The use of tiles and mosaics when finishing indoor surfaces is quite popular, because creating all kinds of designs with these materials makes it easy to find an acceptable option. But in order for repair work to give a high-quality result, you need to use good compounds for sealing seams. A proven product is Litokol grout, which has proven itself to be a quality product with excellent characteristics. It will help protect the surface from the appearance of mold and mildew on the seams. More details about these products will be discussed below.

Features of the material

Epoxy grout consists of two components - a paste based on epoxy resin and a liquid hardener, which are mixed immediately before use. When hardened, the mixture forms a translucent solid mass with a smooth surface, which, unlike its cement counterpart, does not absorb moisture at all.

Colors

Without the addition of dyes, epoxy resin is colorless and resembles glass in its transparency. The introduction of pigments into the grout makes it possible to obtain a material of various colors, and the addition of quartz sand helps to change the degree of transparency.

Litokol epoxy grout is available in a wide range of colors, including shades of all colors of the solar spectrum, as well as black, white, gray and beige tones. This allows you to choose a color that blends harmoniously with tiles of any shade. To achieve a shimmering effect, glitter can be added to the mixture.

The material has high color fastness, it does not fade in the sun and does not fade under the influence of water and detergents, maintaining the brightness of the color throughout its entire service life.

Features and Benefits

Compared to cement-based compounds, epoxy grout has many advantages:

- High degree of adhesion with any facing materials without the use of additional means - primers, etc.

- High strength and durability. Its service life is at least 50 years, it is so durable that it is impossible to remove it without damaging the tiles.

- Absolutely waterproof.

- The durable, smooth surface with zero water absorption prevents the growth of mold and bacteria.

- Resistance to low and high temperatures (from -20°C to +100°C), aggressive chemicals, ultraviolet radiation.

- Hypoallergenic and environmentally safe. It can be exposed to contact with food.

- High aesthetic qualities throughout the entire service life.

- Easy to care for.

Application area

Due to its absolute waterproofness, mechanical strength and high decorative qualities, epoxy grout is used:

- for lining swimming pools;

- wherever moisture resistance and strength are required - in the cladding of countertops, floors exposed to high mechanical loads, rooms with high humidity;

- where chemical resistance to aggressive environments is required;

- in rooms with high requirements for cleanliness;

- for working with glass tiles and mosaics;

- where its aesthetic properties are important.

Varieties

The manufacturing company offers several types of material, each of which has its own distinctive qualities and features.

Starlike Defender is an antibacterial grout mixture for ceramics. Outwardly it resembles a paste with a thick consistency. Designed for seams from 1 to 15 mm. This is an acid-resistant two-component composition for different types of tiles, with high resistance to ultraviolet radiation. This material has good adhesion, does not emit toxic fumes, ensures a uniform color of the cladding, and destroys virtually all bacterial microorganisms.

The area of use of this product is quite large - swimming pools, window sills made of granite and marble, kitchens, bathrooms, industrial and other premises where special strength and wear resistance are required due to aggressive environmental influences.

At the moment, the manufacturer Litokol Starlike has released an innovative product - a grout based on an aqueous dispersion of polyurethane resins, which can also be used for glass mosaics with joint sizes of 1-6 mm. This composition is ready for use, does not contain aggressive and corrosive components, when filling joints with it, the mixture does not remain on the surfaces, thanks to the quartz sand filler.

Types of epoxy grout Litokol

Litokol has 5 types of epoxy grout:

- Starlike C.350 Crystal is a colorless mixture with a chameleon effect, suitable for grouting artistic and glass mosaics. The maximum thickness of seams is 2 mm. It looks most beautiful on transparent bases illuminated from within.

- Starlike Defender is a two-component acid-resistant epoxy-based grout with antifungal and antibacterial effect. Suitable for filling tile joints with a width of 1 to 15 mm, and can also be used for laying tiles and mosaics. Available in 7 color options.

- Starlike Color Crystal – for glass and artistic mosaics with joints less than 2 mm. Sold in 5 colors.

