Electric underfloor heating brings comfort and coziness to your home. It fits under different floor coverings. Laminate plus electric heating is an ideal combination, since the product is cold and walking on it without additional heating is not comfortable.

Laminate can be laid on electromats and infrared film heated floors. The floor covering must have a special marking stating that the material is compatible with heating.

After reading this article, you will become familiar with the types of electric heated floors and will be able to understand which one is most suitable for a bathroom or living room finished with laminate. In addition, you will learn how to lay warm floors under laminate with your own hands.

Infrared film

Infrared heated floor is a thermal film with heating carbon elements that emits infrared waves. The width of the product varies from 30 to 100 mm, and is available in different capacities. The model has been on the market for several years and is popular as it saves up to 20% of electricity.

Advantages of infrared electric film:

- ease of installation and operation;

- does not affect the height of the ceilings, since the film thickness is only 1 mm;

- does not harm human health, since it practically does not emit electromagnetic waves;

- is not afraid of mechanical loads, so it can be installed under furniture.

This type of electric heating does not contribute to the release of formaldehyde, which is contained in the glue of the lamellas, since it is heated by infrared rays.

Almost the only drawback is the high price. But due to the ease of installation and savings during operation, the total cost of the device is not much different from other types.

Installation

You need to start installing an electric warm infrared floor under a laminate by preparing the project and purchasing the material.

Warm flooring under laminate is easy.

Step by step process:

- Installation of a thermostat - the device is mounted at the planned location, a cable placed in a corrugation is laid from it to the film.

- Preparation of the rough base - leveling and cleaning.

- Laying hydro- and heat-insulating material - polyethylene film is placed over the walls, and heat-insulating sheets are glued together with tape.

- Placement of thermal film - copper contacts should be directed downwards, the strips are connected using clamps. The film must be laid carefully so as not to damage it. Cutting should be done strictly along special lines.

- Connection - the cable is connected to the heating elements with terminals, the connection points are insulated with bitumen tape, so that the contacts do not protrude into the heat-insulating material, recesses are made for them.

- Installation of a temperature sensor - it is placed in a corrugation on graphite strips and connected to the thermostat.

- System testing - the heating of each film is checked.

- Film protection - covered with a special material such as “Izospan”, it protects it from abrasion.

- Laying the final finish - laminate.

Installation rules and stages

Rules and stages of laying heated floors under laminate

Installation of heated floors under laminate takes place in several stages. At each of them, you must comply with all the requirements and nuances so that later there are no problems with the operation of the coating.

Set of tools and materials

First of all, you need to stock up on all the required tools and materials. These include:

- kit that comes with the device;

- thermostat;

- heating heat-reflecting film;

- pliers;

- screwdriver;

- scissors or stationery knife;

- special adhesive tape.

The kit must include clamps, connecting electrical cables, and special insulation. After selecting and purchasing the tools, you need to make a plan for the heated floor installed in the future. Based on all calculations, the location of the thermostat is verified to maintain the optimal temperature in the room and control its changes.

It is important to pay special attention to the choice of substrate. It is best to purchase extruded perforated polystyrene. Penofol and cork are good options. In general, manufacturers suggest purchasing special underlays for heated floors, which are available for sale in specialized stores.

Penofol is not used as a substrate for laying infrared floors!

Preparing the base

It is important to properly prepare the foundation

The first stage of work is the removal of the old base. You need to get to the concrete slab or sub-wood floor. After removing the debris, you can begin preparing the base for the electric floor:

- Identify and eliminate all base defects : chips, gouges, cracks, etc. If there are significant unevenness on the concrete floor, the easiest option is to pour a thin screed based on cement and sand. Additionally, damper tape must be laid along the entire perimeter of the room along the walls. This is a kind of compensation layer that will help restrain the thermal expansion of all layers laid on the floor base.

- Place a vapor barrier material on top of the screed or boards : a membrane or plastic film.

- The next layer is insulation. Ideal heat insulators specifically for underfloor heating systems are insulation with foil.

To level the wooden base, choose one of the following options:

- Defects of floorboards - replacing old floorboards with new ones and subsequent consolidation of the floor structure with finishing sanding.

- Laying plywood sheets on top of the floorboards, which are attached to the base itself with self-tapping screws and adhesive. The sheets must be laid staggered with an offset of half the size and must be treated with drying oil on top. The gaps between the sheets are filled with putty. Sometimes plywood is laid in 2 layers, then not only the sheets are laid offset, but also the layers relative to each other.

