Features of epoxy grout

The main feature of this material is its composition.

To prepare the solution, two components are used:

- Liquid epoxy resin. In addition to it, a silicon filler, a bright pigment, and a special plasticizer are used to make the composition more plastic;

- Hardener. It is responsible for the chemical reaction during which the epoxy joint becomes dense and durable.

Unlike cement grout, epoxy resin composition is distinguished by its plasticity, a large selection of shades and increased drying speed. However, I consider the last criterion to be more of a disadvantage than an advantage.

When purchasing epoxy, you need to understand that it is very different from regular grout. For example, when preparing a cement mixture, it is possible that the proportions of substances may not be observed.

When working with epoxy resin for grouting, you need to correctly calculate the ratio of active components. If the dosage is observed, it is possible to obtain a high-quality composition that provides excellent results.

The main differences between epoxy and cement grout are as follows:

- Epoxy grout for joints has good hydrophobic properties. Thanks to them, the seams are smooth and insulated from high humidity. The finished solution evenly fills the space between the ceramic decor. A different color palette allows you to choose any shade to create an exclusive design;

- Epoxy grout-based joints resist chemical compounds. They do not change their appearance under the influence of household chemicals, which contain a high concentration of acids and alkalis;

- Epoxy grout has a long service life. On average, it can last from 15 to 35 years;

- The mixture with epoxy resin is ideal for treating any ceramic-based surfaces. In addition, it perfectly fills glass and marble mosaic surfaces. The seam size can reach from 0.5 mm to 20 cm;

- It is recommended to choose it for rooms where regular humidity and temperature changes are observed. For example, in a bathhouse or sauna;

- Professional craftsmen prefer to use epoxy grout as an installation adhesive for tiles. Thanks to it, it is possible to fix mosaics made of glass, porcelain and even metal.

Tools and accessories

Before starting work, stock up on tools and equipment:

- a drill with a nozzle for mixing grout;

- container for stirring the mixture;

- rubber spatula for forming seams;

- a pastry bag for filling seams;

- a sponge made of cellulose or foam rubber to smooth out seams and wash off the composition;

- scraper for removing composition from tiles;

- spray with water to wet the surface.

In addition, when performing work, use gloves, safety glasses and special clothing that protects the skin.

Figure 4. Tools and accessories for grouting.

To fill the joints with epoxy grout, it is better to use a special bag, like a pastry bag. In this case, the solution is squeezed out of the bag directly into the seam between the tiles.

Disadvantages of epoxy grout

In addition to numerous advantages, this type of finishing composition has significant disadvantages, which are as follows:

- Price. To work, you will need a grout based on two components and a special solution to get rid of plaque. However, if it is necessary to eliminate any defective area, then for this it is necessary to purchase a new volume of working components;

- Experience. Not every craftsman is able to evenly distribute a solution based on epoxy resin. The lack of special experience when working with such a composition will result in uneven seams and cloudy stains that are difficult to get rid of;

- Rough texture. Once dry, the tile joints have a sandpaper-like feel. The fact is that during crystallization, large particles are formed that look like fine sand. Difficulties may arise in the process of cleaning decorative surfaces.

Instructions for working with the composition

Before using the material, you must read the instructions very carefully. It is recommended to practice on an inconspicuous area, first diluting a small portion of the product.

You can also first work with ordinary cement grout - this will also allow you to gain certain skills. Prepare the epoxy mixture in small portions, working as quickly as possible, otherwise the composition will set in the container and deteriorate.

Materials and tools

To work with epoxy, you should definitely buy the following devices, consumables and tools:

- rubber spatula with a durable handle,

- cellulose sponge (can be replaced with foam rubber, but the latter soon fails),

- skipper (bucket with rollers for squeezing),

- grater with a cellulose nozzle for removing drips,

- latex gloves,

- Cleaning agent for tiles and glass.

To mix the grout, it is better to have a drill with a special mixer attachment. Mixing the mixture thoroughly by hand is much more difficult. To wipe the tiles, it is worth buying a cellulose sponge - it can easily handle up to 30 square meters. m of seams without losing appearance and properties.