- Litochrome Starlike is a two-component epoxy grout for filling joints from 1 to 15 mm and laying mosaics or tiles on it. Can be used for interior and exterior work. There are 103 colors available, there are options with glitter, luminescent (glow in the dark), metallic (gold, bronze). To add optical effects to the base color, an additional additive component is purchased.

- Epoxystuk X90 is a two-component acid-resistant epoxy mixture. Suitable for filling joints with a thickness of 3 to 10 mm indoors and outdoors.

Will you use Litokol epoxy grout?

Not really

Usage

Preparatory work boils down to cleaning the joints from dust, mortar and glue residues

If the installation work has been carried out recently, it is important to wait until the adhesive has completely dried. Gaps for filling should be two-thirds free

If you decide to use the material yourself, then it is advisable to carry out the preparation of the mixture and further work according to the instructions:

- the hardener is poured into the paste, while at the same time trying to clean the bottom and edges of the container with a spatula; for this, a steel tool is used;

- mix the solution with a construction mixer or drill;

- the resulting mixture must be applied within one hour;

- under the tiles, the composition is applied with a spatula with teeth corresponding to the size and thickness of the tiles, the fragments are laid with significant pressure;

- the gaps between the tiles are filled with a rubber spatula and excess mortar is removed with it;

- if you need to treat a large area, it is wiser to use an electric brush with a rubberized attachment;

- Cleaning of excess grout is carried out quickly while the mixture remains elastic.

When working with Litokol Starlike grout, you should take into account the temperature; the optimal range is considered to be from +12 to +30 degrees; you should not dilute the solution with solvent or water. This product should not be used if the surface may come into contact with oleic acids.

Reviews about this material are quite contradictory, however, in most cases they are positive: impeccable moisture insulation, strength and durability of the seams are noted. These are truly high-quality products and, when used skillfully, they are ideal for various rooms and types of decoration.

Below is a video on how to properly grout joints with Litokol Starlike grout.

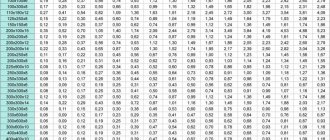

Calculation of material consumption

Epoxy grout for tiles is not cheap, so it is advisable to make an accurate calculation of the required quantity before purchasing. It will depend on:

- distances between tiles (minimum seam when using Litokol grout - 1 mm);

- tile size - the larger it is, the less material is required per 1 m²;

- thickness of the tile - the thicker it is, the deeper the seam, which means the greater the consumption;

- surface smoothness (embossed tiles require more grout).

Knowing all these parameters, you can easily calculate the required amount of epoxy grout by making the following calculations:

- We multiply together: the width of the seam (A) the thickness of the tile (B) and the sum of the width (C) and length (D) of the tile. We take all dimensions in millimeters.

- We multiply the resulting value by the density (specific gravity) of the grout (P). For LITOKOL Litochrom it is 1.9 kg/l, for LITOKOL Starlike - 1.55 kg/l.

- Dividing the result of multiplication by the area of one tile (the length of the tile multiplied by the width (DxW), both parameters in millimeters), we obtain the grout consumption per 1 m².

The full formula is:

Consumption (kg/m²) = (D+C)(mm)xA(mm)xB(mm)xP(kg/l)/(DxC)(mm²)

By multiplying the resulting specific consumption of material by the number of square meters of cladding, we obtain the total required amount of grout. Since a small part of the material remains on the surface of the tile and is then removed, another 10% of the result should be added to the calculated amount.

When covering large areas, it makes sense to first buy the minimum package, and then calculate the required amount of material based on its actual consumption.

Grout amount calculator

Specifications

The combination of resin with a hardener and modifying additives gives the Litokol sealant good performance properties, which are an order of magnitude higher than those of cement compositions. Depending on the type of brand product, the characteristics of the grout differ slightly in material consumption, but the basic technical parameters of the mixture are identical:

- The consistency of the components of the composition is a thick paste and a thick liquid.

- Proportions – 92:8, 100:8, 100:8.3 depending on the labeling of the mixture.

- Application time until hardening is from 45 minutes to an hour.