Installation of heating elements

After thorough preparation of the base, you can begin laying the heating elements. Stages of work:

- Laying heat-reflecting material. A layer of foil material is laid on the rough surface and secured with a construction stapler or metallized tape. The sheets are fixed together with special adhesive tape. When laying, do not allow gaps between the rolls of heating material. Then the circuit will be closed and more efficient. In the absence of thermal insulation sheets, there is a risk of poor thermal conductivity to the coating.

- Laying heating elements. The thermal film roll is rolled out so that the metal strip is located at the bottom. The number and order of rolls must be taken into account when drawing up a project plan. If the sheets are too long compared to the room, trim them. This can only be done in places specially designated for this by the manufacturer, otherwise a short circuit may occur or the system will not work. All rolls are placed according to the laying pattern. It is not necessary to use fragments of the same width. It is important that they do not overlap each other. But there should not be a large distance between the stripes, otherwise the heating will be uneven.

- Connecting insulation. Special bitumen stickers are attached to the places where the roll was cut. They are positioned so that it covers all contacts and copper surfaces. Then you need to carefully connect the wires to the contacts through which electricity will flow, providing heating. The contact itself should be located inside the film with the heating element on one side, and on top of the foil tape on the other. The contact is clamped with pliers and the floor layers are secured with adhesive tape. It is necessary to ensure that the layers remain in their places and do not move. An electrical cable is placed in the contact, then the wires are fixed there with pliers. Bitumen stickers are used to secure the floor and contact points of the heating element.

- Some difficulties may arise with connecting the film if there are more than three fragments. The solution in this situation is to install a terminal of a suitable shape at the ends. The ends of the wire are stripped of insulation, twisted and placed in the “leg” of the contact. Then they are clamped with pliers. This turns out to be one contact that is easier to make.

- Next step. After connecting all sections of the film, the sensor, with the machine switched off, connect the linear wires to the corresponding terminals on the panel.

- Connecting the thermostat. A temperature sensor is mounted under the heating film. You can secure it with an insulating layer of paper. A hole must be made in the heat-reflecting material for such a sensor so that the floor does not change its level of inclination. It is better to also make small holes in the base for all the wires and other equipment. The cables are connected only with special insulating tape. The thermostat mounted on the wall is connected to connecting wires that are routed through a circuit breaker to avoid unforeseen emergency situations.

Checking the system and laying the laminate

Features of laying laminate

At the last stage of installing a heated floor under the laminate, the operation of the equipment is checked. This must be done for each strip of underfloor heating separately in order to accurately determine the malfunction, if any.

Procedure for testing the system:

- turn on the thermostat, check the operation of the main device;

- check each strip for malfunction;

- inspect the wire connections.

The elements should not overheat, spark, or exhibit other uncharacteristic symptoms. If all components are in order, you can immediately begin laying the polyethylene film on which the substrate will be installed. Next, I lay out the laminate panels and complete the installation work. If everything heats up normally, you can install the baseboards.

Carbon rod

Carbon rod TP is a device consisting of self-adjusting carbon rods, they are located in parallel. It is able to regulate the heating level in the room, depending on the ambient temperature.

Powered by current, when it is supplied, infrared waves are emitted, they release heat and heat the room.

Advantages and disadvantages

Thanks to the parallel connection of the rods, when one comes out of standing, the entire structure continues to function. In addition, the core heated floor tolerates moisture well.

This model can be installed under laminate, either with or without a screed. The main disadvantage of screed installation is the complexity and duration of the work.

Installation

Laying a rod electric heated floor under a laminate is similar to installing a film system. You need to start by installing the thermostat and punching grooves (grooves) for the wire on the wall.

Rod carbon heated floor gtmat Caleo – installation from Master Tiler

Next, the rough coating is prepared - leveled and cleaned. A heat-insulating two-layer substrate is spread over it - foam material and lavsan film.

The next step is to lay the rod mats, they are fixed to the insulation, then the device is connected. That is, a temperature sensor is installed, the wires from it and the mat are connected to the regulator.

Filling the rods with concrete or tile adhesive is carried out after testing the system; the screed layer is made no more than 3 cm.

Only after the solution has dried can you begin installing the laminate.

Carbon solid

Solid carbon heated floors are a new model of the heating system. A continuous layer of carbon will be applied to the film. The mats consist of 13 layers - 3 for work and 10 for safety, 5 on each side.

HOW TO MAKE A CARBON WARM FLOOR WITH YOUR OWN HANDS?

This type is safer, more environmentally friendly, and energy consumption is significantly lower. But since it appeared on the construction market recently, it is not used often. Disadvantage: short service life, about 15 years.

