Silicone sealant is widely used in various fields of activity. The material fills voids, seals seams, is well applied to various surfaces, and at the same time prevents the penetration of moisture, which prevents the development of fungal formations and mold. Before work, you need to know the consumption of sealant. To determine the indicator, influencing factors, methods, and manufacturers are taken into account.

Properties of polyurethane sealant

The popularity of polyurethane (silicone) sealant is caused by its properties:

- Not exposed to ultraviolet radiation;

- Inert to aggressive environments;

- Excellent adhesion to any surface;

- Withstands temperature differences of 250 degrees;

- Excellent sealing and waterproofing;

- Does not spread over the surface;

- Possibility of use both at negative temperatures and at large values of the positive range;

- Environmentally friendly;

- The service life exceeds 10 years if the application technology is followed.

How long does it take to dry?

Polyurethane sealants dry fairly quickly. Primary setting when using one-component compositions occurs within an hour. After about a day, the composition acquires maximum strength, and the base can be used.

Two-component formulations can form a durable coating in just 30 minutes. For complete curing you need to wait a day. These indicators are maintained at temperatures up to +20˚С. If the temperature is lower, the drying time will increase.

Types of polyurethane sealants

There are two types of silicone sealant: neutral and acetate. Acetate is suitable for smooth materials such as glass. The composition contains acid, so it cannot be used on metal. Acetate glue can be used in well-ventilated areas.

- The neutral composition can be used on any porous surfaces. It has good adhesion and is not susceptible to temperature changes.

- Silicone sealant with fungicide is intended for use in damp areas. The substance included in the glue prevents the formation of fungus.

The main factor influencing the amount of silicone used is the size of the seam. To reduce the size of a large seam, a special cord is placed in it, which acts as a seal. It is often used to seal log houses.

Polyurethane sealant is difficult to paint - it does not interact with any type of paint. Substances are sold in various shades, so you should take care of the color in advance.

Polyurethane sealants are divided into one-component and two-component. One-component ones are supplied ready to use, while two-component ones require manual mixing of the composition.

Areas of use

The viscous consistency of polyurethane sealant makes it suitable for sealing seams and eliminating defects in the floor, walls, and foundation. The mixture can replace glue for waterproofing, installing tiles and thermal insulation. The sealant reliably glues different types of materials and is resistant to various types of influences:

- moisture and direct sunlight;

- corrosion;

- vibrations;

- aggressive cleaning agents and detergents;

- mechanical damage.

The material is suitable for wooden, ceramic, plastic, metal surfaces. Self-adhesion is a characteristic that distinguishes PU sealant from glue. You can carry out repair work on top of the existing layer and be calm about the integrity of the surface.

PU sealant forms an elastic, durable surface that will withstand frequent temperature changes - the seam, after freezing in winter and the influence of heat in summer, will remain neat and aesthetically pleasing and will not deform.

Formula for calculating sealant per 1m

To calculate the required amount of material, use the formula for calculating the volume of a rectangular parallelepiped: Volume = Length × Width × Depth (seam dimensions). For a triangular seam, the result must be divided by 2. If you have to fill a crack, the amount of glue can be enormous.

The amount of silicone in one package is known; the manufacturer always indicates it; it is easy to count the number of packages. Cartridges are available in volumes of 310 ml and 600 ml. Example: to seal a seam 6 mm wide and 3 mm deep in a bathroom, 20 ml of substance will be needed per linear meter (1 liter = 1000 ml).

There are calculators on the Internet that help determine the amount of goods required for repair.

When calculating the amount of silicone to seal the seams of a log house, you need:

- Calculate (L) glue consumption per linear meter and multiply by the number of meters;

- Determine (W) the distance between the rims, the average value is 5 – 7 mm;

- Height H is taken equal to 1/10 of the thickness of the log: measure the diameter of the log, divide by 10 and round down. The formula for calculation is: M = L*H*W*r.