- Complete hardening takes 5-10 days, depending on the drying temperature.

- The mixture should be applied at an optimal temperature of +12 to +30°C.

- It is frost-resistant, operating conditions from -20 to +100°C.

- Shrinkage of the material after polymerization does not exceed 1.5 mm/m.

- Chemical resistance - alkalis, acids, solvents, fuels and lubricants.

The mixtures are packaged in plastic buckets weighing from 1.5 to 10 kg. Wholesale quantities are delivered in pallets. The consumption of epoxy grout varies, depending on the viscosity of the finished paste, the size of the tile or mosaic, on average it is 1.1-1.5 kg/m2 of cladding. All grouts from the manufacturer Litokol can be used for interior work (kitchen space, bathrooms, showers, hallways) and exterior finishing (terraces, facades).

Instructions for use

Each package of epoxy grout for Litokol tiles comes with detailed instructions, which are recommended to be read before using the material. We present the main provisions of the instructions, as well as advice from experienced craftsmen who will help you master high-quality sealing of tile joints with epoxy-based grout.

How to divorce?

To obtain a working mixture, it is necessary to mix the bulk with a liquid hardener. The main thing you need to know before you start mixing: the mixture must be used up within 40 minutes. After this period, the epoxy grout hardens and becomes unusable.

In 40 minutes, it is necessary not only to seal the seams, but also to rinse the treated surface with water. Therefore, you need to mix the mixture components in small portions. For beginners, for the first time it is enough to dilute 200-250 g of the mixture.

To prepare the grout you will need:

- scales;

- clean plastic container;

- mixing spatula;

- latex gloves.

Dilute the mixture in a proportion of 8 g of liquid hardener for every 100 g of epoxy mass; this proportion should be clarified in the instructions for the grout.

Let's describe this process step by step:

- The corner of the bag with the hardener is cut off to create a small hole. This will allow you to store the opened package for a long time.

- Place the container on the scale and pour the calculated amount of hardener into it, for example, 20 g.

- Using a spatula, add the epoxy mixture to the same container in the calculated amount, for our example - 250 g.

- Remove the container from the scales and thoroughly mix the contents with a spatula until the liquid fraction completely disappears and the mixture becomes homogeneous.

It is not recommended to use mixers with a high number of revolutions for stirring, since if the rotation is too fast, the mixture self-heats and its hardening time is reduced.

To obtain a shimmering effect, glitter is added to the prepared mixture in an amount of 3% of its volume. Stir them carefully, away from drafts, as they easily rise into the air.

How to apply?

Before preparing the grout, the surface for its application must be completely prepared. The optimal air temperature for work is +18-23°C; at temperatures below +12°C it is not recommended to use epoxy grout.

It is convenient to rub the seams with a special rubber float. The grout is applied to the float with a spatula, then the material is spread with a float over the surface of the tile with diagonal movements, rubbing into the seams. Use the edge of a grater to scrape the mixture off the tiles and rub it back into the joints.

To grout the corners, use a spatula and a special corner with a 45° chamfer. After using all the diluted mixture, the treated area is cleaned with a clean rubber float and poured with plenty of cold water, after which it is wiped with a cellulose sponge, rinsing it thoroughly. This helps to create an even and smooth surface for the seams.

After grouting, a film appears on the surface of the tile from the epoxy mixture, which must be removed the next day, otherwise indelible yellow stains will remain. This is done using a special product called Litonet, which is applied every other day according to the instructions and left for half an hour. After this, the surface is washed with water using a stiff brush or white felt and wiped dry with a cotton cloth.

Only on the fifth day after cleaning can you begin using the treated surface. Before this, you should not cover it, splash it with water or other liquids, walk on it, place objects on it, or expose it to temperature changes. Therefore, it is advisable to lay the floor tiles last.

Plaque removal

The next day you need to remove the epoxy coating using Litonet. It is not cheap, but it is a concentrate, so it will last a long time.

- Spray the surface with the product, wait according to the instructions and clean. There will be a lot of foam; it is most convenient to remove it with a self-squeezing mop or a washing vacuum cleaner.