The construction process is similar to laying any carbon mats, but it is easier to do the installation yourself, since it is done without pouring a screed.

After preparing the base and laying the insulation, the film is laid. The strips are connected by soldering, which is much more reliable than conventional fasteners.

In addition, it is possible to cut the film anywhere and place it under furniture. Laminate flooring is installed using a floating method.

Amorphous metallic

The basis of this design is an amorphous-metal alloy, which has:

- high efficiency;

- increased resistance to moisture and corrosion;

- strength and flexibility;

- electromagnetic safety;

- good level of thermal conductivity.

These properties make the floor universal; it can be installed under different surfaces, including laminate.

Advantages of a device based on metal alloys:

- uniform heating of the room;

- easy installation;

- efficiency in energy consumption;

- Possibility of installation under furniture;

- warranty period up to 25 years.

Installation

Installing an amorphous metal floor is much easier than installing other systems.

A substrate is laid on the prepared concrete base, on which heating mats are placed; a laminate is placed on top; a concrete screed is not required.

Connects to a thermostat that is installed on the wall.

Warm floor made of amorphous metal. Why is it better than analogues?

Water heating coating

Water heating systems are multi-layered. Their base is waterproofed, and then a layer of thermal insulation is laid, which will not allow heat to escape downwards. Then pipes of small diameter are installed, which are covered with concrete screed or gypsum fiber. Only after this is the flooring laid.

In this case, it is very important to know which laminate is suitable for heated floors so that you can make the most correct choice. Laminated panels for such purposes must be:

- made of high quality material;

- have a high density;

- protective covering.

If the laminate meets all these requirements, then it will be ideal for installing a water floor system. Heating on such a basis is characterized by high humidity. Conventional laminate panels are unable to withstand such conditions for a long time, but high-quality laminated materials can maintain their excellent appearance and performance for a long time. This is why it is best to choose:

- laminate class 33 (12 mm);

- moisture resistant;

- marked H2O.

When operating a heated floor, it is imperative to observe a certain temperature regime. The indicator should not be higher than +27 degrees, as otherwise the panels may become deformed and lose their appearance.

Installation of sensors: temperature, thermostat

Thermostat is a device for controlling the heating of a room and for adjusting the temperature level. The device can be mechanical or electronic.

How to connect a heated floor to a thermostat

If the regulator is installed on the wall, then the wires from it are covered with a plastic box. For internal installation, a recess is made into which the box is placed, and grooves are punched for the wires.

It is placed on the wall 1 - 1.5 meters from the floor, preferably near sockets, and also away from windows.

The temperature sensor is the main element of the heating system. It is small in size and has two wires that connect to the regulator.

The operation of the device depends on how accurate the temperature sensor readings are. Therefore, the choice of location for its installation must be taken seriously.

It should be placed with a distance from the wall of no less than 60 cm, and preferably 1 meter, in the middle of the film or between the cable loops. In cases with a cable floor that is filled with screed, the temperature sensor is placed in a corrugated hose; it will protect it from the solution and simplify the process of replacing it.

This device is very vulnerable and often breaks. But it is not expensive, so the costs are not significant.

Comparison of electric floors, which one to choose?

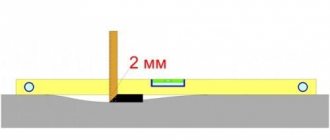

The first step when choosing an electric heating device is to calculate the level of floor elevation when laying each model. If the ceilings are not high, or you do not want to raise the floor, then it is better to opt for models that do not require screeding - infrared systems or thin cable mats.

If the ceiling height allows, then you can use the cable type under the screed. In such a “pie” the cable is thicker than in mats, the insulation is at least 20 mm, and the screed is at least 30 mm. Pouring concrete mortar up to 50 mm is allowed; the strength of such a structure is higher, but the warm-up time increases significantly.

It is necessary to choose a heating system together with the laminate, as they must fit together. After all, when heated, the product can release formaldehyde, so you definitely need to check whether the model is compatible with heated floors. In this regard, infrared structures benefit, since heating is produced by infrared rays.

What affects thermal resistance

Simply choosing a laminate with a certain marking is not enough. One of the most important criteria is the thermal resistance coefficient. According to European standards, this figure should be higher than 0.15 m2 K/W.

This also applies to the substrate, so to obtain the required indicators, you will simply need to add the CTS of the substrate and the laminate. The resistance level is affected by the thickness and density of the product.