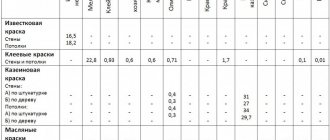

Average consumption

The consumption of the composition for sealing, connecting, and sealing seams depends largely on the base material with which you will need to work. Depending on the type of material, you can find out the standard value that is set during construction and installation work. On average it is 6 mm. In some cases it is necessary to determine this value individually. If the joints have significant parameters - depth and width, then a special silicone cord is used for the work, which acts as a seal. Its use is especially important when working with wooden bases.

The average calculation of the consumption of a substance allows you to determine the appropriate container in which it is sold. To avoid unnecessary consumption, for example, if the depth and width of the opening are 5 mm, and its length varies within 10 meters, then 0.25 kg of sealant will be needed. Therefore, you can safely buy a 0.3 kg tube, leaving a little substance in reserve.

It is important when performing work, after carrying out average calculations of the consumption of the sealing composition, to observe these indicators when applying the substance. Therefore, it is necessary to first prepare the surface, clean it from debris, dust, and other substances, and degrease it. Both sides of the surfaces adjacent to the seam should be covered with masking tape to prevent sealant from getting on them. After this, it is important to correctly make a cut on the spout of the tube with sealant, after first placing it in the mounting gun. If all the preparatory work and consumption calculations are carried out correctly, then the substance fits ideally evenly into the gap and is leveled using a spatula.

It doesn’t matter whether repair and sealing work is being carried out outside or inside, or whether silicone sealant is selected for exterior work or to solve everyday problems. It is very important to spend a little time on preliminary calculations of substance consumption and become familiar with the correct technology. This way, every master will be able not only to avoid overuse of substances, but also to save budgetary funds, as well as carry out the work of filling joints as quickly and efficiently as possible.

Working with sealant, tips from the experts (2 videos)

Sealant consumption per 1 m of seam (16 photos)

How to economically apply sealant

Polyurethane sealant or glue is an economical material: a seam with dimensions of 5 mm and 10 mm and a length of 10 meters will require only 2 cartridges of 310 ml.

- The experience of the craftsman plays an important role in the economical use of sealant. Saving material affects the quality of work; overspending results in an unsightly appearance. The required middle can be provided by a professional or a trained amateur master.

- The choice of tool is of great importance for savings; if you use a spatula, the consumption will increase significantly. It is possible to reduce the amount of silicone by using a special gun into which a tube of sealant is inserted.

- Some models bend when pressed hard. You should choose a high-quality metal one, with a powerful tubular pusher. Having purchased a reliable professional tool, you will definitely be able to save on material.

Preparation of the workplace

Preparation of the workplace is of no small importance. It is not enough to sweep away the debris; the area where the sealant will be applied must be cleaned and degreased. Silicone will not stick to the surface, which will make the whole job pointless. Subject to all technologies, it is economical to work with any surfaces and under any conditions.

Each cartridge has a plastic tip, which must be cut at an angle of 45 degrees; the gun must be held at the same angle to the plane. Correct application of sealant helps to save it. You need to level the seam with a spatula with a 6 mm edge. The applied composition should not be touched until it is completely dry.

To prevent the silicone from sticking to the spatula and being dragged behind it, you can moisten the tool with soapy water - the seam will be smooth and of the required size.

Surface treatment with primer

Before sealing concrete cracks, the surface should be treated with a primer. After drying, the polyurethane will firmly bond to the ground.

It should be remembered that polyurethane hardens faster with increased humidity (similar to polyurethane foam), so leveling should be done quickly. Like any substance, sealant has an expiration date, it is worth paying attention to. To avoid hardening, tubes should be stored in a cool place.

High-quality polyurethane application plays a role in saving money. If the sealing of the product is carried out efficiently, it will last for many years, and there will be no need to redo it after a short time by purchasing the material again.

Safety precautions

GOST 12.1.007 standards classify polyurethane sealant as low-hazard substances. The material is safe for human health, but with prolonged direct contact it can cause dermatitis and skin irritation.