Preparation of the solution

The two-component material requires preparation before application. Components A and B should be mixed strictly in the proportions indicated on the label. The ratio may vary between brands.

It is worth measuring no more than 300 g of the mixture, calculating the proportions and mixing. Weighing should be done on a kitchen scale - they are very accurate. If necessary, the color is added to the ready-made mass. We must remember that its vitality is no more than 30 - 60 minutes, so it is better to start working right away.

Rubbing seams

Before applying the tiles, the tiles must be dry, clean, and any remaining adhesive has been removed from the cracks. The crosses and leveling system are also removed. To reduce labor intensity, you can cover the edges of the tiles with paper tape. For mashing you will need a rubber spatula.

Operating procedure:

- apply the mixture with a spatula, carefully distribute it along the seams of the tile area,

- form joints, completely filling the seams,

- take a sponge, dip it in clean water, carefully wash out the seams (do not go all the way to the end of the seams, so as not to wet the unrubbed area),

- after forming the seam, rinse the sponge again and wipe it clean (the grout will remain semi-liquid),

- After half an hour, when the joint has dried, you can spray it with water from a spray bottle and iron it again.

During work, large excess grout is removed immediately using a clean sponge or grater with a fiber attachment. After just 5 – 10 minutes it will be much more difficult to remove them.

Cleaning tiles

It is almost impossible to complete the job without deposits appearing on the tiles. You will have to clean it with special detergents (for example, Litonet for stains).

In order not to damage the formed seams, cleaning is done only after a day, not earlier. You will need a microfiber cloth or soft sponge. You need to wash off the plaque several times, periodically changing the water. Next, wipe the tiles dry. The contaminants will be completely washed off only during operation.

Possible mistakes

The most common mistake made by beginners is preparing grout without accurately measuring the proportions. You cannot prepare the material by eye; you must strictly follow the instructions. Otherwise, the mass will be spoiled.

Another possible mistake is leaving the grout on the tiles in the hope of removing it after the job is complete. The composition will have to be cleaned mechanically, because the material does not dissolve in water, and there is a high risk of damage to the tiles.

You should not work with epoxy mixture using conventional tools that were previously used for cement grout. You should purchase a special spatula and other tools, otherwise the application technique will become much more complicated.

Color palette of epoxy grout for tiles

Agree that the grout palette affects the result. Experts recommend taking into account the ratio of shades to each other. Modern pigments provide any color to fill the spaces between tiles. In addition, additional additives in the form of fine sand and glitter can be used.

It is these details that are responsible for the beauty of the ceramic coating.

With a large variety, it is not always possible to choose the right option. An alternative solution would be to add special pigments to the white composition.

The intensity of the finished shade can be controlled by maintaining the proportions.

What to look for when choosing a palette? To do this, consider the following:

- Light shades of beige, milky and white help create a feeling of a unified composition. It is recommended to choose dark colors to create contrasting details. With the right combination of several tones, it is possible to highlight certain zones;

- If more than three colors and complex patterns are used in the room, then it is recommended to choose lighter colors to emphasize the result. This way the design of the room will seem uniform;

- To grout plain ceramic tile surfaces, you can choose shades that are used around the perimeter of the interior. It is better to select grout immediately with decorative elements. Thus, it will not stand out too much against the general background, but on the contrary will emphasize the beauty of ceramic surfaces;

- If mosaic tiles are used indoors, then it is better to choose beige or white grout for decoration. This way the working composition will allow you to highlight the decorative parts;

- If there is a complex and geometric pattern on the surface of the ceramic tile, then the color shade of the epoxy grout should be beige or white. This way it will be possible to maintain balance.

Designers do not recommend combining more than 3 shades in small spaces. As a result, the interior will turn out tasteless and uncomfortable. Two primary colors should be evenly spaced across the room, and the third should be used as contrasting details.

Main component

Epoxy resin, being the main component in this material, also contains other substances, including silicon and various types of plasticizers.

All this allows the epoxy resin to give the final composition the required viscosity for ease of application of the material to the seams between the tiles.