If the value of the coefficient is quite large, then there is a risk of overheating of the substrate. In addition, the heating circuit can quickly break down.

How to choose a laminate?

Laminate is an MDF product, the front side of which is made of polymer. When choosing it for heated floors, you need to consider:

- The presence of an icon indicating that the product is not afraid of high temperatures and meets the standards of the European Union.

- The amount of harmful substances - they should not be more than normal, otherwise when heated the material will release harmful substances.

- Thermal resistance - the higher the better.

- The thickness of the lamellas - the thicker they are, the less heat enters the room.

In addition, the method of fastening the panels is important; if there is glue, then they are not suitable for heated floors. There is no need to take very cheap products - they are of low quality.

Laying laminate

The principle of laying laminate depends on the type of heated floor:

- Cable - you can lay the finishing coating only after the screed has completely dried. A substrate is placed on it - polystyrene sheets of small thickness, or a special insulator. It is possible to lay laminate directly on concrete, but then the level of sound insulation will be reduced.

- Film - since it is laid without a screed, dense polyethylene is laid to protect the conductive product from mechanical damage and moisture. The laminate is already placed on it.

Laying laminate flooring on a warm floor. Making the right substrate.

In all cases, the finishing coating is assembled in a standard way - the panels are attached to each other by snapping locking connections.

Some tips for safe operation

When planning the installation of heated floors, do not forget that neither electrical cables nor water pipes should be laid under heavy pieces of furniture. Also, you should not install heated floors in close proximity to a wood-burning, gas fireplace, stove or other heating devices.

For rooms for various purposes, you can program different temperature conditions, for example, in the bathroom and living rooms it will be comfortable at 22-24°C, and in the kitchen and corridor 20°C is enough

Practical nuances:

- After completing the repair, you should leave the heating system on and maintain the same temperature for 3-5 days. This precaution will allow the entire floor “pie” to be heated evenly and thoroughly and ensure reliable operation of the system.

- At the beginning of the heating season, you need to properly prepare the floor heating system for operation. To do this, you should increase the heating degree by 5-7 units every day until the temperature reaches the required value. This approach will avoid sudden temperature changes that can damage laminate and other materials. Similarly, the heating is turned off during the warm period.

- Do not forget that film infrared floors do not tolerate moisture well. Therefore, it is not recommended to install it in rooms with a humidity level above 70%, and after wet cleaning, wipe the laminate dry.

- The optimal temperature for heated floors is considered to be within 20-30 degrees.

And lastly, do not cover the heated laminate flooring with carpets or other furnishings that interfere with the effective distribution of heat.

Top manufacturers

When choosing an electric heated floor, you should give preference to manufacturers who have been producing products for several years.

Teplolux

Technolux is a Russian company that produces economical, efficient devices for additional and main heating of premises. There are different types of models - cable, mats, rugs. They are inexpensive and easy to install. However, in these systems the thermostat quickly fails.

Unimat

Unimat (Korea) - produces infrared rod floors with increased resistance to moisture. The systems are economical, prices are not high, and the warranty period is 20 years. But this heating cannot be used as the main one at high sub-zero temperatures.

Devi

Devi is a Danish manufacturer. The company produces high-quality cable products at an affordable cost. Heating devices from this manufacturer are easy to install, they do not dry out the air, and the warranty period is more than 20 years. The disadvantage is high energy consumption.

ReXva

ReXva (South Korea) - produces infrared self-regulating floors. The kit includes a thermostat and sensor. A special feature of the devices is the ability to automatically lower the temperature in overheated areas. The advantages include cost-effectiveness, moisture resistance, they extend the life of the laminate. The price is high, but it is justified by the quality. The downside is that it attracts dust.

Caleo

Caleo is an infrared floor made in South Korea, designed for quick dry installation. It has good heat dissipation and is equipped with all elements for installation. The only negative is fragility.

Heat Plus

Heat Plus (South Korea) - flexible infrared film with carbon stripes. The device emits long-wave infrared rays that are not dangerous to humans. The film is universal - suitable for both floors and walls, durable, used without a thermostat. The disadvantage is the high cost.

Rehau

Rehau (Germany) - the company produces two-core self-regulating electrical cable of a certain length. It has increased resistance and a double insulating coating on the outside. The price of this product is high, but it is justified by its quality.

Having decided to install not a water, but an electric heated floor under a laminate in your home, you should familiarize yourself with the characteristics not only of each brand of heating system, but also with the description of each laminate model. After comparing all the pros and cons, making sure that the heating device is combined with the finished product, you can choose the right model for your apartment.