Work with PU sealant must be carried out in personal protective equipment: rubber gloves, overalls. If the mixture gets into your eyes, rinse the mucous membrane with running water. If the burning sensation and discomfort do not go away, consult a doctor. After the sealant comes into contact with unprotected areas, wash off the mixture with a solvent, then wash the skin with running water and soap.

Photo of polyurethane sealant

Trinkvassersilicon

Bostik Trinkwasser-Silicon

Silicone sealant, which does not deteriorate its quality during prolonged contact with drinking water.

Silicone sealant Triquassersilicon is intended for drinking water supply systems (tanks, pipes, etc.). Suitable for possible contact with food products, for example on counters and racks, in refrigeration units, etc., for aquariums with a capacity of up to 300 liters, in industry, in repair shops. It vulcanizes under the influence of air humidity and turns into an extremely stable, heat-resistant ranging from - 50 o C to + 150 o C, odorless, elastic material. Silicone sealant was tested at the Institute of Hygiene of the University of Bonn in accordance with the requirements of the German Federal Office of Health for synthetic materials that come into contact with drinking water. The temperature of the base during application should be in the range from + 5 o C to + 40 o C. When filling joints, their edges must be strong, dry, free of dirt, dust, oils and foreign substances. Primer is first applied evenly to them. Immediately after the primer has dried, squeeze out the sealant evenly. Fill the seams completely, avoiding air inclusions. Then level the surface of the seam with a damp spatula, jointer or other suitable tool (you need to add detergent to the water to moisten it to form a 1-2% solution).

CONSUMPTION

With seams measuring 10 x 10 mm, one package is enough for approximately 3 linear meters.

DELIVERY FORM

Direct deliveries from Germany.

Cartridge - 300 ml, color - transparent.

Underwater silicone

Bostik Unterwassersilicon

One-component silicone sealant for underwater use with a neutral curing system.

Silicone sealant Underwater silicone is used for sealing joints and expansion joints indoors and outdoors in swimming pools and damp areas. Resistant to prolonged exposure to salt water and water containing disinfectants used in swimming pools. Silicone sealant Underwater silicone vulcanizes under the influence of air humidity into an exceptionally stable, odorless elastic material with temperature resistance from -40°C to +150°C, has a fungicidal effect, and is not used in aquariums. After completing the work on sealing the seams in the swimming pool premises, it is necessary to maintain a period of 14 days at a temperature of 20°C and a relative humidity of 50% for the sealant to completely dry before filling the pool bowl.

CONSUMPTION

Consumption is calculated using the formula: seam width (mm) x seam depth (mm) = cm 3 / sealant consumption in ml per linear meter of seam.

DELIVERY FORM

Direct deliveries from Germany.

Cartridge - 300 ml, color - gray.

Bausilicon

Bostik Bausilicon

One-component neutral silicone sealant.

Designed for sealing connecting and expansion joints during internal and external work for general construction purposes. Silicone sealant Bausilicon is recommended for use in the installation of heating and ventilation systems, in instrument making and the automotive industry, and in repair shops. Bausilicon silicone sealant vulcanizes under the influence of air humidity, turning into an exceptionally stable, odorless, elastic material with temperature resistance after vulcanization ranging from - 50 ° C to + 200 ° C (for a short time more than + 250 ° C). The temperature of the base during application should be from + 5°C to + 60°C. When applying to metals and galvanized steel, it is recommended to use NSK one-component Primer 5004. Copper and brass, paint and synthetic materials, and porous substrates require a preliminary adhesion test.

When applying silicone sealant, Bausilicon is evenly squeezed into the seam. Fill the seams completely, avoiding air inclusions. Immediately treat the surface with a damp spatula, jointer or other suitable tool (you must add detergent to the water to obtain a 1-2% solution). Some metals, such as lead, steel and copper, can corrode when exposed to acetic acid. Protective measures must be applied.

CONSUMPTION

With a seam size of 10mm x 10mm, one cartridge is enough for 3.10 linear meters.

DELIVERY FORM

Direct deliveries from Germany.

Cartridge - 300 ml, color transparent, white, gray, black, brown.