Photos of ideal seams with epoxy grout

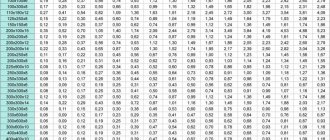

Flow calculator

Use this calculator to find out the average consumption of epoxy grout from Litokol. It is recommended to add a margin of 10% when calculating.

| Grout type | |

| Tile size (mm) | |

| Seam width (mm) | |

| Laying area (sq.m.) | |

| Calculation data | |

| Grout consumption (kg/sq.m.) | |

| Required amount of grout (kg) | |

When using 15x15 glass mosaic 4 mm thick with 2 mm seams, the Starlike consumption was approximately 1.6 kg per square meter.

Litokol grout mixture consumption table

Consumption of EPOXYSTUK X90

Characteristics

In the hardened state, the two-component tile grout forms a fairly strong, airtight and durable connection. Epoxy mortars are also distinguished by increased resistance to various aggressive components, but cement mortars cannot boast of a similar property. The former are more appropriate to use for processing seams in swimming pools, saunas and other rooms with high humidity. Another positive quality is resistance to temperature changes.

As a rule, the instructions for use are quite simple, although there are some types of grout that only professionals can work with, but this is more of an exception. So even a beginner in the field of finishing can get a smooth and tight seam that does not absorb moisture, is easy to clean and has an antiseptic effect.

Two-component grout compositions are characterized by good adhesion, lack of shrinkage and mechanical strength. And although the main function of these materials is not decoration, but protection from fungi and mold, the varied palette of individual types of grout still allows you to choose the necessary shade to fit even such little things as seams into the overall interior design.

Kinds

There are two types of grout. Depending on the composition, they are divided into cement and epoxy. The former have sufficient strength, good moisture resistance and protection from ultraviolet rays. They are produced in the form of dry mixtures and ready-made formulations. Both options have their advantages. Dry mixtures, for example, are advisable to use for small-volume jobs. So, you take the required amount of powder and mix it with liquid, the rest can be stored in a dry place. But ready-made solutions are more convenient to use, since you just need to open the container and mix the contents. But it is advisable to produce them in a short interval.

Buyers' opinions on quality

Consumer reviews regarding Litokol epoxy mixtures are mostly positive. Experienced craftsmen believe that working with paste is difficult, but if you follow the instructions and recommendations of the manufacturer, the result will definitely please you. Buyers note that grouts are expensive and mistakes should not be made when working. Due to the short pot life (45-60 minutes), the paste must be processed immediately and the surface must be cleaned at the same time.

In terms of quality characteristics, epoxy compounds are much better than cement mixtures. The resulting seams do not fade over time, do not allow moisture to pass through, and are easily washed off from any contaminants.

The brand's colored grouts have a stunning optical effect and convey the beauty of tile and mosaic compositions well. Litokol epoxy pastes compete with other materials and fully meet the stated characteristics.

Price

Among the variety of grouts from the Litokol company, Litochrome Starlike grout is very popular because of its versatility and reliability. It has a rich range of shades, a good price, the grout is easy to use, safe, and has improved aesthetic and strength characteristics. Let's find out how much it will cost us to purchase this brand of grout.

It should be noted right away that the price will largely depend on what type of composition you choose. Well, depending on the weight of the packaging, it is clear that the greater the weight of the packaged products, the cheaper the price and vice versa.

Thus, the average price of a 2.5 kilogram can of Litochrome Starlike epoxy grout in a neutral shade will cost the buyer an average of 2,400 rubles. A five-kilogram package will cost 4000-4100 rubles. Agree, the savings are significant - it is more profitable to buy large quantities than several small ones.

Lithochrome Starlike of dazzling white color with a capacity of 2.5 kg will cost 2,700 rubles. Interesting and unusual colors, such as turquoise, lilac and others, will cost a little more than the usual neutral brown and beige. Their average price for a 2.5 kg jar is 2,500 rubles. Crystal-transparent grout weighing 5 kg will cost around 4800 rubles.

Thus, we can conclude that no matter what color you choose, the average price for a 2.5 kg jar will be from 2300 to 2700 rubles, and for a 5 kg package – from 3700 to 4800 rubles. Keep this in mind when going to a hardware store.