- Using a “hairy” dishcloth (or a special cellulose sponge), remove the remaining grains of sand and plaque.

- Glossy tiles are easy to clean, so the product can be diluted with water 1 to 4. For matte surfaces, it is better to work with a concentrated solution or dilute it in small proportions (1 to 1).

- After cleaning, let the surface dry and check for gaps where plaque remains. If you paid little attention to washing with water, or you use clinker, clay tiles, terracotta, you may even need 2-3 passes. If you use relief decors, it is better to seal them in advance to save yourself some work.

Litostrip gel is used to remove plaque 24 hours or more after applying grout.

How to use

Let's look at how to use the epoxy composition Litokol, and what are the features of its operation.

Before applying the mixture to the seams, the latter must be properly prepared. Namely, remove the old coating, dirt, glue and cement screed residues. Only on a clean surface will the grout last for the amount of time guaranteed by the manufacturer.

After some time, you can apply grout to the seams

Attention: it is not recommended to stir the mixture by hand; it is better to do this with a mechanical stirrer-drill

It is important that the components are thoroughly mixed together - in this case the mixture will be uniform and of high quality

Video showing the use of epoxy grout:

Do not use solvents, water, or any other additional components when preparing the mixture. Any addition of unnecessary ingredients can greatly deteriorate the adhesive, aesthetic and strength characteristics of the grout.

To apply, use a special wide spatula. The grout is applied diagonally along the seams of the tiles. During the process, it is constantly necessary to remove excess so that there are no large deposits on the surface of the tile. It is necessary to apply the composition as evenly as possible so that the overall impression of the result of the work is organic.

After grout has been applied to all seams, it is necessary to clean the surface of the tile within 45 minutes from dirt and stains left by the grout. This must be done quickly; after hardening, the epoxy mixture will be difficult to remove with anything, only with caustic solvents. To make the tile surface clean, you need to use a damp cloth or a rubber spatula soaked in water and remove the grout using wide circular movements.

Then you need to wait until the mixture dries completely

The waiting time depends on several factors: it is important that the room has a suitable temperature - from plus 16 to plus 25 degrees. And second: different grout compositions dry differently

After the cleaning activities are completed, it is recommended to walk on the tiles no earlier than a day later. And for the composition to completely harden, it will take about 5 days.

The consumption of the grout mixture depends on the width of the tile used. It is clear that the larger the area of the tile, the less grout it will require, and vice versa - the smaller the tile, the more fastening grouting composition will be needed. The width of the joints between the tiles is also important.

Useful tips

When purchasing epoxy grout in the cold season, make sure that it is not exposed to freezing temperatures for a long time. When crystals form in the hardener, it loses its properties.

When washing off traces of grout, do not use fabrics with lint, because... it can change the color and texture of the surface of rubbed seams.

When working with natural porous stone tiles, it is recommended to choose the closest possible shade and carry out a test application, as there is a high risk of staining.

Summarizing

Working with epoxy grout has its own difficulties - you need to clean and dry the surface, it is difficult to remove plaque, the impossibility of forming internal corners within one day, the need to use a large amount of water for rinsing. In addition, the high price, durable seams and labor-intensive process do not allow mistakes, because correcting mistakes will cost much more.

But there are also undoubted advantages - dirt does not accumulate in the seams, they are easy to clean, do not change color when wet, and can be washed with any means. After processing, the seams resemble plastic, a little rough, which is why it may have a rough surface.

Whether to choose epoxy grout for grouting or not - everyone makes their own decision.

Price

Among the variety of grouts from the Litokol company, Litochrome Starlike grout is very popular because of its versatility and reliability. It has a rich range of shades, a good price, the grout is easy to use, safe, and has improved aesthetic and strength characteristics. Let's find out how much it will cost us to purchase this brand of grout.

It should be noted right away that the price will largely depend on what type of composition you choose. Well, depending on the weight of the packaging, it is clear that the greater the weight of the packaged products, the cheaper the price and vice versa.

