

- Filling the joints can only begin after the tile adhesive has completely hardened. They must be clean and dust-free to at least 2/3 of the thickness. If cement grout will be applied to highly absorbent types of tiles or on surfaces with elevated temperatures, you must first moisten the base with plain water.

- Dilute the mixture in the indicated proportions. The components of epoxy grout are already distributed by weight, and cement types need to be measured manually or by eye. Mix the mixture with a mixer at low speed. Allow the solution to mature for a few minutes and stir it again before using. You will have limited time to use the solution as it will soon begin to set.

- Fill all tile joints firmly using a rubber trowel or Mapei branded float. Using diagonal movements, skim off excess mixture before it hardens.

- After 15-20 minutes, the grout will dry out, become matte and non-plastic. At this time, you can begin to remove the residue. This is done in diagonal movements using a clean and damp sponge. To wash the sponge, it is better to have two separate containers: one for removing excess mixture, the second for rinsing.

- After about an hour, you need to sand the seams with a hard, damp sponge. As they harden, you will need to sand them a few times to keep them from looking like sandpaper.

- You can finally clean the surface using a felt glove or a dry cloth.

- If white marks remain, they can be removed after at least 24 hours using Keranet acid detergent from Mapei.

An easy way to separate epoxy grout components by eye

Fill the seams with the mixture

Remove excess and wash the surface when the mixture dries

Apply grout with a float faster than with a rubber spatula

If grout is applied in hot or dry weather, it should not be allowed to dry quickly. It is advisable to moisten the surface with water after a couple of hours.