Thus, the average price of a 2.5 kilogram can of Litochrome Starlike epoxy grout in a neutral shade will cost the buyer an average of 2,400 rubles. A five-kilogram package will cost 4000-4100 rubles. Agree, the savings are significant - it is more profitable to buy large quantities than several small ones.

Lithochrome Starlike of dazzling white color with a capacity of 2.5 kg will cost 2,700 rubles. Interesting and unusual colors, such as turquoise, lilac and others, will cost a little more than the usual neutral brown and beige. Their average price for a 2.5 kg jar is 2,500 rubles. Crystal-transparent grout weighing 5 kg will cost around 4800 rubles.

Thus, we can conclude that no matter what color you choose, the average price for a 2.5 kg jar will be from 2300 to 2700 rubles, and for a 5 kg package – from 3700 to 4800 rubles. Keep this in mind when going to a hardware store.

Colors

A distinctive feature of Litokol brand grouts is their decorative appeal. The rich range of shades of pastes allows you to create very beautiful compositions from tiles, mosaics and other facing materials. When choosing a grout color, you need to take into account the main background of the finish. The color palette of Litocol grout mixtures based on epoxy resin is no less impressive. The compositions are presented in several collections:

The classic range includes silver, anthracite, titanium shades, delicate colors Sabbia, Travertino, white undertones Bianco Assoluto, Avorio, Bianco Ghiaccio, gray options Grigio Seta, Ardesia, Neutro, rich brown mixtures Pietra d`Assisi, Moka and light variations Tortora, Grigio Portland, Grigio Fango.

The glamorous collection attracts with its richness and variety of shades from soft coral to dark purple: Corallo, Rose, Zaffiro, Melanzana, Lime, Ciclamino, Lilla, Artic Blu, Turchese, Mela, Lemon, Arancio, Azzurro Pastello, Verde Salvia, Verde Pino . You can choose interesting pastel and bright colors.

The Metallic grout line has an attractive shine, ideally complements the main background of mosaics and tiles, and does not lose color saturation and depth over time. The compositions are presented in a palette of variations: rusty antique, copper, bronze, bright gold, platinum.

The crystal collection of cool shades combines several color solutions, so you can choose an interesting option for tiles of different colors. The choice is light Crystal, rich pink Rosso Pompei, dark green Verde Capri, cool blue Azzurro Taormina, Beige Havana, Rosa Kyoto.

Epoxy tile grout litokol for tile joints of the EPOXYSTUK X90 line is made in a neutral white version and calm pastel colors of gray and beige. Cement mixtures LITOCHROM 1-6, LITOCHROM 1-6 LUXURY, LITOCHROM 3-15 are presented in primary colors (white, yellow, brown) and additional shades (wenge, kiwi, melanzana, cyclamen) - many options.

Buyers' opinions on quality

Consumer reviews regarding Litokol epoxy mixtures are mostly positive. Experienced craftsmen believe that working with paste is difficult, but if you follow the instructions and recommendations of the manufacturer, the result will definitely please you. Buyers note that grouts are expensive and mistakes should not be made when working. Due to the short pot life (45-60 minutes), the paste must be processed immediately and the surface must be cleaned at the same time.

In terms of quality characteristics, epoxy compounds are much better than cement mixtures. The resulting seams do not fade over time, do not allow moisture to pass through, and are easily washed off from any contaminants.

The brand's colored grouts have a stunning optical effect and convey the beauty of tile and mosaic compositions well. Litokol epoxy pastes compete with other materials and fully meet the stated characteristics.

Mix the mixture

The polyurethane type is sold ready-to-use; the epoxy composition must be mixed. The kit contains two components; they are mixed until a paste-like consistency is obtained; work after mixing must be started immediately, because the composition dries quickly. For mixing, it is more convenient to use a construction mixer, which will produce a high-quality mix, and the solution will turn out to be the desired consistency.

Mixing instructions are also included on the packaging; before starting work, you must carefully study it to know all the nuances.

For mixing, it is more convenient to use a construction mixer, which will produce a high-quality mix, and the solution will turn out to be the desired consistency.